Copper furnace for continuously casting copper-aluminium composite material

A copper-aluminum composite material and copper furnace technology, which is applied in the field of copper-clad aluminum casting, can solve the problems of uneven temperature of copper liquid, poor heat preservation effect, inaccurate temperature measurement, etc., and achieves good heat preservation effect, is conducive to slag removal, and uniform temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

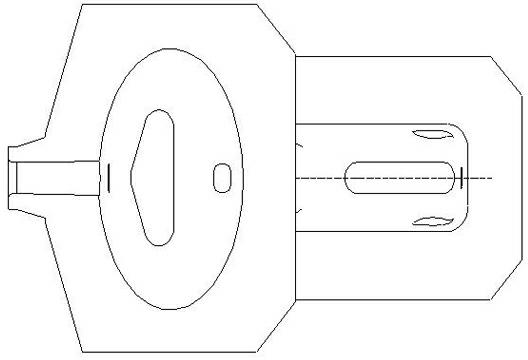

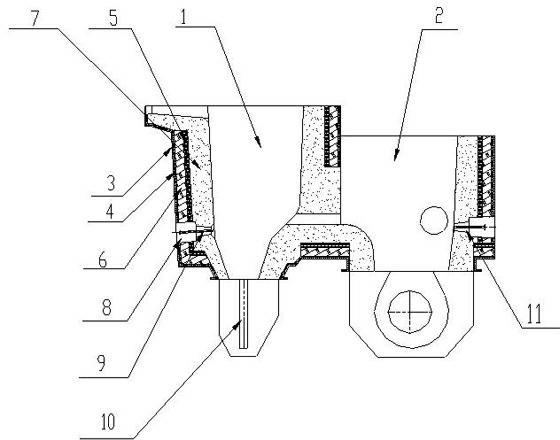

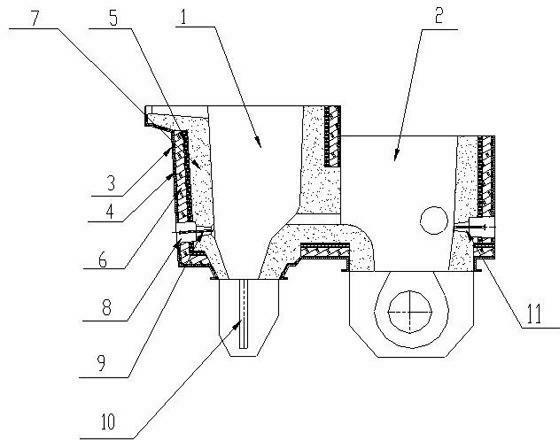

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described: a kind of copper furnace that is used for continuous casting copper-aluminum composite material, comprises melting furnace hearth 1, holding furnace hearth 2 and furnace shell 3, in furnace shell 3 there are successively asbestos board 4, heat preservation Bricks 6, refractory bricks 5 and castables 7 have good thermal insulation and high temperature resistance, and can effectively adapt to changes in the temperature of the furnace body. The lower sides of the melting furnace hearth 1 and the holding furnace hearth 2 are respectively provided with temperature measuring ports 8. A thermocouple with a cermet tube 9 is set inside the temperature port 8, and the temperature measuring port 8 is filled with refractory castables 11. The outer diameter of the cermet tube 9 is ?15mm, and the front end of the cermet tube 9 is 1,0 The inner wall of the furnace chamber 2 is 300mm, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com