Potassium fixing method for biomass fuels

A technology of biomass fuel and silica sol, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve problems such as adverse effects, achieve the effect of preventing adverse effects and improving slagging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

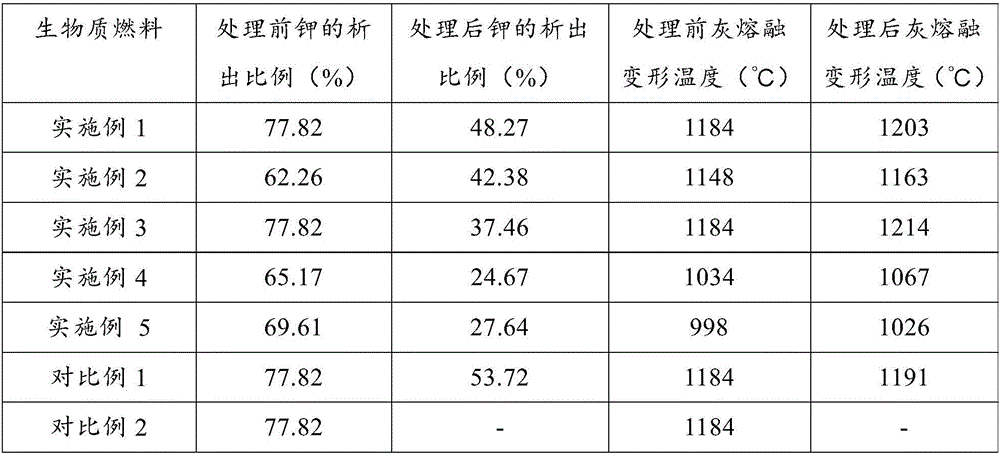

[0027] A kind of biofuel potassium fixing method is implemented as follows: evenly spray 10% silica sol solution 8.65kg (the amount of silica sol solution) on 10kg biomass fuel (75% corn stalk+25% cotton stalk, potassium element content 2.81%) The amount is determined according to the use of 2 moles of silicon dioxide per mole of active potassium-containing components), after spraying, place it for 2 hours, and carry out hot air (temperature 105 ° C) drying treatment to obtain dried biomass fuel. The fuel was applied in a muffle furnace and burned at a temperature of about 900°C. The obtained ash samples were tested for potassium content and ash melting point. See Table 1 for the corresponding data and results.

Embodiment 2

[0029] A method for fixing potassium in biomass fuel is implemented as follows: evenly spray 40% silica sol solution 3.87kg (consumption of silica sol solution) on 10kg biomass fuel (75% corn stalk+25% sawdust, potassium element content 3.35%) According to the use of 3 moles of silicon dioxide per mole of active potassium-containing components), after spraying, place it for 2 hours, and carry out hot air (temperature 105 ° C) drying treatment to obtain dried biomass fuel, the biomass fuel It is applied in a muffle furnace and burned at a temperature of about 900 ° C. The obtained ash sample is tested for potassium content and ash melting point. The corresponding data results are shown in Table 1.

Embodiment 3

[0031] A kind of biofuel potassium fixing method is implemented as follows: to 10kg biomass fuel (75% corn stalk+25% cotton stalk, potassium element content 2.81%) evenly spray 80% silica sol solution 2.16kg (silica sol solution The amount is determined according to the use of 4 moles of silicon dioxide per mole of active potassium-containing components), after spraying, place it for 2 hours, and carry out hot air (temperature 105 ° C) drying treatment to obtain dried biomass fuel. The fuel was applied in a muffle furnace and burned at a temperature of about 900°C. The obtained ash samples were tested for potassium content and ash melting point. See Table 1 for the corresponding data and results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com