Biomass granular fuel and preparation method thereof

A technology of biomass particles and biomass raw materials, which is applied in the directions of biofuel, waste fuel, fuel, etc., can solve the problems of short service life, low combustion efficiency and high ash content of boilers, achieve stable combustion rate, prolong combustion time, Stable bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

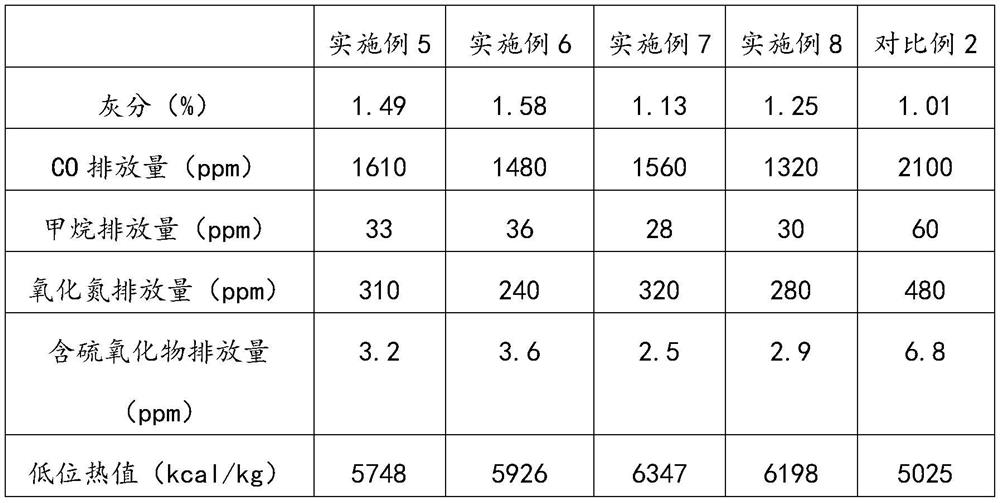

Examples

Embodiment 1

[0036]A kind of biomass pellet fuel, which is to dry and crush 100kg of biomass raw materials to obtain powder, then add 2kg of lignin-based binder to the powder, stir it evenly through a mixer, and then pass mechanical compression, granulation and cooling later income. Wherein, the moisture content of the powder is ≤20%, the particle size of the powder is ≤0.5mm, and the particle size of the lignin-based binder is 0.03-0.06mm.

[0037] The preparation method of the above-mentioned lignin-based binder comprises the following specific steps:

[0038] (1) adjusting the pH value of the papermaking waste liquid to 3.5-6 with a hydrochloric acid solution to obtain a suspension containing lignin particles;

[0039] (2) Dissolve 0.2kg of urea in water, then add 1kg of polyacrylic acid, 1.2g of ammonium persulfate and 2.4g of glutaraldehyde, stir evenly, and adjust the pH value to 7-8 with a mass fraction of 50% sodium hydroxide solution , slowly raising the temperature to 60-70°C, ...

Embodiment 2

[0044] A kind of biomass granular fuel, which is to dry and crush 100kg of biomass raw materials to obtain powder, then add 5kg of lignin-based binder to the powder, stir it evenly through a mixer, and then pass mechanical compression, granulation and cooling later income. Wherein, the moisture content of the powder is ≤20%, the particle size of the powder is ≤0.5mm, and the particle size of the lignin-based binder is 0.03-0.06mm.

[0045] The preparation method of the above-mentioned lignin-based binder comprises the following specific steps:

[0046] (1) adjusting the pH value of the papermaking waste liquid to 3.5-6 with a hydrochloric acid solution to obtain a suspension containing lignin particles;

[0047] (2) Dissolve 0.5kg of urea in water, then add 1kg of polyacrylic acid, 4.5g of ammonium persulfate and 7.5g of glutaraldehyde, stir evenly, and adjust the pH value to 7-8 with a mass fraction of 50% sodium hydroxide solution , slowly raising the temperature to 60-70°...

Embodiment 3

[0052] A kind of biomass granular fuel, which is to dry and pulverize 100kg of biomass raw materials to obtain powder, then add 3.5kg of lignin-based binder to the powder, stir evenly through a mixer, and then pass mechanical compression, granulation and obtained after cooling. Wherein, the moisture content of the powder is ≤20%, the particle size of the powder is ≤0.5mm, and the particle size of the lignin-based binder is 0.03-0.06mm.

[0053] The preparation method of the above-mentioned lignin-based binder comprises the following specific steps:

[0054] (1) adjusting the pH value of the papermaking waste liquid to 3.5-6 with a hydrochloric acid solution to obtain a suspension containing lignin particles;

[0055] (2) Dissolve 0.4kg of urea in water, then add 1kg of polyacrylic acid, 3.2g of ammonium persulfate and 4.8g of glutaraldehyde, stir evenly, and adjust the pH value to 7-8 with a mass fraction of 50% sodium hydroxide solution , slowly raising the temperature to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com