Wear-resistant pulverized coal concentration separation device

A technology for separation of concentration and thinness, and briquette, which is applied in the combustion type, burner, burner and other directions of burning powder fuel, can solve the problems of poor separation effect of pulverized coal, poor stable combustion ability under low load, low combustion efficiency, etc., to avoid Frequent cleaning, improve wear resistance, improve the effect of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

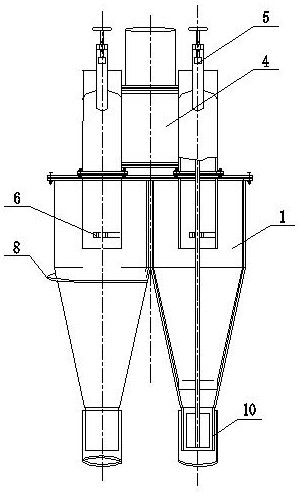

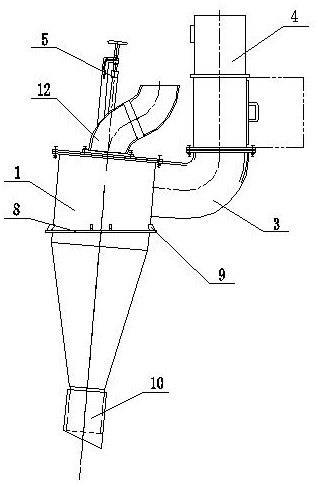

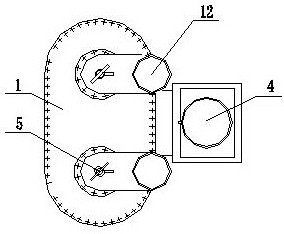

[0035] A wear-resistant pulverized coal concentration separation device of the present invention includes a cylinder body 1, the cylinder body 1 is a cylindrical structure connected with a cone, the taper of the cone body is 25°, and the cylinder body 1 is arranged obliquely, and The included angle between the vertical pulverized coal feed port 4 is 3°; the inside of the cylinder 1 is inlaid with wear-resistant ceramics 2, and the wear-resistant ceramics 2 is a dovetail structure, and the bottom is provided with a dovetail with a narrow bottom and a wide top. strip, and a stud welding stepped hole 21 is provided in the middle; specifically, the wear-resistant ceramic 2 has a thickness of 10mm, and is fixed in the cylinder body 1 by means of high-temperature inorganic adhesive and stud welding. Surface; the cylinder body 1 is provided with two, and symmetrically arranged side by side; the top side of the cylinder body 1 is connected to the side elbow 3 embedded with an integral ...

Embodiment 2

[0037] A wear-resistant pulverized coal concentration separation device of the present invention includes a cylinder body 1, the cylinder body 1 is a cylindrical structure connected with a cone, the taper of the cone body is 30°, and the cylinder body 1 is arranged obliquely, and The included angle between the vertical pulverized coal feed port 4 is 5°; the inside of the cylinder 1 is inlaid with wear-resistant ceramics 2, and the wear-resistant ceramics 2 is a dovetail structure, and the bottom is provided with a dovetail with a narrow bottom and a wide top. strip, and a stepped hole 21 for stud welding is provided in the middle; specifically, the wear-resistant ceramic 2 has a thickness of 20mm, and is fixed in the cylinder body 1 by means of high-temperature inorganic adhesive and stud welding. Surface; the cylinder body 1 is provided with two, and symmetrically arranged side by side; the top side of the cylinder body 1 is connected to the side elbow 3 embedded with an integ...

Embodiment 3

[0039] A wear-resistant pulverized coal concentration separation device of the present invention includes a cylinder body 1, the cylinder body 1 is a cylindrical connection cone structure, the taper of the cone body is 45°, and the cylinder body 1 is inclined The included angle with the vertical pulverized coal feed port 4 is 10°; the inside of the cylinder 1 is inlaid with wear-resistant ceramics 2, and the wear-resistant ceramics 2 is a dovetail structure with a lower narrow upper Wide dovetail strips, and a stepped round hole 21 for stud welding is provided in the middle; specifically, the wear-resistant ceramic 2 has a thickness of 30mm, and is fixed to the cylinder by dual methods of high-temperature inorganic adhesive and stud welding 1; the cylinder body 1 is provided with two, and symmetrically arranged side by side; the top side of the cylinder body 1 is connected to the side elbow 3 embedded with an integral wear-resistant ceramic sleeve, and the side elbow 3 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com