Level layer blow-out type biomass particle burner

A biomass particle and burner technology, which is applied in the combustion method, combustion equipment, combustion product treatment and other directions to achieve the effects of improving stability, low flue gas resistance and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

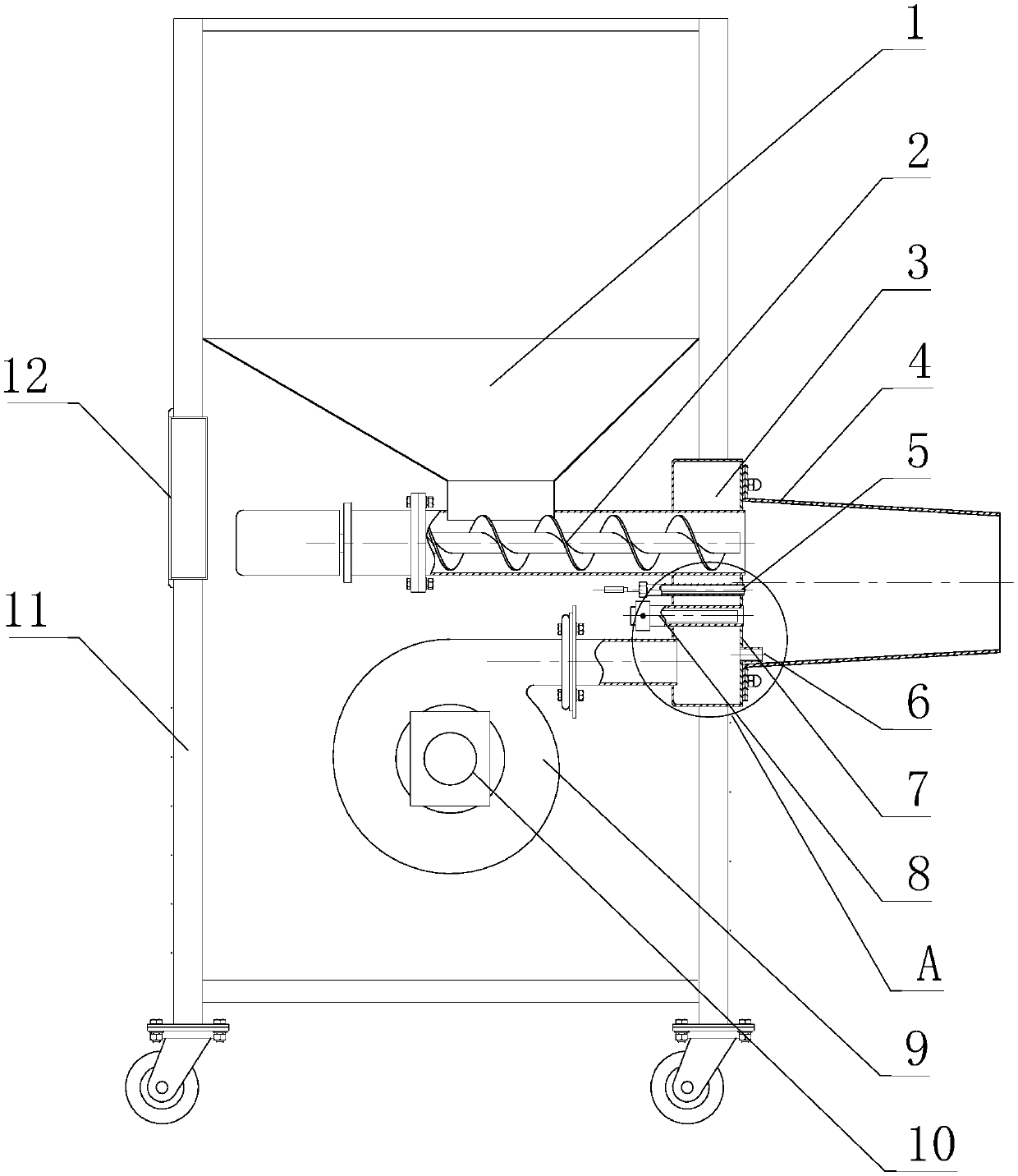

[0042] see Figure 1~2. The flat layer blow-out biomass pellet burner shown in this embodiment includes a silo 1 , a feeding mechanism 2 , a burner 4 and an ignition device 8 . The discharge end of the feeding mechanism 2 communicates with the end of the burner 4 for continuous delivery of biomass particle fuel to the burner. The burner 4 is in the shape of a truncated cone installed horizontally, and the bottom surface of the truncated cone is the end of the burner 4 .

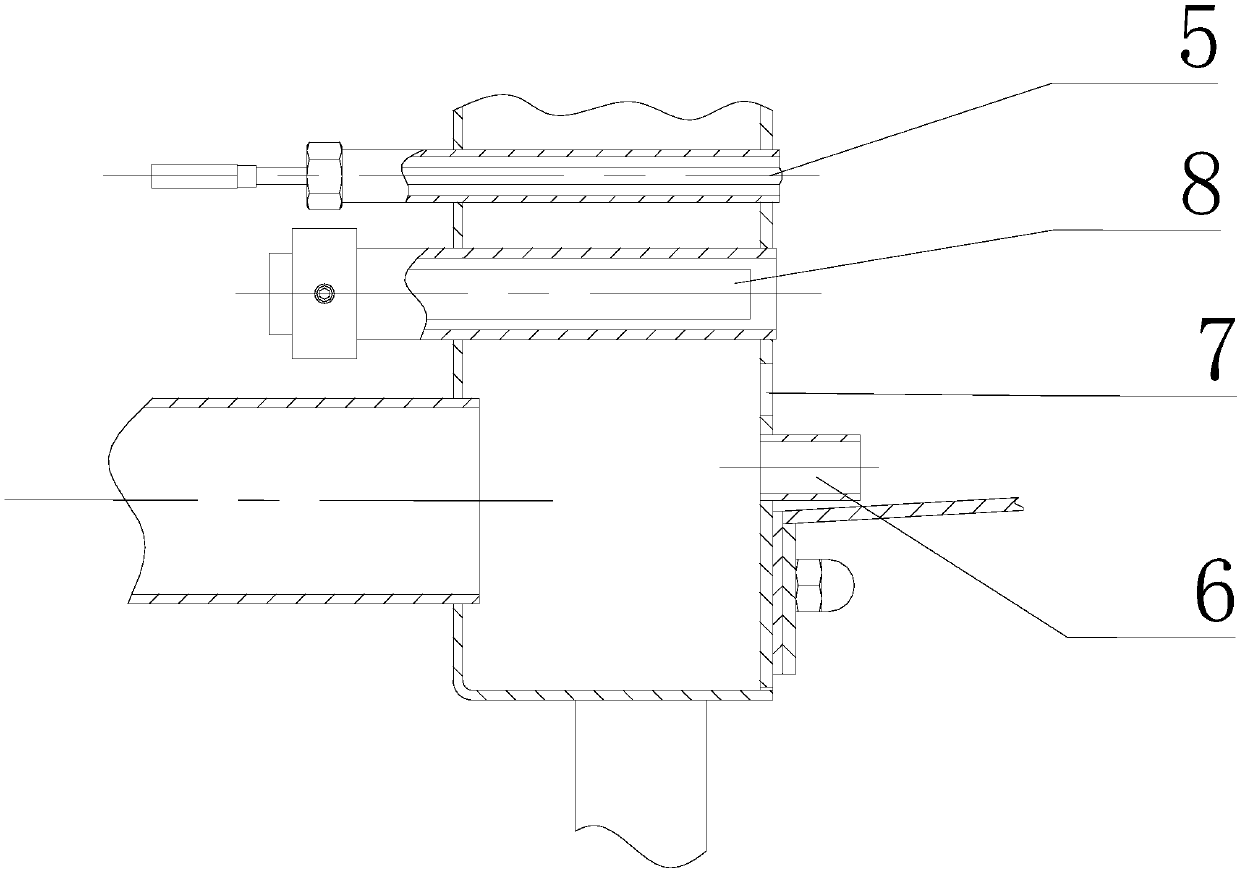

[0043] The flat layer blown-out biomass pellet burner shown in this embodiment also includes an air distribution chamber 3 connected to the end of the burner 4 and communicated with the air outlet pipe of the combustion-supporting fan 9 . Preferably, the air distribution chamber 3 is in the shape of a hollow ring, and the feeding mechanism 2 and the ignition device 8 pass through the air distribution chamber 3 from the hollow.

[0044] The air distribution chamber 3 has a combustion-supporting air pipe 7 p...

Embodiment 2

[0047] In order to facilitate the control of the firepower of the flat-bed blow-out biomass pellet burner, on the basis of Embodiment 1, this embodiment further sets a plurality of evenly distributed combustion-supporting air ducts 7 in the air distribution chamber 3, and in the combustion-supporting fan The air inlet of 9 is equipped with an electric damper 10 and a temperature sensor 5, which is inserted into the inner cavity of the burner 4 from the end of the burner 4, and the temperature sensor 5 is arranged above the slag blowing pipe 6. In this way, the combustion conditions in the burner 4 are monitored in real time through the temperature sensor 5, and parameters such as fuel feed rate and air flow are controlled individually or jointly, so that the input firepower of the burner can be freely adjusted.

Embodiment 3

[0049] This embodiment demonstrates the control method of the flat layer blow-out biomass pellet burner shown in Embodiment 1.

[0050] The biomass particles leak into the feeding mechanism 2 from the bottom of the silo 1, and the feeding mechanism 2 transports the biomass particles to the end of the burner 4 and accumulates near the ignition device 8.

[0051] The biomass particles are ignited through the work of the ignition device 8; the combustion-supporting air is sent into the air distribution chamber 3 through the combustion-supporting fan 9, and then horizontally enters the end of the burner 4 from the combustion-supporting air pipe 7, so that the biomass particles are fully Combustion: The ashes after combustion are directly blown out of the burner 4 horizontally through the slag blowing pipe 6 to ensure continuous combustion of biomass particles.

[0052] A controller 12 is installed on the frame 11 to control the feeding speed of the feeding mechanism 2 . When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com