A low-nitrogen gas burner based on heat pipe heat exchange

A gas burner, heat pipe heat exchange technology, applied in the direction of gas fuel burners, burners, indirect heat exchangers, etc., to achieve the effect of reducing nitrogen oxide emissions, reducing the generation of nitrogen oxides, and avoiding the risk of backfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

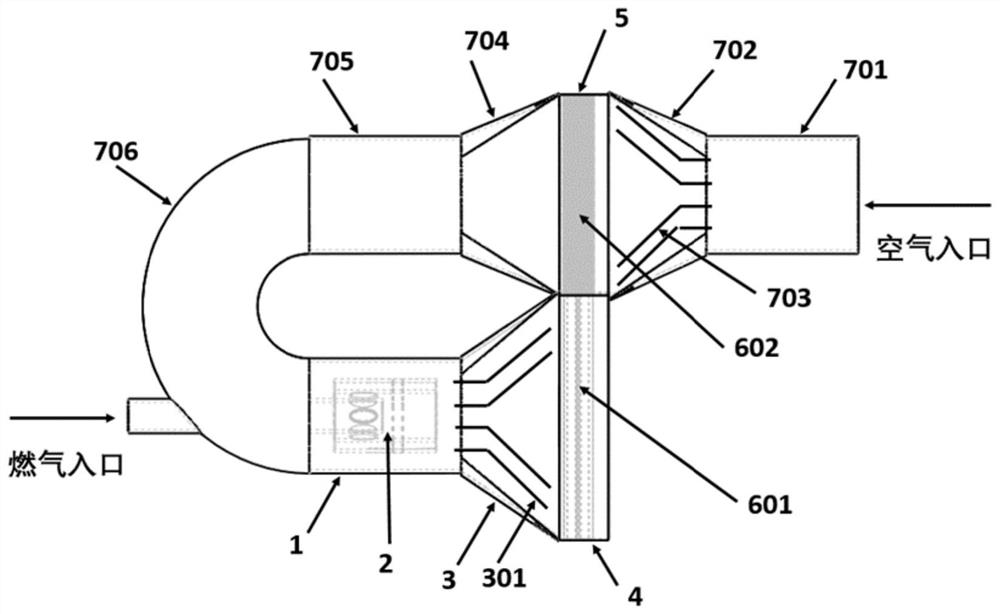

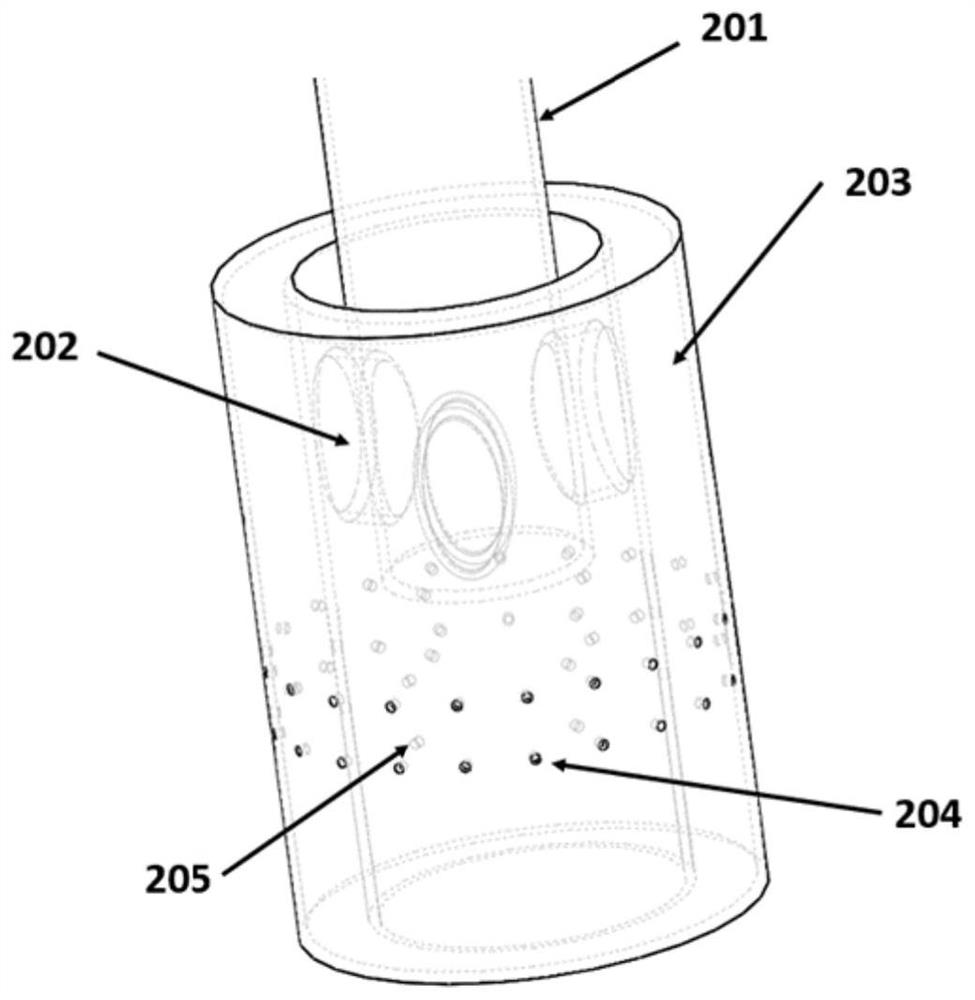

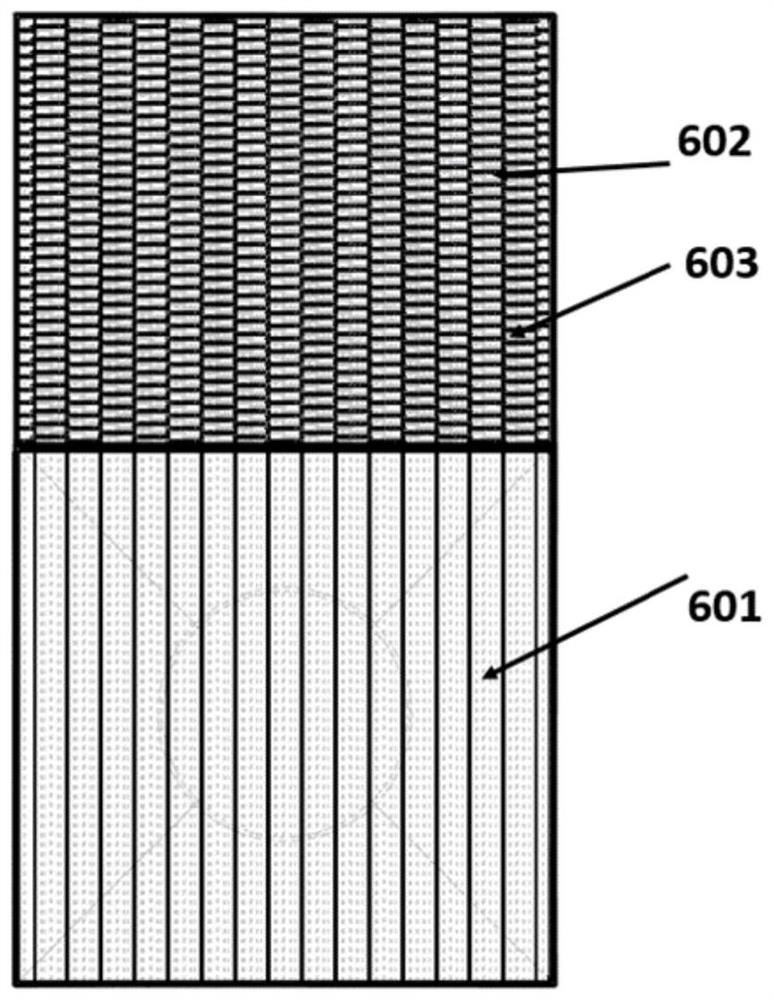

[0043] The present invention is a low-nitrogen gas burner based on heat pipe heat exchange, such as figure 1 As shown, it includes the air-fuel mixing section 1 and the combustion head connected in sequence along the gas flow direction; several tube bundles in the heat pipes 6 constituting the combustion head are arranged in a flat plate shape, and the condensing device adopts an air preheater 5 arranged in a box type In the tube bundle, the evaporating and heat-absorbing section 601 of the heat pipe is arranged to form a combustion gap as a combustion head. The heat-pipe evaporating and heat-absorbing section 601 is arranged vertically to the gas flow direction at the entrance of the furnace 9 to form a flat burner 4, and the heat-pipe condensing and exothermic section 602 is provided with an air preheater 5 And arranged outside the furnace 9; according to the air inlet direction, it includes air inlet 701, air equalizing section 702, air preheater 5 (heat pipe condensation he...

Embodiment 2

[0052] The present invention is a low-nitrogen gas burner based on heat pipe heat exchange, such as Figure 5 As shown, in addition to air cooling, the condensing and exothermic section 602 of the heat pipe can also adopt a water-cooled cooling method. The condensing and exothermic section 602 of the heat pipe is provided with a cold water inlet 11 and a hot water outlet 12; The structures of the air-fuel mixing section 1 , the gas nozzle 2 , the mixed gas uniform flow section 3 and the flat burner 4 in the embodiment are all the same as those in the embodiment 1.

Embodiment 3

[0054] The present invention is a low-nitrogen gas burner based on heat pipe heat exchange, such as Figure 6 As shown, several tube bundles in the heat pipe 6 of the combustion head can be arranged in a ring shape in addition to being arranged in a flat plate type, and an end plate is provided at the end of the ring-shaped tube bundle; The heat pipes 6 in the pipe row are arranged in gaps, and the heat pipe evaporation and heat absorption section 601 is arranged in the center of the inlet of the furnace 9 along the gas flow direction to form an annular burner 10; the annular burner 10 is connected to the output end of the air-fuel mixing section 1; a part of the air Through the air inlet, it enters the heat pipe condensation heat release section 602 to exchange heat with the heat pipe 6, and the heated air flows into the air main pipe through the turning flue 13;

[0055] Among them, the outer annular tube row directly exchanges heat with the combustion zone in the furnace 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com