Electric vehicle-mounted complete closed internal liquid cooling, external wind cooling type switch reluctance motor

A switched reluctance motor, fully enclosed technology, applied in the direction of electric components, cooling/ventilation devices, electrical components, etc., can solve the problems of low heat dissipation efficiency, reduced service life, uneven heat dissipation of the motor, etc., to improve work efficiency and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

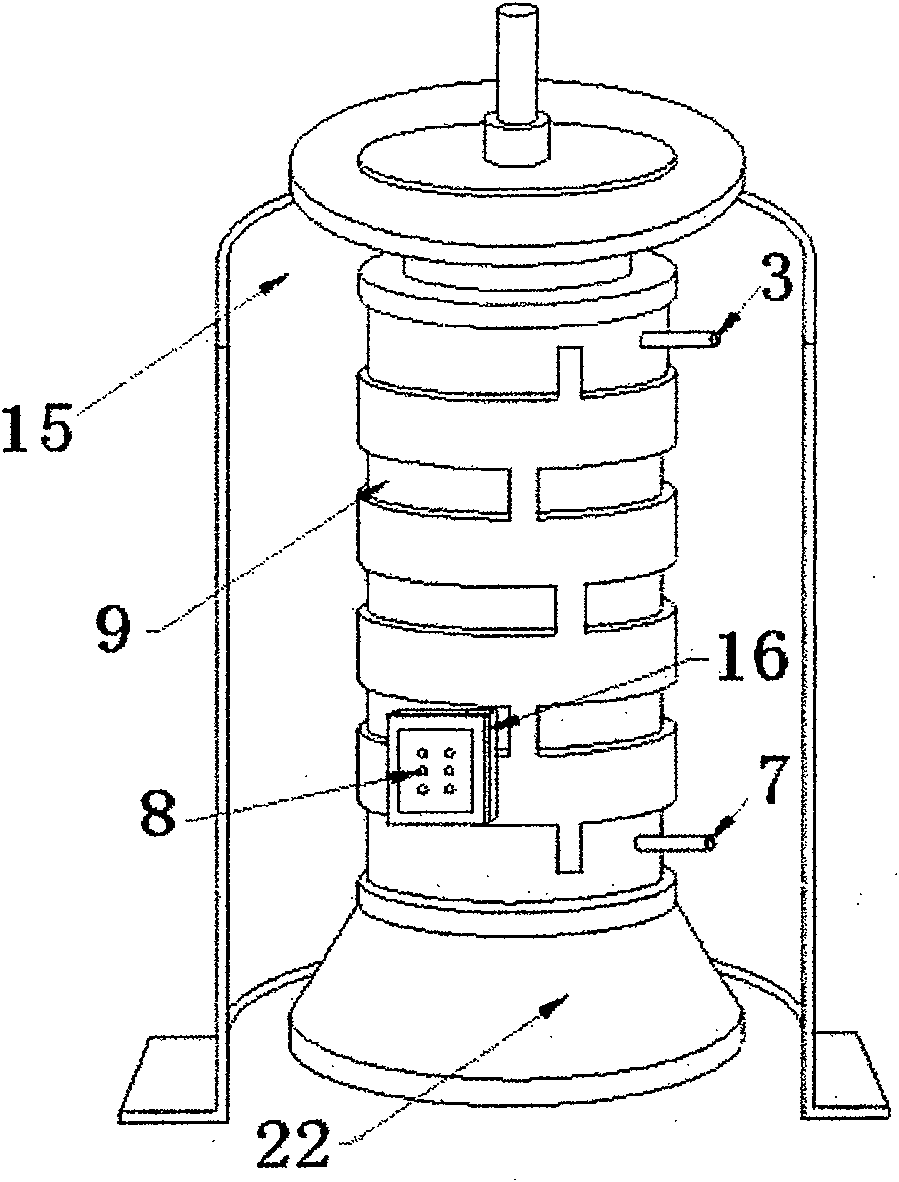

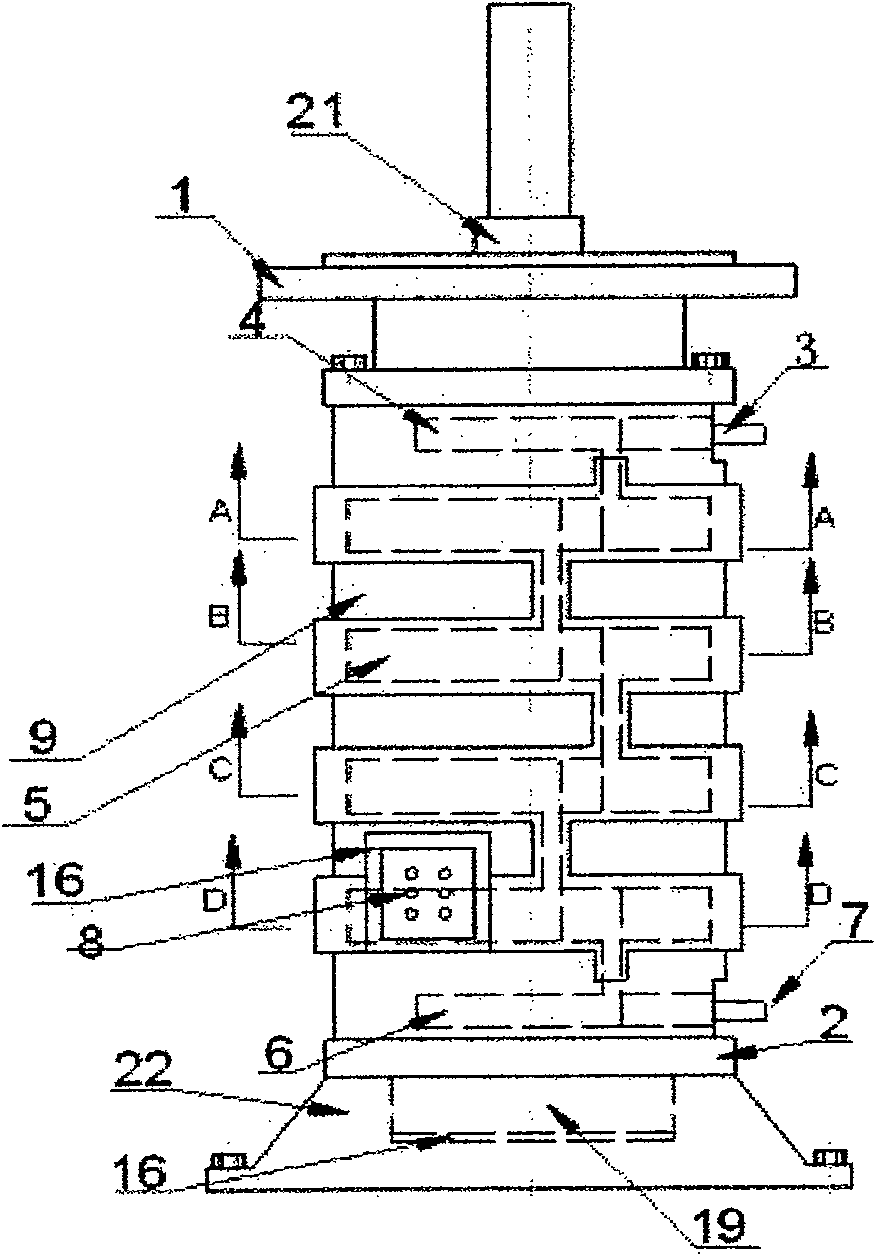

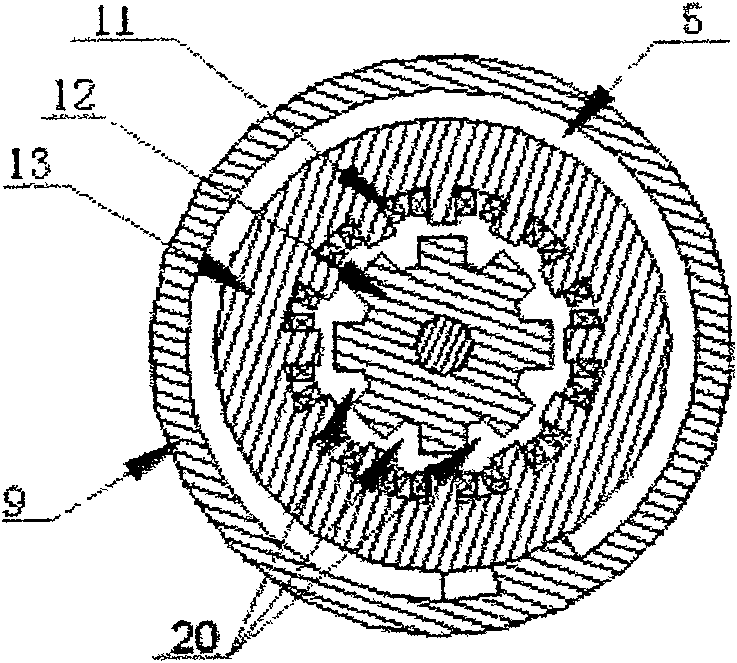

[0033] According to the attached Figure 1-17 Be explained:

[0034] Fully enclosed internal liquid-cooled and external air-cooled switched reluctance motors for electric vehicles include front end cover 1, rear end cover 2, interfaces 3, 7, 23 and 24, cooling liquid ring pipes 4 and 6, casing heat pipe 5, motor Junction box 8, sealed casing 9, B-type thermal wedge 10, stator winding 11, rotor 12, stator 13, A-type thermal wedge 14, windshield 15, waterproof rubber pad and sealing ring 16, cooling liquid pipes 17 and 18 , Closed position sensor 19, rotor sealing filler 20, waterproof ring 21 and machine base 22.

[0035] Heat dissipation design of fully enclosed switched reluctance motor with internal liquid cooling and external air cooling for electric vehicles:

[0036] Behind the switched reluctance motor, an arc-shaped windshield 15 facing the front of the vehicle is provided.

[0037] On the inner surface of the aluminum sealed casing 9, a spiral cooling chamber and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com