Gas detection device and gas detection method

A detection device, gas technology, applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., to achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

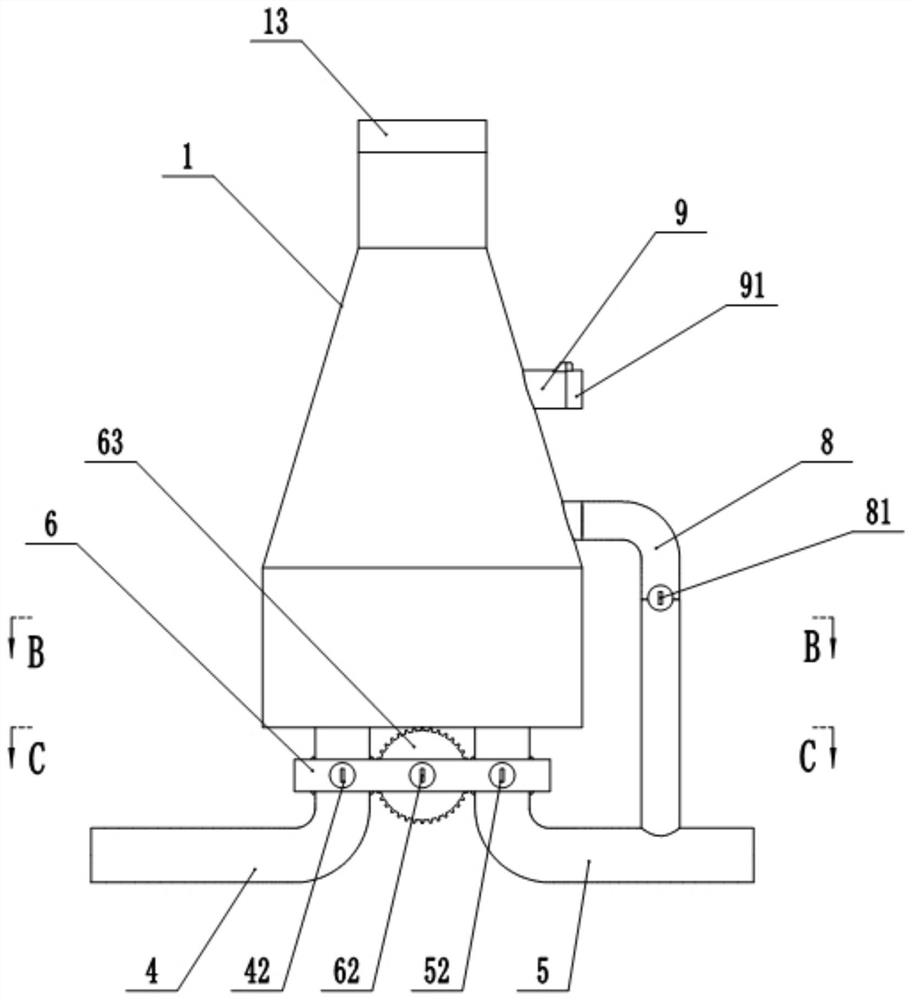

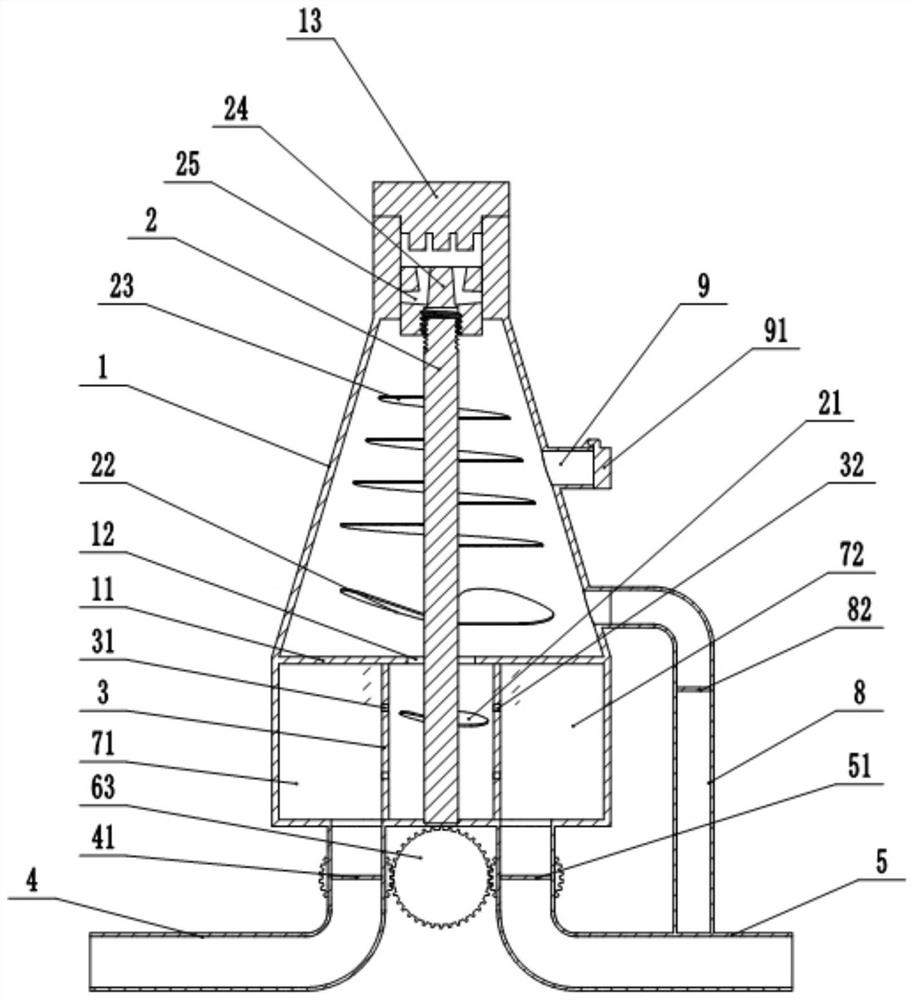

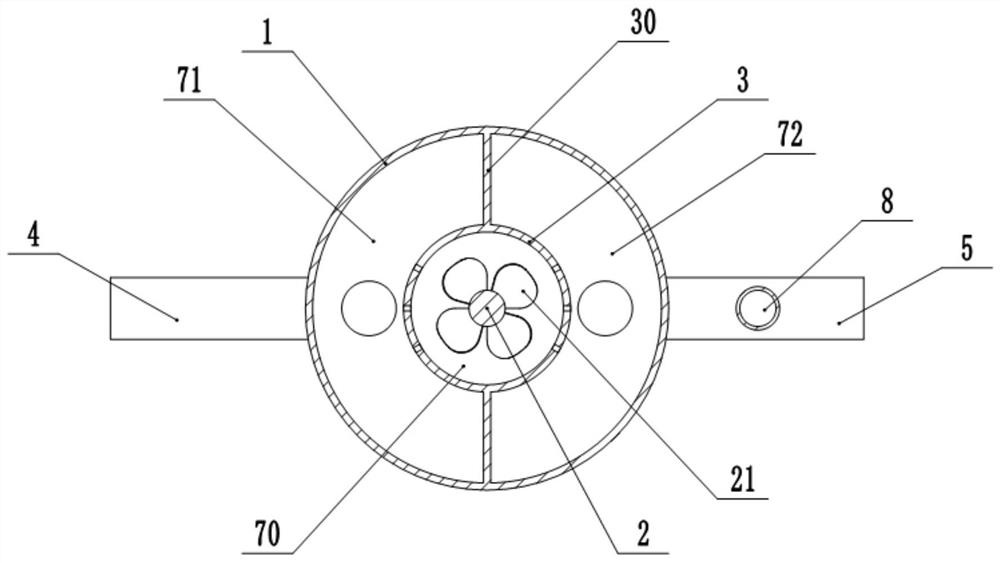

[0033] A gas detection device, such as figure 1 with 2 As shown, it includes the gas delivery equipment to be tested, the catalytic gas delivery equipment, the mixer 1 and the catalytic combustion sensor 13, the catalytic combustion sensor 13 is installed on the top of the mixer 1, and the top of the mixer 1 is equipped with a device to guide the mixed gas to catalytic combustion. The guide notch of sensor 13, the plunger 24 that is used to close guide notch is slidably installed in the guide notch, is formed with some gas passages 25 in the plunger 24, and the air inlet of gas passage 25 is positioned at the side wall of plunger 24, and gas The gas outlet of the passage 25 is located at the top of the plunger 24 and communicates with the guide notch, and the inner diameter of the gas passage 25 gradually increases from the inlet to the outlet.

[0034] Such as figure 1As shown, the mixer 1 is provided with a partition plate 11, which divides the interior of the mixer 1 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com