Oxygen-free copper rod mold

An oxygen-free copper rod and crystallizer technology is applied in the field of copper alloy upward casting and continuous casting. The effect of production efficiency and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

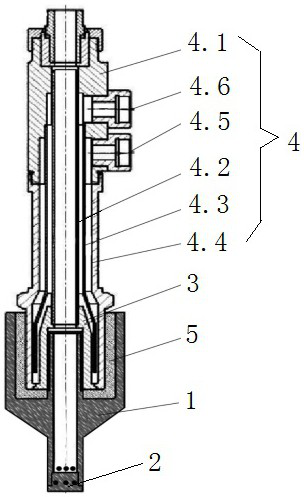

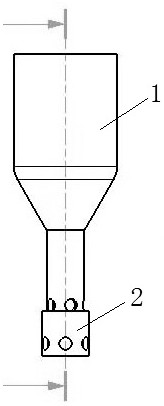

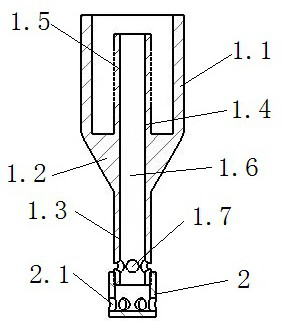

[0021] see Figure 1-5 , the present invention relates to an oxygen-free copper rod crystallizer, which includes an integrated graphite mold 1, the integrated graphite mold 1 includes a large-diameter cylindrical section 1.1, a cone section 1.2 and a small-diameter cylindrical section 1.3 arranged in sequence, the large-diameter cylindrical section 1.3 A cavity is provided in the diameter cylindrical section 1.1, a boss 1.4 is arranged in the cavity, an external thread 1.5 is provided on the top of the boss 1.4, a through hole 1.6 is arranged in the boss 1.4, and a through hole 1.6 is arranged in the boss 1.4. 1.6 extends downward to connect the cone section 1.2 and the small-diameter cylindrical section 1.1.

[0022] The bottom of the small-diameter cylindrical section 1.3 is covered with a graphite cap 2, the graphite cap 2 is provided with internal threads, the bottom of the small-diameter cylindrical section 1.3 is screwed into the graphite cap 2, and the small-diameter cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com