Cooling device for variable frequency controller

A frequency conversion controller, cooling device technology, applied in the output power conversion device, cooling/ventilation/heating transformation, heat exchanger type and other directions, to achieve the effect of saving space, reasonable layout and effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

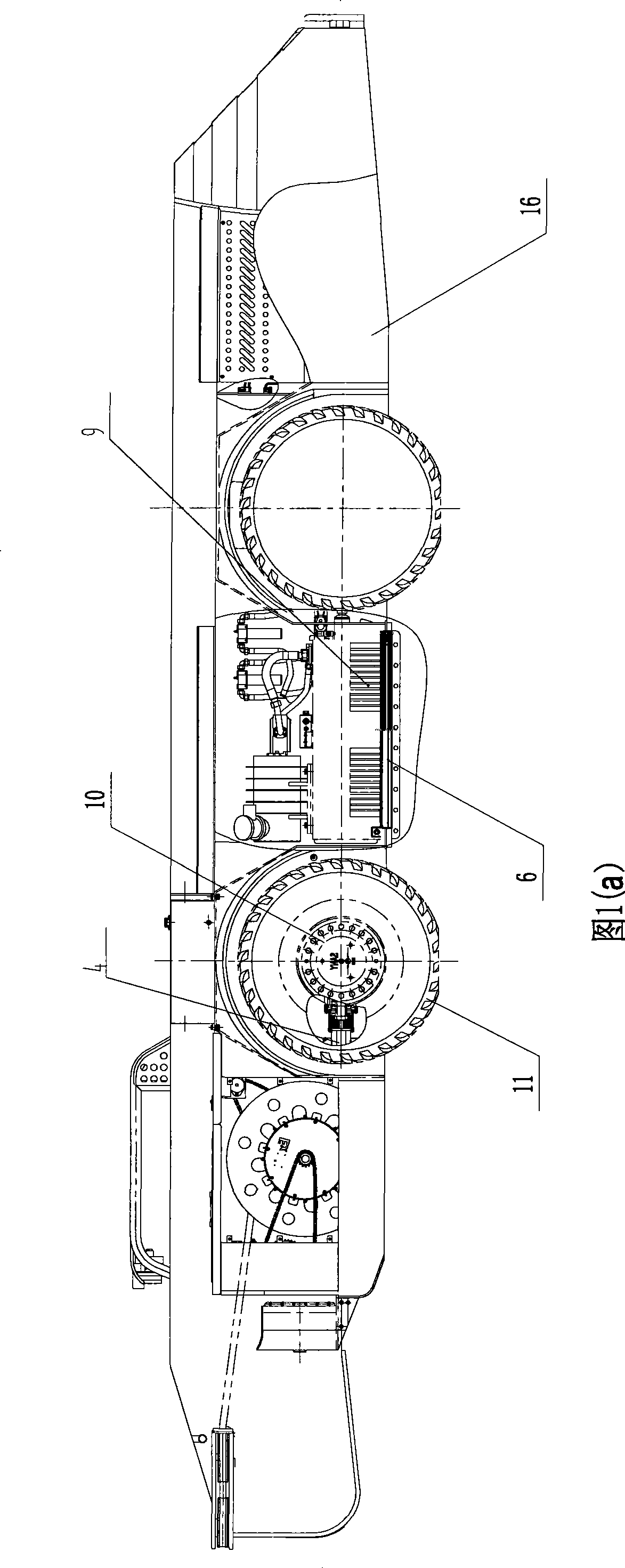

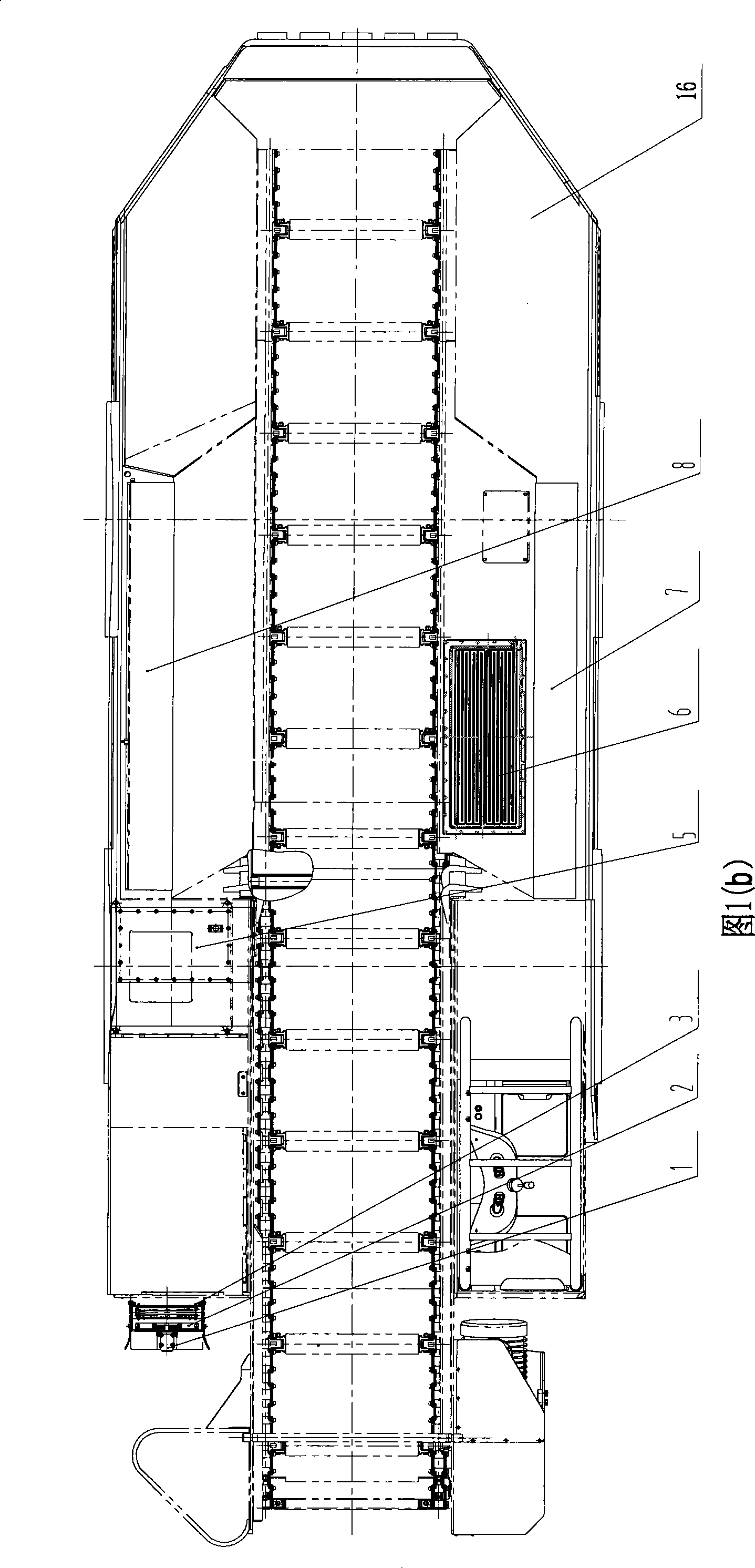

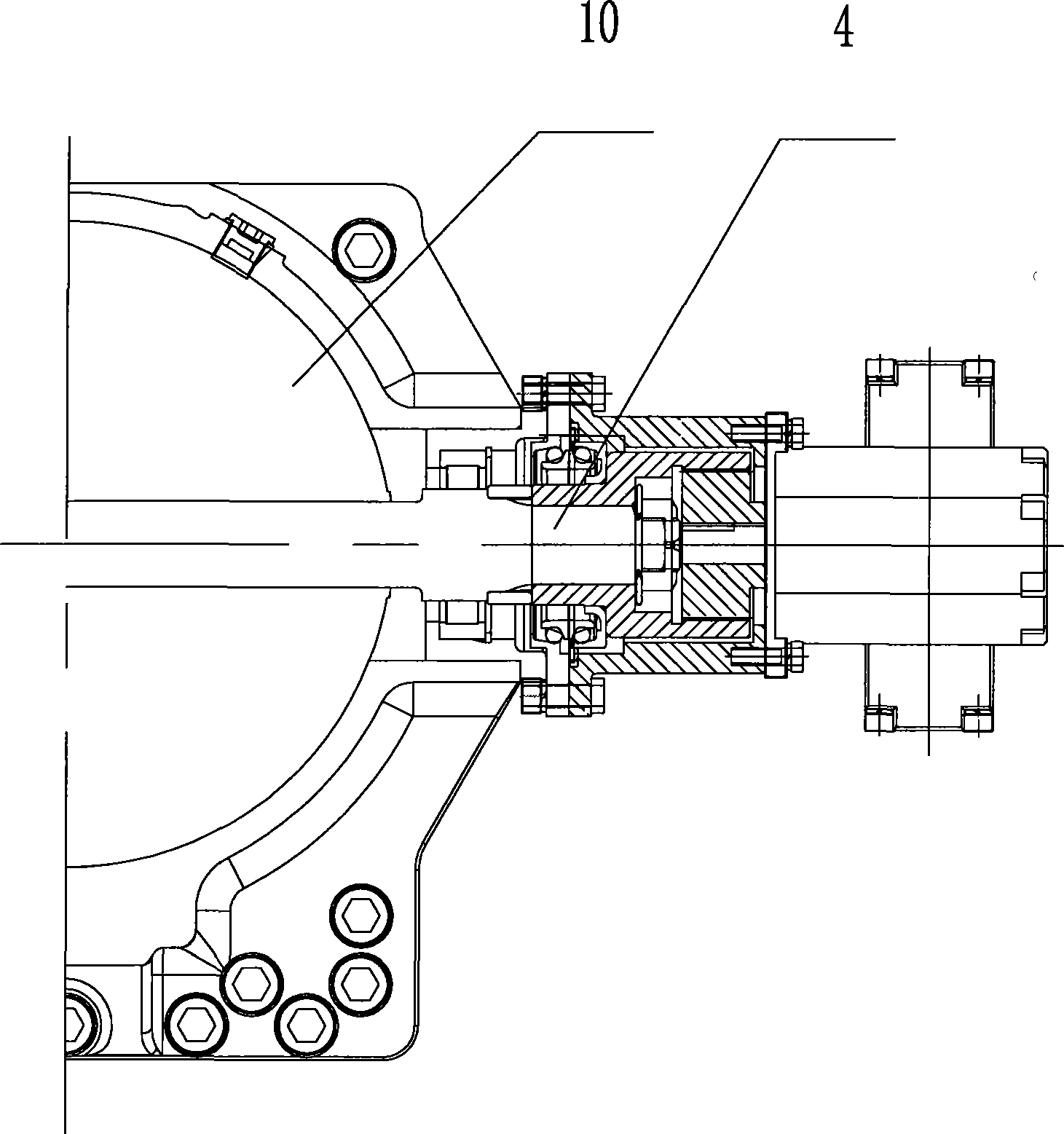

[0019] As shown in Figure 1 (a)-Figure 1 (b), the cooling device of the frequency conversion controller 9 of the present invention is integrally installed on the car body 16 of the mine shuttle car, and the device includes: a fan motor 1, a fan 2, a heat exchanger Device 3, circulating power system 4, water tank I5, circulating water channel 6, water tank II7, water tank III8, etc. The cooling water circulation channel 6 is placed at the bottom of the frequency conversion controller 9, and the circulation channel 6 is a double-inlet and double-outlet serpentine pipe loop composed of two independent serpentine waterways I12 and serpentine waterways II13 (Fig. 3(a)-Fig. 3 (b)). Water tank I5 is placed in the right front upper part of the car body 16, water tank II is placed in the right middle and upper part of the car body 16, water tank III8 is placed in the left middle and upper part of the car body 16, the fan 2 and the heat exchanger 3 are placed in the right front part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com