Triode composition constant-current winding type auto-control preheating burner

A triode and burner technology, which is applied in the direction of burners, controlled combustion, gas fuel burners, etc., can solve problems such as the mismatch between air intake and gas input, high anode production costs, and inability to fully utilize the temperature. Achieve the effect of improving the use effect and service life, improving the utilization efficiency and effect, and improving the effect of preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

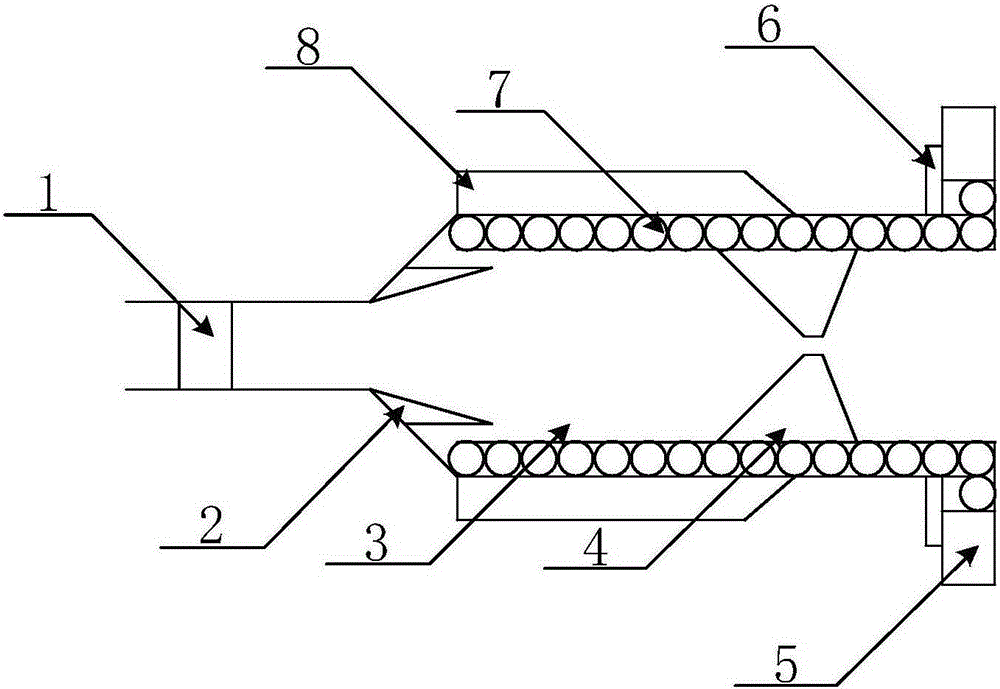

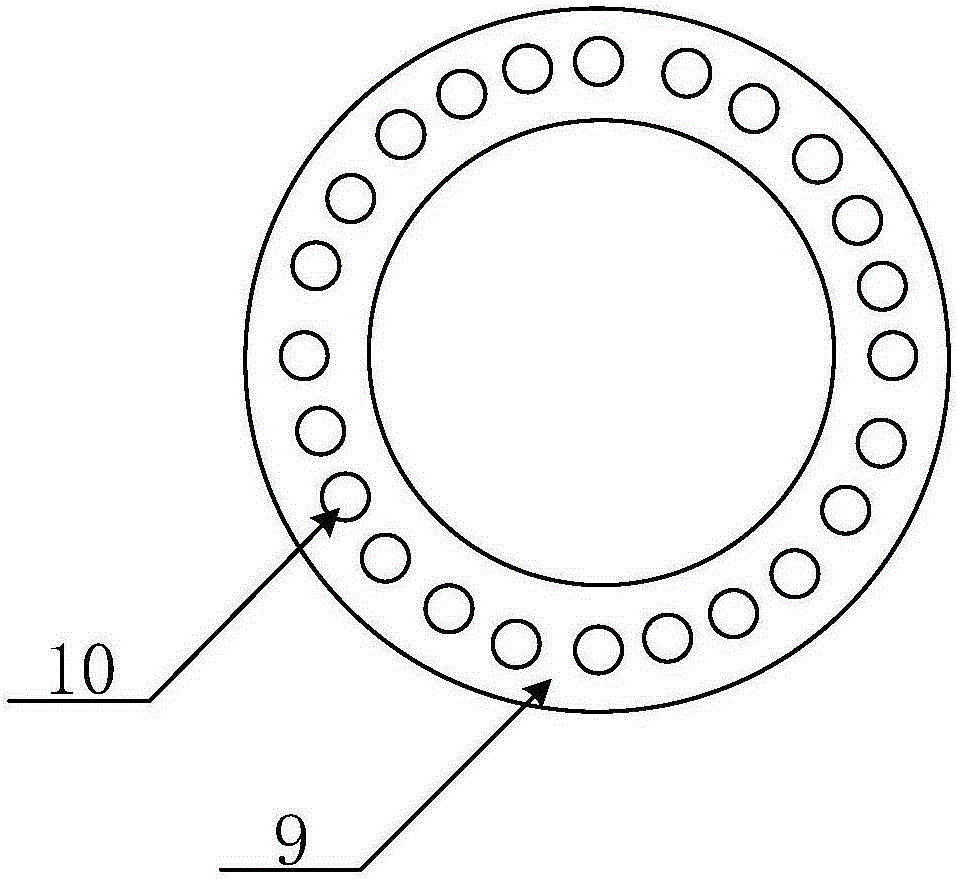

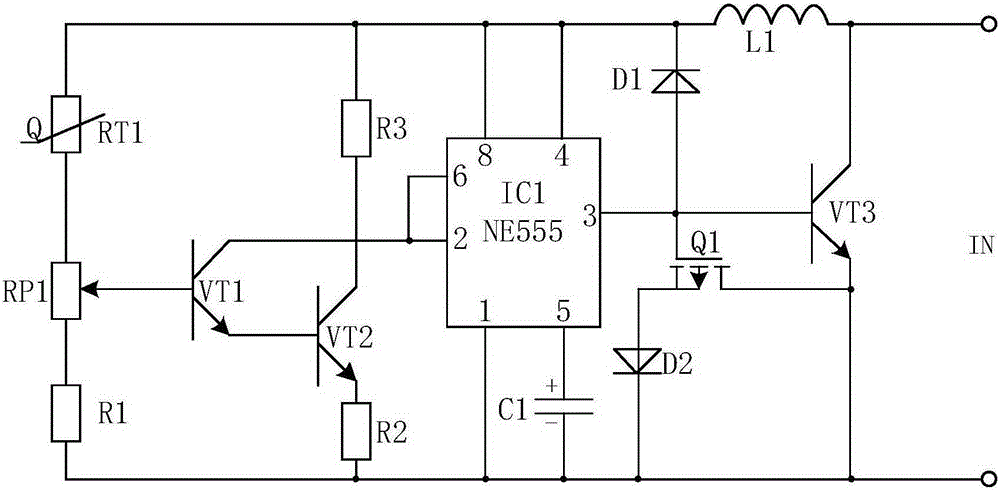

[0025] Such as figure 1 As shown, the triode combined steady flow winding self-control preheating burner includes a burner body, a mixing chamber 3 and a combustion chamber are arranged inside the burner body, and a valve communicating with the mixing chamber 3 is arranged at the end of the burner body. The gas pipeline is provided with a gas valve 1 on the gas pipeline, and an annular air channel is also provided on the inner wall of the burner body, which communicates with the mixing chamber 3. The partition plate 2 separated by it is also provided with a spacer ring 4 between the mixing chamber 3 and the combustion chamber, an air inlet structure 6 is also arranged on the air duct, and an air inlet structure 6 is arranged on the outside of the burner body. The connected control motor 5 and the control box 8 connected to the control motor 5 are also provided with a temperature feedback control circuit and a triode combined current stabilization circuit connected in series in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com