Patents

Literature

35results about How to "Play the role of steady flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

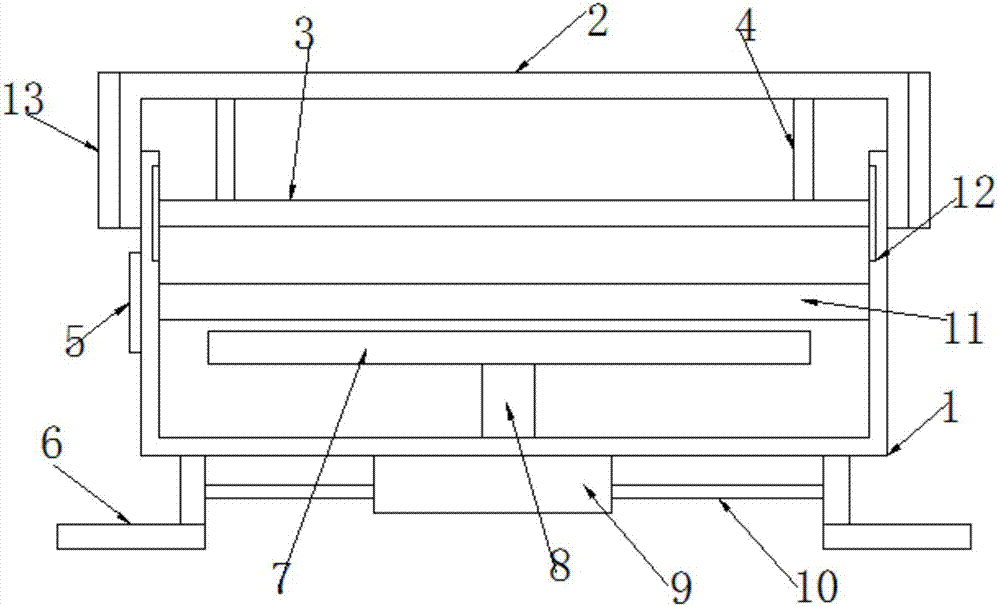

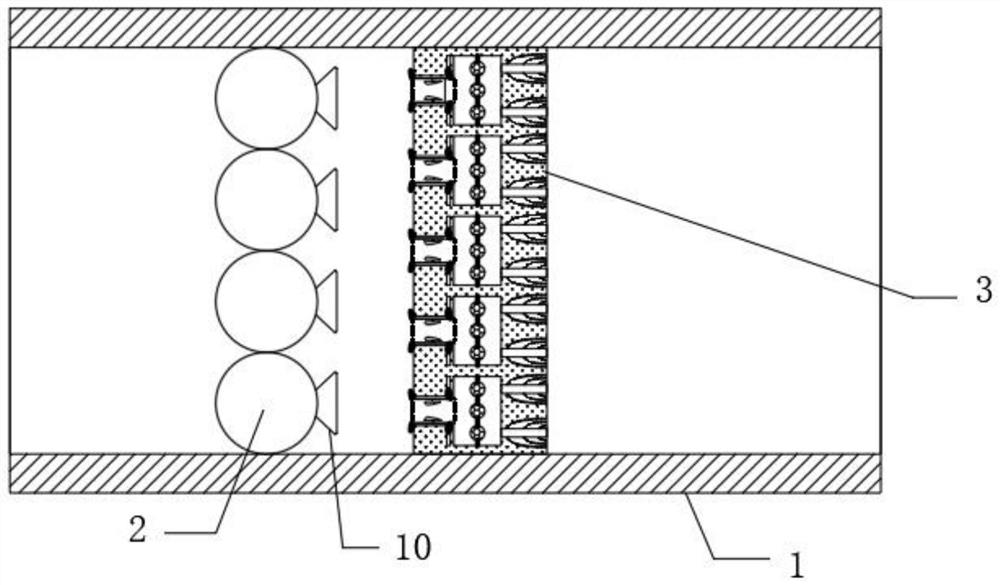

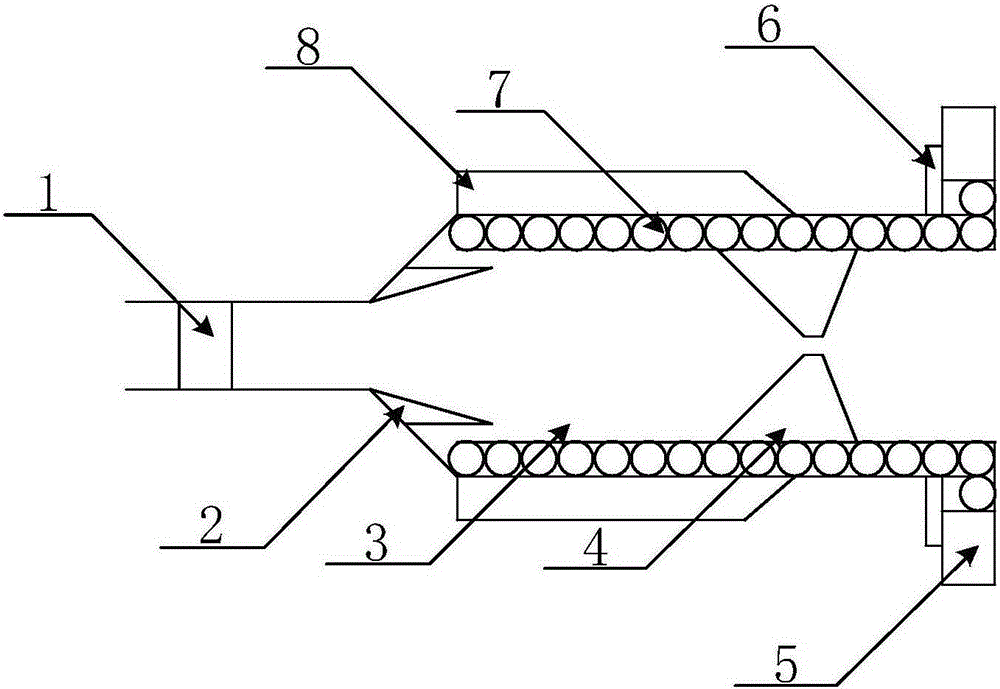

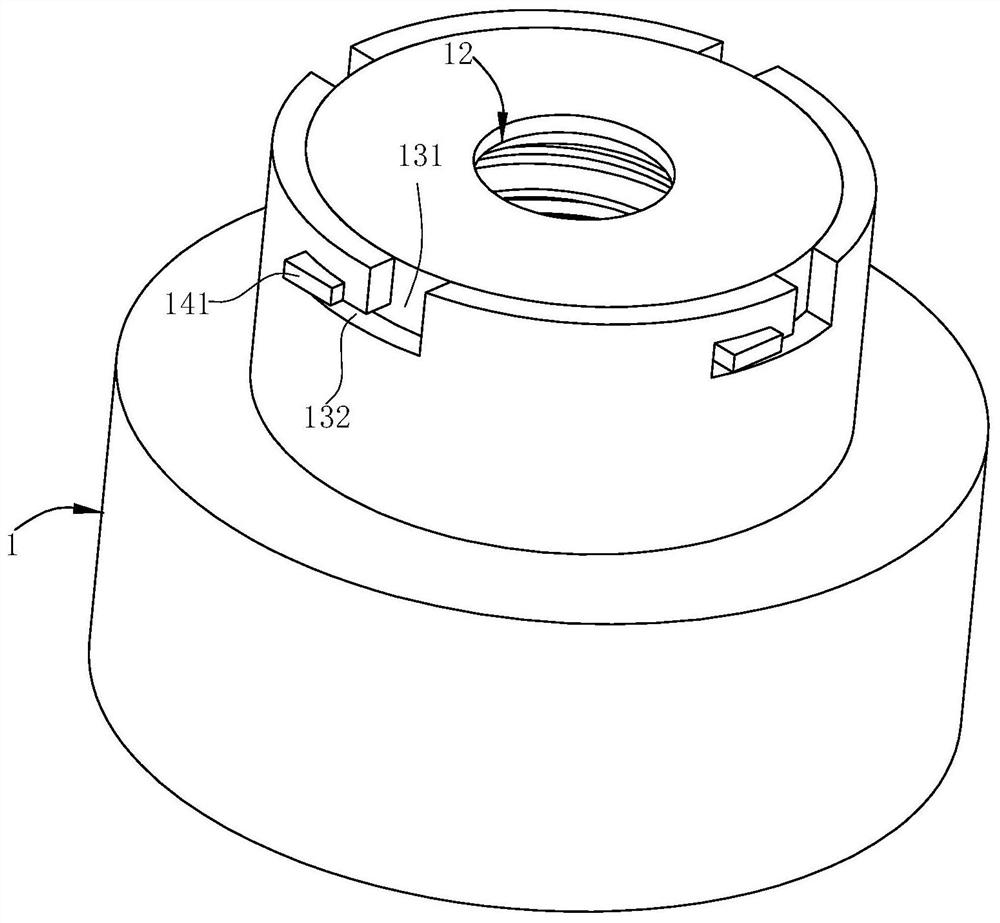

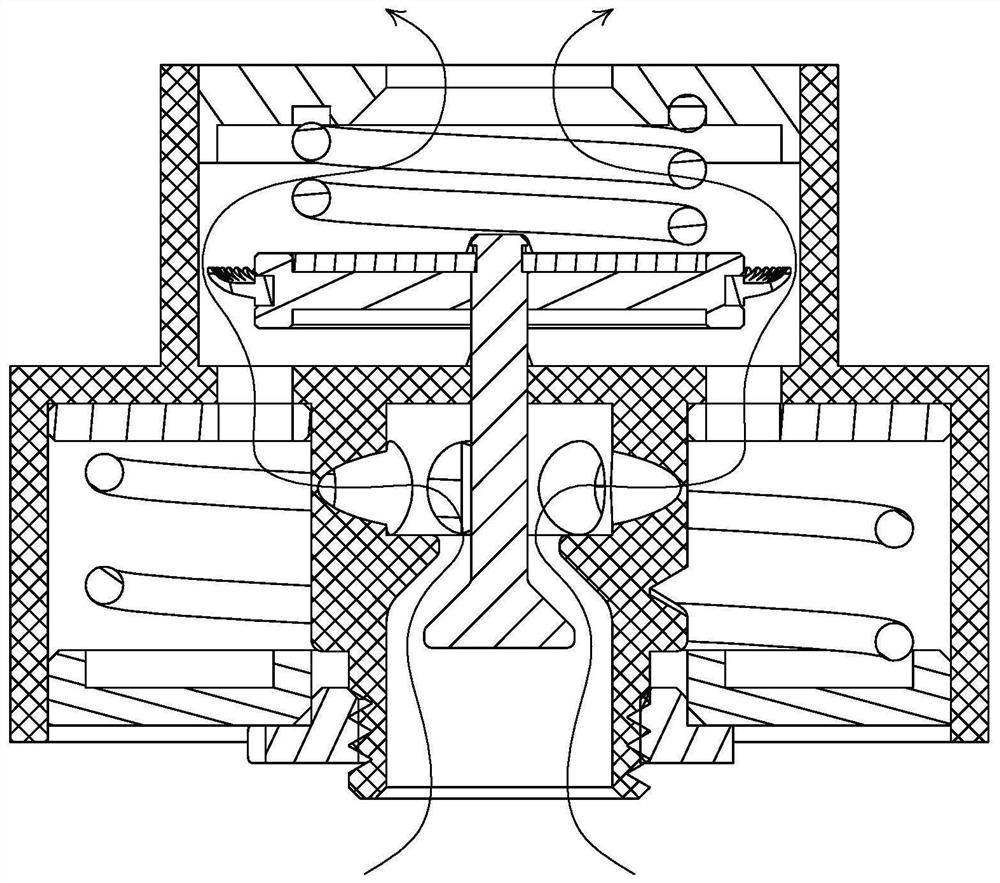

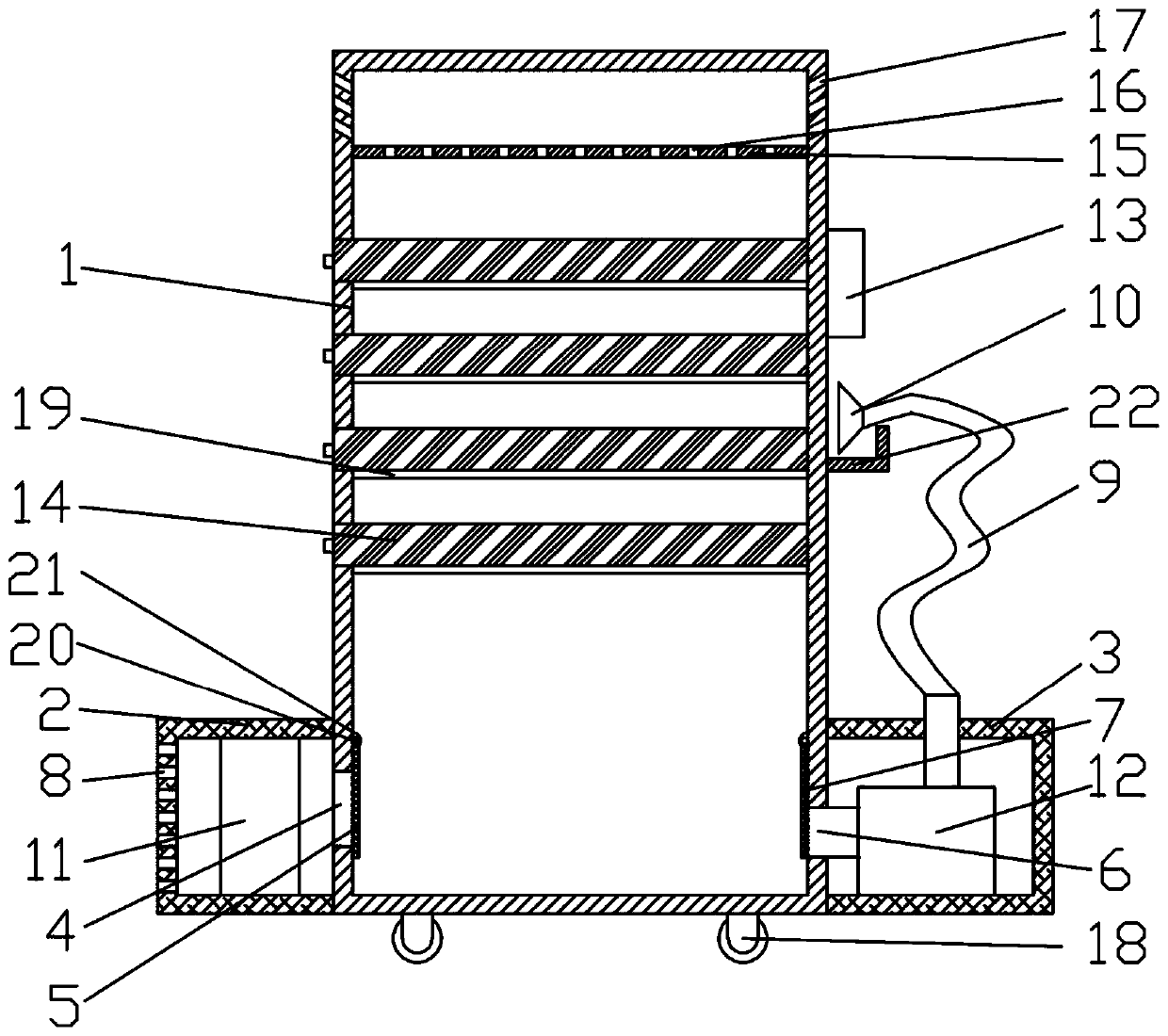

Factory purification ventilation system and work method thereof

ActiveCN106582126ALess investmentImprove applicabilityDispersed particle filtrationEngineeringExpansion chamber

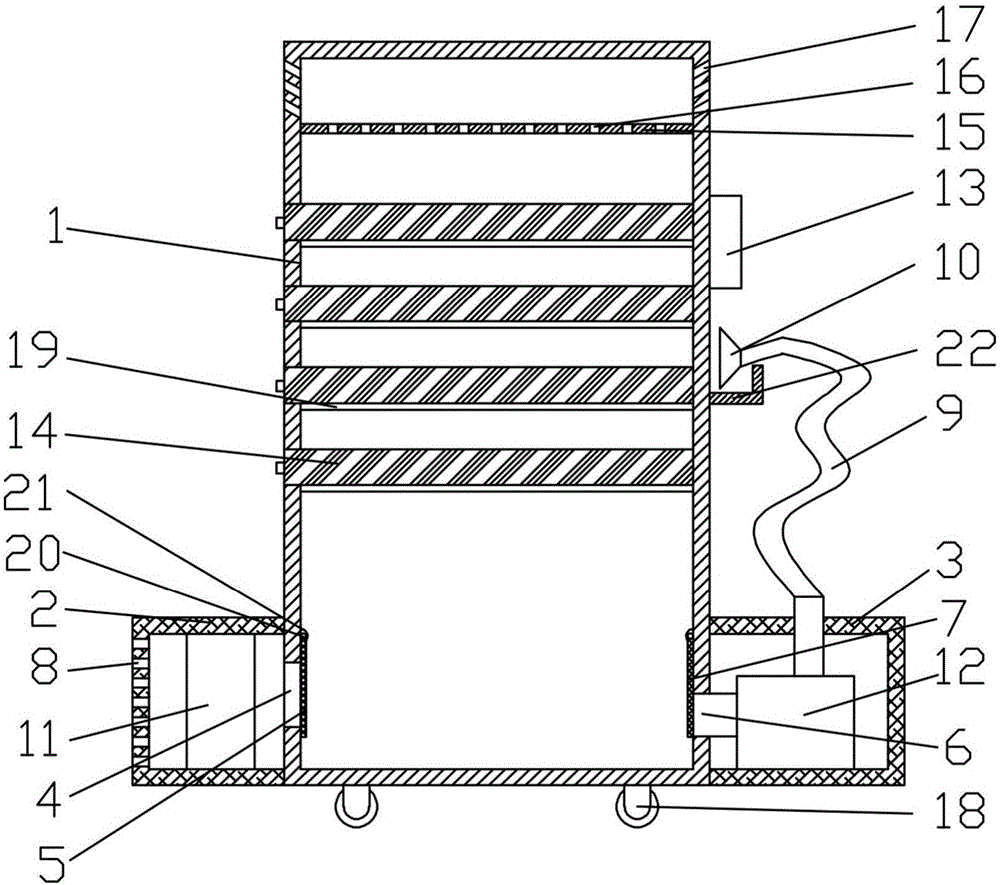

The invention discloses a factory purification ventilation system, which comprises a casing, wherein a left expansion chamber casing is arranged at the left lower end of the casing; a right expansion chamber casing is arranged at the right lower end of the casing; air passing passages are arranged in a connecting position of the left expansion chamber casing and the casing and a connecting position of the right expansion chamber casing and the casing; a movable plate is arranged in the position of each air passing passage; an air inlet hole is formed in the left end of the left expansion chamber casing; the upper end of the right expansion chamber casing is connected with a gas collecting head through an air inlet hose; a left air inlet fan is arranged in the left expansion chamber casing; a right air inlet fan is arranged in the right expansion chamber casing; an active carbon adsorption drawer is arranged in the casing; the upper end of the active carbon adsorption drawer is provided with a current stabilizing plate; air passing holes are formed in the current stabilizing plate; and air outlet holes are formed in the upper ends of the left and right side walls of the casing. The factory purification ventilation system has the advantages that through the movable purification ventilation equipment, purification circulation treatment is performed in waste gas generating positions, the investment of the purification equipment is greatly reduced; the left air inlet fan can be selected to be switched on to start the fixed air suction mode, or the right air inlet fan can be selected to be switched on to start the air suction mode; and the applicability is high.

Owner:福建众辉环保设备有限公司

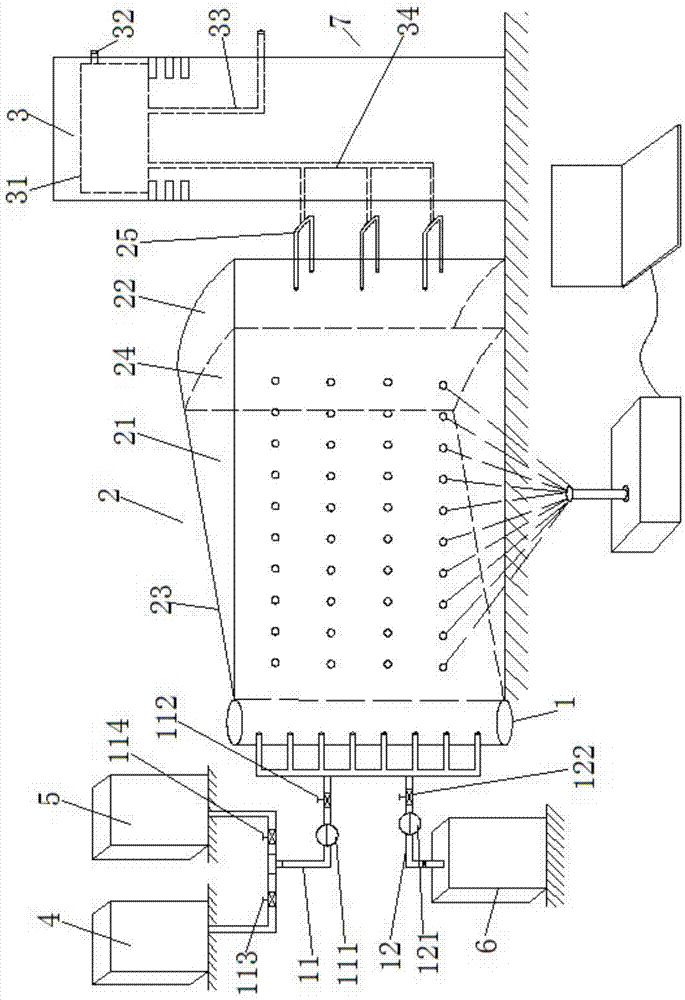

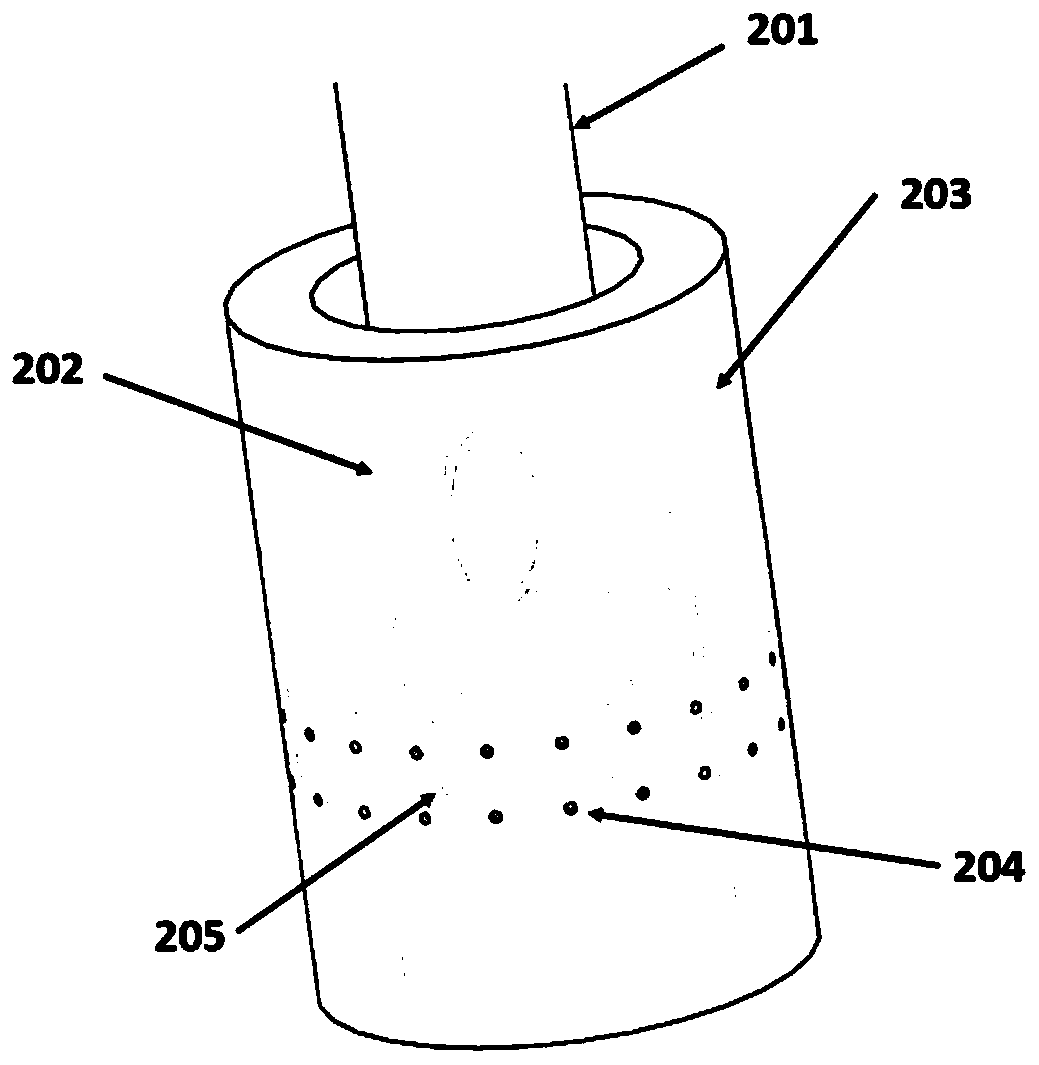

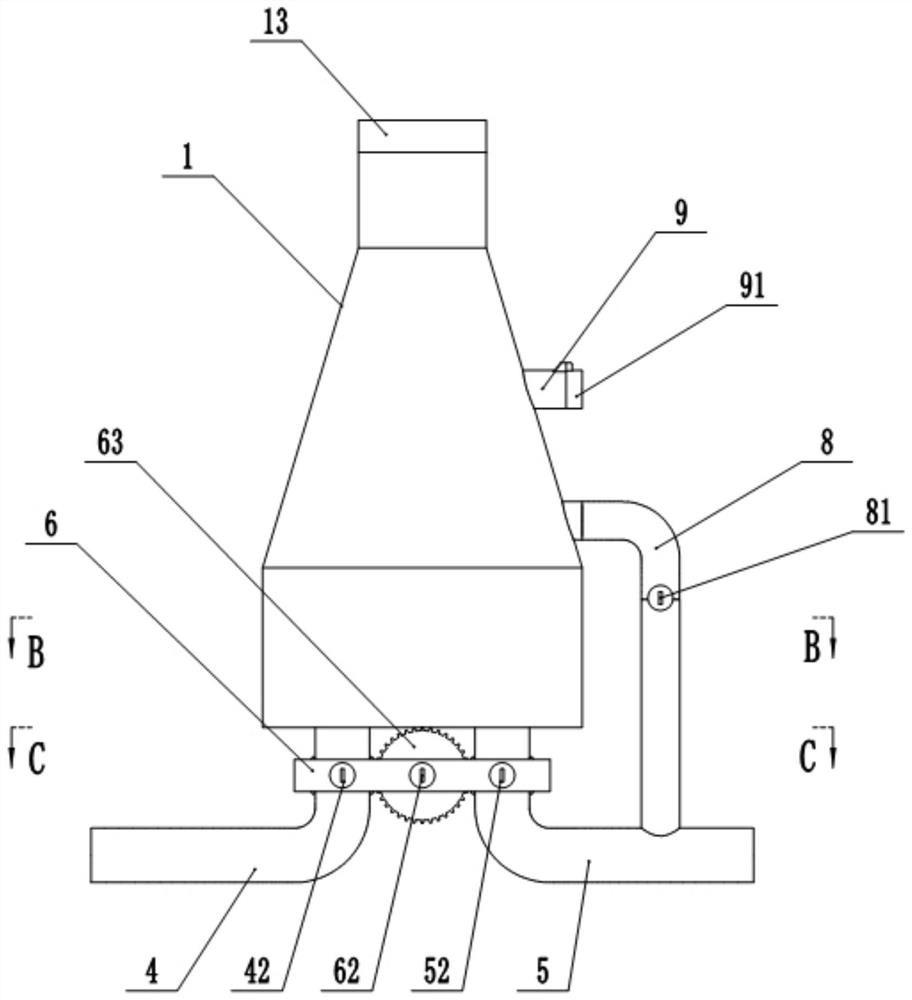

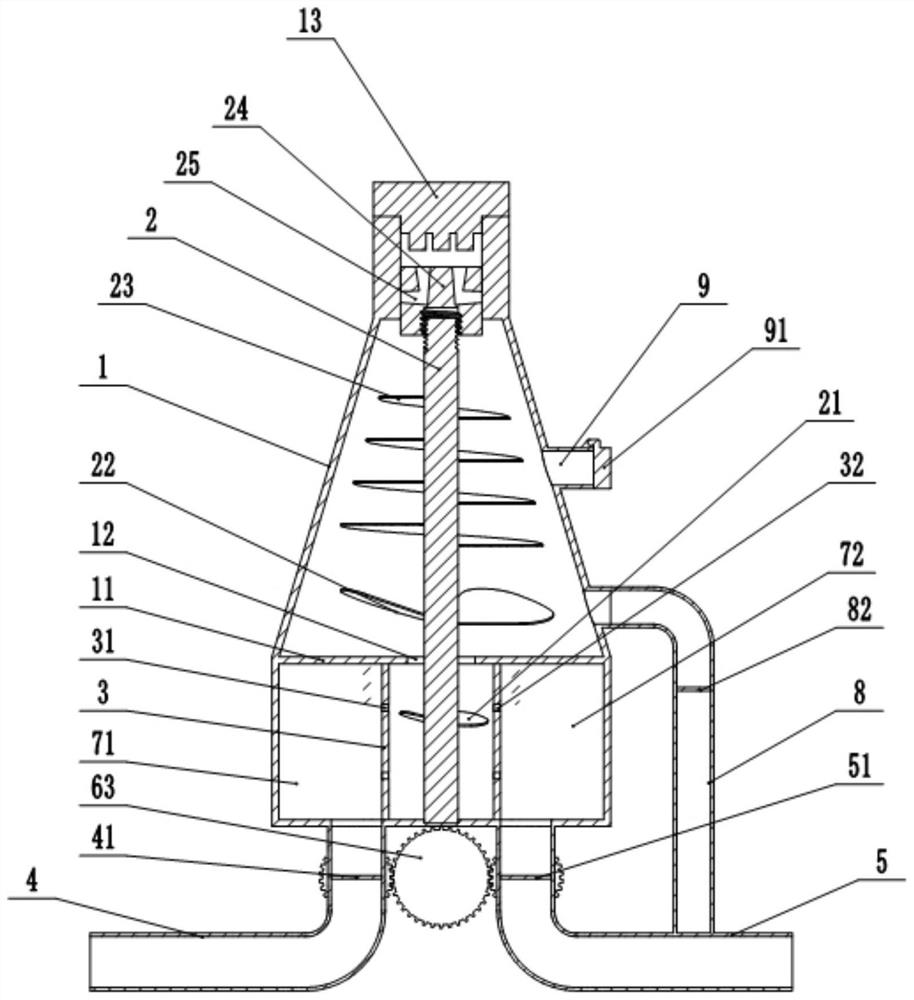

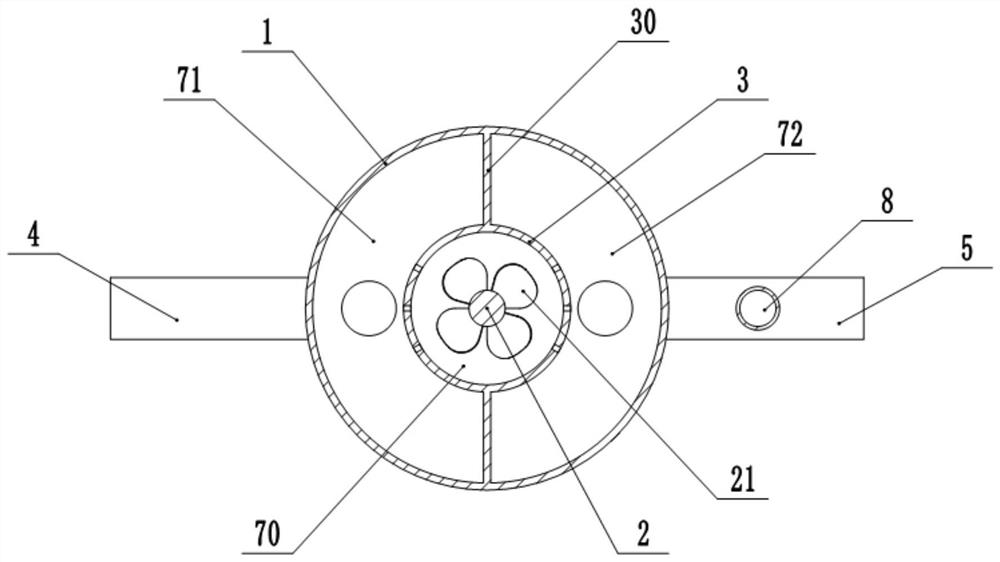

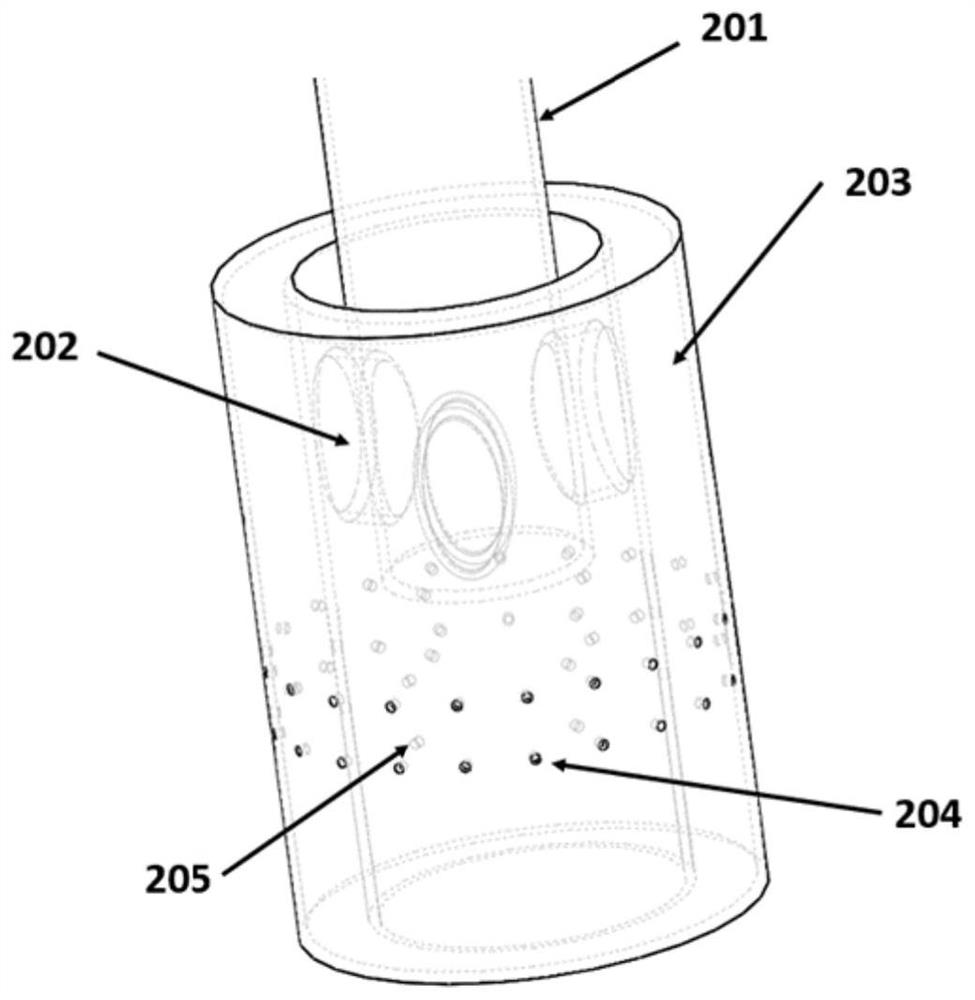

Single well-injection and water-suction tracer experiment simulation analysis system

PendingCN107462497ASimple structureEasy to operateCosmonautic condition simulationsSurface/boundary effectTracer experimentEngineering

The invention relates to a single well-injection and water-suction tracer experiment simulation analysis system. The single well-injection and water-suction tracer experiment simulation analysis system comprises a well body, a geological water-containing layer simulation module, an overflow device, a distilled water box, a tracer box, a sucked liquid storage box, and a background data processing and simulation analysis terminal, wherein a water containing area and a flow stabilizing area, which are communicated with each other, are arranged in the geological water-containing layer simulation module, and are respectively filled with a water-saturated medium and a flow stabilizing medium; the well body and the overflow device are respectively communicated with the water containing area and the flow stabilizing area; a liquid inlet pipe and a liquid outlet pipe are arranged on the well body, and the distilled water box and the tracer box are respectively communicated with the liquid inlet pipe through pipelines; one end, away from the well body, of the liquid outlet pipe is communicated with the sucked liquid storage box; a plurality of layers of liquid concentration sensors are uniformly distributed in the water containing area, and a plurality of liquid concentration sensors are arranged on each layer; the liquid concentration sensors are electrically connected with the background data processing and simulation analysis terminal. The single well-injection and water-suction tracer experiment simulation analysis system has the advantages that the structure is simple, the operation is convenient, and the testing of single well-refilling and water suction tracer experiment can be performed at high accuracy and high frequency.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

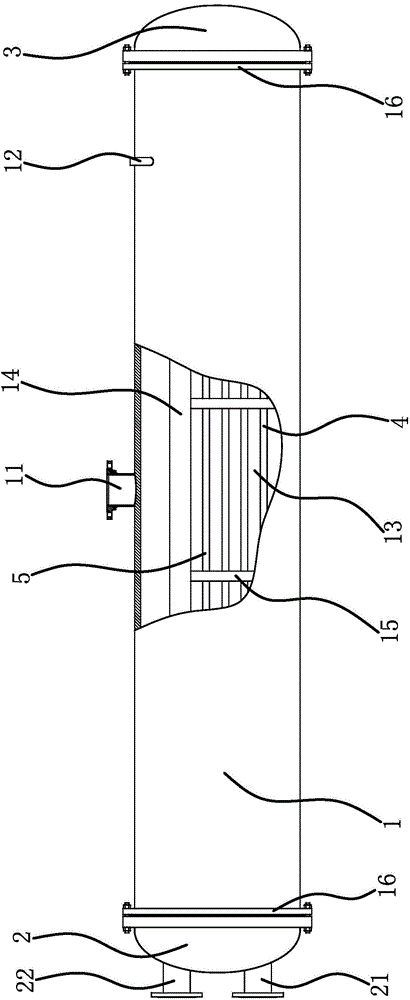

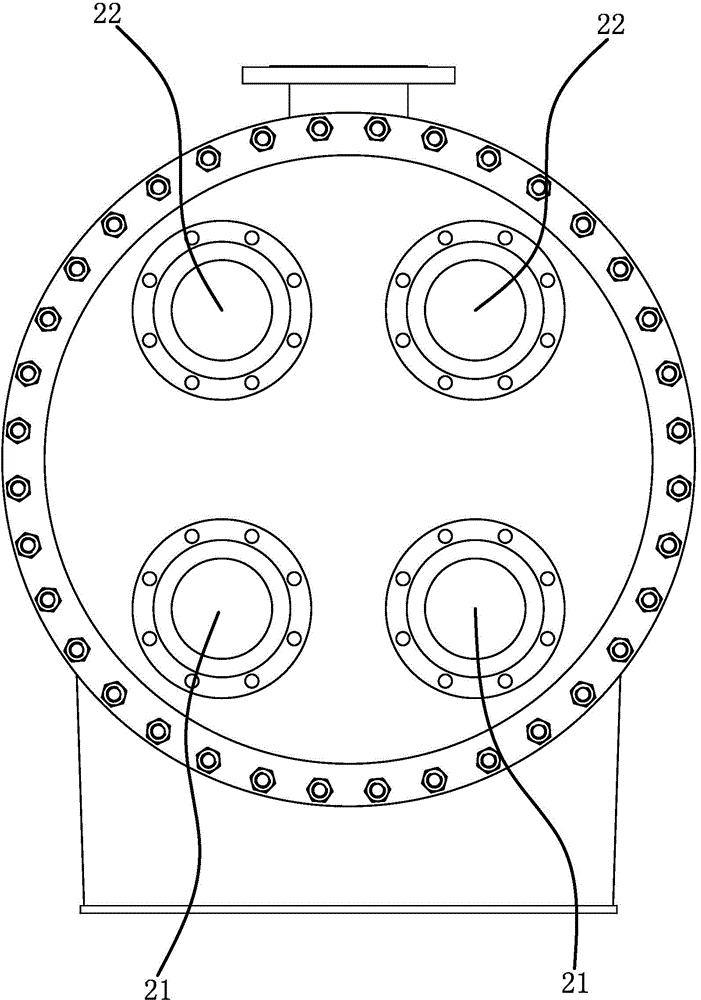

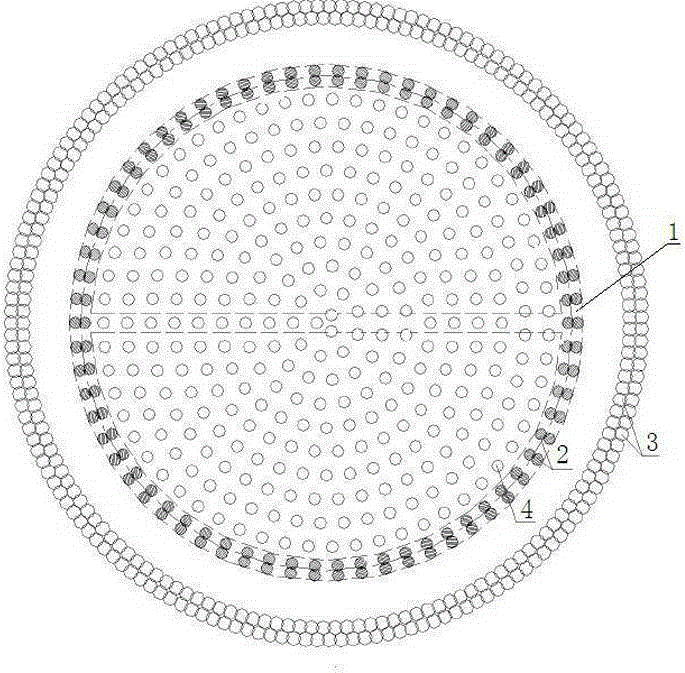

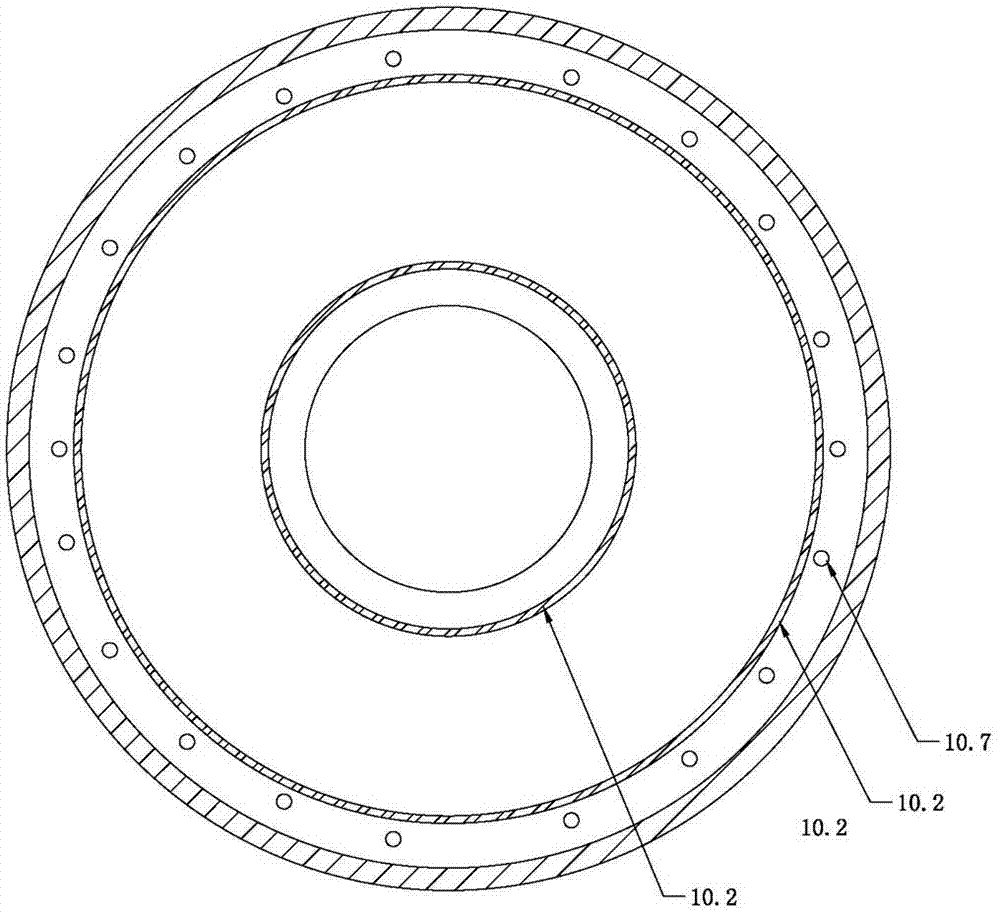

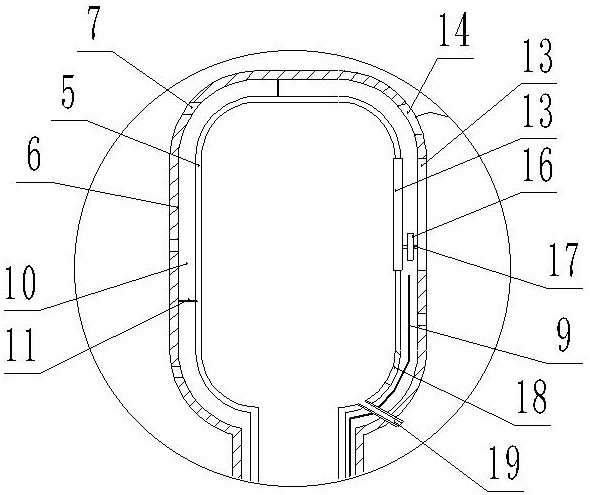

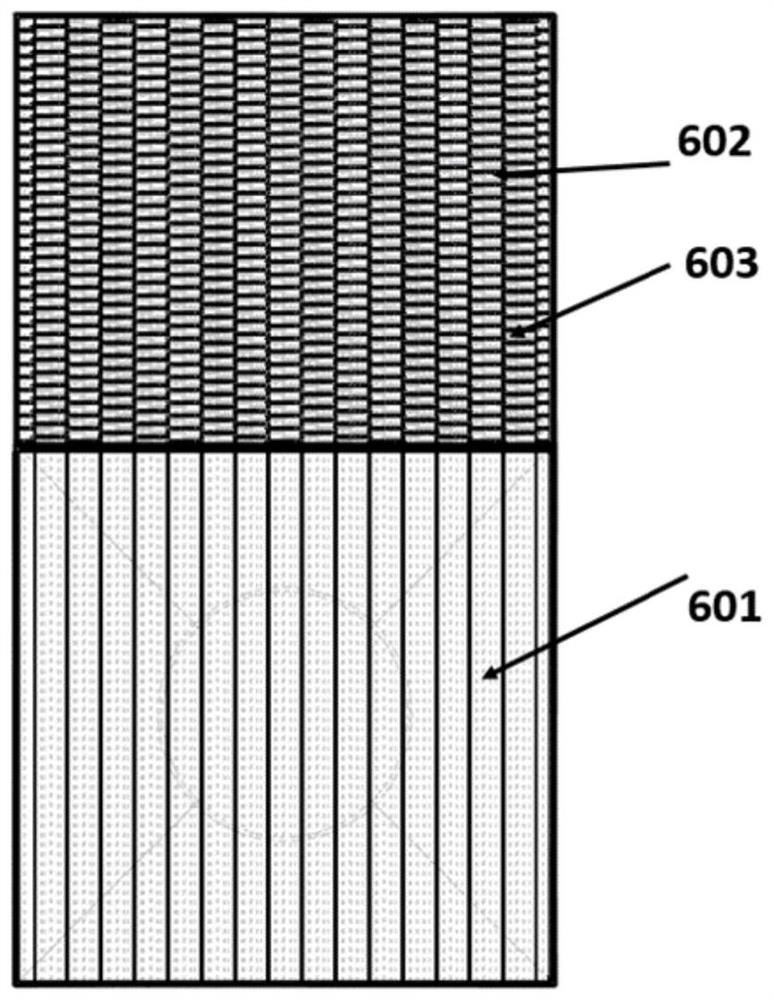

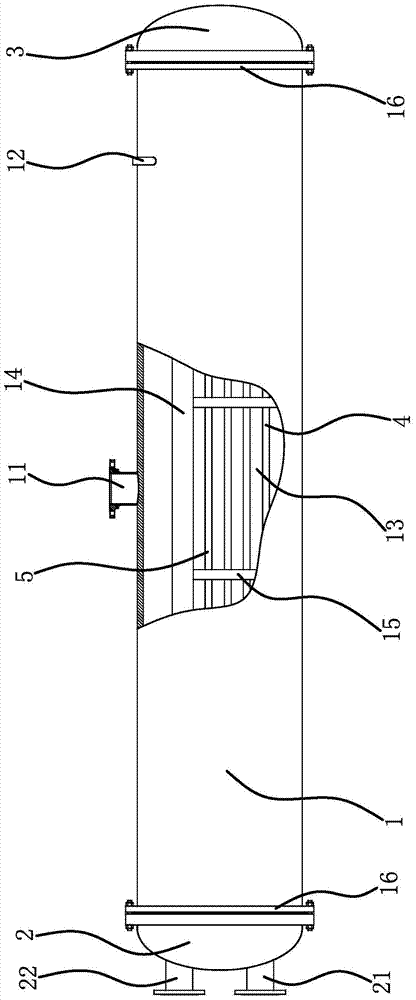

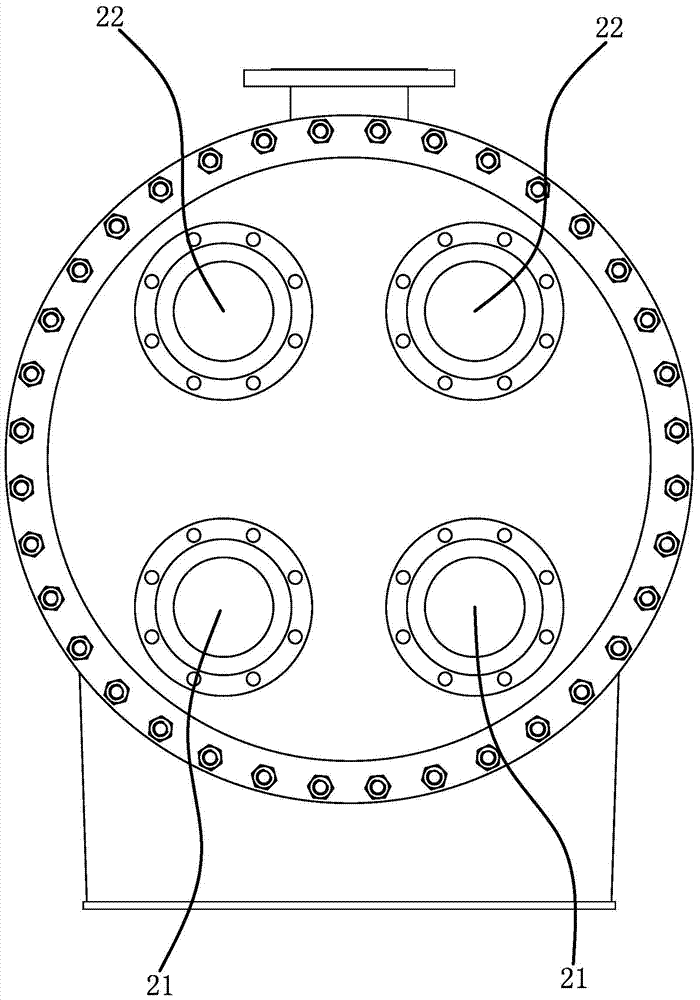

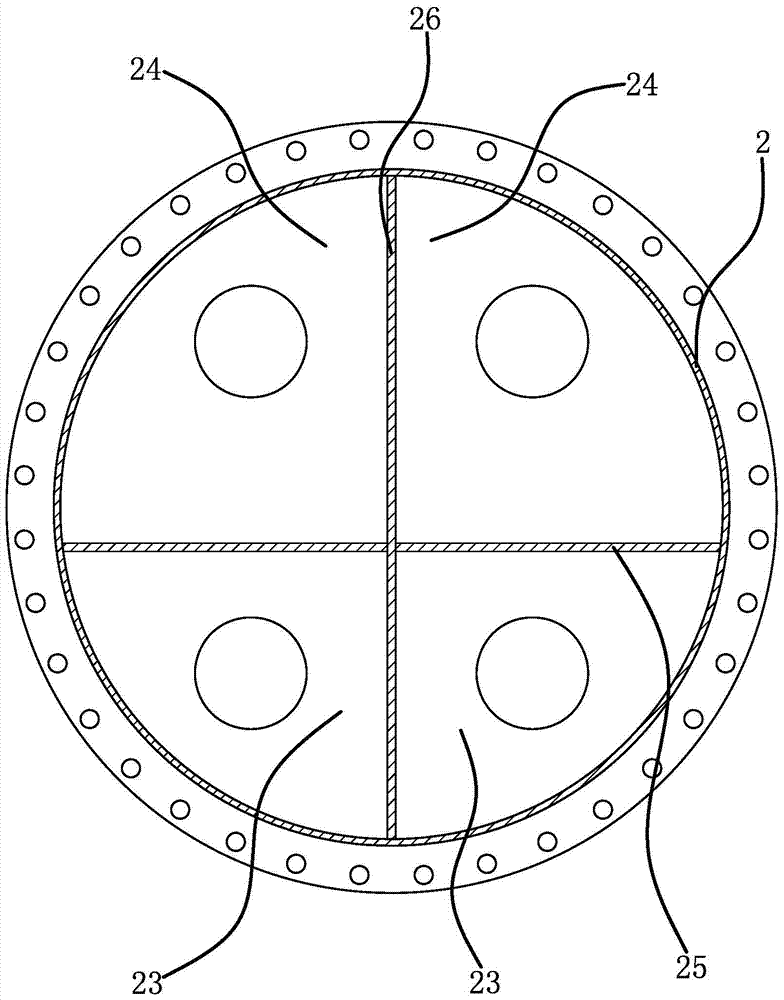

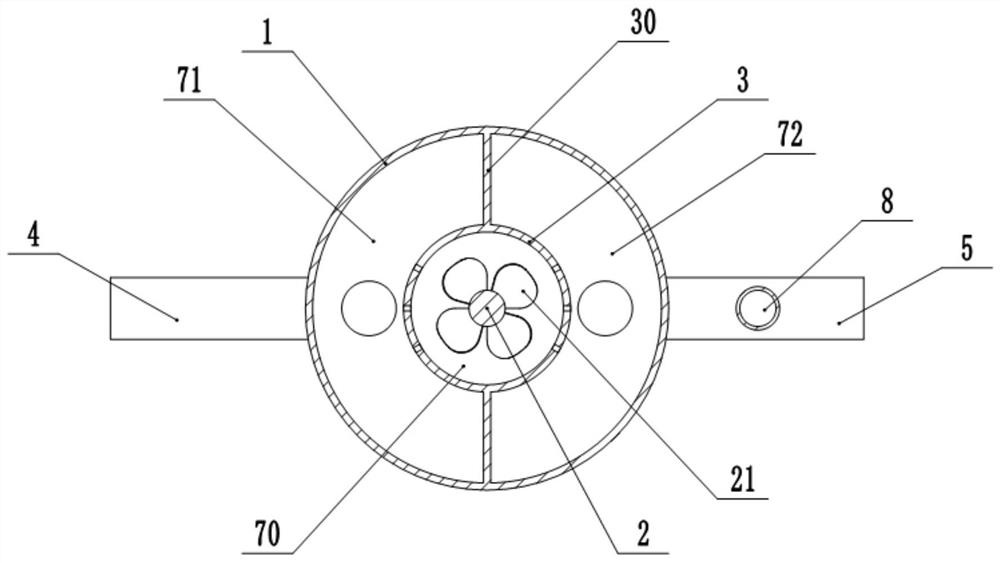

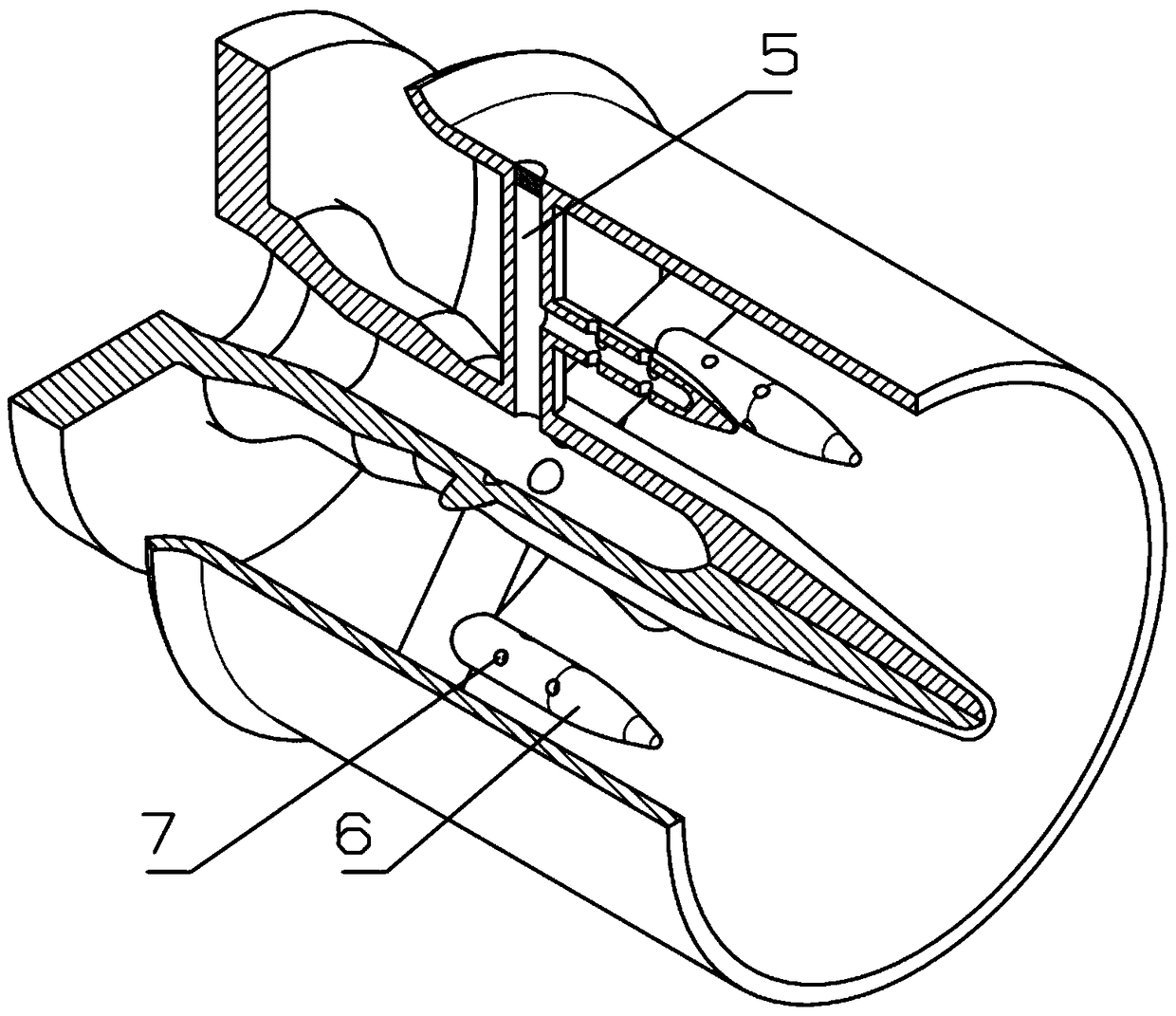

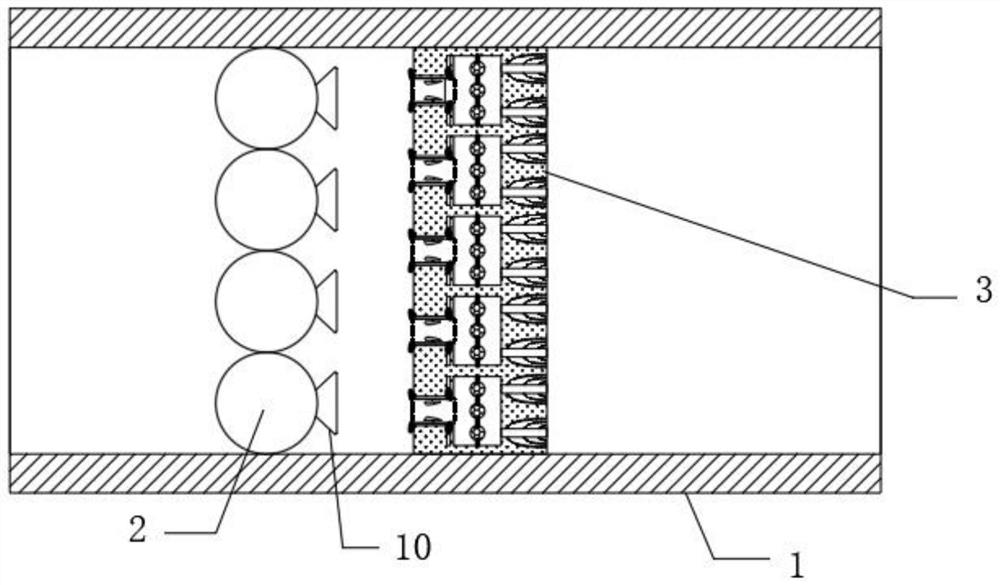

Multi-system flooded evaporator

The invention provides a multi-system flooded evaporator and belongs to the technical field of water chilling units. The multi-system flooded evaporator is used for solving the problems of refrigerant waste and use cost increase of the existing flooded evaporator. The multi-system flooded evaporator comprises a barrel, a front channel, a rear channel and at least two refrigerating circuits; each refrigerating circuit comprises a water inlet pipe, a water inlet cavity, a water outlet cavity, a refrigerating cavity and a reflux cavity; the water inlet pipe is communicated with the water inlet cavity; the water outlet pipe is communicated with the water outlet cavity; one ends of a plurality of inflow heat exchange tubes and one ends of a plurality of reflux cavities all are communicated with the reflux cavity; the other ends of the inflow heat exchange tubes all are communicated with the water inlet cavity; the other end of the plurality of reflux heat exchange tubes all are communicated with the water outlet cavity. A plurality of systems in the multi-system flooded evaporator are capable of running independently or running simultaneously; as a result, the multi-system flooded evaporator is more flexible to use and lower in use cost.

Owner:TAIZHOU LONGJIANG CHEM MACHINERY TECH

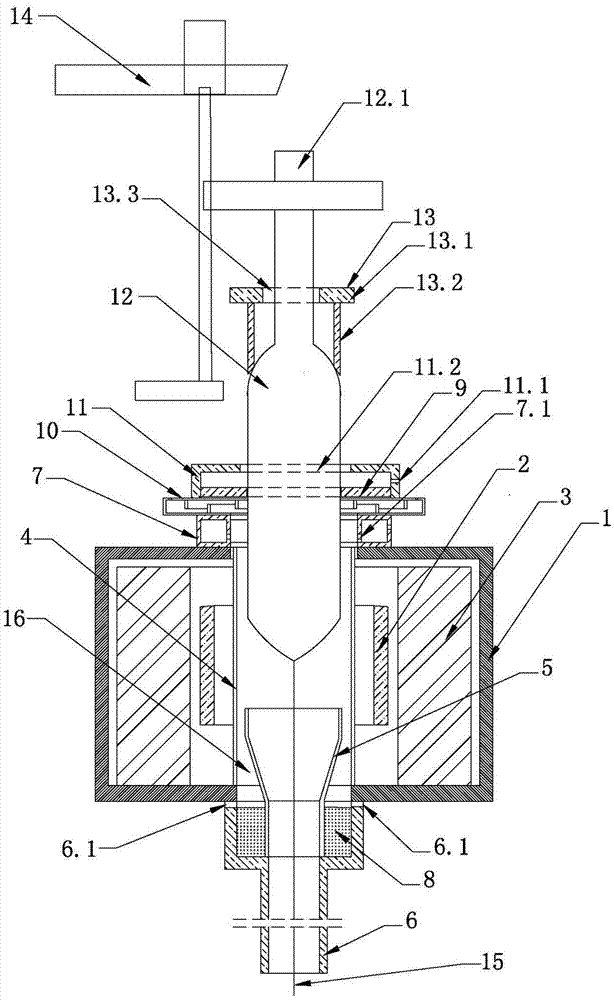

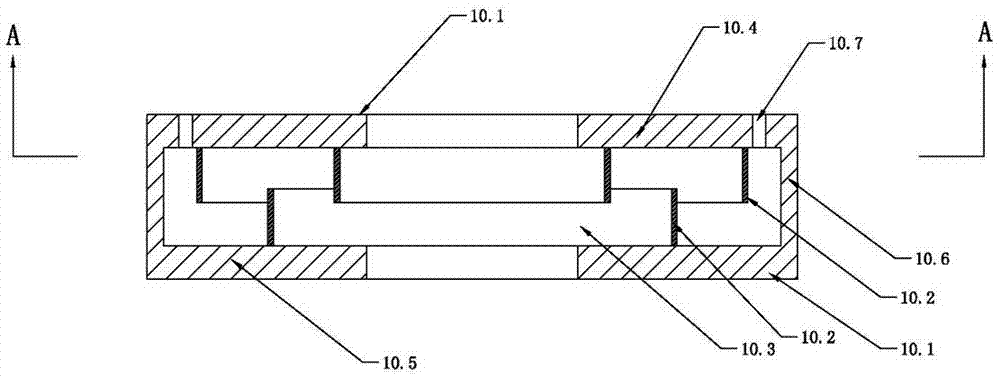

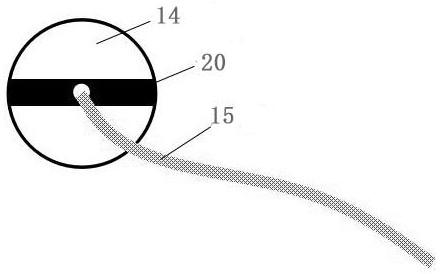

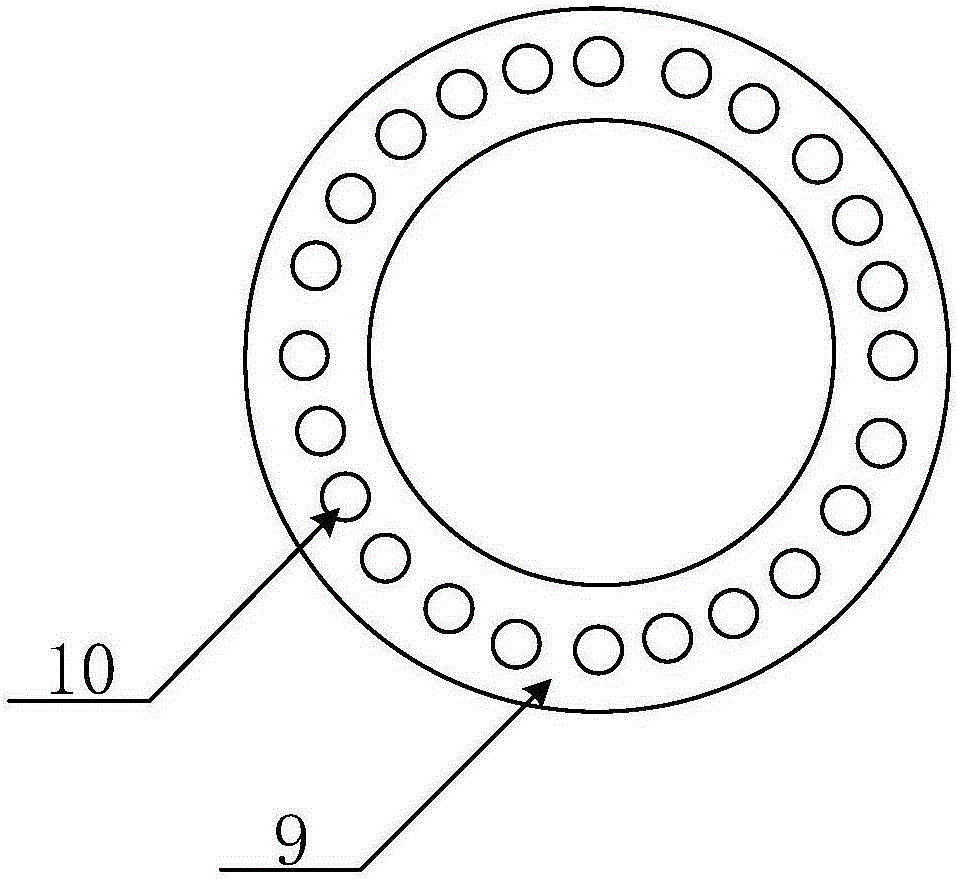

Optical fiber drawing furnace

ActiveCN103342463APlay a collection roleNot easy to stickGlass making apparatusOptical fiber cableGraphite dust

The invention relates to an optical fiber drawing furnace comprising a furnace body, a heating element, a heat preservation element, a middle casing pipe, a flow guide pipe, an extension pipe and a furnace top gaseous disc. The optical fiber drawing furnace is characterized by further comprising a lantern ring, an elastic graphite ring and a gas guide disc. The gas guide disc is mounted on the furnace top gaseous disc. The elastic graphite ring is mounted on a hollow ring plate. The lantern ring is arranged between the flow guide pipe and the extension pipe. A plurality of first air inlet holes can be formed in the side wall of the extension tube at the upper end of the lantern ring. The optical fiber drawing furnace has the advantages of being applicable to drawing prefabricated bars in large diameter and optical fiber prefabricated bars with large diameter fluctuation, meanwhile ensuring that graphite dust has less possibility of being adhered to the prefabricated bars, and effectively controlling the air flow state in the drawing furnace.

Owner:JIANGSU FASTEN PHOTONICS

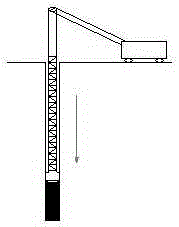

Improving method for open caisson sinking construction in geology of sludge layer

InactiveCN105256819APrevent slope collapsePrevent scurryingCaissonsBulkheads/pilesSludgeWell drilling

The invention relates to an improving method for open caisson sinking construction in geology of a sludge layer. Sinking stability piles are changed from cement powder spraying piles into after-drilling injection grouting pillars. Construction of the after-drilling injection grouting pillars comprises the steps that (1) site leveling is conducted, surveying and lining are conducted to determine the positions of the after-drilling injection grouting pillars, and a drill is put in a position; (2) holes are formed by drilling an open caisson with the adoption of a single spiral drill; and (3) after the holes are formed, grouting is conducted to hole bottoms, after the hole bottoms are solidified, grouting is conducted while a drill bit is lifted, the after-drilling injection grouting pillars are formed until the drill bit is retreated from the formed holes. The after-drilling injection grouting pillars are stable in structure and good in uniformity. No large chiseling height difference is generated when opposite-chiseling is conducted. The open caisson sinking process is more stable.

Owner:CHINA FIRST METALLURGICAL GROUP

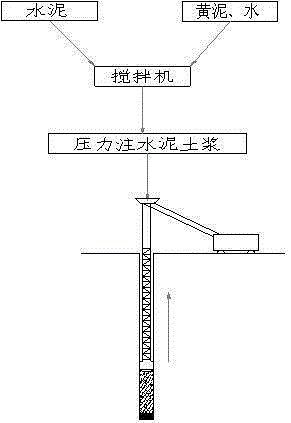

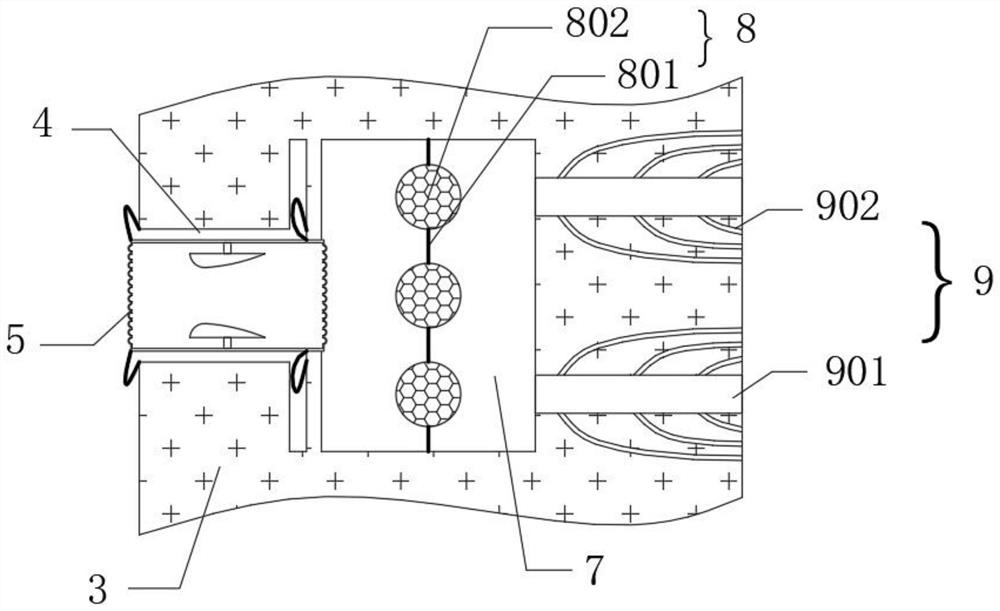

Heat-pipe-based heat exchange low-nitrogen gas burner

ActiveCN111121022AEmission reductionAvoid destructionIndirect heat exchangersIndirect carbon-dioxide mitigationWater circulationNitrogen gas

The invention discloses a heat-pipe-based heat exchange low-nitrogen type gas burner. The burner comprises an air-fuel mixing section and a combustion head which are sequentially connected in a gas flow direction, wherein a gas nozzle is arranged in the air-fuel mixing section, the combustion head comprises a plurality of heat pipes arranged in a pipe bundle mode, a heat pipe evaporation heat absorption section in the pipe bundle is arranged to form a combustion gap as the combustion head, and a heat pipe condensation heat release section is provided with a condensing device and is arranged outside a furnace. According to the burner, the combustion head formed through intermittent arrangement of the plurality of heat pipes is arranged between the furnace and the air-fuel mixing section, two phase-change heat exchange processes of evaporation heat absorption and condensation heat release in a heat pipe heat transfer process have the advantages of good heat conductivity, isothermal property and the like, so that pipe inner working media in the heat pipes are evaporated into steam when the heat pipe evaporation heat absorption section absorbs heat of a combustion zone of the furnace,the condensation device of air cooling, water cooling and the like is adopted for condensation and heat releasing, liquid after the steam in the pipes is subjected to heat releasing and condensation flows back the heat absorption section under the action of gravity, and the damage caused to a boiler hydrodynamic cycle of a water-cooled combustor water cycle is effectively solved.

Owner:XI AN JIAOTONG UNIV +1

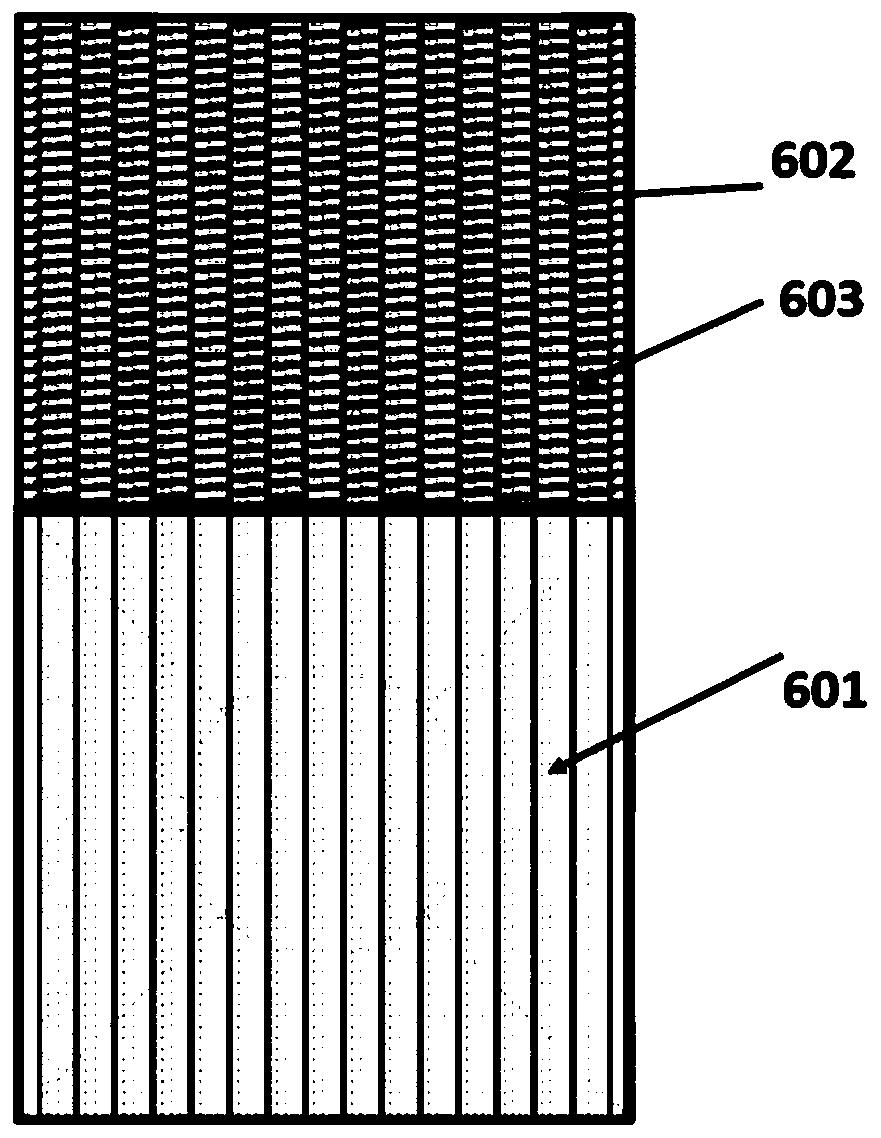

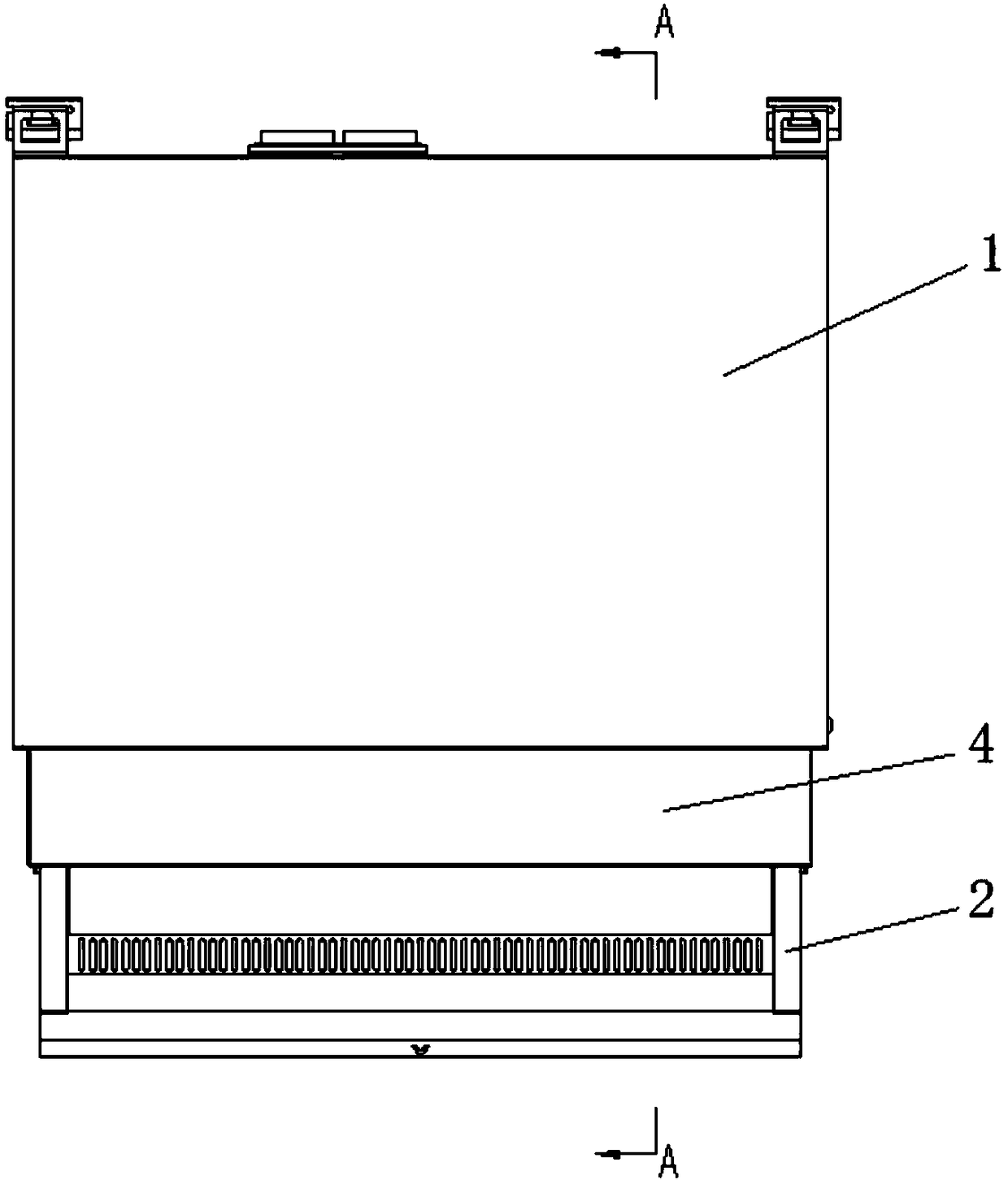

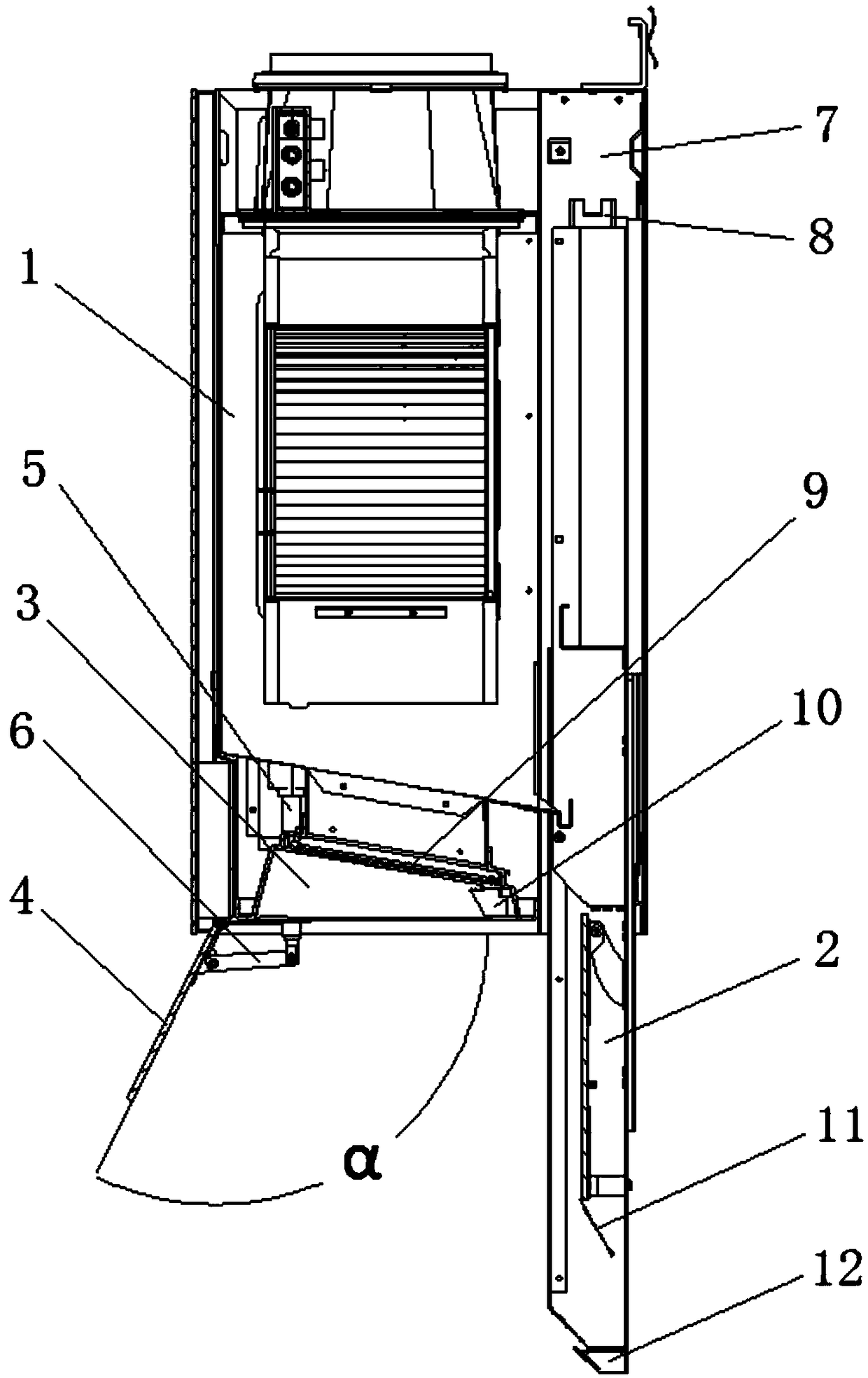

Full-embedded range hood and opening and closing control method thereof

InactiveCN108644839AAny opening and closing angleAchieve hoverDomestic stoves or rangesLighting and heating apparatusElectricityControl system

The invention discloses a full-embedded range hood comprising a range hood main body, a main smoke collection cavity, an auxiliary smoke collection cavity, a steady flow plate, a first driving mechanism, a second driving mechanism, an oil smoke sensor and an electrical control system. The steady flow plate is opened and closed rotationally at the bottom of the auxiliary smoke collection cavity. The first driving mechanism drives the steady flow plate to rotate. The second driving mechanism drives the main smoke collection cavity to move up and down. The oil smoke sensor detects the oil smoke concentration of an oil smoke area in real time and feeds back the oil smoke concentration to the electrical control system. The electrical control system is in electric connection with the first driving mechanism and the second driving mechanism. The electrical control system judges the magnitude of the oil smoke concentration to control the strokes of the first driving mechanism and the second driving mechanism and then controls opening and closing angles of the steady flow plate and the moving-down stroke of the main smoke collection cavity. The invention further discloses an opening and closing control method of the full-embedded range hood. With the adoption of the full-embedded range hood and the opening and closing control method thereof, the work utilization rate of the range hood can be increased effectively, and the smoke collection effect of the full-embedded range hood can also be improved effectively.

Owner:GUANGDONG VANWARD ELECTRIC

High-pressure injection pump

The invention belongs to the technical field of water pumps, and particularly relates to a high-pressure injection pump. The high-pressure injection pump includes a rotor body, a collecting main, wherein the rotor body includes impellers and a rotor cavity, and the collecting main includes diffusion sections and an outlet pipe; the outer surfaces of the diffusion sections of the collecting main are in streamline shapes; and the diffusion sections of the collecting main are evenly distributed in an array mode in the circumferential direction of the outlet pipe, the number of the diffusion sections of the collecting main is at least 3, the outlet pipe of the collecting main is made of elastic materials, and the inner diameters of the cross sections of the outlet pipe are gradually decreasedfrom the left to the right. According to the high-pressure injection pump, the number of the diffusion sections of the collecting main is at least 3, thus water amount flowing into inner cavities of the diffusion sections is increased, rate of flow of water flowing into the outlet pipe and pressure of the water flowing into the outlet pipe are increased, the pressure and the rate of flow of the water flowing out of the outlet pipe are increased, the inner diameters of the cross sections of the outlet pipe are gradually decreased from the left to the right, thus when water flow passes the outlet pipe from the left to the right, water pressure is gradually increased, and thus the pressure of the water flowing out of the outlet pipe is increased.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

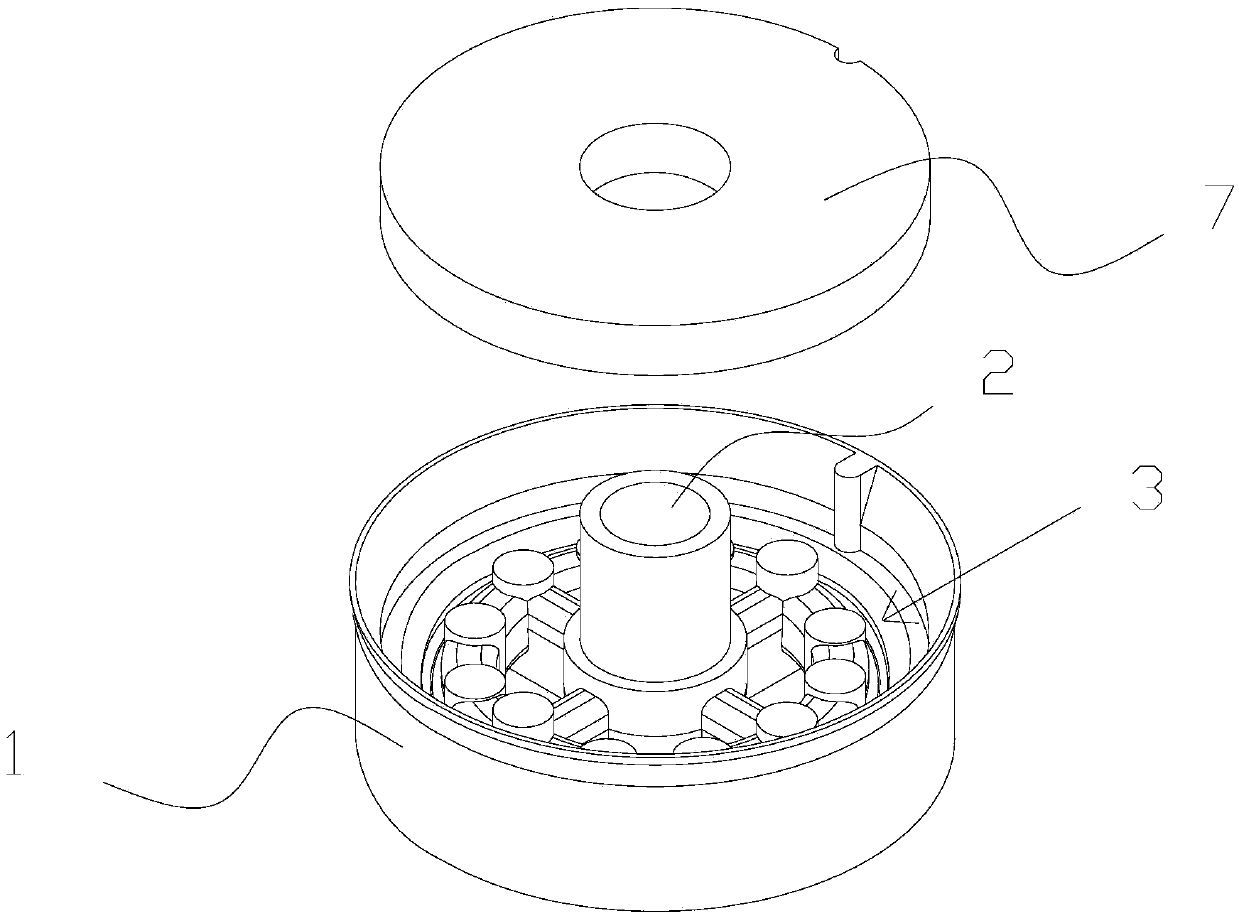

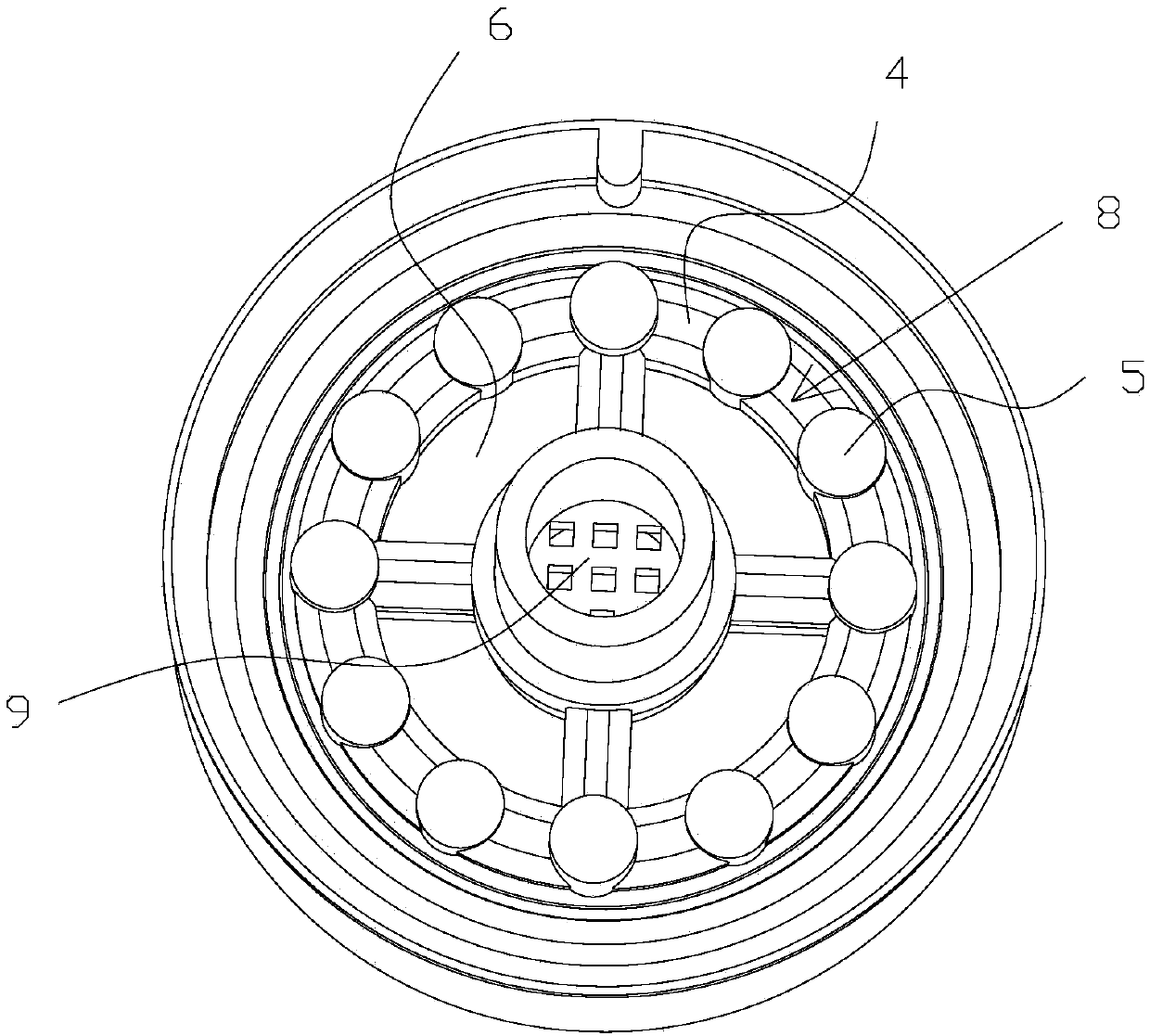

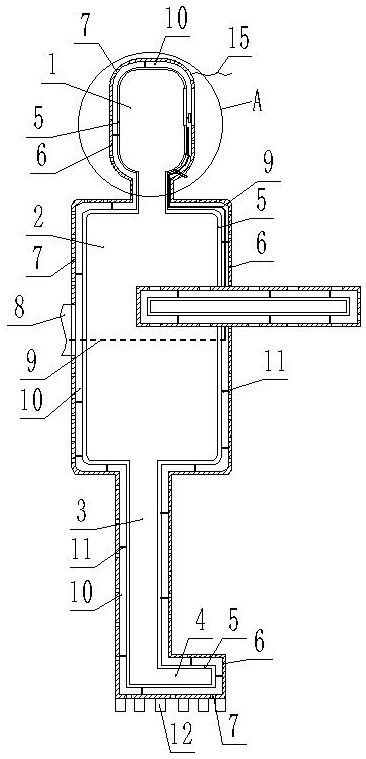

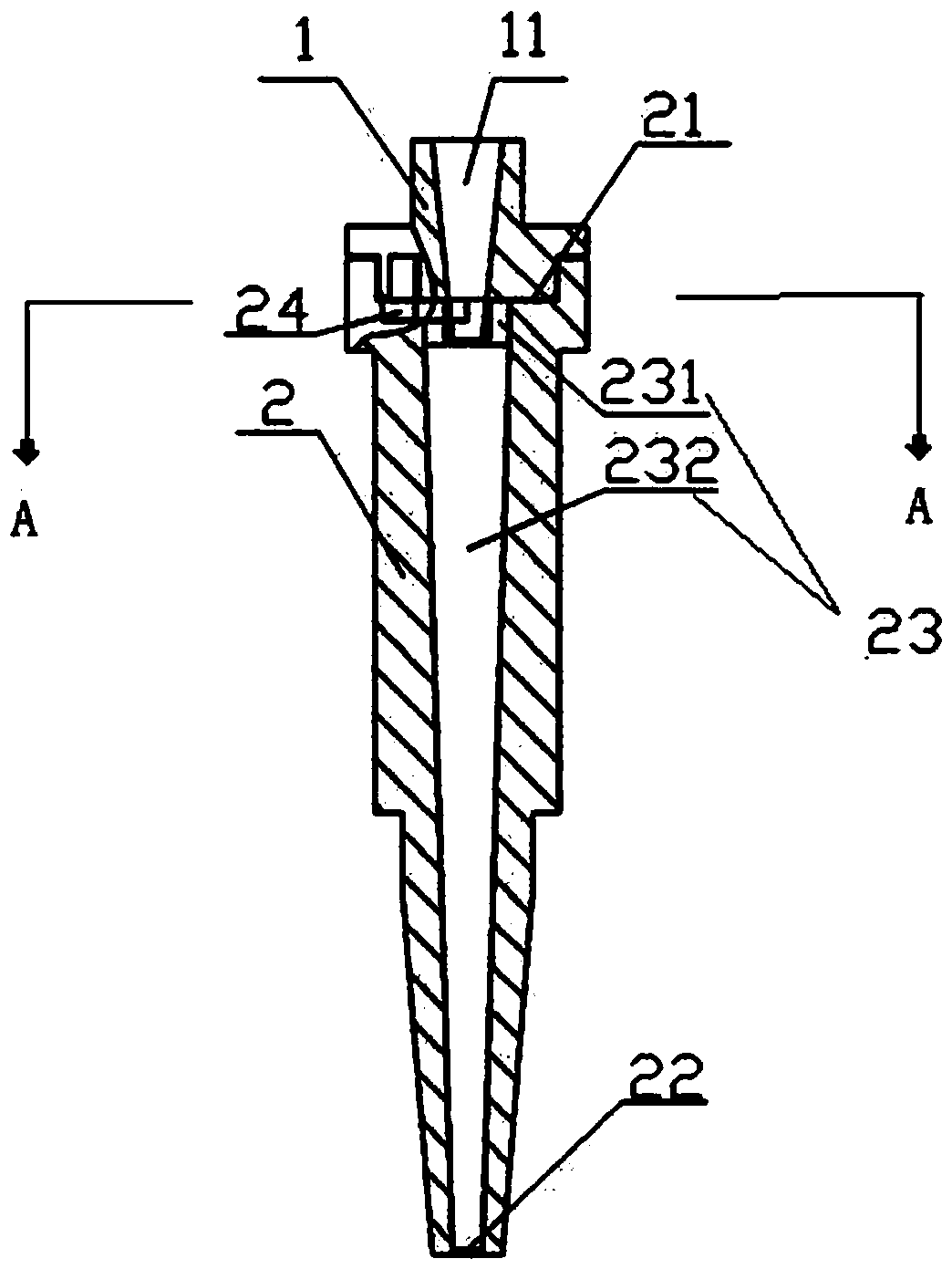

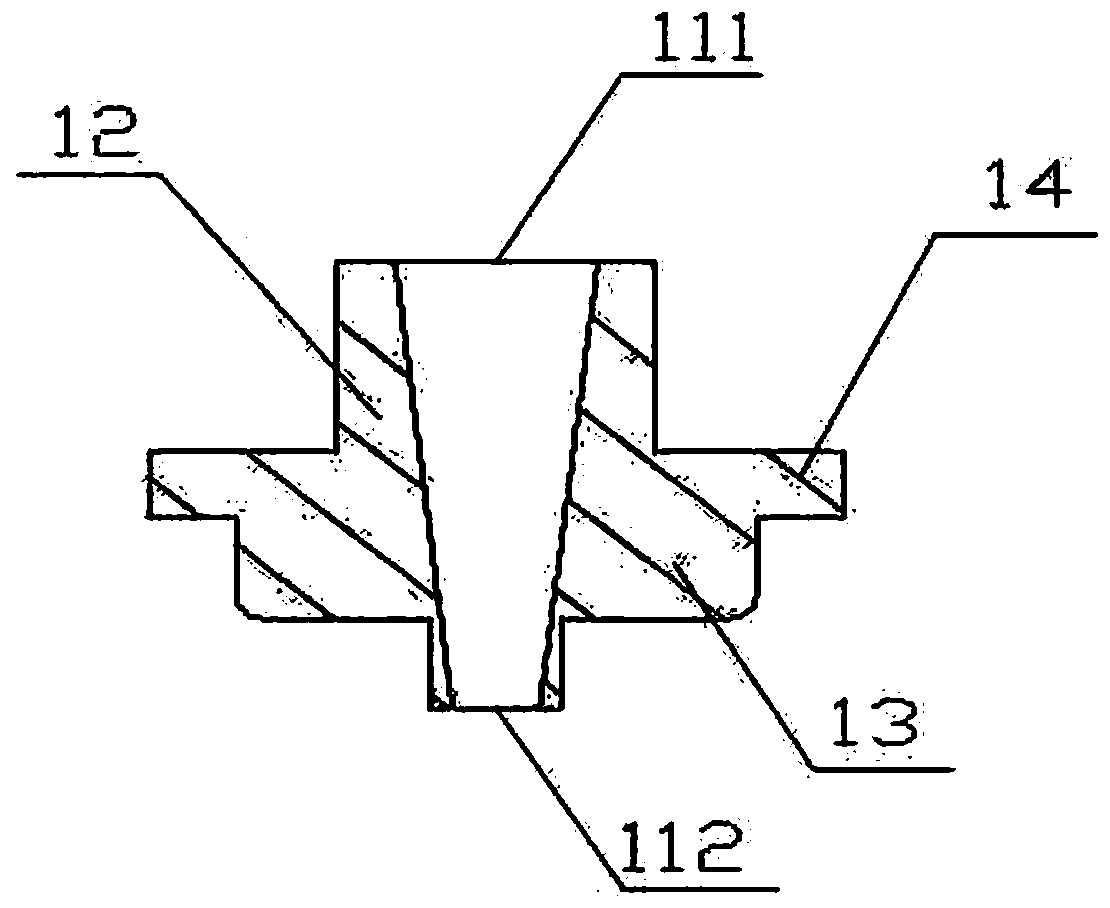

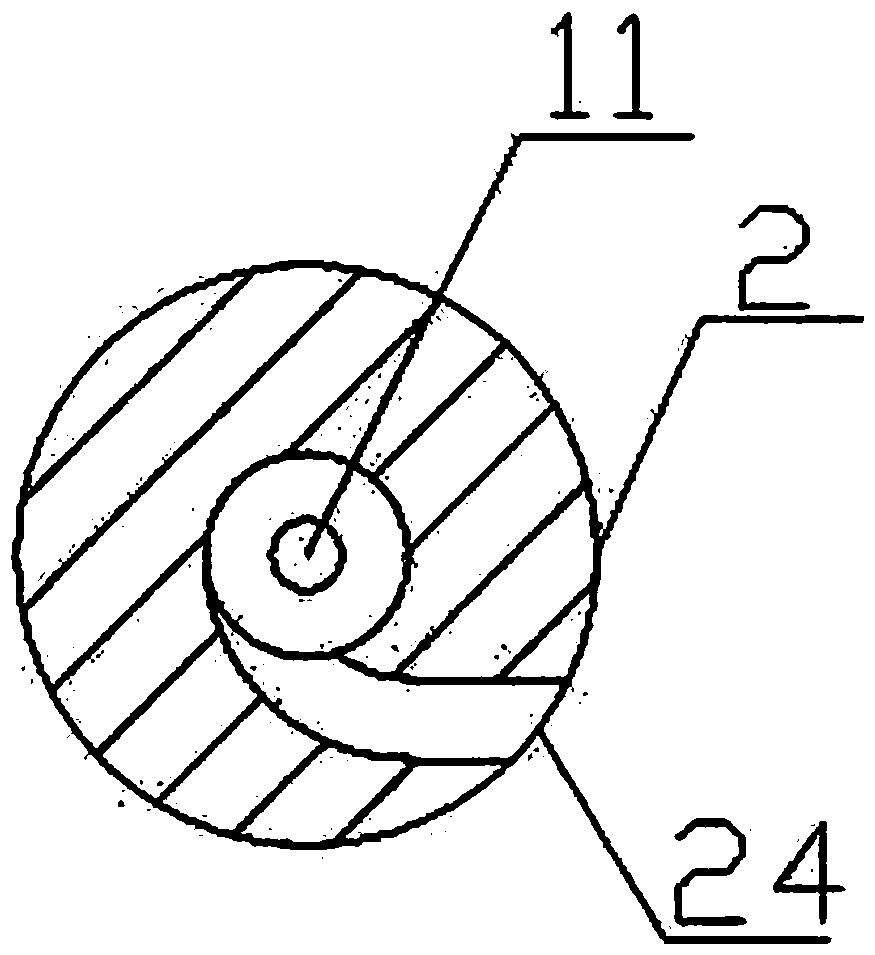

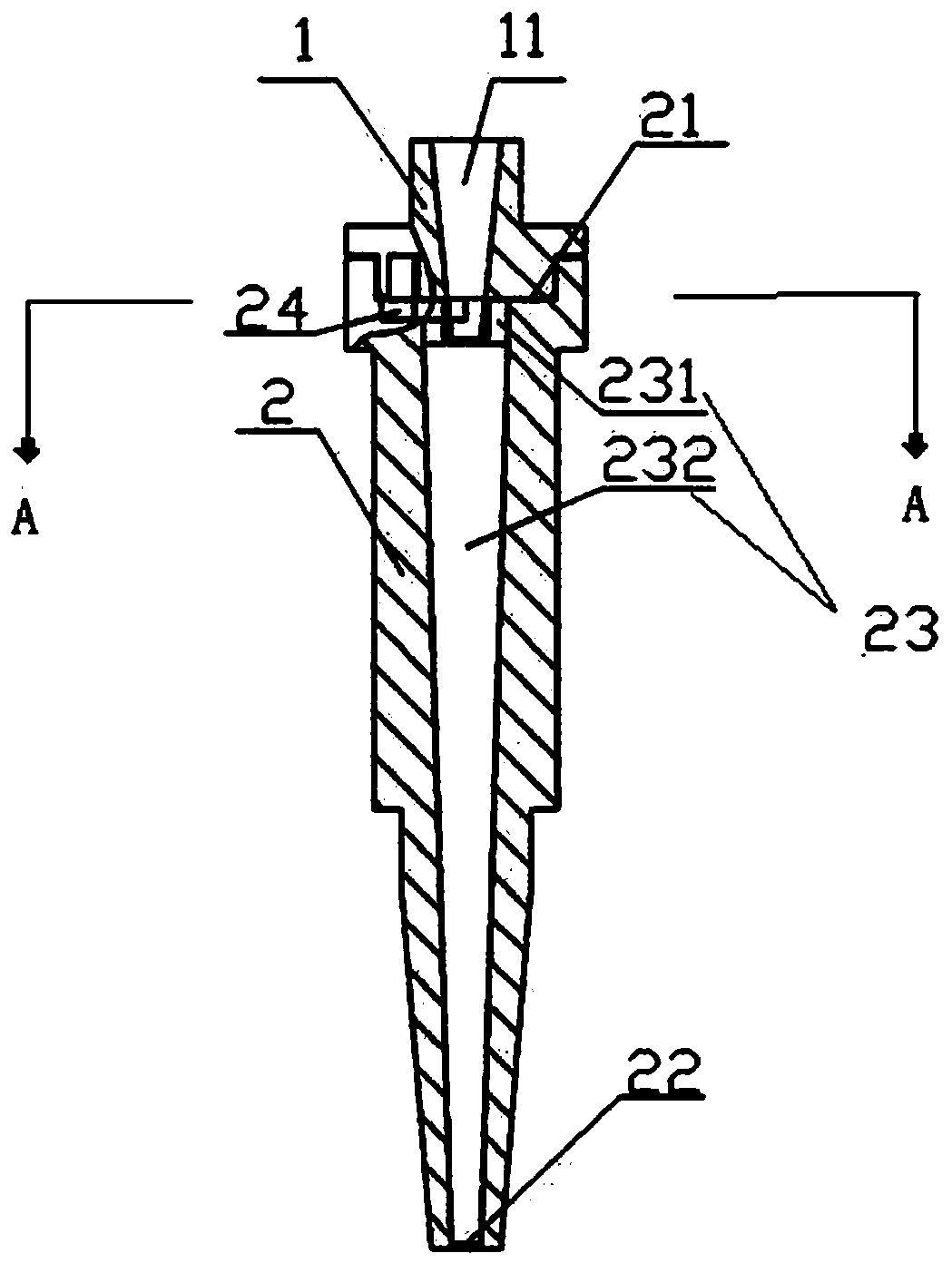

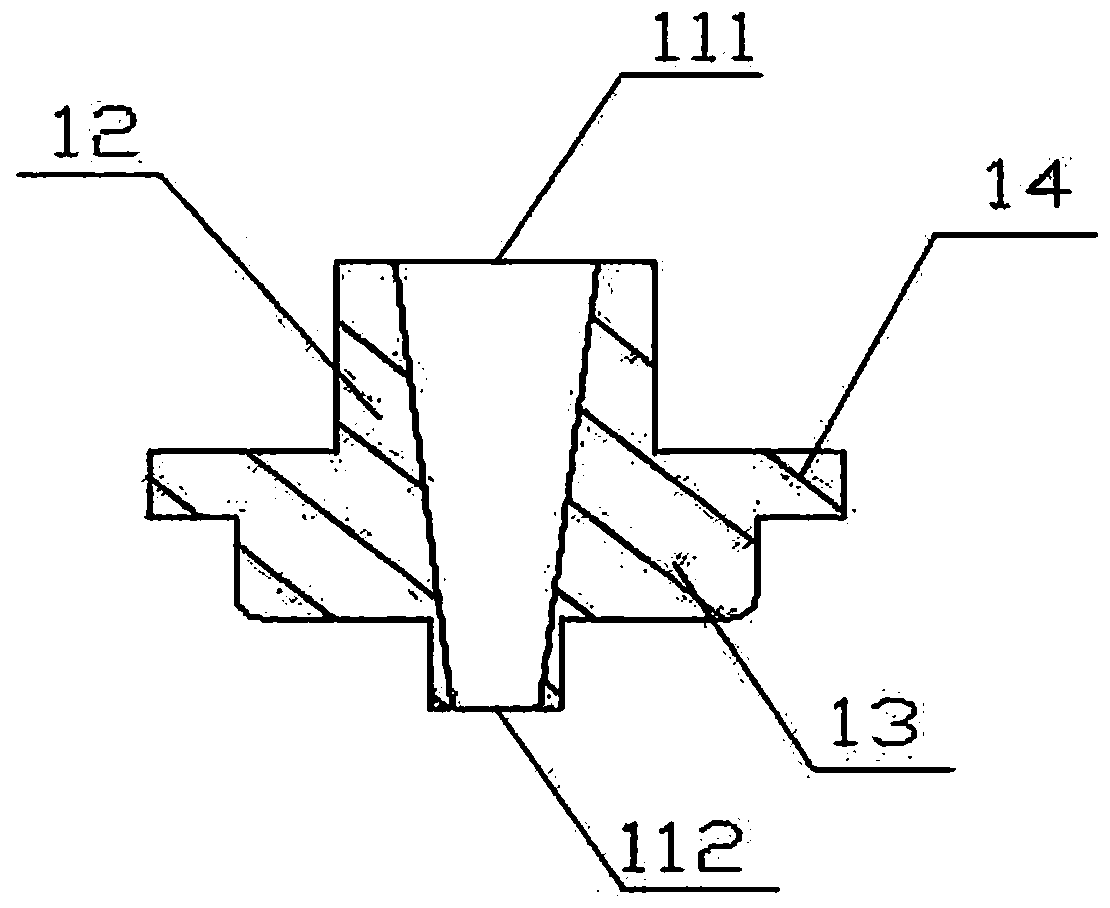

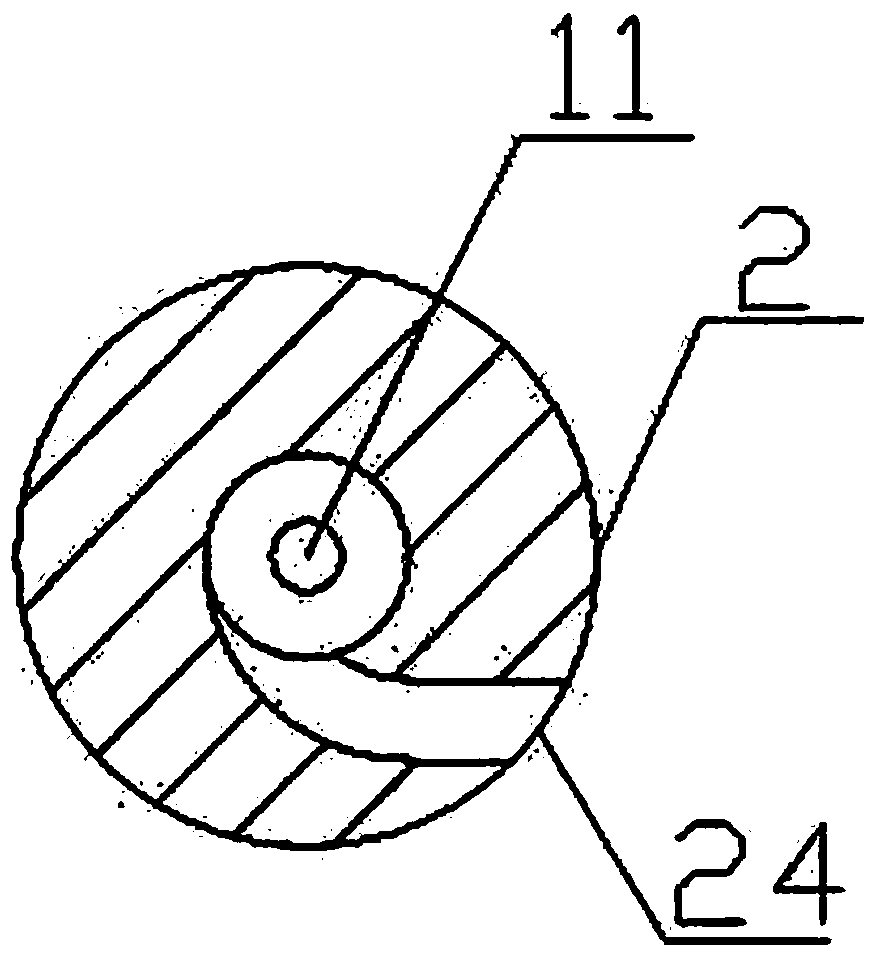

Temperature sense regulating valve spool

ActiveCN105864500APlay the role of steady flowOperating means/releasing devices for valvesWater flowEngineering

The invention discloses a temperature sense regulating valve spool which comprises a front cover, a flow stabilizing core, a pressure spring, a balance cover and a regulating plate, wherein a threaded connection part of the flow stabilizing core is in threaded fit with a threaded hole in the balance cover and extends out of the balance cover; the threaded connection part is in threaded fit with the regulating plate; a diversion gap is formed between the regulating plate and the balance cover; the regulating plate covers the diversion hole; the end part of a cylinder part of the flow stabilizing core is fixed to a guide hole; one end of the pressure spring is matched with a bottom plate of a body part of the front cover, while the other end of the pressure spring is matched with the balance cover; an opening end of the balance cover extends into the body part of the front cover and is matched with the body part in a sliding manner. With adoption of such a structure, the regulating plate is rotated to regulate the gap between the regulating plate and the balance cover, so as to regulate the water flow; the balance cover and the front cover moves relatively to play a role of stabilizing the water flow.

Owner:SIYUAN ELECTRIC APPLIANCES

Optical fiber drawing method for large-diameter optical fiber preform rod

ActiveCN103304135BNot easy to stickControl air flowGlass fibre drawing apparatusShielding gasOptical fiber cable

The invention relates to an optical fiber drawing method for a large-diameter optical fiber preform rod. The method comprises the following steps: continuously moving the large-diameter optical fiber preform rod downwards to enter an optical fiber drawing furnace through a lifter, heating and drawing to form a finished optical fiber, inputting protective gas into the furnace body through an extension pipe at the furnace bottom, allowing the protective gas to flow upwards, allowing the gas to flow out of a gas outlet of a gas guide disc, and allowing the protective gas input by the gas guide disc and a gas sealing cover to flow out of the gas outlet of the gas guide disc. The method has the advantage that the large-diameter optical fiber preform rod can be drawn to form the optical fiber with stable quality.

Owner:JIANGSU FASTEN PHOTONICS

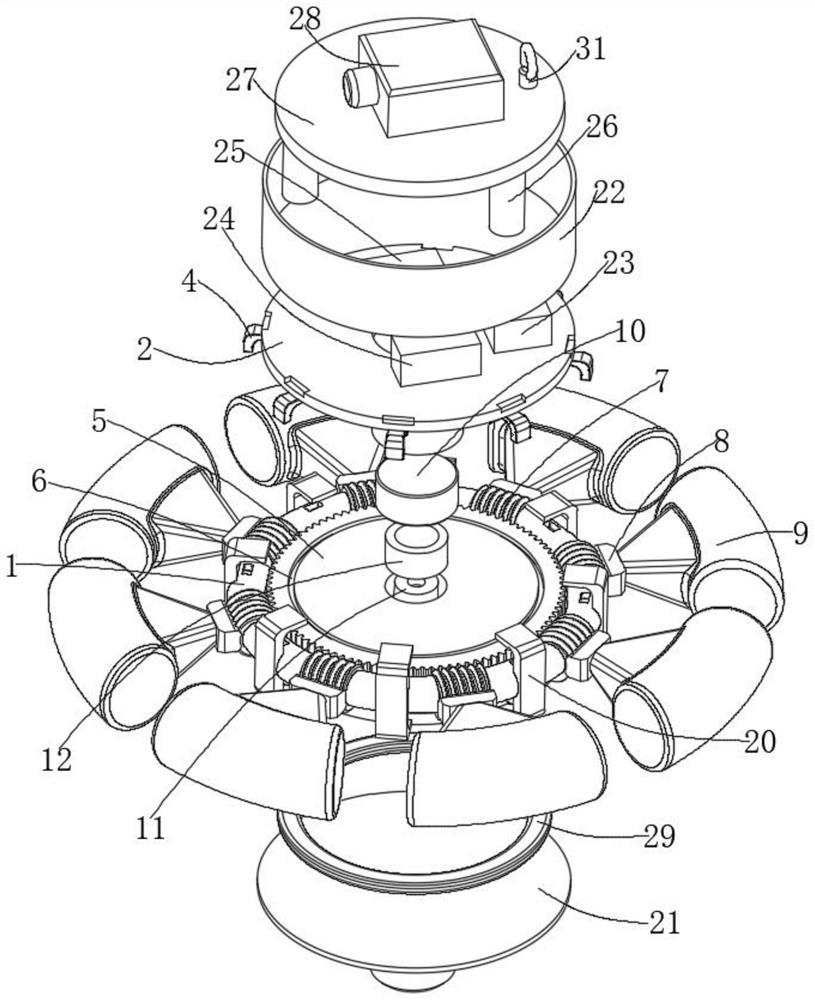

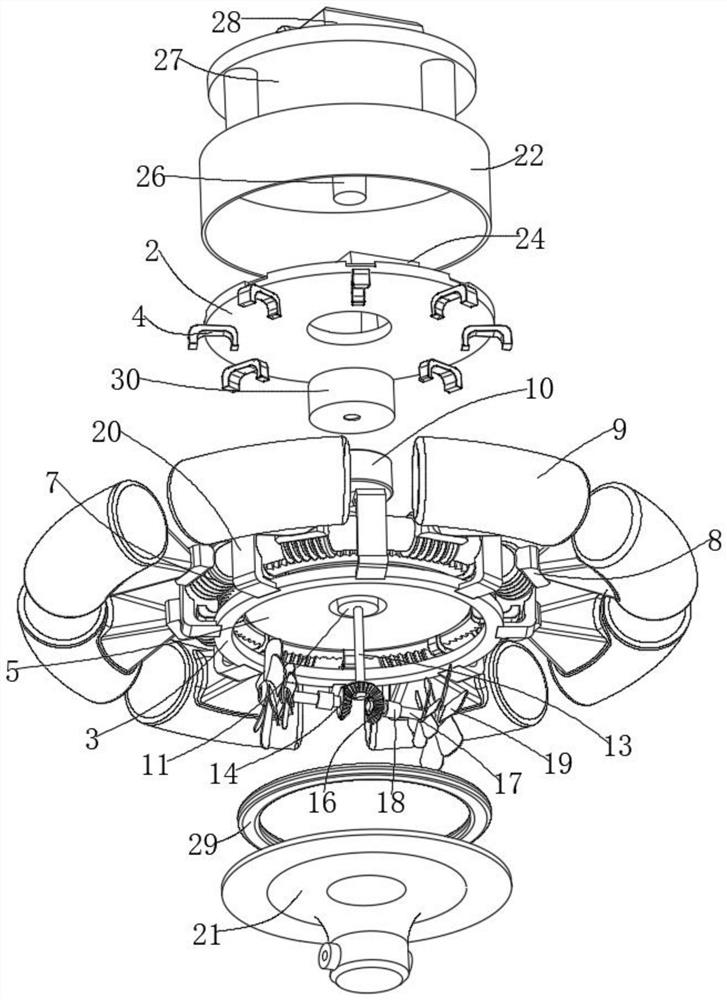

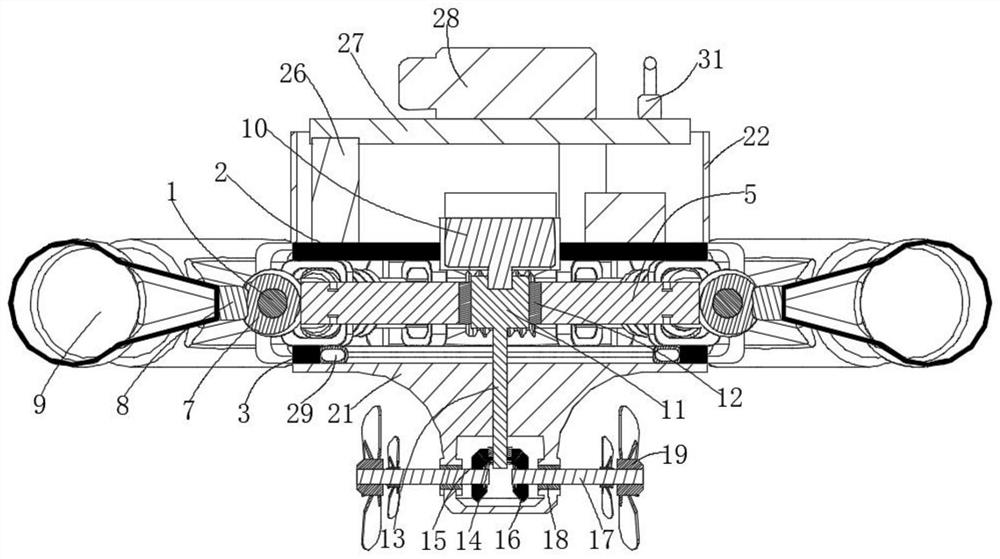

Intelligent device for shooting and collecting water quality surface environment

ActiveCN112874703ALarge displacementIncrease buoyancyWaterborne vesselsNon-rotating vibration suppressionElectric machineryEnvironmental geology

The invention discloses an intelligent device for shooting and collecting water quality surface environment, and relates to the technical field of water area operation mechanical equipment. The device comprises a main body, and the top and bottom of the main body are fixedly provided with a fixed top plate and a fixed bottom plate respectively. The outer side of the main body is evenly and rotatably connected with multiple sets of worms, the inner side of the main body is provided with the worm gears meshed with the multiple sets of worms, the worm gears are driven to rotate through positive and negative rotation of a motor, and the multiple sets of worms can drive overturning hollow buoys to overturn by a certain angle up and down. When the density is small, the overturning hollow buoys stretch into the water surface, so that the overall displacement of the device is increased, the overall buoyancy of the device is increased, and the device can better adapt to waters with lower water density. When the density is large, the hollow buoys are overturned upwards, so that the overall displacement of the device is reduced, the overall floating height of the device in the water area with the high water density is reduced, and then the overall gravity center of the device is reduced.

Owner:安徽圣恩智能科技有限公司

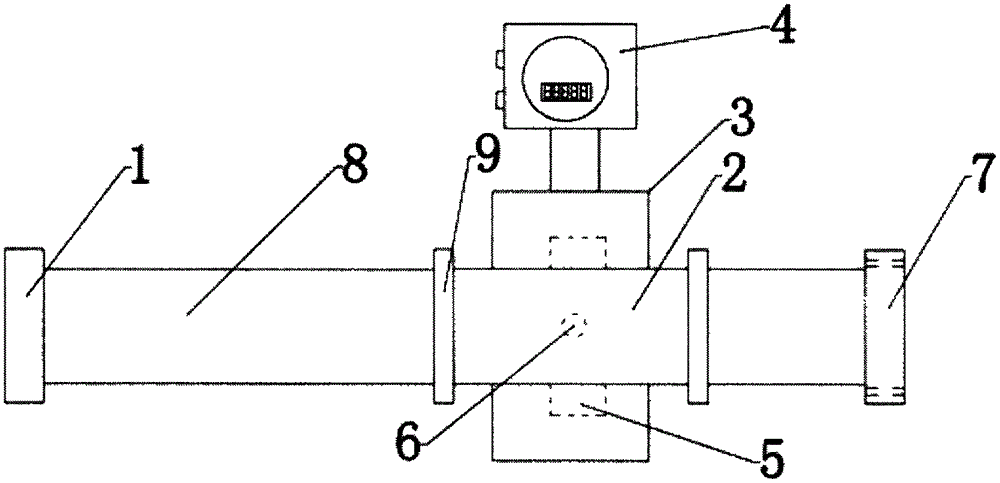

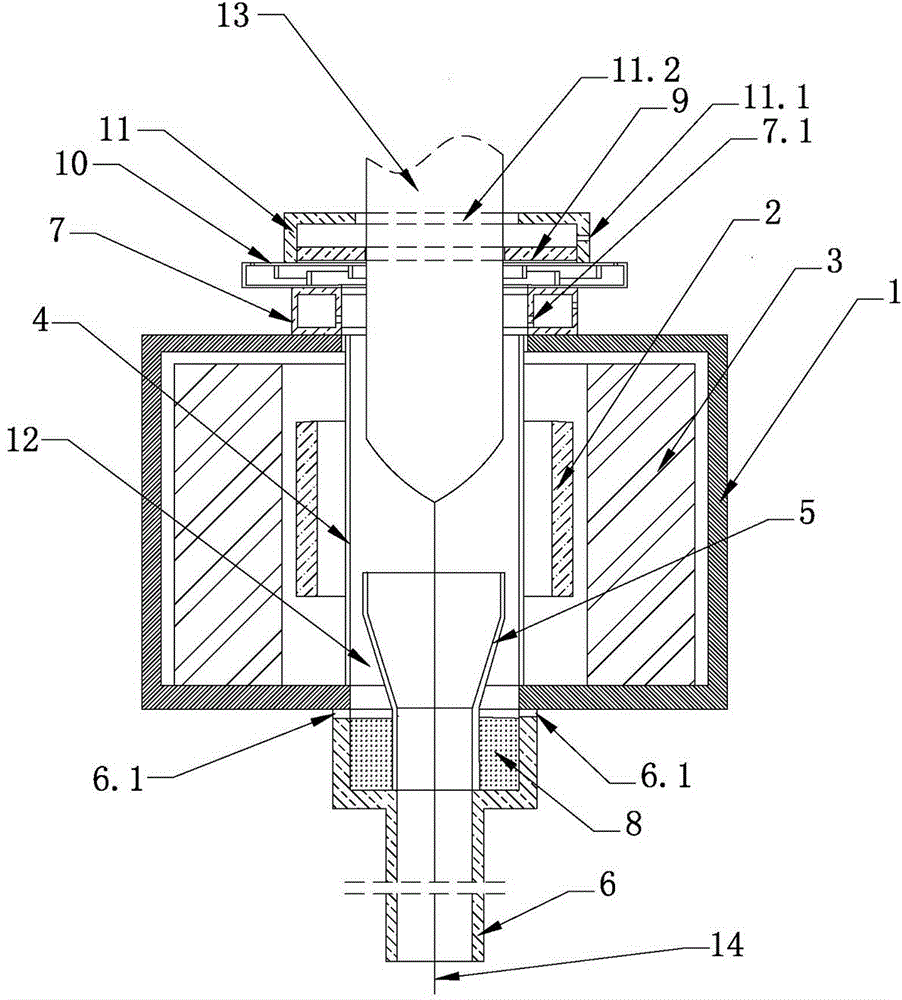

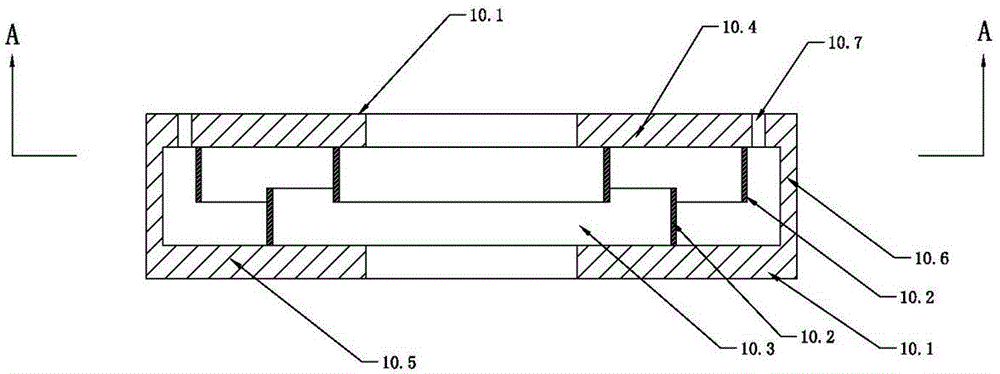

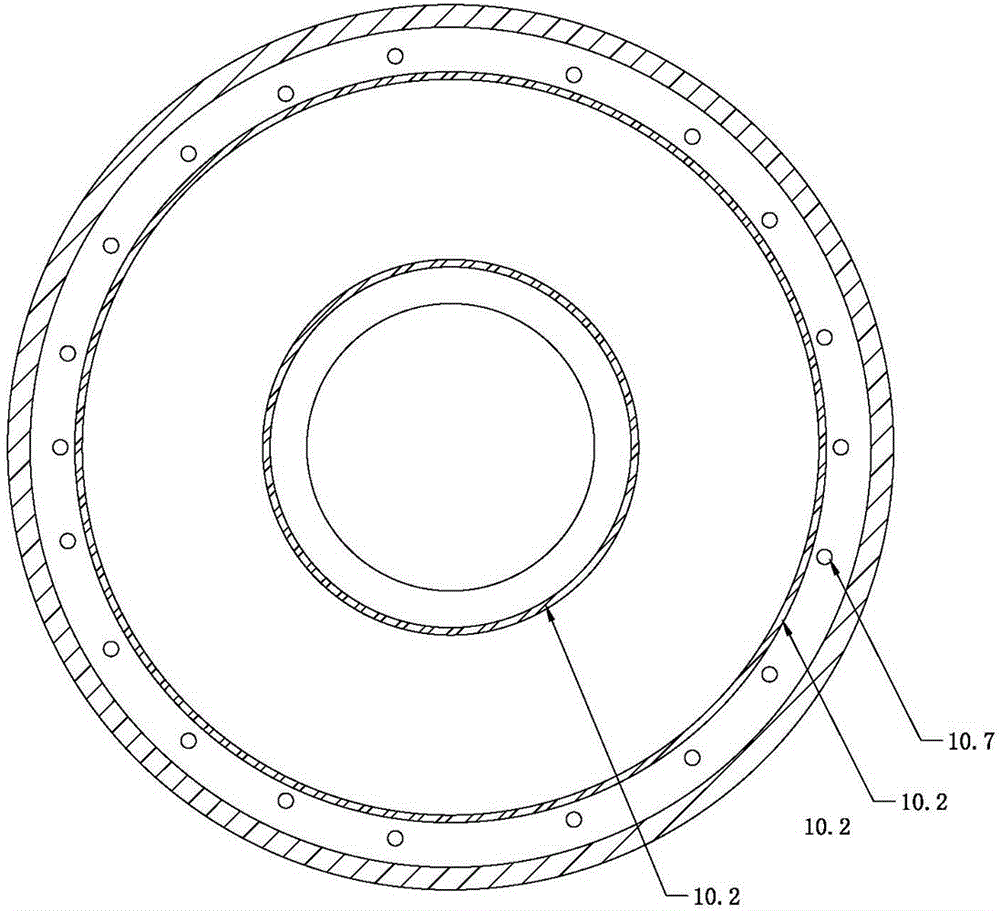

An electromagnetic flowmeter

InactiveCN106813733AFluid flow rate is stableGuaranteed measurement accuracyVolume/mass flow by electromagnetic flowmetersElectromagnetic flowmeterEngineering

The invention discloses an electromagnetic flowmeter, which comprises a water inlet flange, a measuring tube, a measuring tube shell, a converter, a coil, an electrode and a water outlet flange. The water inlet flange is located at one end of the measuring tube, and the water outlet flange is located at At the other end of the measuring tube, the converter is installed in the measuring tube housing, the coil and electrodes are installed on the measuring tube and located in the measuring tube housing, and also includes a straight-through pipe connected to the water inlet method In this way, the average flow velocity in the cross-section of the measuring tube can be stabilized through the straight-through tube to solve the problems of low reliability, poor stability and low measurement accuracy.

Owner:CHANGZHOU CHENTONG TELECOMM EQUIP FACTORY

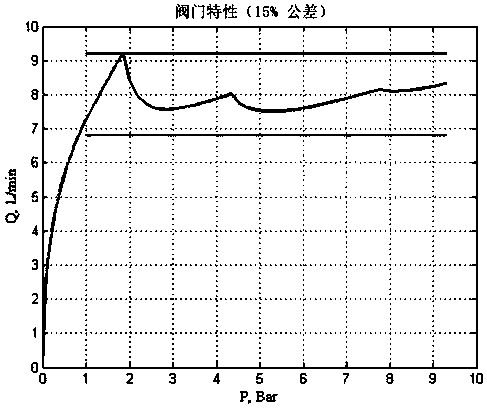

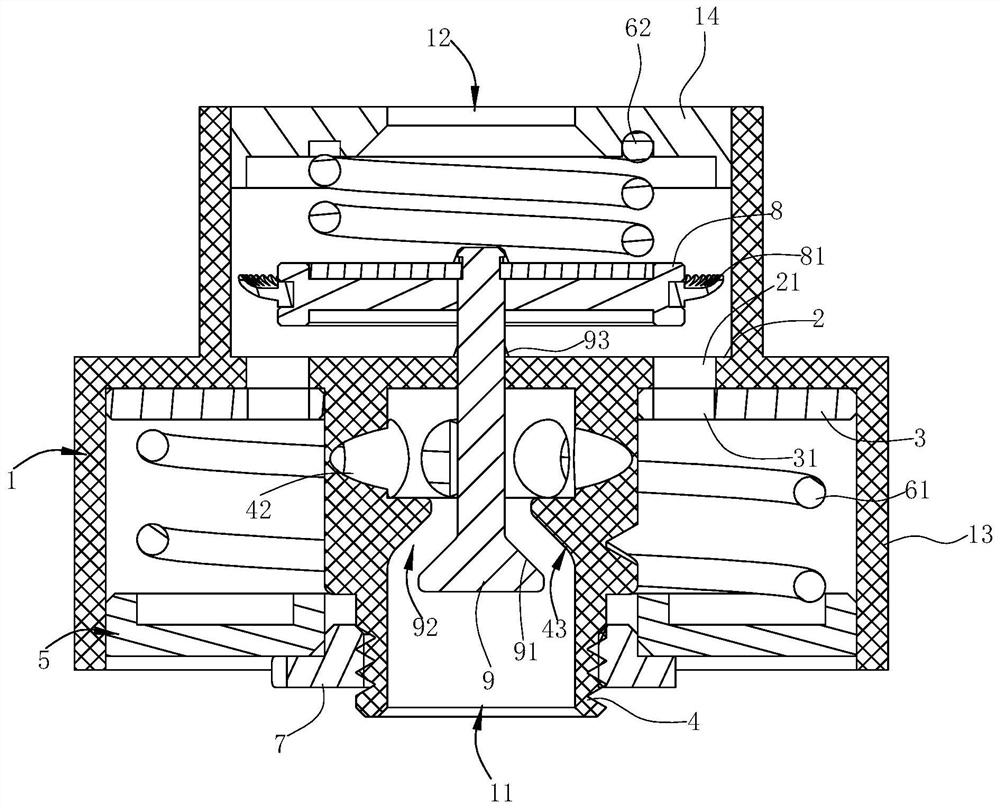

Water inlet valve, flow rate calculating and calibrating method and flow rate calculating and calibrating device

PendingCN109578614APlay the role of steady flowDiaphragm valvesEngine diaphragmsInlet valveEngineering

The invention relates to the field of valve bodies and provides a water inlet valve, a flow rate calculating and calibrating method and a flow rate calculating and calibrating device. The water inletvalve comprises a valve body, wherein a central channel is arranged in the middle of the valve body; a flow rate control device is arranged on the outer side of the central channel and comprises a flow rate seat; a plurality of flow rate columns are arranged on the flow rate seat and are made of elastic material; a water passing area is arranged between the flow rate seat and the central channel;the valve body is matched with a rubber sheet; and a hollow water passing gap is formed among two adjacent flow rate columns, the flow rate seat and the rubber sheet and communicates with the water passing area. A flow rate and pressure characteristic analyzing system and calculating method combine the variable and constant elements of the water inlet valve. The variable is the water passing areabetween the heights of different flow rate columns of the flow rate seat and the rubber sheet under different pressures and aims to analyze and master the flow rate variation values within different pressure scopes. A model disclosed by the invention can be used in a computer or independently.

Owner:JINHUA HONGCHANG ELECTRLCAL EQUIP CO LTD

Dual-modulation type plate-like capacitor

InactiveCN107275088AEasy maintenanceExtended service lifeCapacitor with electrode distance variationElectrical connectionEngineering

The invention discloses a double-adjustable plate capacitor, which comprises a No. 1 body and a No. 2 body. The No. 1 body is a cylindrical cylinder with an open upper end. A lower capacitor plate is arranged in the No. 1 body, and the lower capacitor plate is supported by The column is connected and fixed with the No. 1 body. The No. 1 body is covered with the No. 2 body. The upper capacitor plate is installed under the No. 2 body. The upper capacitor plate is connected and fixed with the No. 2 body through the boom. The No. 2 body and the No. 1 body The bodies are connected by threads, and the inner wall of the upper end of the No. 1 body is clamped with a metal ring. The metal ring is in sliding contact with the upper capacitor plate. The electric connection pin is connected to the two input terminals of the rectifier through the conductive rod. The structure of the present invention is simple and reasonable, and the capacitor can be adjusted from two aspects, so as to achieve the effect of variable capacitance, which is convenient to use and helps to improve the performance of the capacitor body. service life.

Owner:深圳市创星信息科技有限公司

A gas detection device and detection method

ActiveCN111766330BPlay the role of steady flowImprove detection accuracyChemical analysis using catalysisChemical analysis using combustionCombustible gasEngineering

The invention relates to the technical field of gas detection, and discloses a gas detection device and a detection method. The detection device comprises a mixer, a gas delivery device to be measured, a catalytic gas delivery device and a catalytic combustion sensor, and a flow guide is arranged in the mixer. A premixed material area, a first air guide area and a second air guide area are formed in the mixing area. The gas conveying equipment to be tested is connected to the first air guide area, and the catalytic gas conveying equipment is connected to the second air guide area. The area is connected and can transport catalytic gas to the premixed material area, the gas to be tested and the catalytically promoted gas are mixed in the premixed material area to form a mixed gas, and the mixed gas is guided to the catalytic combustion sensor through the diversion area; the detection method comprises S1: The gas to be tested and the catalyst-promoting gas are delivered to the mixer for mixing to obtain a gas sample to be tested; S2: the gas sample to be tested is detected by a catalytic combustion sensor to obtain a flammable gas concentration value.

Owner:南京三鸣智自动化工程有限公司

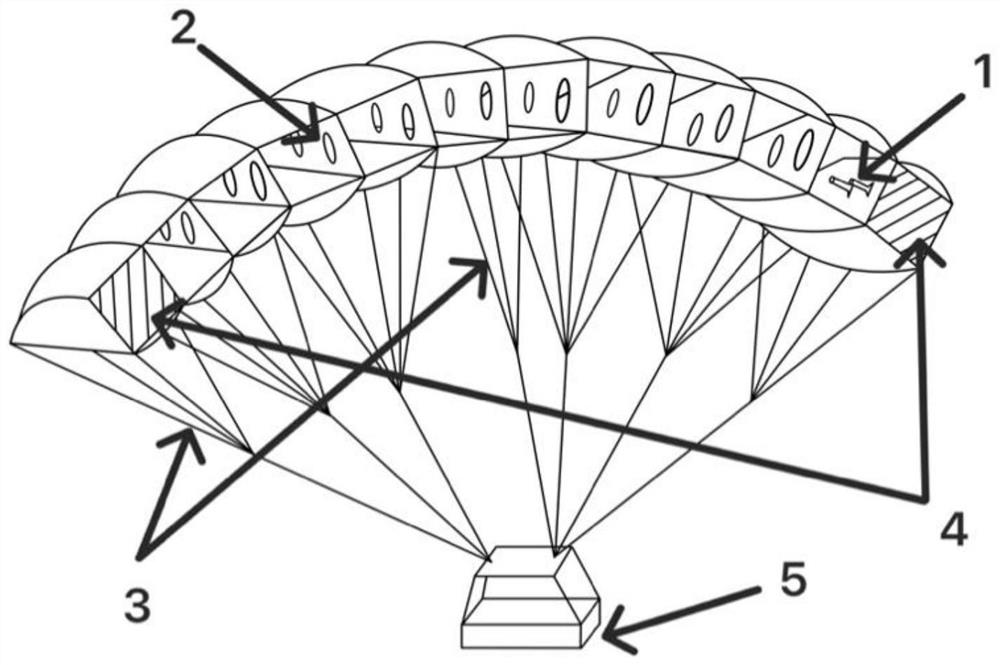

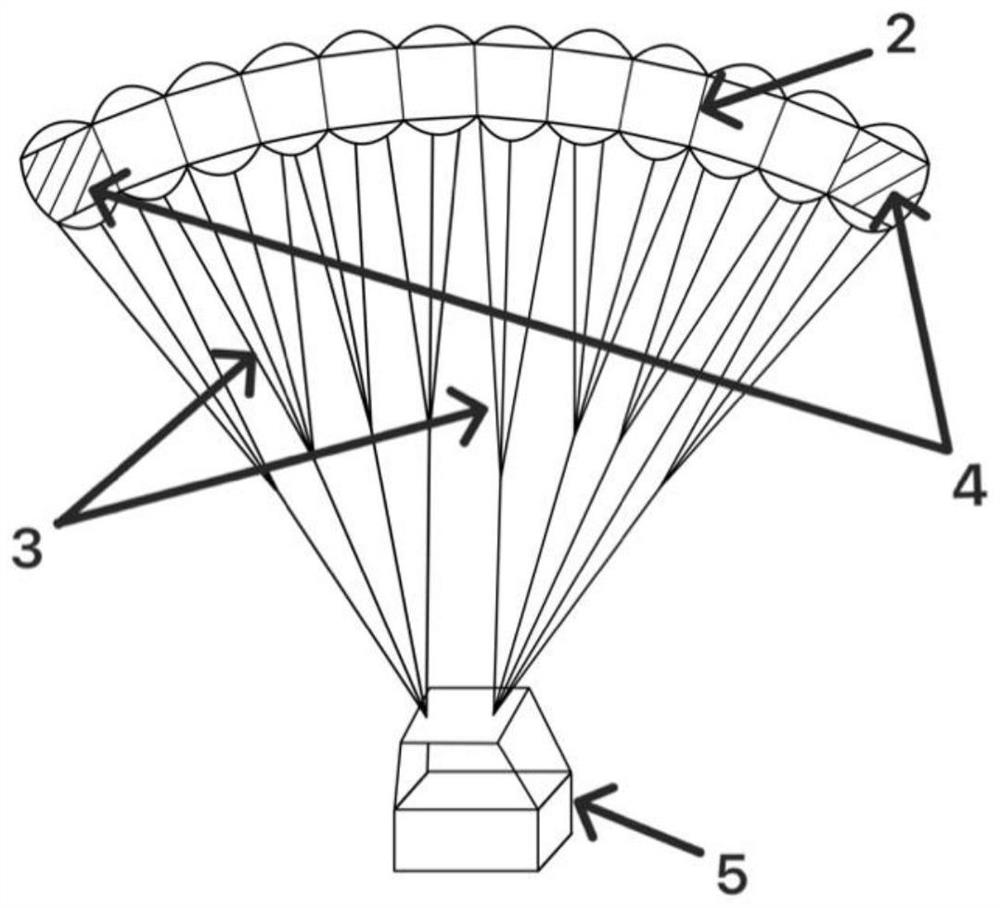

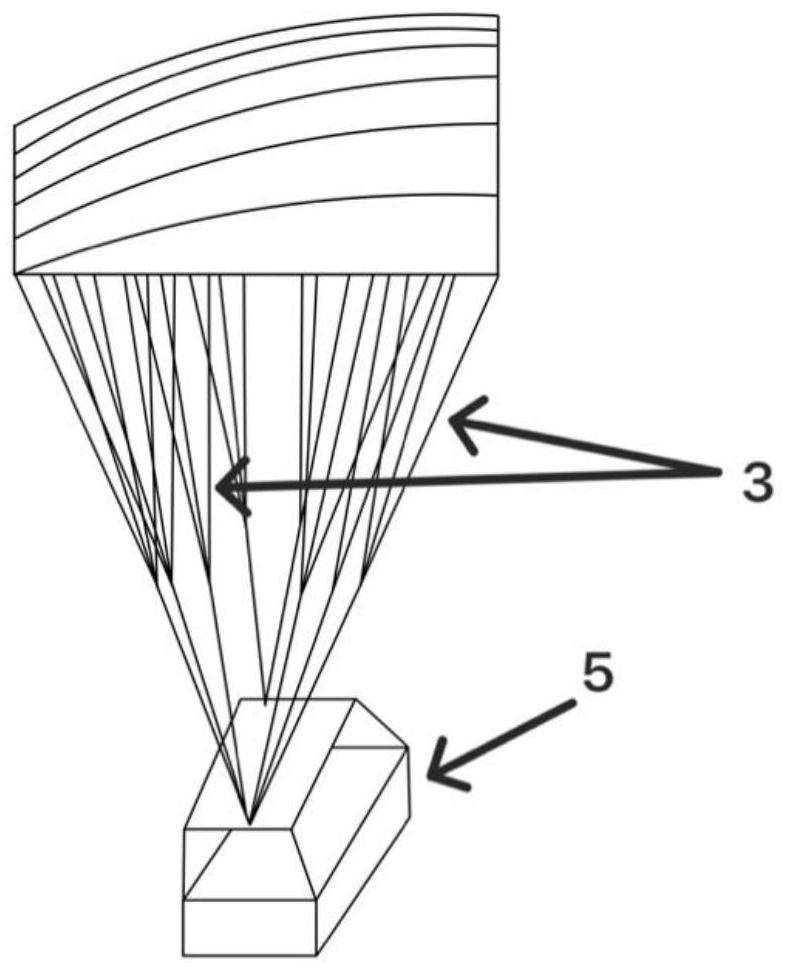

Rapidly-opened parafoil structure and opening method thereof

The invention provides a parafoil structure capable of being quickly opened and an opening method thereof. The parafoil structure comprises a hollow cavity with the front edge open and the rear edge sealed, the center of the cavity is divided into a plurality of air chambers through wing ribs, vent holes are formed in the wing ribs, and the lower ends of the wing ribs are connected with parafoil cords; the left end and the right end of the cavity are connected with inflation channels in a fully-closed state, the inflation channels are connected with the adjacent air chambers through pressure release valves, and inflation devices and deflation valves are arranged in the inflation channels. The parafoil inflating structure provided by the invention can help the parafoil to quickly form an inflating opening state for normal sliding of the parafoil after the parafoil is thrown out of an aircraft cabin, so that the air-drop safety of the parafoil is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Air-blowing steady-flow heat-dissipation protective clothing and using method thereof

PendingCN112674408AAvoid overall overheatingPlay a protective effectSolesLighting and heating apparatusMechanical engineeringAir blast

The invention relates to an air-blowing steady-flow heat-dissipation protective garment which comprises an integrated protective garment body, the integrated protective garment body comprises a protective hood, a protective jacket, protective trousers and protective foot sleeves; and plackets for wearing and taking off are arranged on the protective hood and the protective jacket, and zippers are mounted at the plackets. The integrated protective garment body comprises an inner protective layer and an outer protective layer, wherein a cavity is formed between the inner protective layer and the outer protective layer; a plurality of pull wires connected with the inner protective layer and the outer protective layer are uniformly distributed in the cavity; and one end of each pull wire is fixedly connected with the inner protective layer, and the other end of each pull wire is fixedly connected with the outer protective layer. The protective garment can be used for a long time in a high-temperature area by means of air blowing of the fan, is good in protective effect, guarantees personal safety, does not need additional oxygen, and can be widely applied to production and life.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD +1

A small air compressor for environmental protection construction and its use method

ActiveCN111810383BImprove noise reductionRealize dynamic changesPositive displacement pump componentsPositive-displacement liquid enginesStructural engineeringEnvironmental engineering

The invention discloses a small-sized air compressor for environmental protection construction and its use method, which belongs to the field of air compressors. It uses the principle of aerodynamics to make two pneumatic parts approach each other under the action of air flow, so that the front and rear sections There is a large mutation in the area to improve the noise reduction effect, and the greater the airflow intensity, the greater the change in the cross-sectional area of the aerodynamically deformable shell, and the better the noise reduction effect. The annular cavity inside the aerodynamic weakening part is used to weaken the airflow The flow rate, and two air inlet holes and one air outlet hole can allow the airflow to form convection, which has a certain noise reduction effect. The porous airflow disturbance ball is used to further weaken the airflow velocity, and finally the airflow passes through the airflow distribution pipes with different inner diameters. Ejection, once again uses the sudden change of the cross-sectional area to reduce noise, and further improves the noise reduction effect. Compared with the existing technology, it realizes the dynamic change of the cross-sectional area, and strengthens the effect of using the sudden change of the cross-sectional area to reduce noise.

Owner:汉尼米克(山东)智能科技有限公司

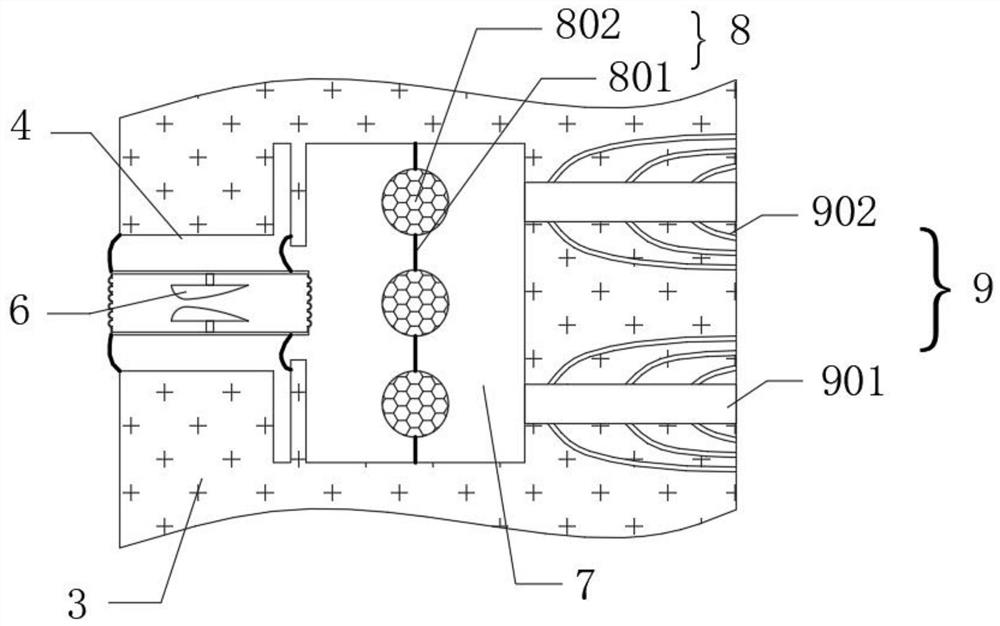

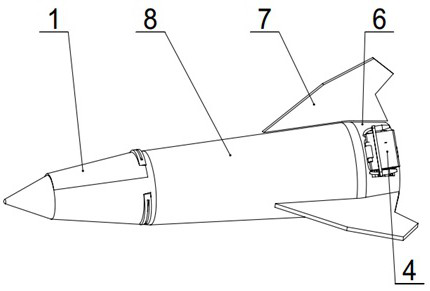

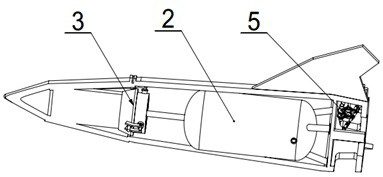

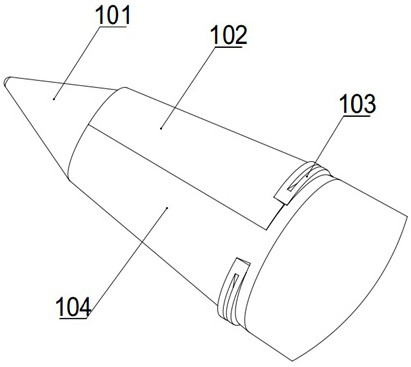

A forest fire extinguishing missile

ActiveCN111569314BQuick fightStrong thrustFire rescueSelf-propelled projectilesFire - disastersStructural engineering

A forest fire extinguishing missile, comprising: a missile main body, a storage tank, a fire extinguishing injection device, a side injection device, an attitude adjustment device, the storage tank stores fire extinguishing agent and forward fuel of the missile, and the side injection device and the attitude adjustment device are controlled by a gear connecting rod. Spray at different angles to control the route of the missile, so that the missile can reach the fire area accurately. The fire extinguishing device sprays the fire extinguishing agent powerfully to cover the fire extinguishing area. The fire extinguishing agent is in the form of solid particle powder, which can make full use of the advantages of terrain and wind speed to extinguish the fire. , The forest fire extinguishing missile can be reused, respond in time after finding a fire, quickly reach the fire area, extinguish the forest fire, avoid the casualties of firefighters, and reduce the loss caused by the forest fire.

Owner:山东同其数字技术有限公司

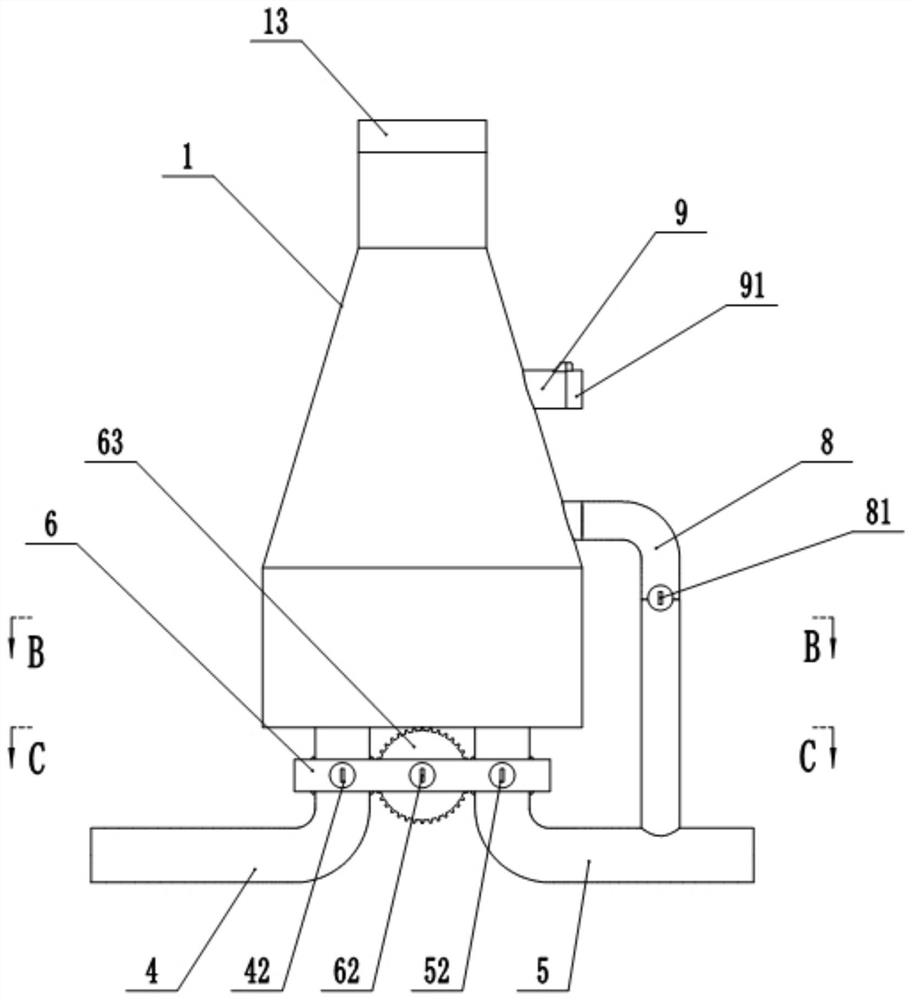

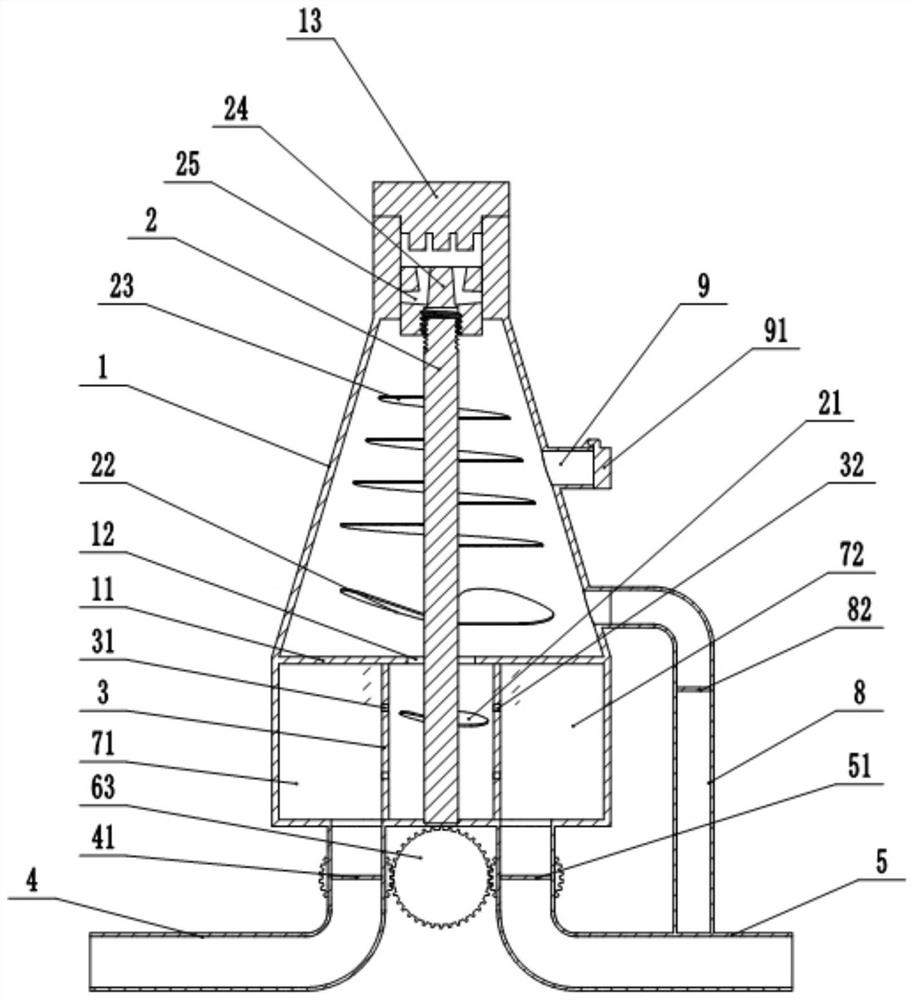

Supersmall-diameter cyclone and production method thereof

ActiveCN107619276AImprove wear resistanceImprove toughnessReversed direction vortexCycloneWear resistant

The invention relates to a supersmall-diameter cyclone for sorting ultrafine particles and a production method thereof. The supersmall-diameter cyclone which is wear-resistant, is toughened and is smooth in surface is prepared by a processing technology comprising the following steps: using zirconium oxide, neodymium oxide and aluminum oxide as raw materials, using an aluminate coupling agent as amodifying agent, uniformly mixing, performing dry-pressing moulding and performing high-temperature firing. The diameter of the large end face of the lower chamber of the prepared cyclone is 4.9-9.9mm, and a current stabilizing channel is arranged at a feed port, so that short-circuit current is effectively avoided; and the cyclone is used for sorting the ultrafine particles with the particle size range d50 of 0.1-1 micron, and the sorting efficiency is high.

Owner:李航

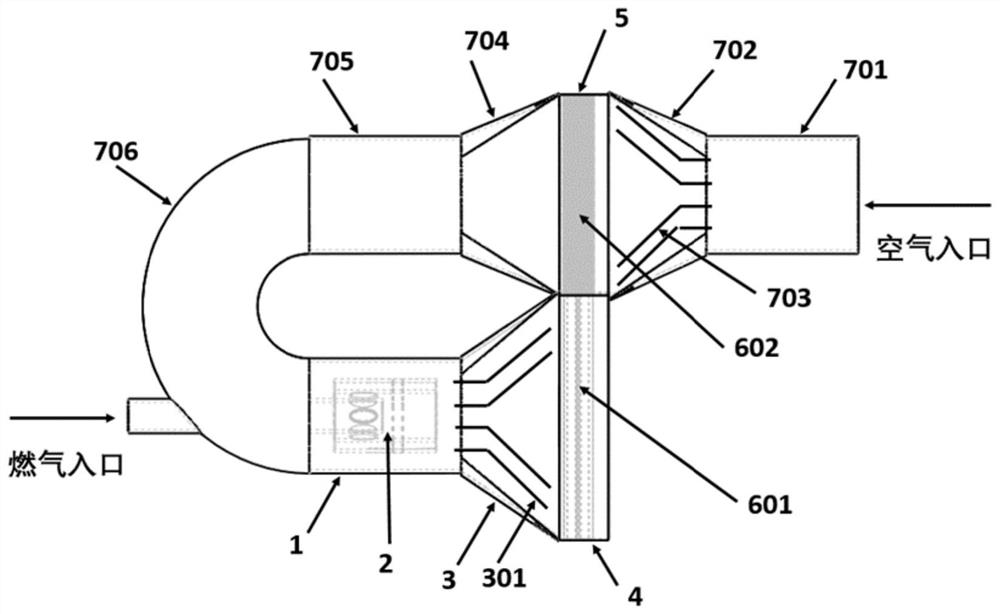

A low-nitrogen gas burner based on heat pipe heat exchange

ActiveCN111121022BEmission reductionAvoid destructionIndirect heat exchangersIndirect carbon-dioxide mitigationCombustorLow nitrogen

The present invention is a low-nitrogen gas burner based on heat pipe heat exchange, which includes an air-fuel mixing section and a combustion head sequentially connected along the gas flow direction; a gas nozzle is arranged in the air-fuel mixing section; the combustion head includes several The heat pipes are arranged in a tube bundle. The evaporation heat absorption section of the heat pipe in the tube bundle is arranged to form a combustion gap as a combustion head, and the condensation heat release section of the heat pipe is provided with a condensing device and arranged outside the furnace. In the present invention, the combustion head consisting of several heat pipes arranged intermittently is arranged between the furnace and the air-fuel mixing section, and the two phase-change heat processes of evaporation heat absorption and condensation heat release in the heat transfer process of the heat pipes have good thermal conductivity and isothermal properties and other advantages, so that the working fluid in the tube of the heat pipe absorbs the heat of the combustion zone of the furnace in the heat pipe evaporation heat absorption section and evaporates into steam, and condenses and releases heat by using a condensing device such as air cooling or water cooling, and the liquid in the tube after the steam releases heat and condenses flows back to the suction through gravity. The hot section effectively solves the damage caused by the water circulation of the water-cooled burner to the boiler hydrodynamic circulation.

Owner:XI AN JIAOTONG UNIV +1

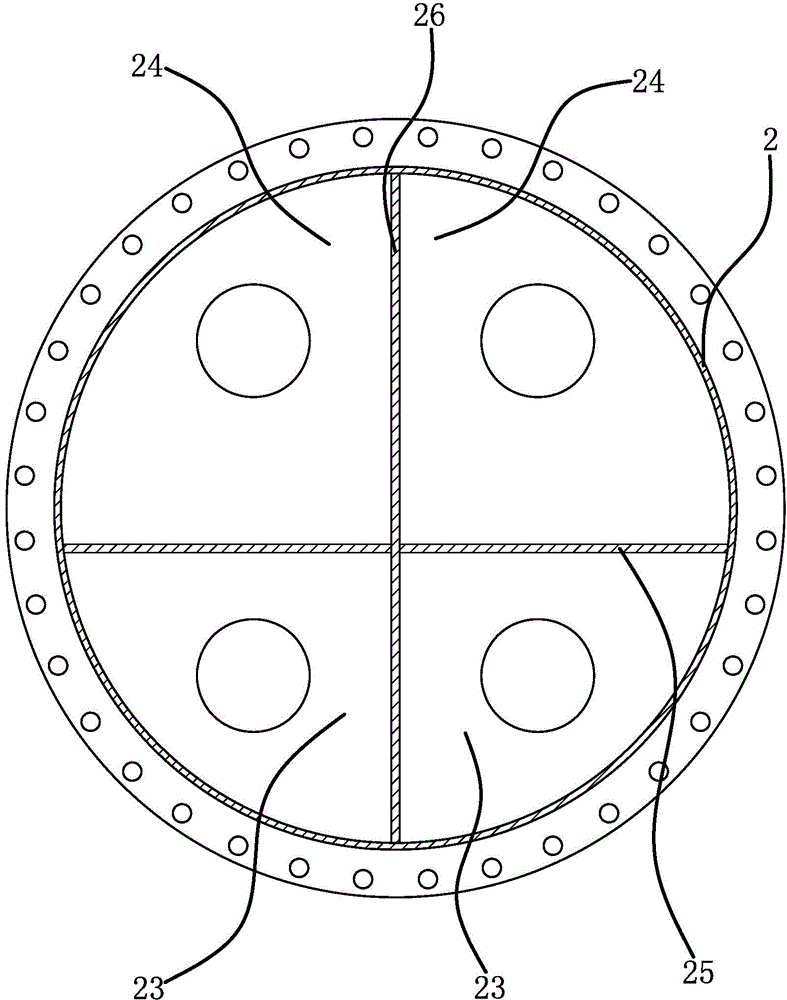

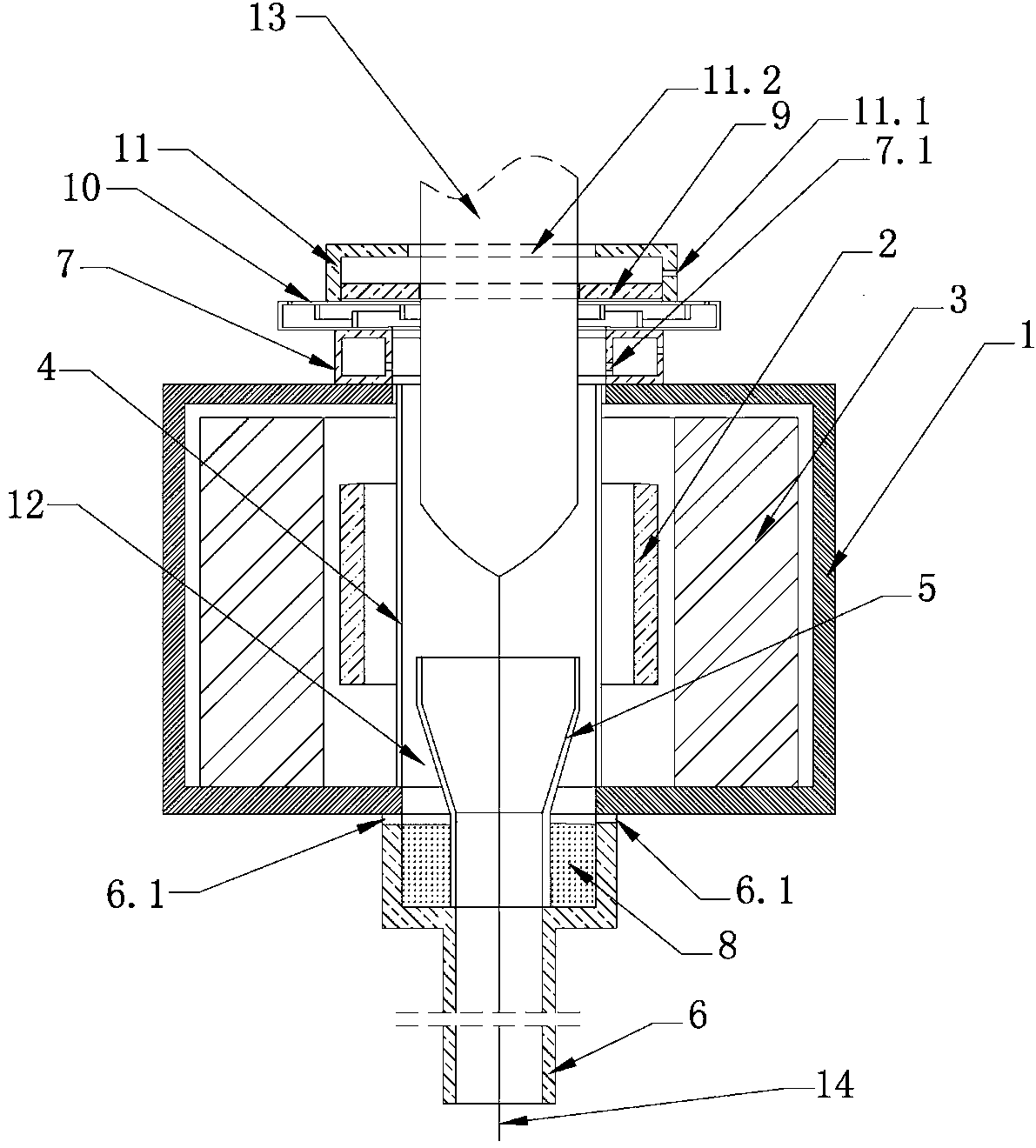

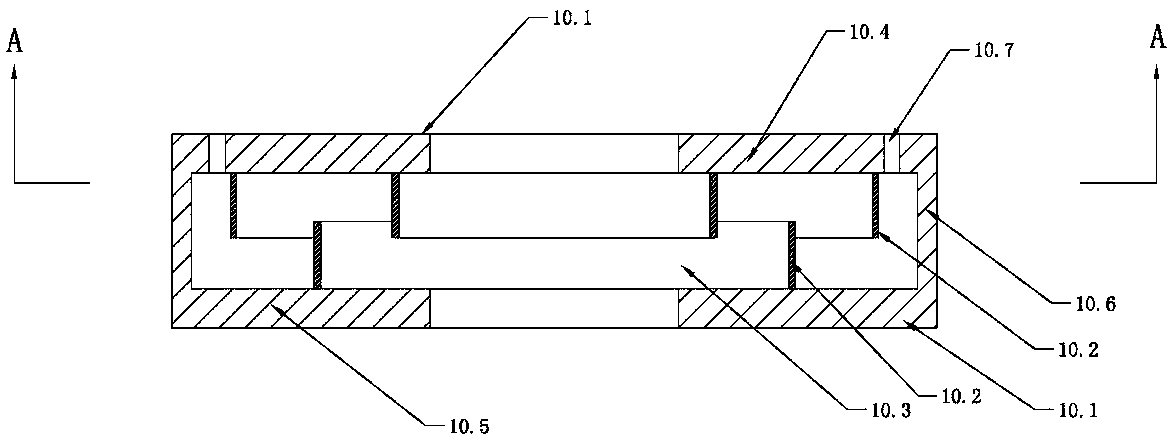

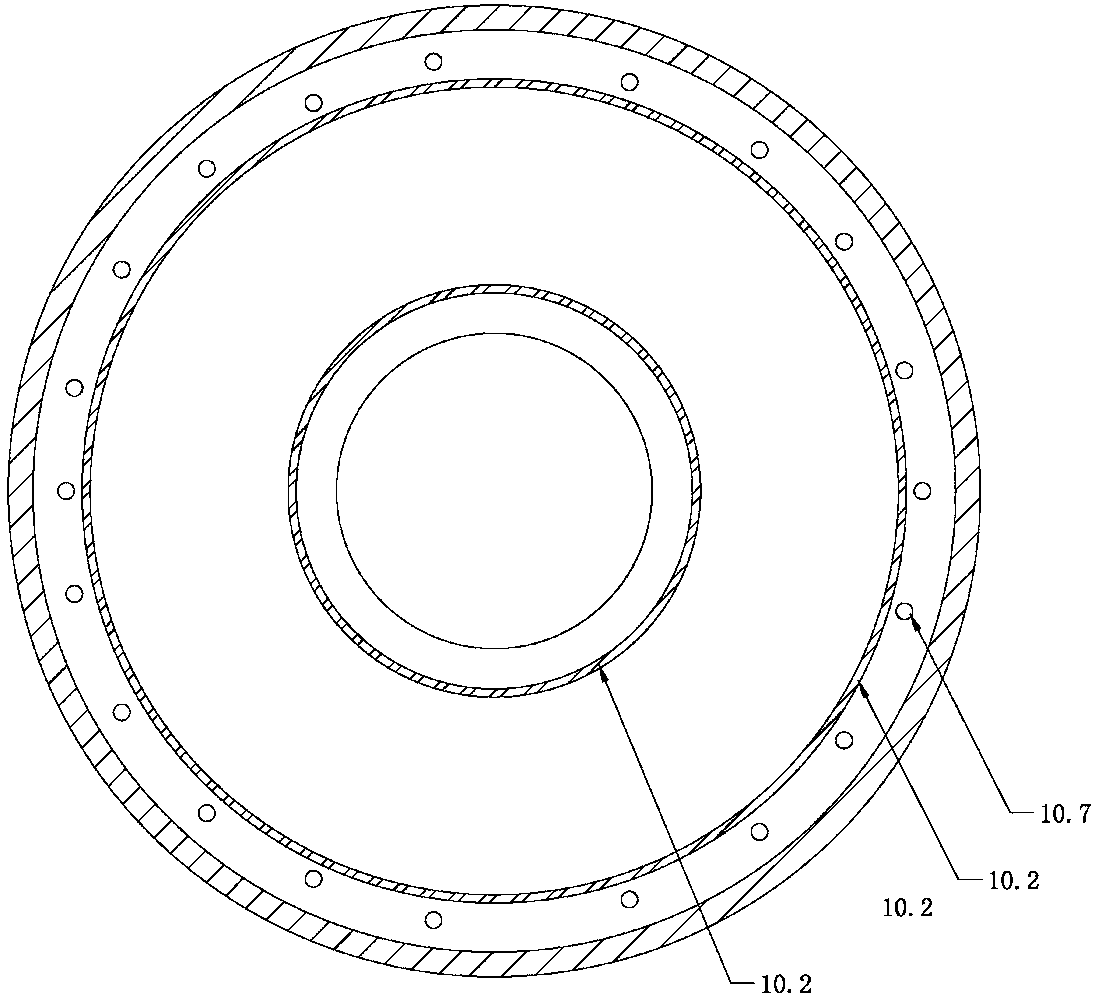

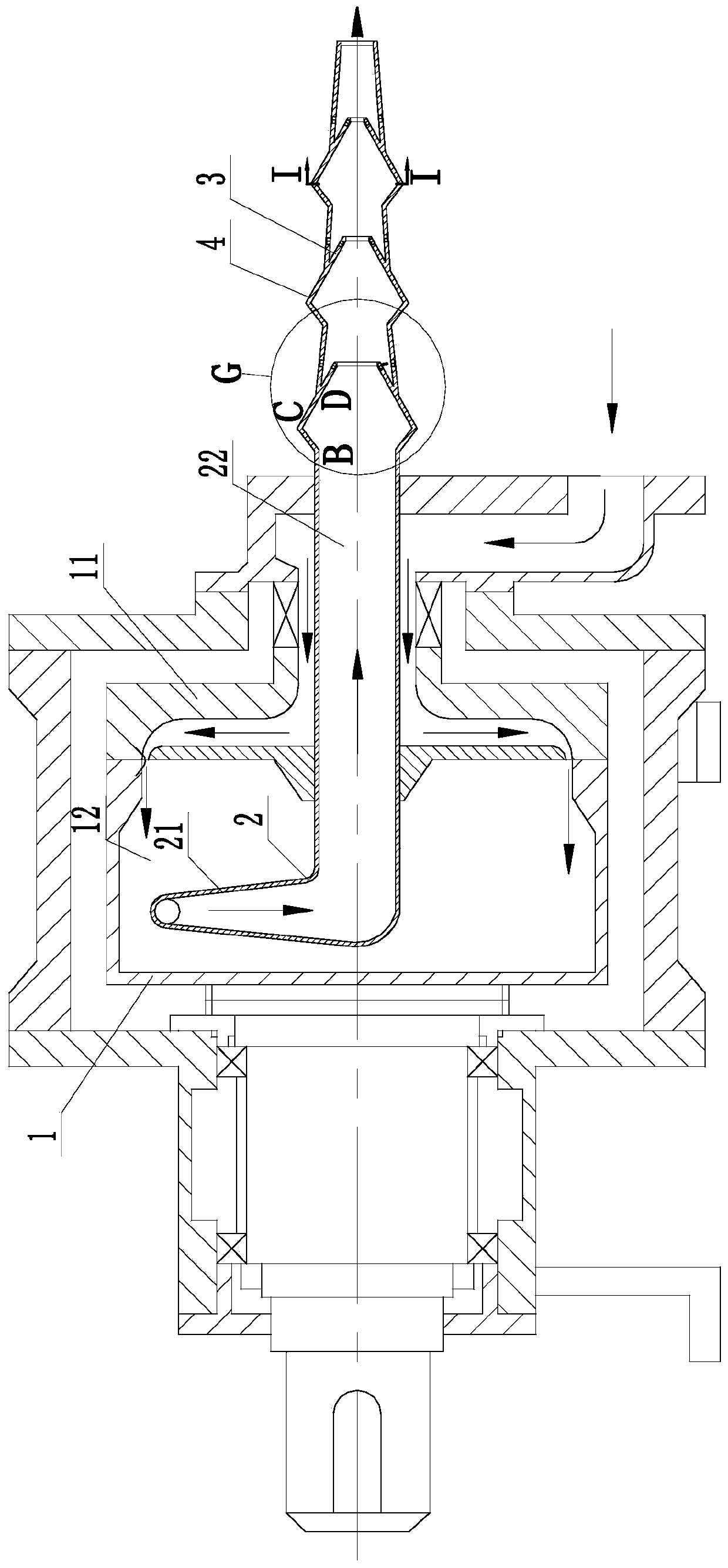

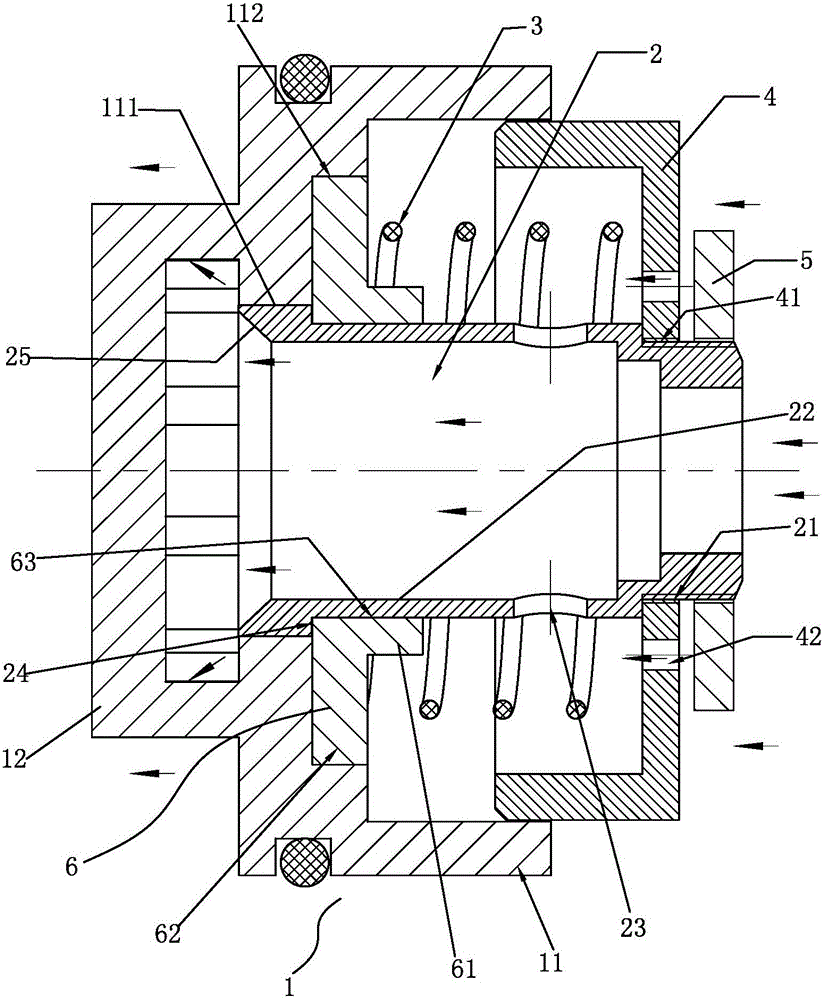

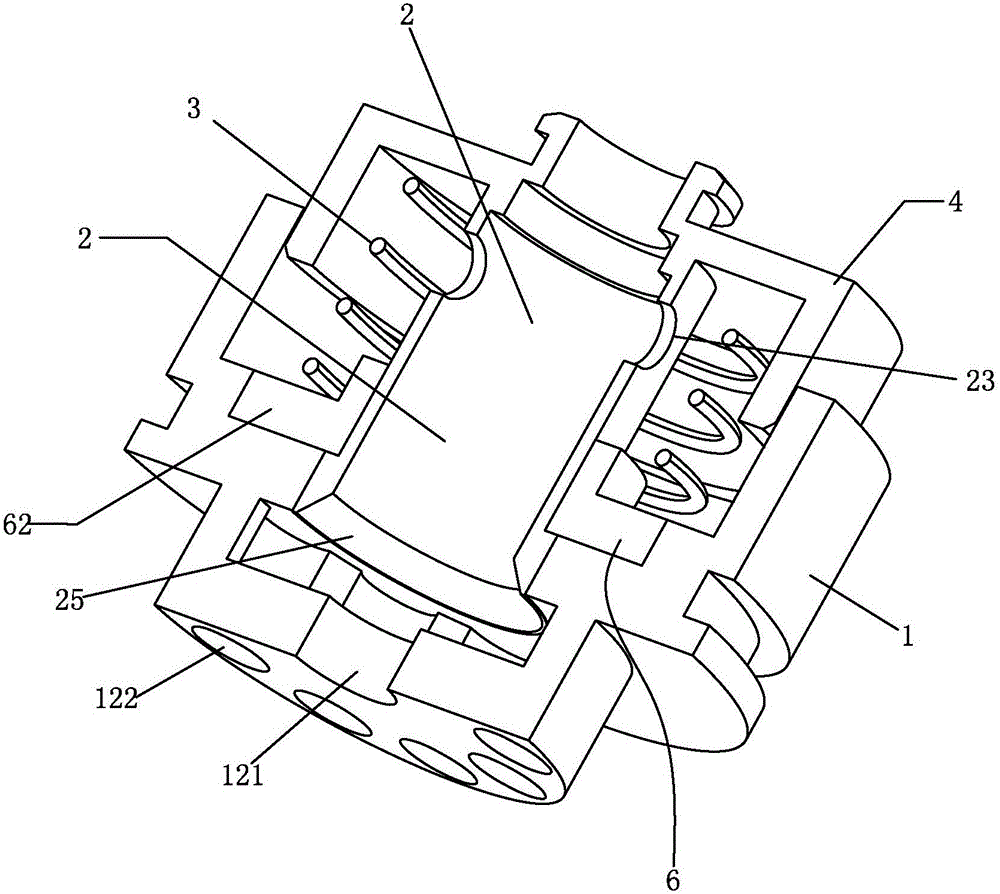

A multi-system flooded evaporator

The invention provides a multi-system flooded evaporator and belongs to the technical field of water chilling units. The multi-system flooded evaporator is used for solving the problems of refrigerant waste and use cost increase of the existing flooded evaporator. The multi-system flooded evaporator comprises a barrel, a front channel, a rear channel and at least two refrigerating circuits; each refrigerating circuit comprises a water inlet pipe, a water inlet cavity, a water outlet cavity, a refrigerating cavity and a reflux cavity; the water inlet pipe is communicated with the water inlet cavity; the water outlet pipe is communicated with the water outlet cavity; one ends of a plurality of inflow heat exchange tubes and one ends of a plurality of reflux cavities all are communicated with the reflux cavity; the other ends of the inflow heat exchange tubes all are communicated with the water inlet cavity; the other end of the plurality of reflux heat exchange tubes all are communicated with the water outlet cavity. A plurality of systems in the multi-system flooded evaporator are capable of running independently or running simultaneously; as a result, the multi-system flooded evaporator is more flexible to use and lower in use cost.

Owner:TAIZHOU LONGJIANG CHEM MACHINERY TECH

Gas detection device and gas detection method

ActiveCN111766330APlay the role of steady flowImprove detection accuracyChemical analysis using catalysisChemical analysis using combustionThermodynamicsCombustible gas

The invention relates to the technical field of gas detection. The invention discloses a gas detection device and a gas detection method. The detection device comprises a mixer, to-be-detected gas conveying equipment, catalysis assisting gas conveying equipment and a catalytic combustion sensor. A flow guide area and a mixing area are arranged in the mixer; a premix area, a first gas guide area and a second gas guide area are formed in the mixing area; the to-be-detected gas conveying equipment is connected with the first gas guide area, the catalysis assisting gas conveying equipment is connected with the second gas guide area and can convey catalysis-assisting gas into the premix area, the to-be-detected gas and the catalysis-assisting gas are mixed in the premix area to form mixed gas,and the mixed gas is guided to the catalytic combustion sensor through the flow guide area. The detection method comprises the following steps: S1, conveying to-be-detected gas and catalysis-assistinggas into a mixer for mixing to obtain a to-be-detected gas sample; and S2, detecting the to-be-detected gas sample through a catalytic combustion sensor to obtain a combustible gas concentration value.

Owner:南京三鸣智自动化工程有限公司

Ultra-small diameter cyclone and manufacturing method thereof

ActiveCN107619276BImprove wear resistanceImprove toughnessReversed direction vortexMetallurgyAluminium oxides

The invention relates to a supersmall-diameter cyclone for sorting ultrafine particles and a production method thereof. The supersmall-diameter cyclone which is wear-resistant, is toughened and is smooth in surface is prepared by a processing technology comprising the following steps: using zirconium oxide, neodymium oxide and aluminum oxide as raw materials, using an aluminate coupling agent as amodifying agent, uniformly mixing, performing dry-pressing moulding and performing high-temperature firing. The diameter of the large end face of the lower chamber of the prepared cyclone is 4.9-9.9mm, and a current stabilizing channel is arranged at a feed port, so that short-circuit current is effectively avoided; and the cyclone is used for sorting the ultrafine particles with the particle size range d50 of 0.1-1 micron, and the sorting efficiency is high.

Owner:李航

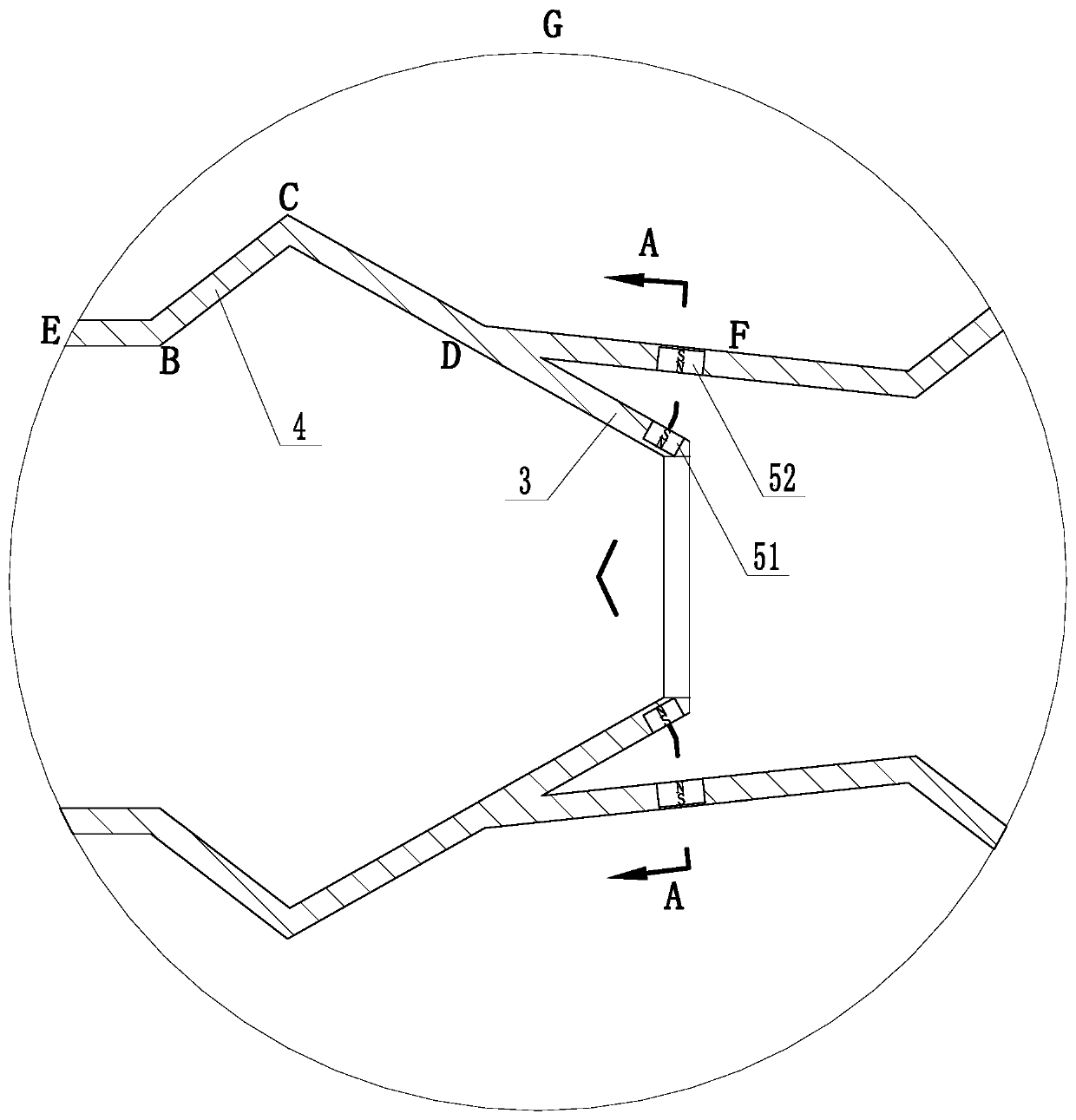

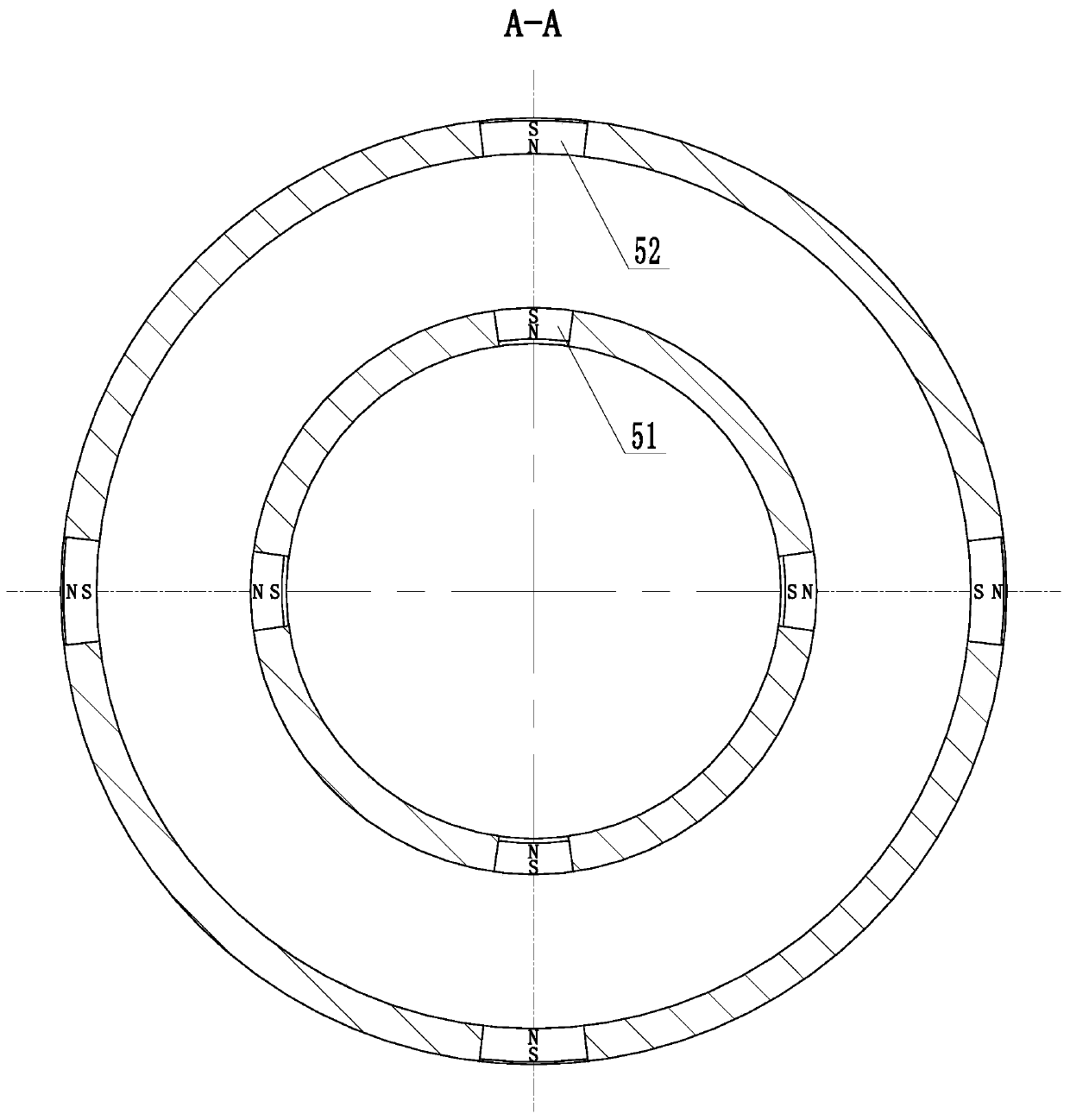

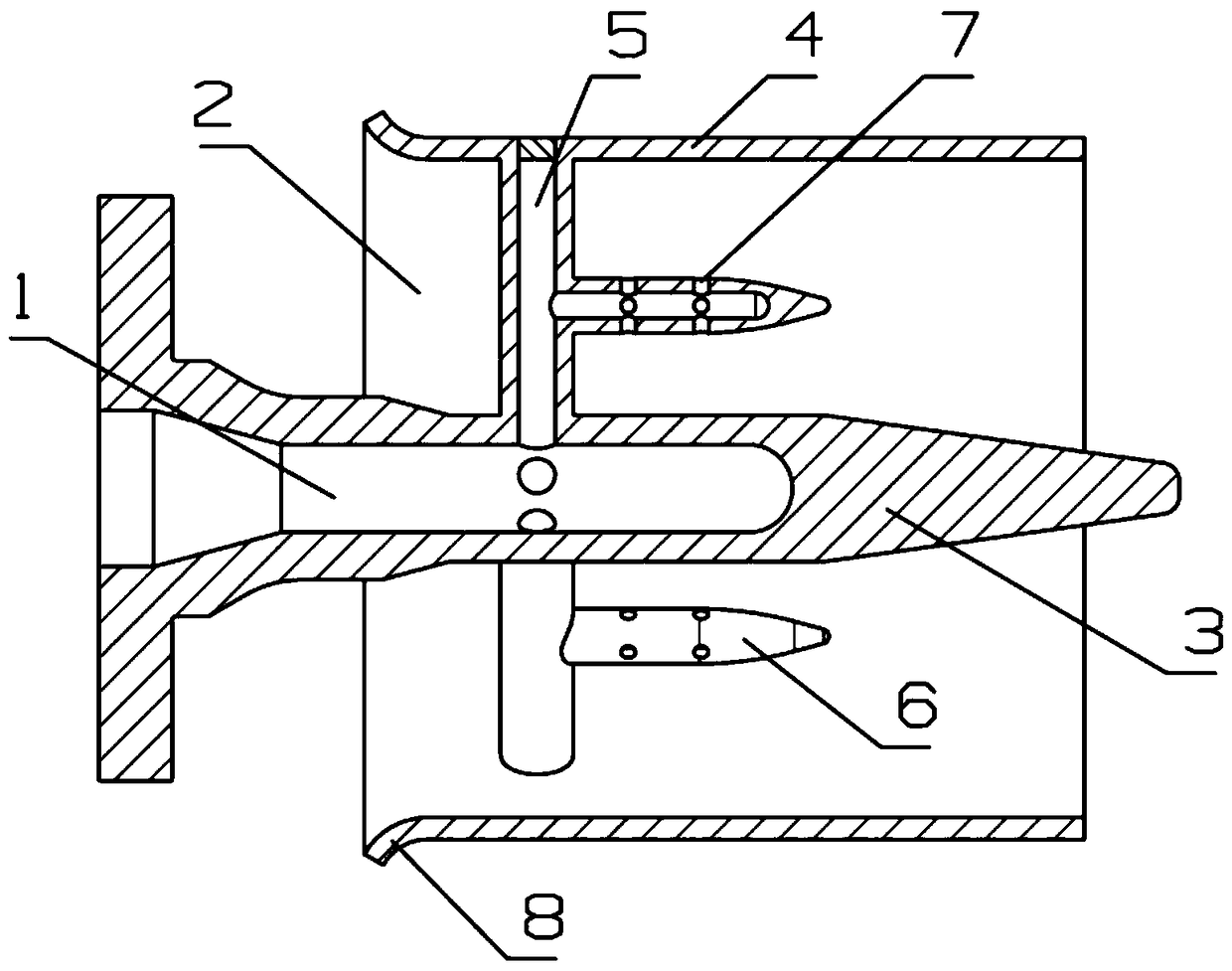

Gas Turbine Combustor Premixed Fuel Nozzles

ActiveCN104315540BSimple structureImprove versatilityContinuous combustion chamberCombustorEngineering

The invention relates to the technical field of gas turbines, and specifically discloses a premixed fuel nozzle for a combustion chamber of a gas turbine, comprising: a central cone, the central cone is a hollow structure, and the hollow cavity of the central cone is a central fuel passage; The flow shell is set on the periphery of the central cone and arranged coaxially with the central cone, and there is an annular air passage between the flow guide shell and the central cone; the radial fuel pipe is arranged radially on the central cone Between the body and the diversion shell; the auxiliary cone, the auxiliary cone is arranged on the radial fuel pipe and arranged parallel to the central cone, the auxiliary cone is a hollow structure, and the hollow cavity of the auxiliary The central fuel channel is connected, and fuel injection holes are arranged on the auxiliary cone. The invention can reasonably control the flow of fuel and air to produce a better mixing effect and form a stable flame downstream of the nozzle.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

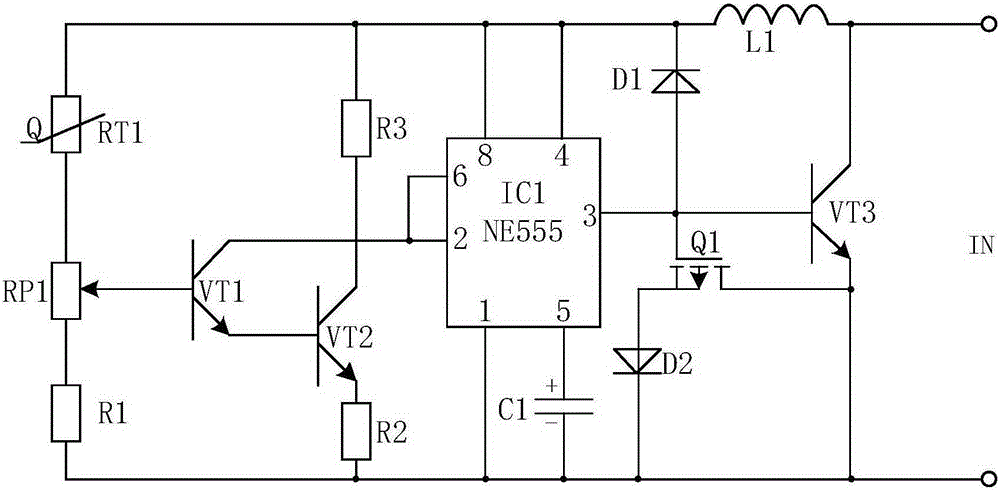

Triode composition constant-current winding type auto-control preheating burner

InactiveCN105202540APrevent intrusionAvoid safety hazardsIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention discloses a triode composition constant-current winding type auto-control preheating burner, which comprises a burner main body, wherein a mixing chamber and a combustion chamber are arranged in the inner part of the burner main body; the tail end of the burner main body is provided with a gas pipeline communicated with the mixing chamber; a gas valve is arranged on the gas pipeline; an annular air duct is further arranged on the inner wall of the burner main body; the air duct is communicated with the mixing chamber; a separator for separating the air duct from the gas pipeline is further arranged between the air duct and the gas pipeline; a spacer ring is further arranged between the mixing chamber and the combustion chamber; an air inlet structure is further arranged on the air duct; a control motor connected with the air inlet structure as well as a control box connected with the control motor are further arranged at the outer side of the burner main body; the control box is further internally provided with a temperature feedback control circuit and a triode composition constant-current circuit which are mutually connected in series. The triode composition constant-current winding type auto-control preheating burner provided by the invention can better promote the sufficient combustion of gas, and at the same time can make further utilization of heat of combustion of the gas, and thus, loss of the heat is reduced.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

Optical fiber drawing furnace

ActiveCN103342463BPlay a collection roleNot easy to stickGlass making apparatusGraphite dustOptical fiber cable

The invention relates to an optical fiber drawing furnace comprising a furnace body, a heating element, a heat preservation element, a middle casing pipe, a flow guide pipe, an extension pipe and a furnace top gaseous disc. The optical fiber drawing furnace is characterized by further comprising a lantern ring, an elastic graphite ring and a gas guide disc. The gas guide disc is mounted on the furnace top gaseous disc. The elastic graphite ring is mounted on a hollow ring plate. The lantern ring is arranged between the flow guide pipe and the extension pipe. A plurality of first air inlet holes can be formed in the side wall of the extension tube at the upper end of the lantern ring. The optical fiber drawing furnace has the advantages of being applicable to drawing prefabricated bars in large diameter and optical fiber prefabricated bars with large diameter fluctuation, meanwhile ensuring that graphite dust has less possibility of being adhered to the prefabricated bars, and effectively controlling the air flow state in the drawing furnace.

Owner:JIANGSU FASTEN PHOTONICS

A water flow steady flow valve and a gas water heater using the valve

ActiveCN112253826BChange overlap areaReduced flow areaFluid heatersEqualizing valvesWater flowEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A factory purification ventilation system and its working method

ActiveCN106582126BLess investmentImprove applicabilityDispersed particle filtrationEngineeringExpansion chamber

The invention discloses a factory purification ventilation system, which comprises a casing, wherein a left expansion chamber casing is arranged at the left lower end of the casing; a right expansion chamber casing is arranged at the right lower end of the casing; air passing passages are arranged in a connecting position of the left expansion chamber casing and the casing and a connecting position of the right expansion chamber casing and the casing; a movable plate is arranged in the position of each air passing passage; an air inlet hole is formed in the left end of the left expansion chamber casing; the upper end of the right expansion chamber casing is connected with a gas collecting head through an air inlet hose; a left air inlet fan is arranged in the left expansion chamber casing; a right air inlet fan is arranged in the right expansion chamber casing; an active carbon adsorption drawer is arranged in the casing; the upper end of the active carbon adsorption drawer is provided with a current stabilizing plate; air passing holes are formed in the current stabilizing plate; and air outlet holes are formed in the upper ends of the left and right side walls of the casing. The factory purification ventilation system has the advantages that through the movable purification ventilation equipment, purification circulation treatment is performed in waste gas generating positions, the investment of the purification equipment is greatly reduced; the left air inlet fan can be selected to be switched on to start the fixed air suction mode, or the right air inlet fan can be selected to be switched on to start the air suction mode; and the applicability is high.

Owner:福建众辉环保设备有限公司

Small-sized air compressor for environmental protection construction and using method thereof

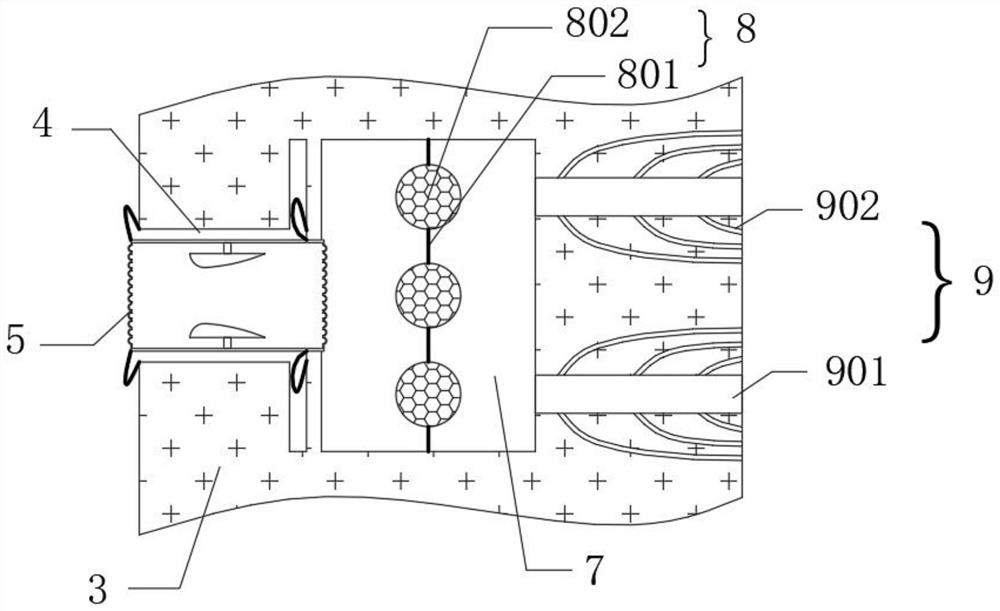

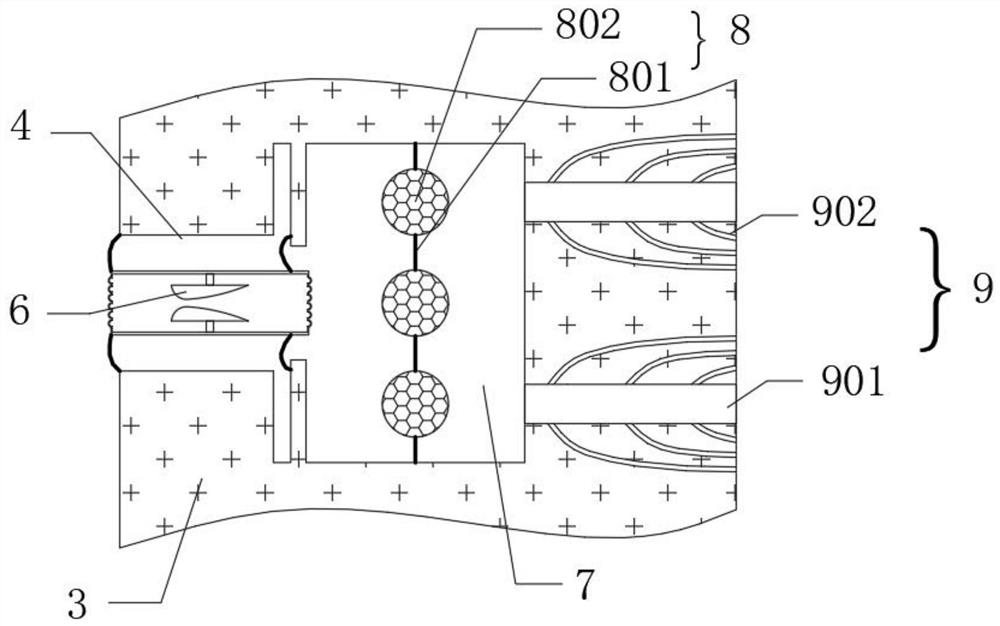

ActiveCN111810383AImprove noise reductionRealize dynamic changesPositive displacement pump componentsPositive-displacement liquid enginesEnvironmental engineeringAir compressor

The invention discloses a small-sized air compressor for environmental protection construction and a using method of the small-sized air compressor, belongs to the field of air compressors. Accordingto the small-sized air compressor for environmental protection construction, the aerodynamic principle is utilized, two pneumatic parts get close to each other under the action of air flow, so that the front section area and the rear section area are greatly changed suddenly, the noise reduction effect is improved, and the larger the air flow strength is, the larger the section area of a pneumaticdeformation shell is changed, and the better the noise reduction effect is; an annular cavity in the inner part of a pneumatic weakening part is used for weakening the air flow velocity, and two airinlets and one air outlet can enable the air flow to form convection, so that a certain noise reduction effect is achieved; a porous air flow disturbance ball is used for further weakening the air flow velocity, finally, the air flow is sprayed out through air flow dispersing pipelines with different inner diameters, and noise reduction is carried out again through sudden change of the cross section area, so that the noise reduction effect is further improved; and compared with the prior art, dynamic change of the cross section area is achieved, and the noise reduction effect through sudden change of the cross section area is enhanced.

Owner:汉尼米克(山东)智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com