Patents

Literature

66results about How to "Continuous automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

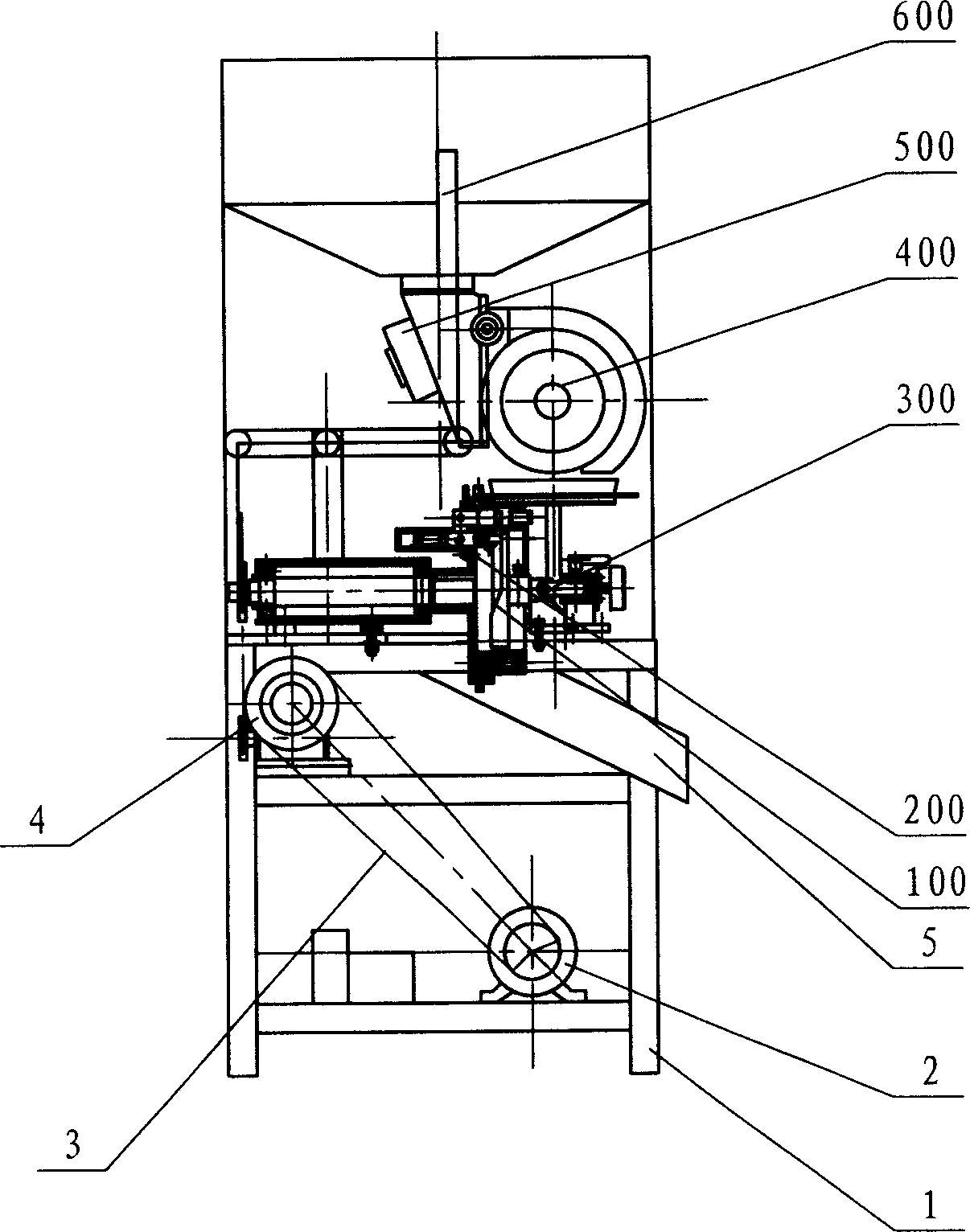

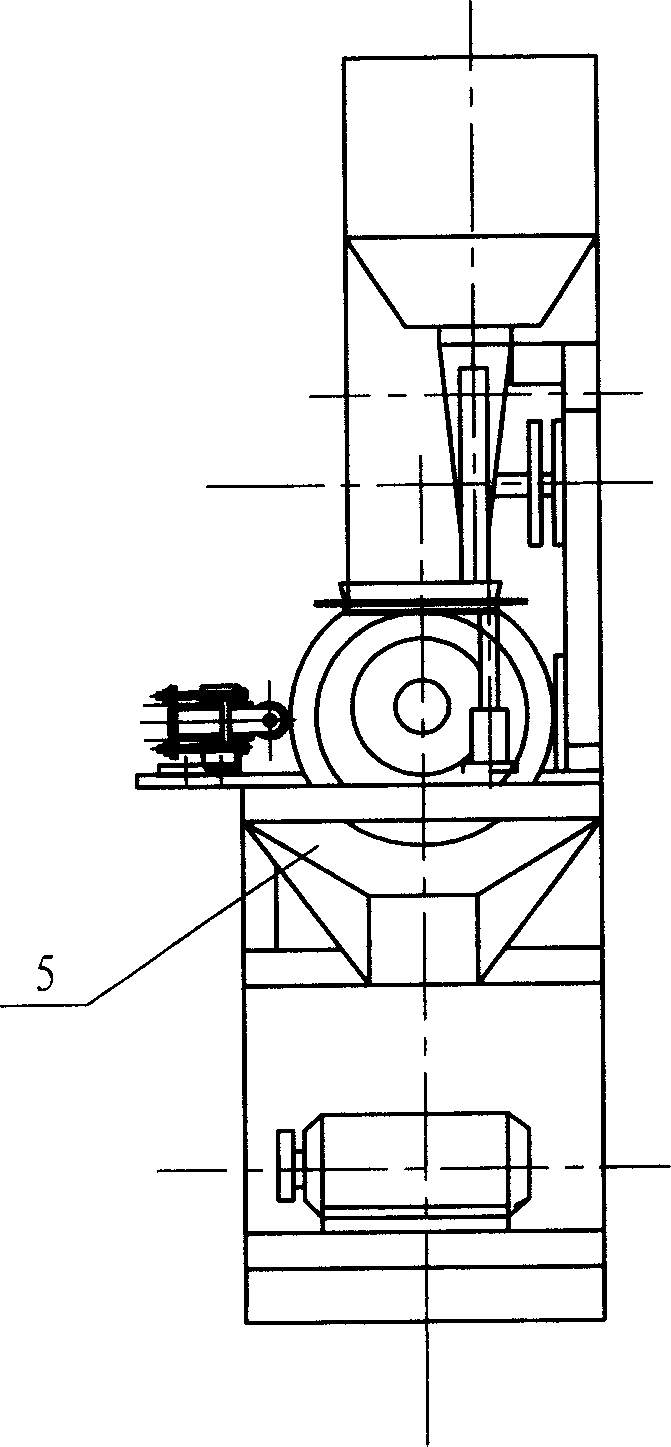

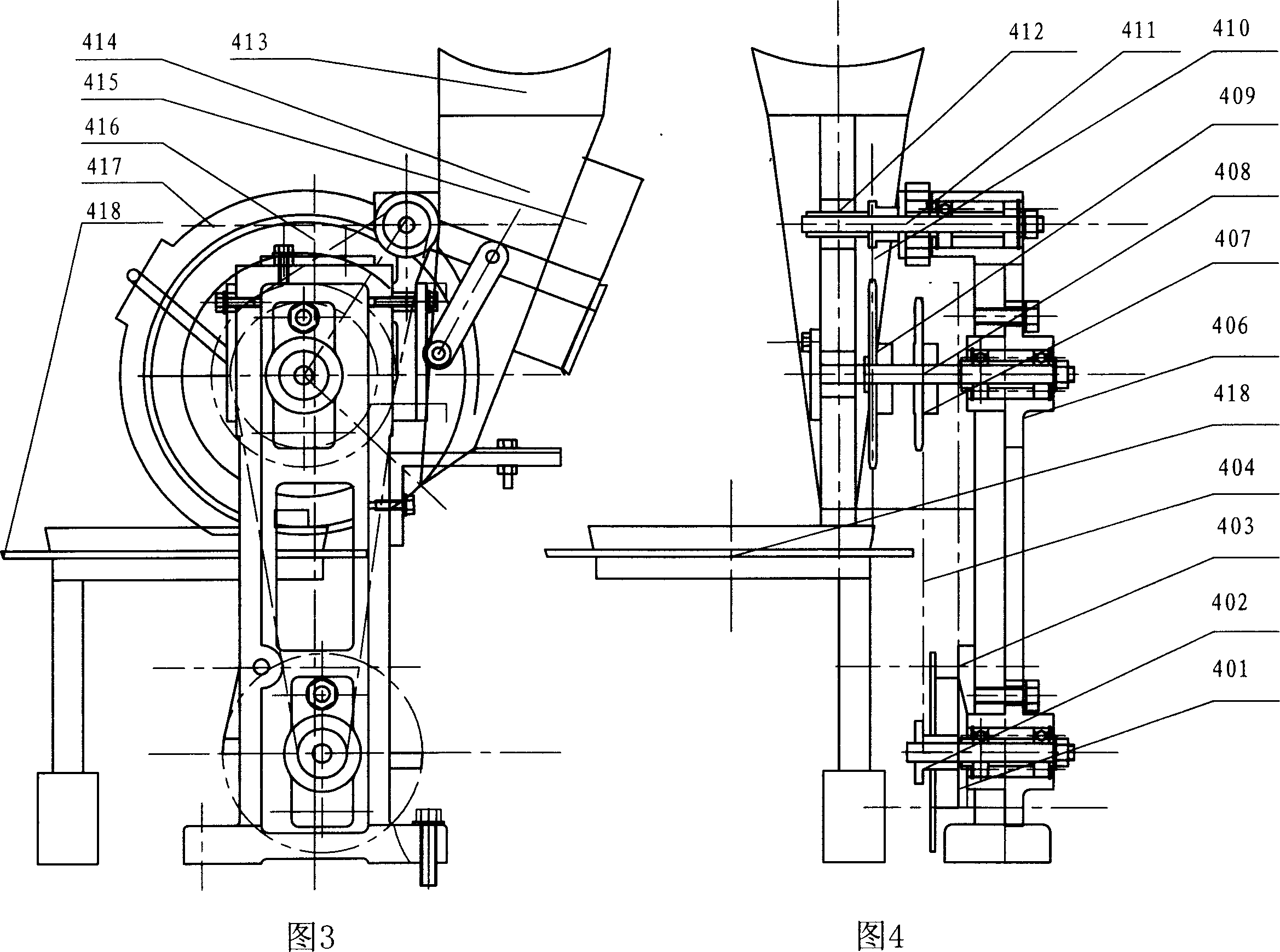

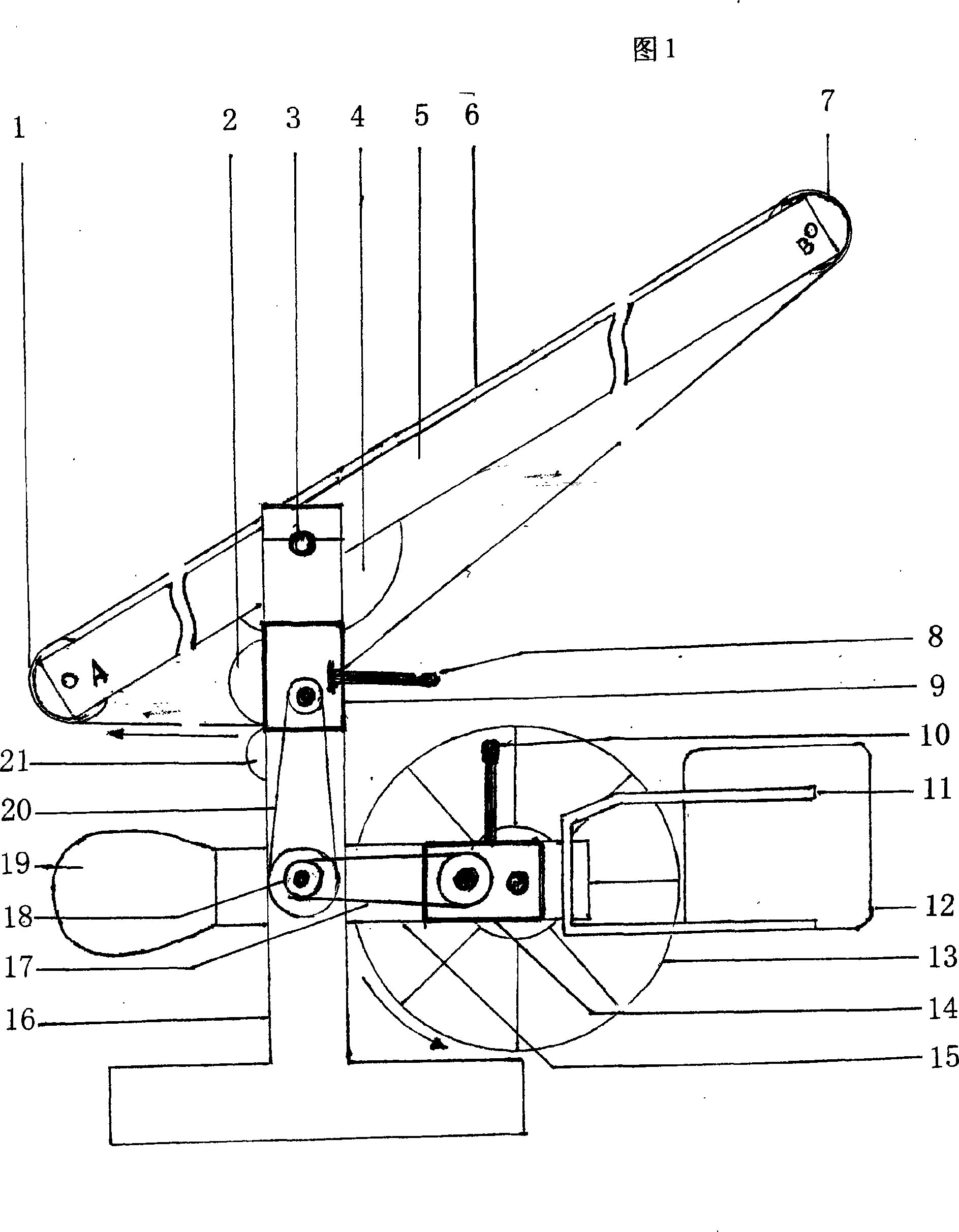

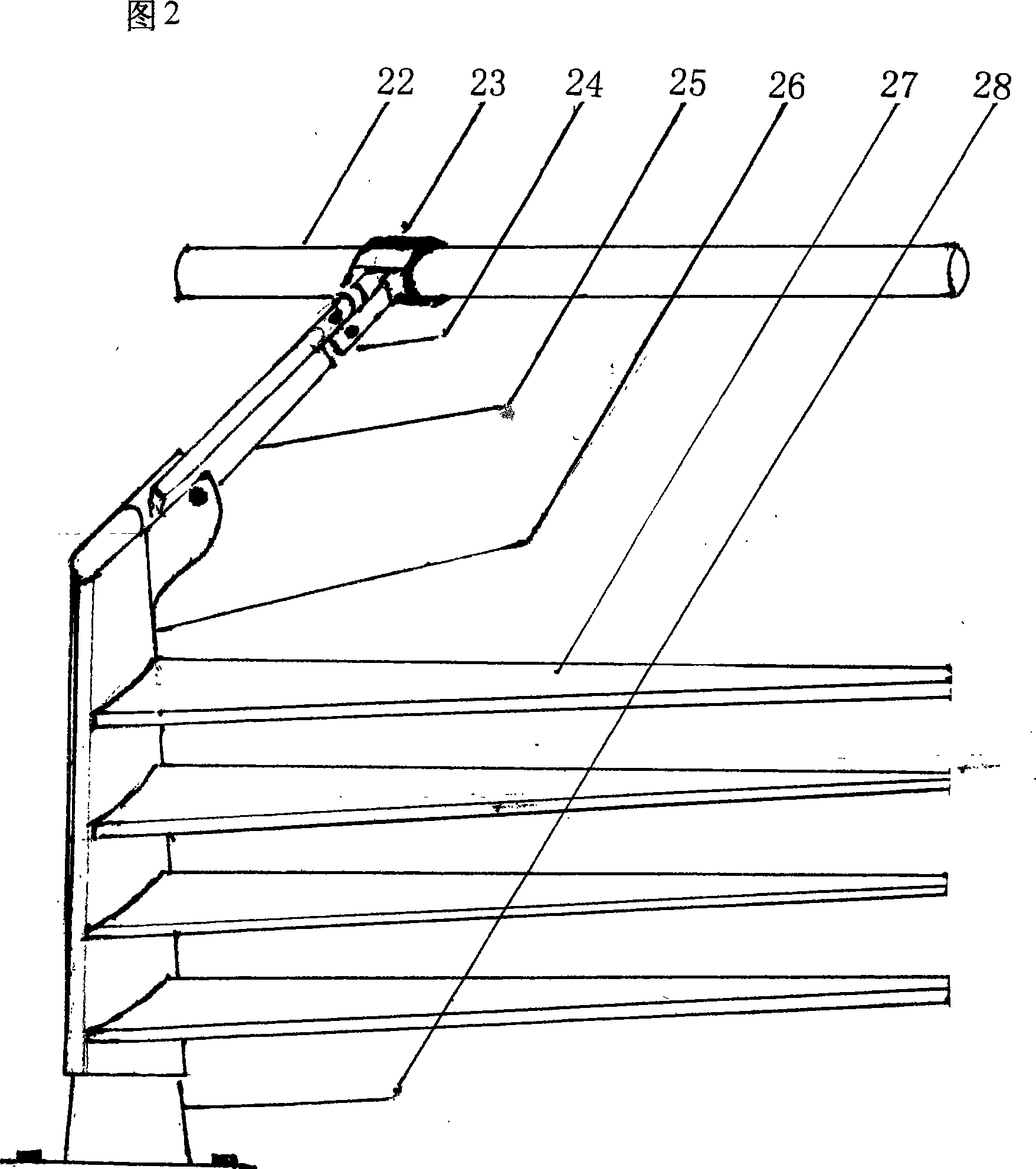

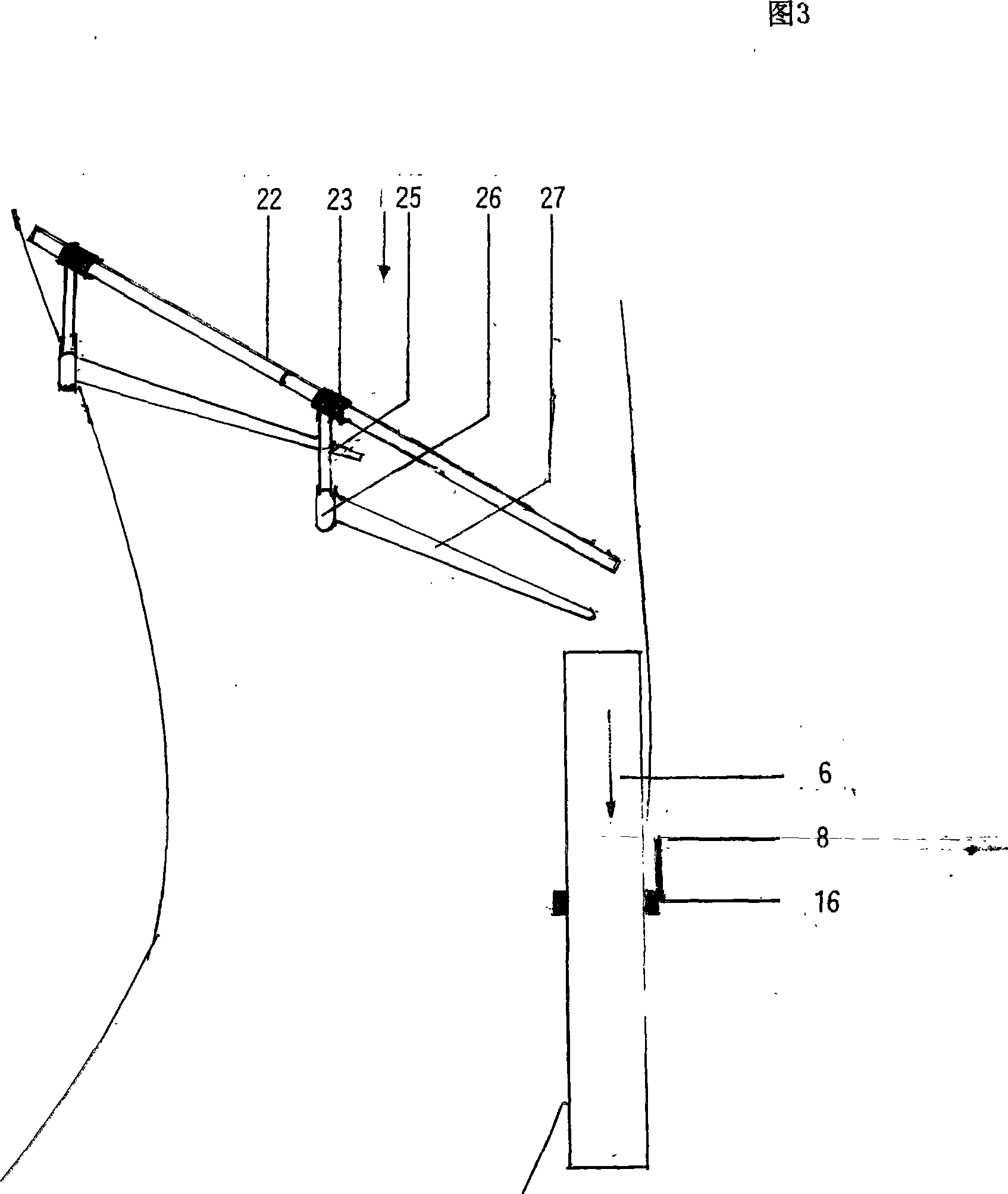

Veridical lifting type monomer copying cotton topping machine

InactiveCN102845242ASimple structureGood profiling adaptabilityCuttersCutting implementsEngineeringMechanical engineering

The invention relates to a veridical lifting type monomer copying cotton topping machine based on electric hydraulic control, comprising a combined rack, a drive system, an electrical system, copying platforms and a topping device. The copying platforms are arranged at the lower part of the combined rack, the number of the copying platforms are accordant with the work line number of the topping device, the copying platforms are respectively connected with a lifting oil cylinder fixed on the rack and a topping device cutter shaft arranged in a sleeve drive system by a pin and a bearing base, and the electric system is fixed at the front end and the upper part of the combined rack. The veridical lifting type monomer copying cotton topping machine is characterized in that the topping device cutter shaft not only can rotate but also can be vertically lifted up and down in a sleeve along with the copying platforms; the front-and-back position of a copying device on the copying platforms can be adaptive to various work speeds of the topping machine; and the assembled rack of the topping machine can meet the requirement of the different work widths or line numbers according to the number of the copying platforms.

Owner:SHIHEZI UNIVERSITY

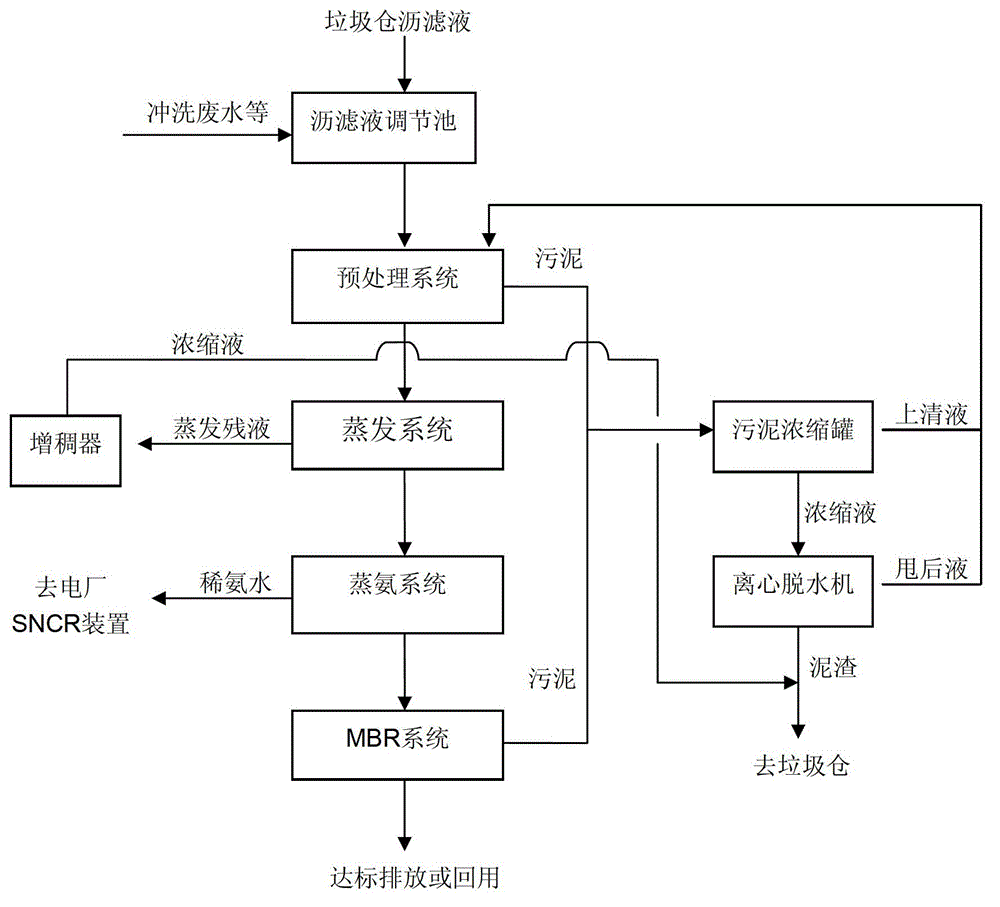

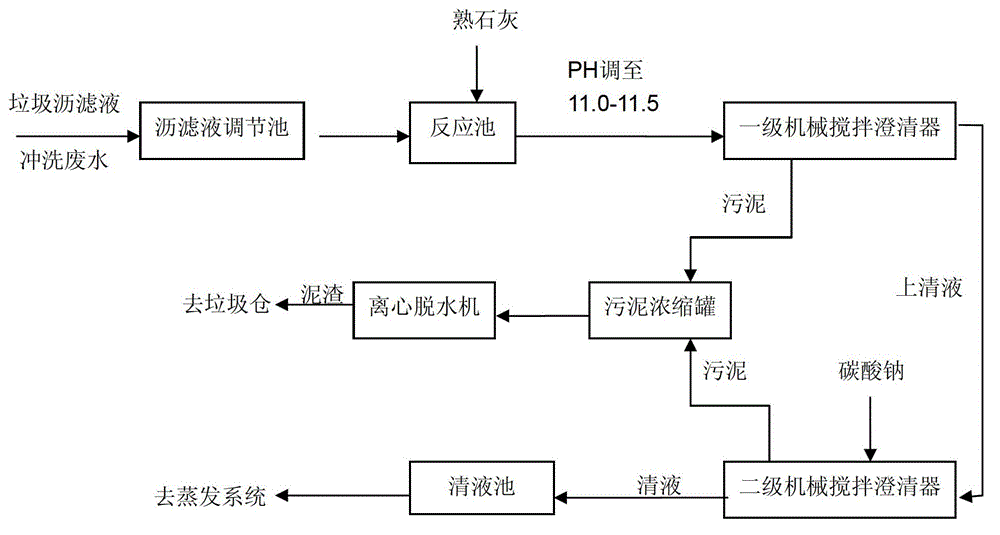

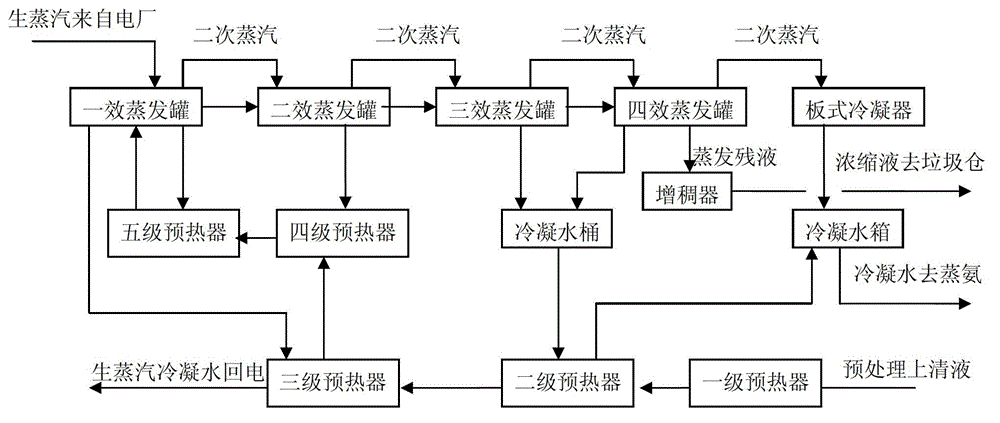

Garbage leachate disposal method and system

InactiveCN102976543AContinuous automationStable automationTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a garbage leachate disposal method and system, aiming at solving the problems of low ammonia removal efficiency, instability in operation, ammonia direction in an ammonia blowing-off process of the ammonia blowing-off technology adopted by the method for reducing ammonia nitrogen and chemical oxygen demand (COD) content in the existing garbage leachate disposal process, and a series of problems of remarkable inlet water quality fluctuation of a biochemical system, serious influence on stable operation and outlet water quality of the biochemical system. According to the garbage leachate disposal method and system disclosed by the invention, ammonia removal treatment is implemented on evaporating condensed water of the garbage leachate by a rectifying method, so the problems of low ammonia removal efficiency, instability in operation, ammonia direction in an ammonia blowing-off process in the process of operating the ammonia removal process of the high-concentration ammonia nitrogen wastewater of the existing ammonia blowing-off method, and a series of problems of remarkable inlet water quality fluctuation of the biochemical system, serious influence on stability in operation and outlet water quality of the biochemical system are effectively solved.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

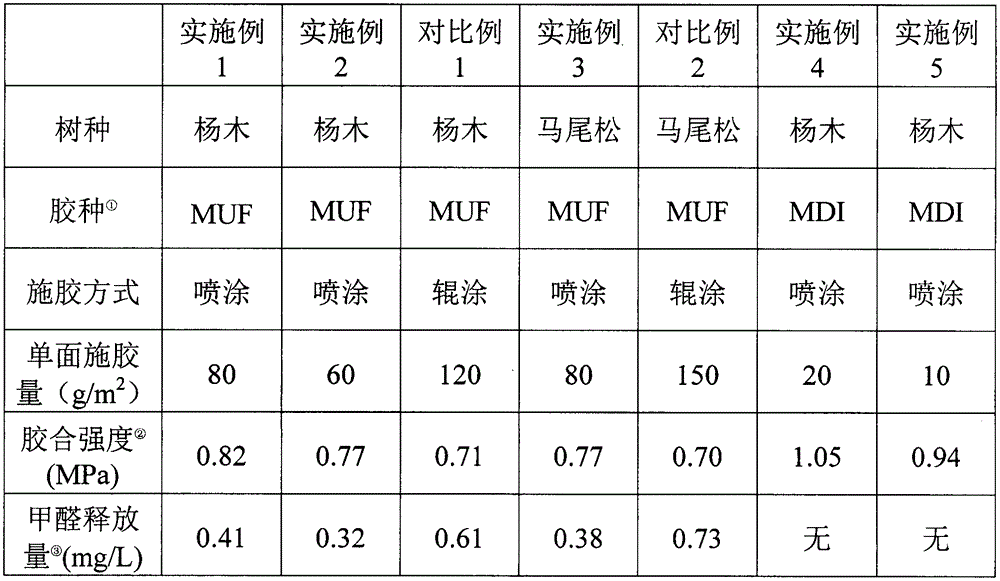

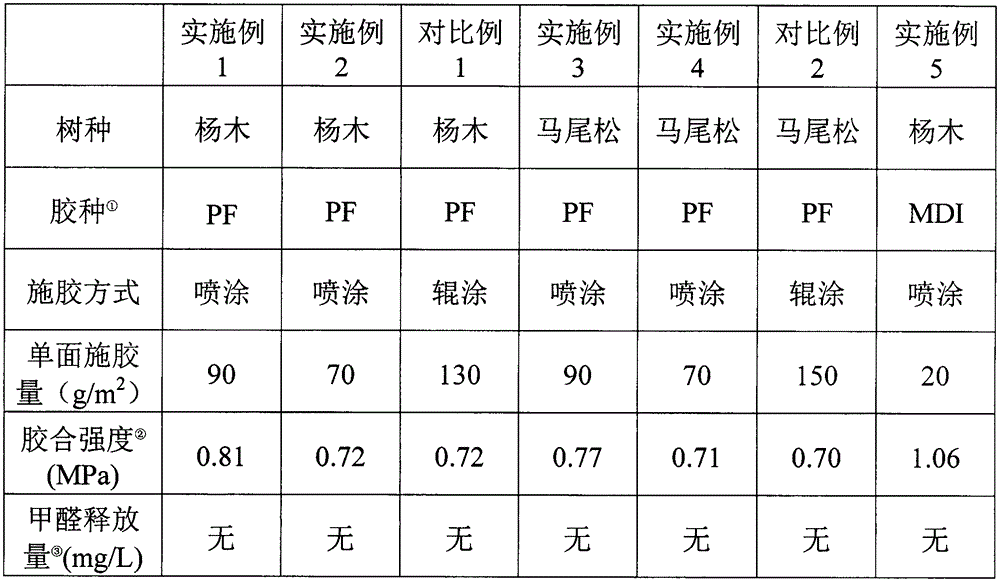

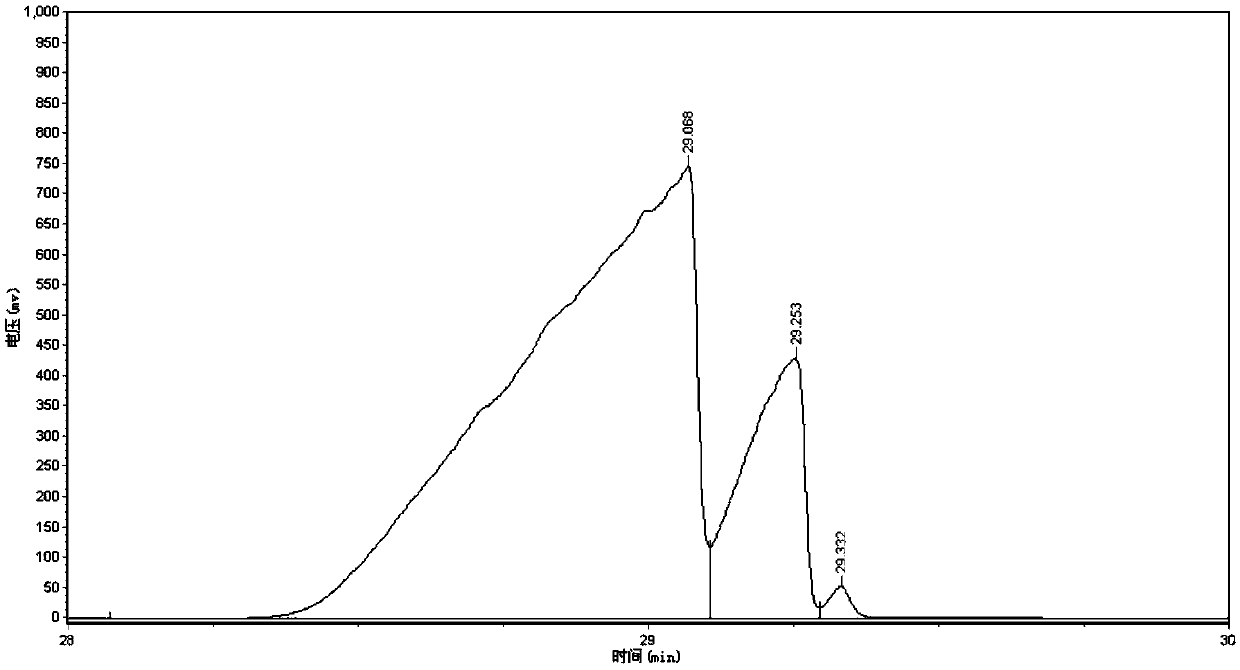

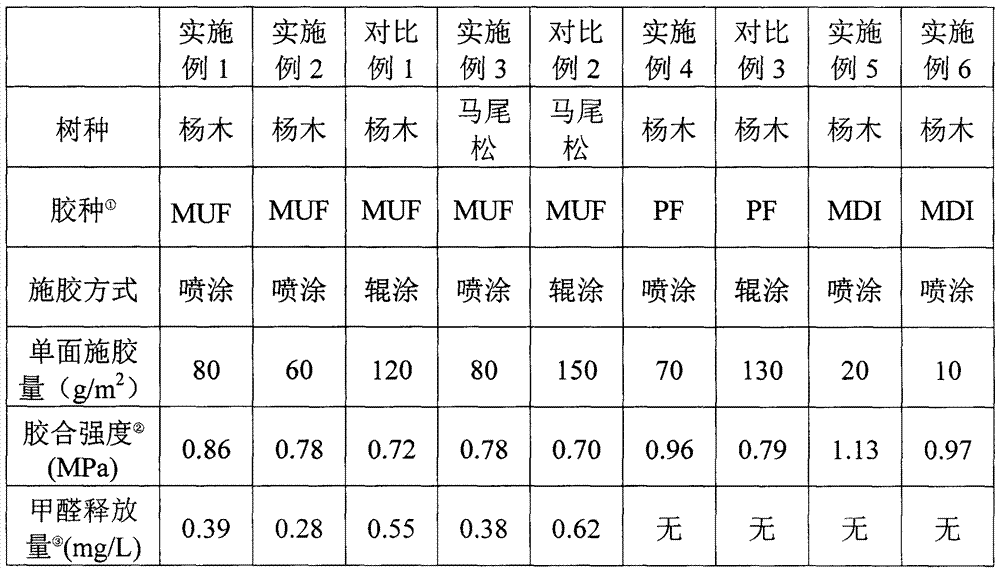

Manufacturing method for low-adhesive-consumption environment-friendly multi-layer solid wood composite floor

ActiveCN105856343ASimple and fast operationImprove qualityOther plywood/veneer working apparatusTree debarkingEnvironmental resistanceFiber

The invention relates to a manufacturing method for a low-adhesive-consumption environment-friendly multi-layer solid wood composite floor and belongs to the technical field of artificial board manufacturing. The method includes the steps that short-cut wood is subjected to rotary-cutting into 1-3 mm wooden veneers, and the veneers are dried, so that the moisture content is adjusted to be 8%-12%; the double sides of the veneers are subjected to normal-pressure low-temperature plasma modification treatment; through ultrasound and cyclone synergistic effect, an adhesive is atomized into particles with the diameter being smaller than 40 [mu]m, then the particles are sprayed onto the tight sides of the veneers, and the adhesive consumption of a single side is controlled to be 10-80 g / m<2>; mutually vertical assembly is performed according to fiber texture directions of the adjacent-layer veneers; and hot-pressing and sliced wood veneer lamination are conducted, and then the low-adhesive-consumption environment-friendly multi-layer solid wood composite floor is obtained. The properties of the low-adhesive-consumption environment-friendly multi-layer solid wood composite floor meet the requirement of national standards; the formaldehyde emission reaches E0 grade; the adhesive consumption is decreased by 30%-70% compared with that of a traditional adhesive coating mode; the product quality is remarkably improved; and the production cost is dramatically reduced. Besides, the production process of the method achieves energy saving and environment protection, production equipment is easy and convenient to operate, high in efficiency and good in controllability, and continuous automatic operation can be achieved.

Owner:NANJING FORESTRY UNIV

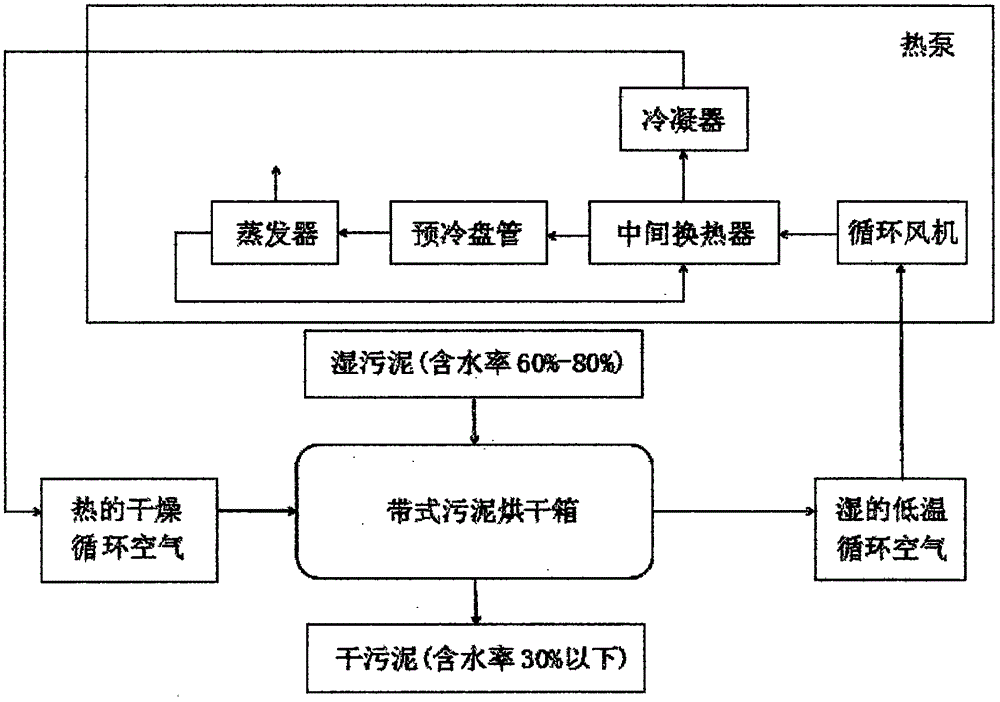

Low-temperature sludge drying technology

InactiveCN106673392AReduce energy consumptionHigh energy consumptionSludge treatment by de-watering/drying/thickeningSludgeIntercooler

The invention discloses a low-temperature sludge drying technology and relates to the field of a sludge drying technology. The technology comprises the following steps: crushing wet sludge and carrying out extrusion moulding, entering a belt-type sludge drying box, carrying out heat transfer and mass transfer with hot dry circulating air to obtain dry sludge and wet low-temperature circulating air, inhaling the wet low-temperature circulating air into a heat pump through a circulating fan, further lowering temperature by heat exchange between the air blown from a circulating fan into an intermediate heat exchanger and evaporated outlet air, discharging air out of the intermediate heat exchanger, lowering temperature by a water-cooling pre-cooling coil pipe, evaporating by an evaporator after air-out, separating out condensed water, carrying out heat exchange between evaporated outlet air and heat-pump return air through an intercooler, raising air-outlet temperature and then entering a condenser, and letting hot dry air obtained after temperature rise enter a band-type sludge drying oven for cycling treatment. The invention has the following advantages: energy consumption is low; there is no secondary pollution; drying temperature is low; safety is high; degree of automation is high; and sludge drying cost is reduced.

Owner:上海东诚环保科技有限公司

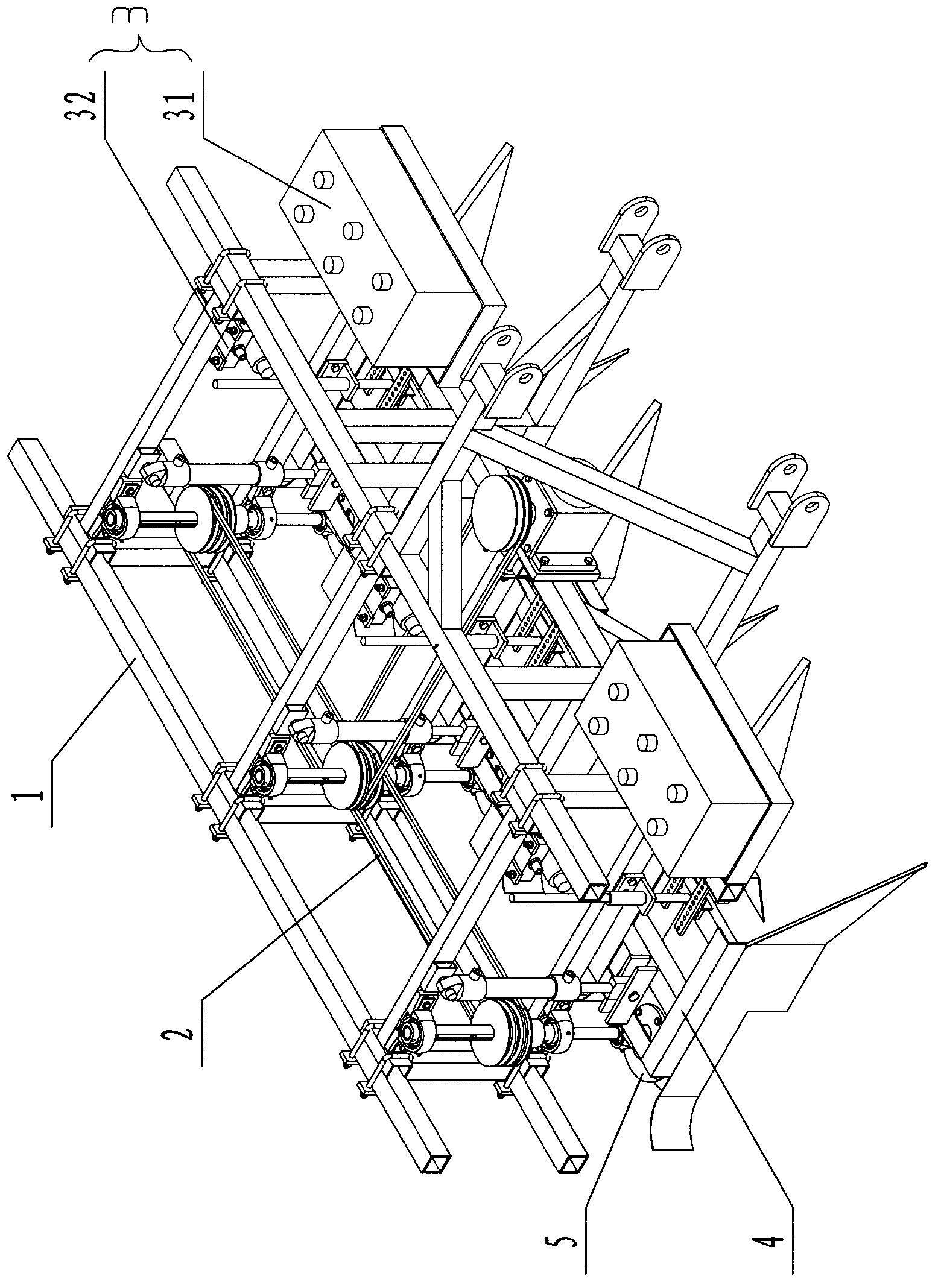

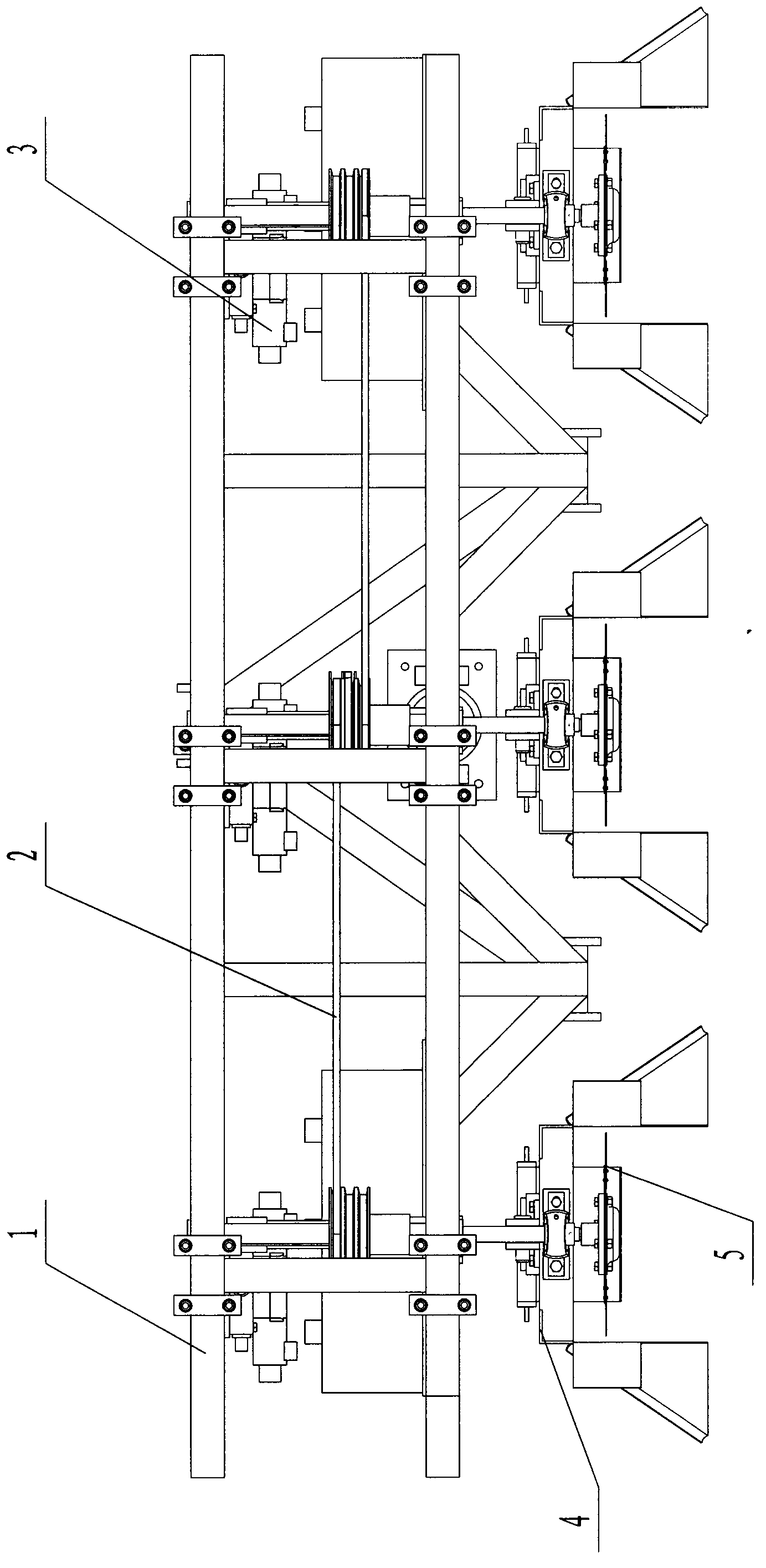

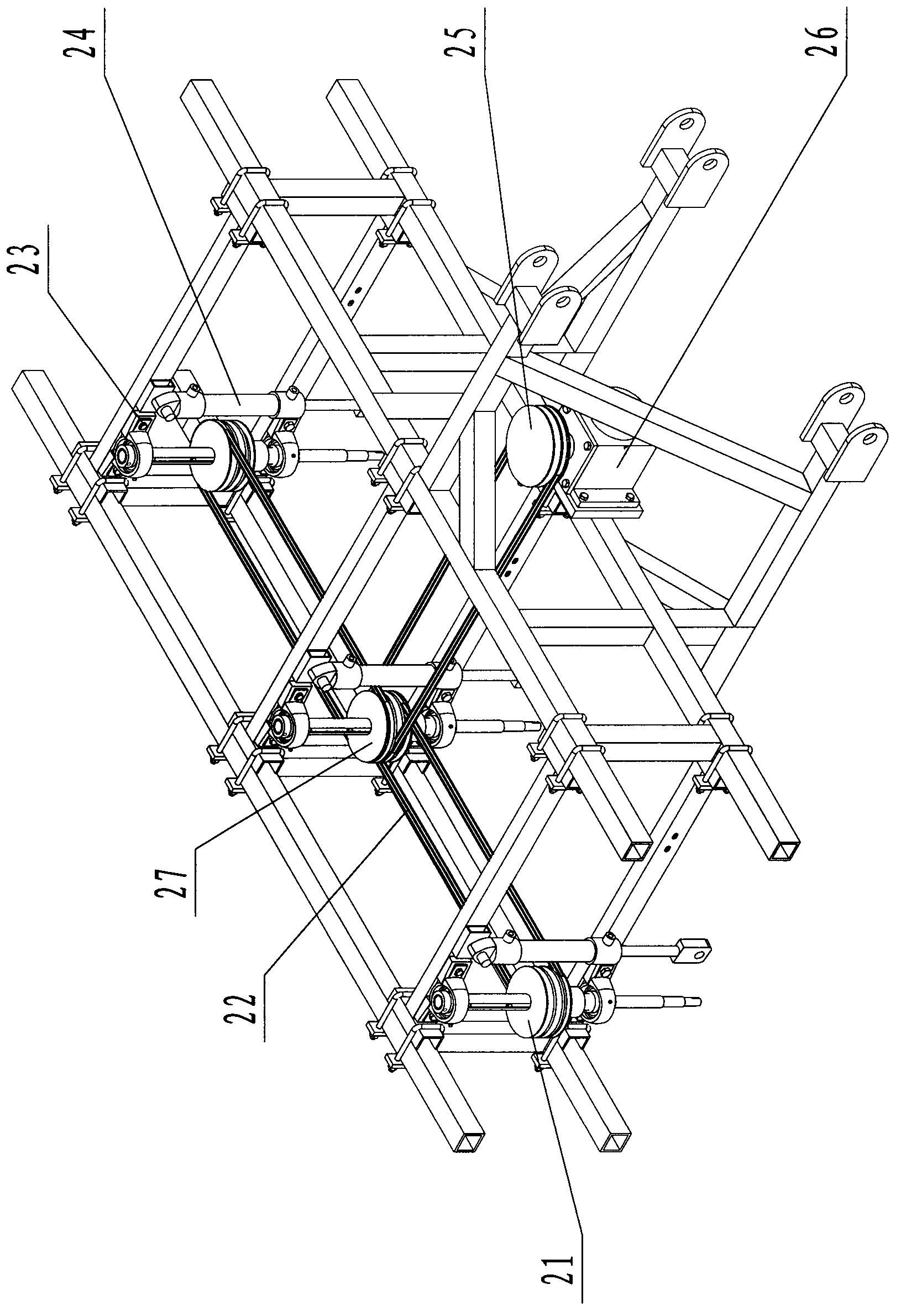

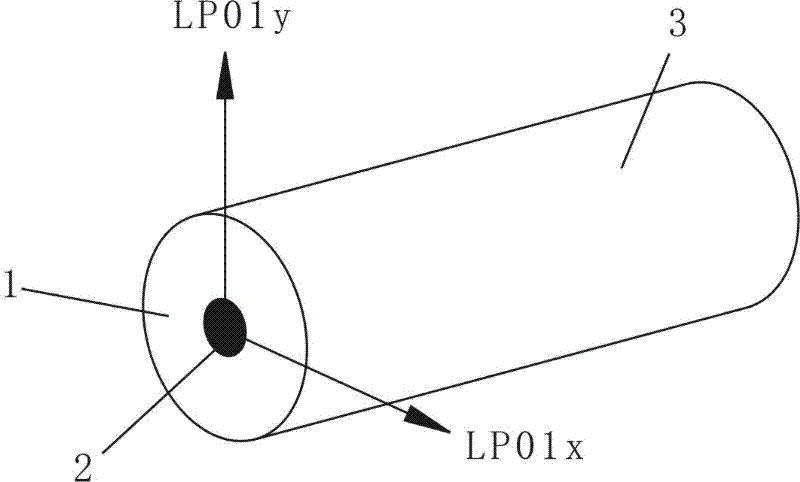

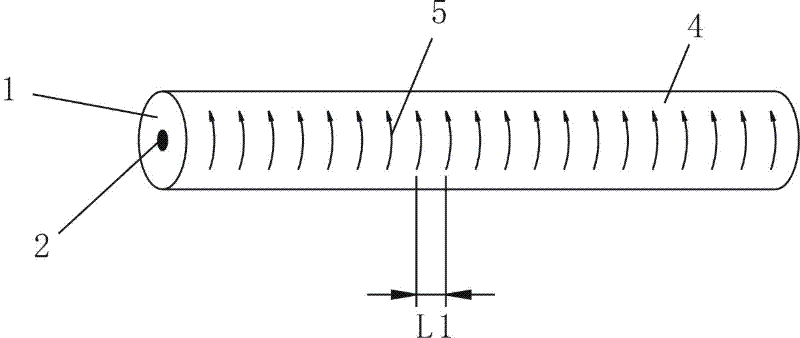

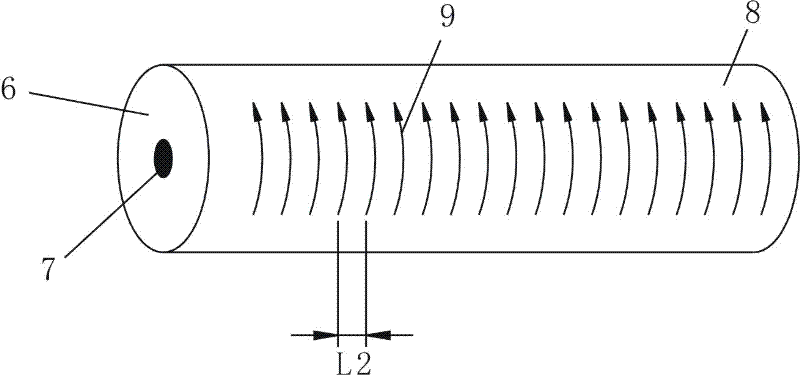

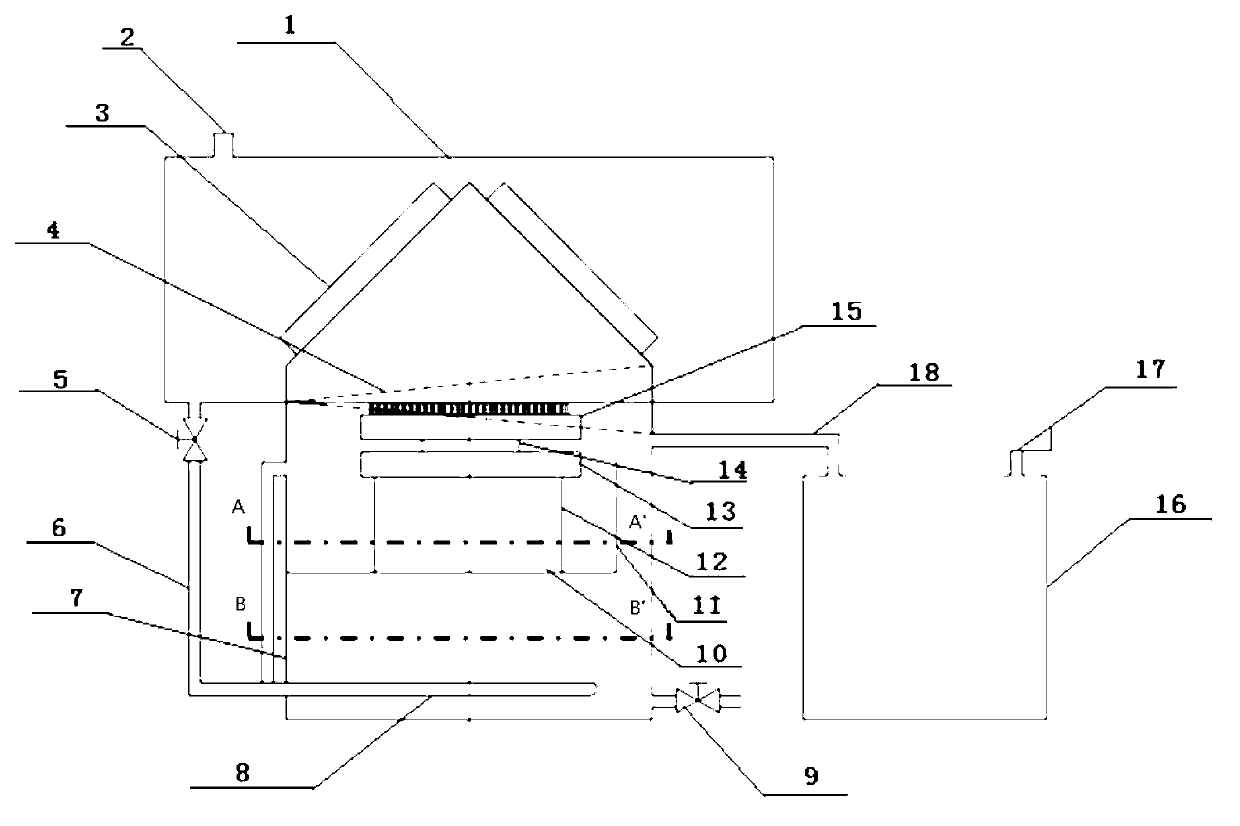

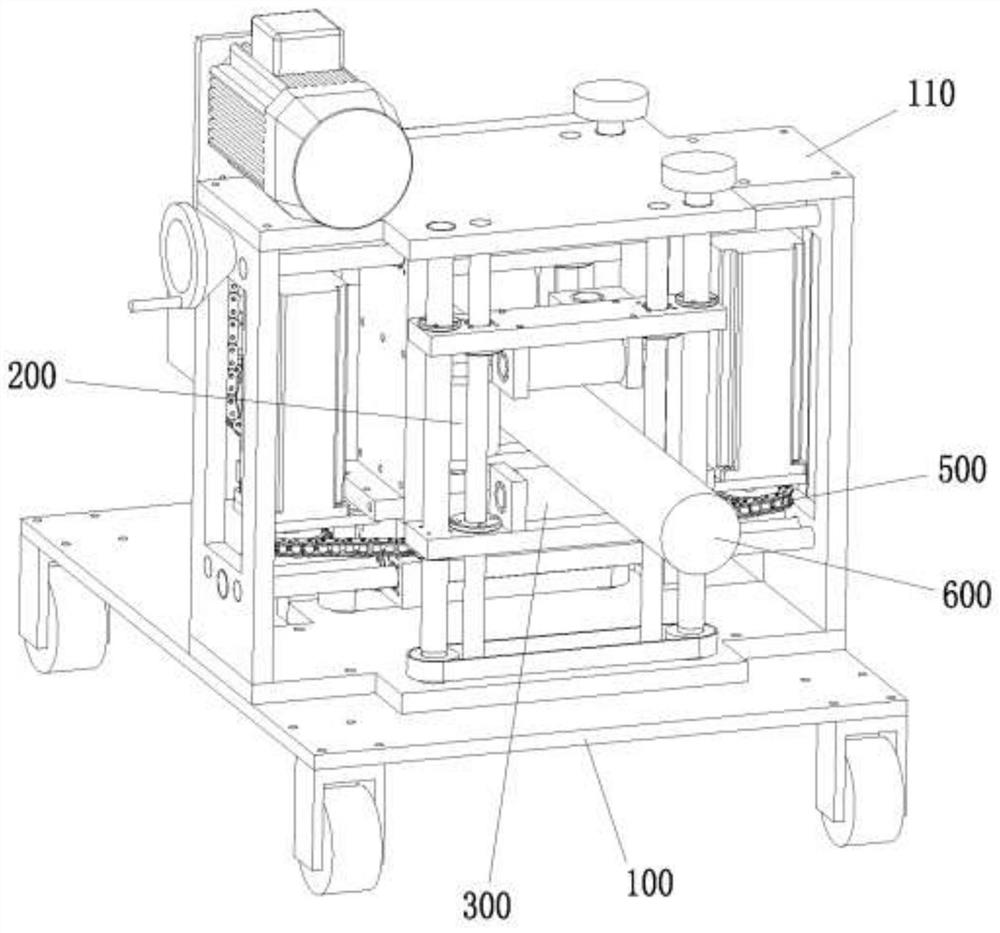

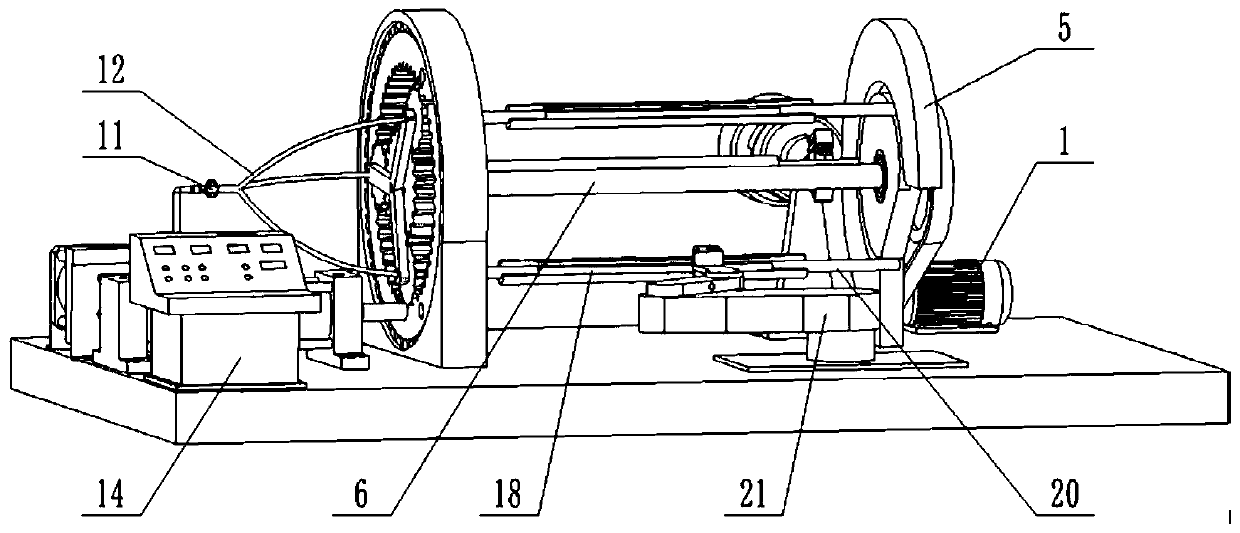

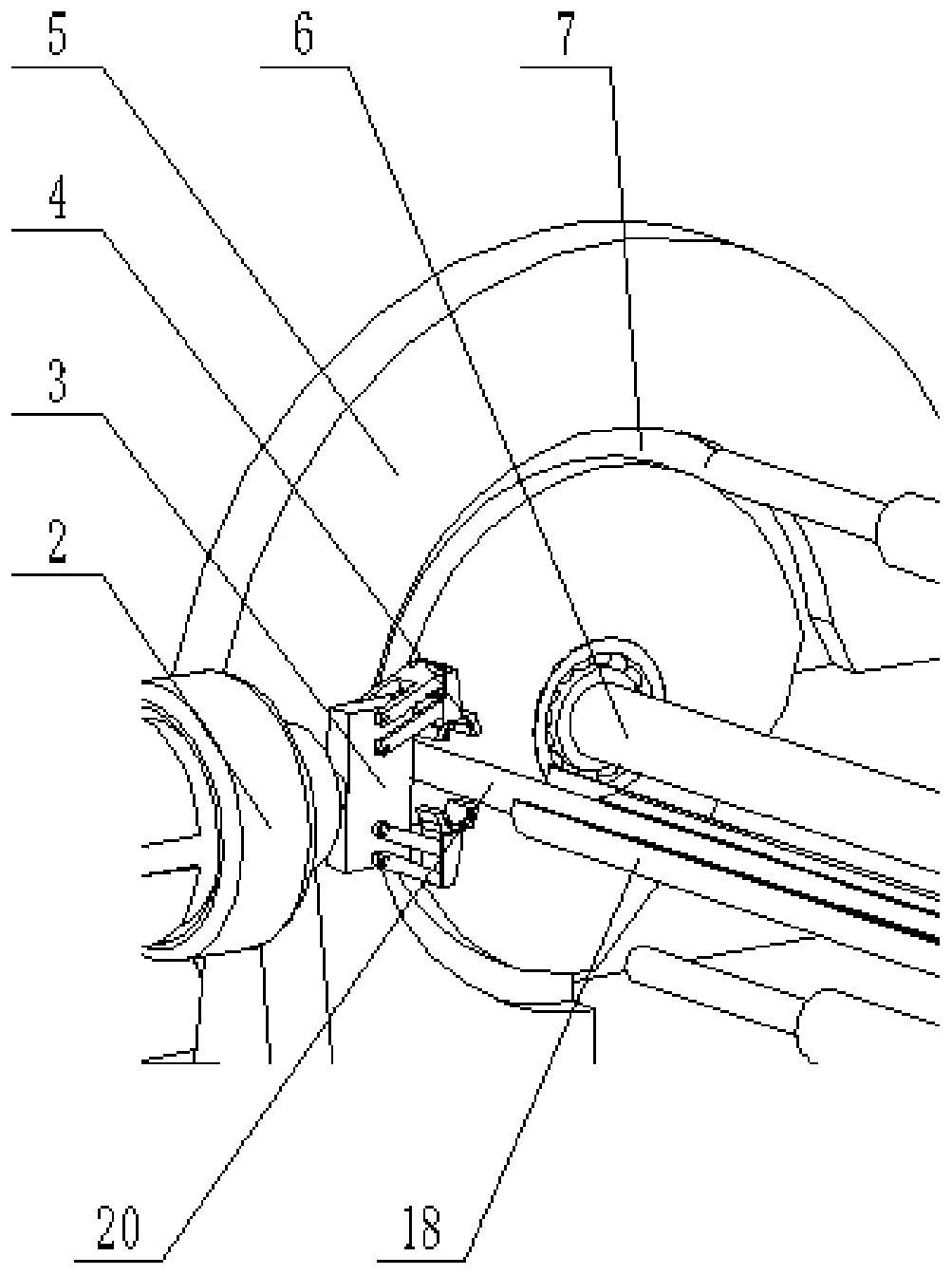

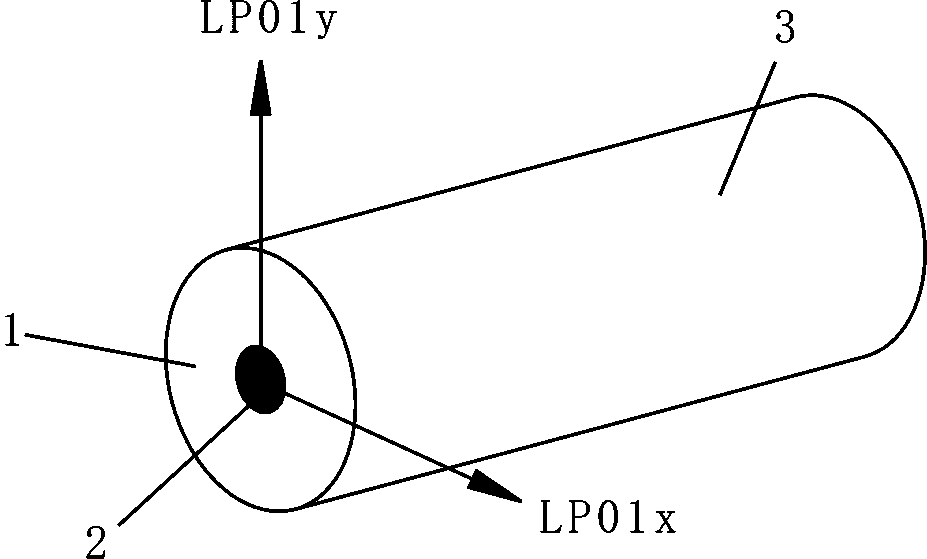

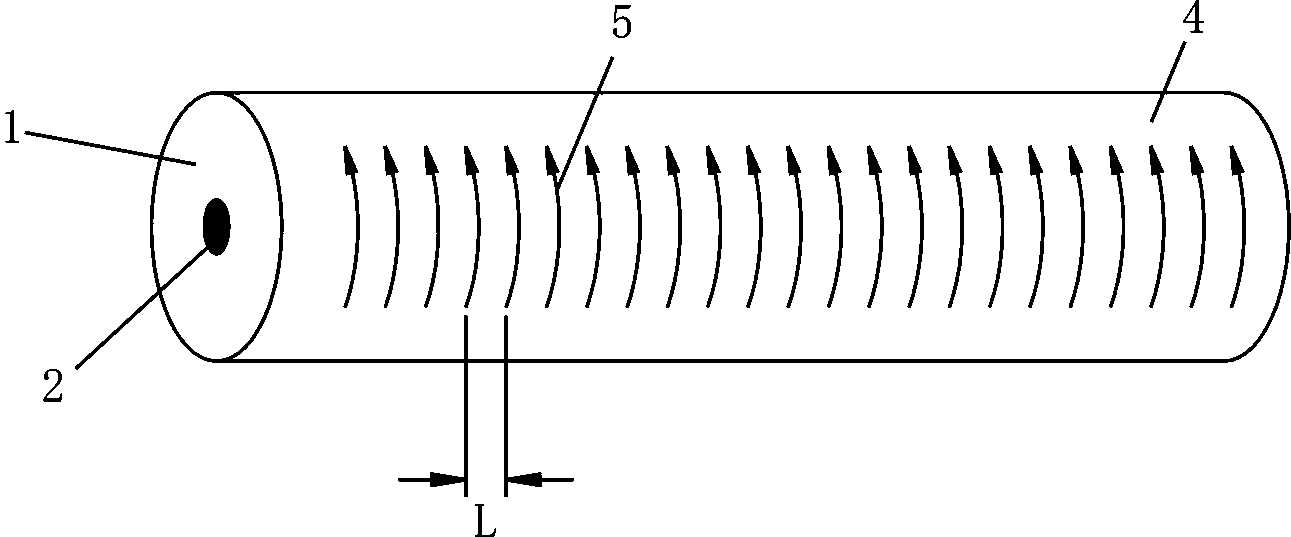

Method for manufacturing ultra-low birefringence optical fibre and rotary stretching tower

The invention relates to a method for manufacturing an ultra-low birefringence optical fibre, which comprises a step of manufacturing an optical fibre preform and a step of drawing the optical fibre preform and is characterized by further comprising the following steps of: before the step of drawing the optical fibre perform, at least locally heating and softening the manufactured optical fibre preform and rotating and stretching the manufactured optical fibre preform along an axial direction, and rotating, stretching and fixing the formed optical fibre preform in the cooling process of the optical fibre preform. A rotary stretching tower for manufacturing the ultra-low birefringence optical fibre comprises an upper clamping head, a lower clamping head, an upper end and a lower end, wherein the upper clamping head and the lower clamping head are vertically arranged; the upper end and the lower end are respectively used for clamping the optical fibre preform; the upper clamping head and the lower clamping head can rotate about the axis of the optical fibre preform respectively; furthermore, the upper clamping head and the lower clamping head can translate along the axis of the optical fibre perform respectively; and a heating furnace capable of translating along the axis of the optical fibre preform is also arranged between the upper clamping head and the lower clamping head and used for at least locally heating and softening the optical fibre preform.

Owner:武汉长盈通光电技术股份有限公司

Seawater desalting device

InactiveCN103274486AImprove power utilizationContinuous automationGeneral water supply conservationSeawater treatmentExternal energyEnergy supply

The invention discloses a seawater desalting device. The seawater desalting device comprises a seawater storing device, an evaporation condensation room and a fresh water storing device, wherein the seawater storing device is connected with the evaporation condensation room through a seawater pipe; the evaporation condensation room is connected with the fresh water storing device through a fresh water pipe; the evaporation condensation room is internally provided with a semiconductor chilling plate; the energy of the semiconductor chilling plate is supplied by an energy supplying device; and the seawater storing device is provided with a normal-pressure keeping opening. The seawater desalting device disclosed by the invention is small in volume, light in weight and high in efficiency; the seawater desalting device can be continuously and automatically operated so that the seawater desalting device is particularly suitable for coastal regions with sufficient wind power resources and solar energy, and other external energy sources are not needed, namely a water lacking problem of parts of islands can be solved.

Owner:ZHEJIANG UNIV

Manufacturing method of soft package battery

ActiveCN105226330ASimple processEasy to operateFinal product manufactureSecondary cells manufactureCooking & bakingEconomic benefits

The invention relates to a manufacturing method of a soft package battery. The manufacturing method comprises the following machining steps: feeding materials; drying; weighing for the first time; injecting; standing; sealing; weighing for the second time; and discharging. According to the method provided by the invention, a battery cell is subjected to vacuum drying, vacuum injection, vacuum standing, vacuum sealing and the like by using a soft package battery vacuum baking, injection and sealing machine; the process is simple, the operation is easy, the production efficiency is high, the automation degree is high and the drying efficiency of the battery cell is high and is about 48 times as much as the drying speed of a vacuum drying room; the drying effect is good, manpower and material resources are saved and the occupied space is small; the steps of injecting, standing and sealing are carried out under a vacuum sealed condition so that moisture in air is prevented from being injected into the battery cell along with electrolyte; and the performance of the soft package battery is guaranteed, the defective percentage is reduced and the economic benefits are improved.

Owner:SHENZHEN XINPU AUTOMATIC EQUIP CO LTD

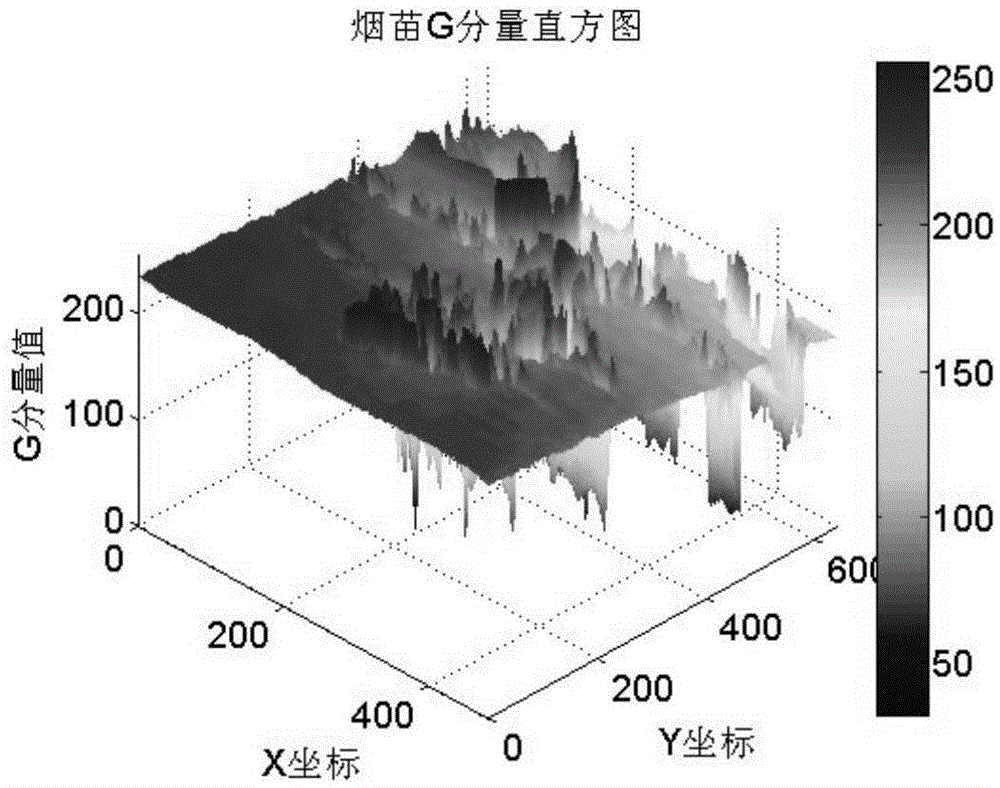

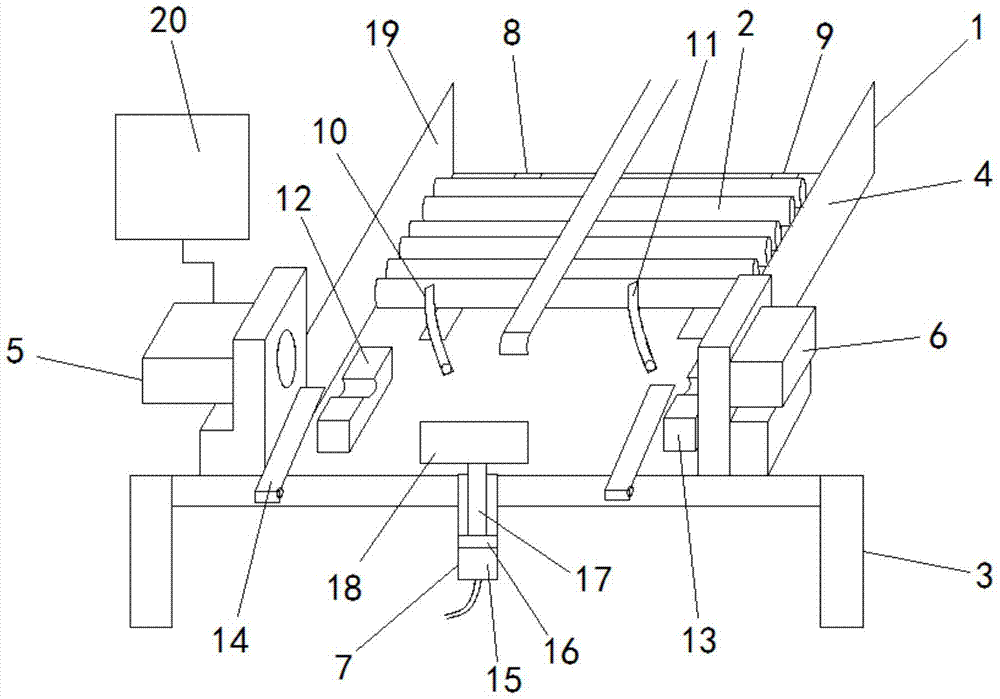

Tobacco topping sprouting inhibition detection control system based on machine vision

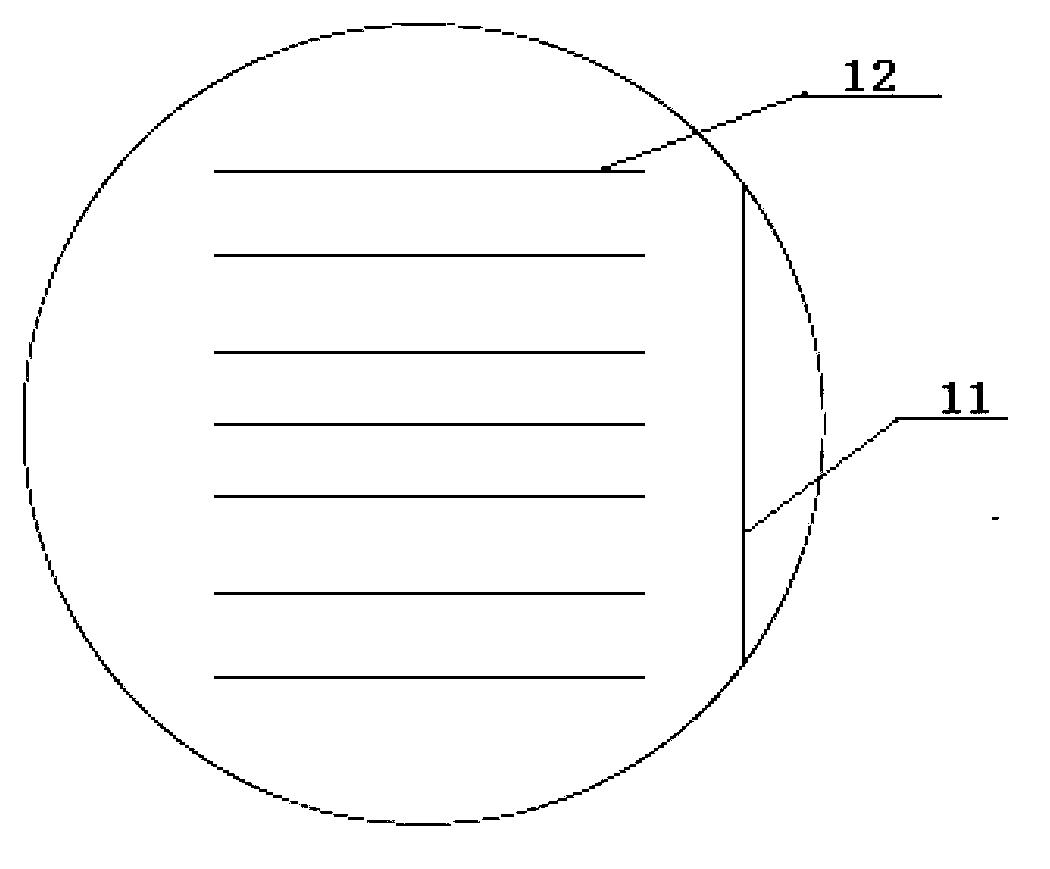

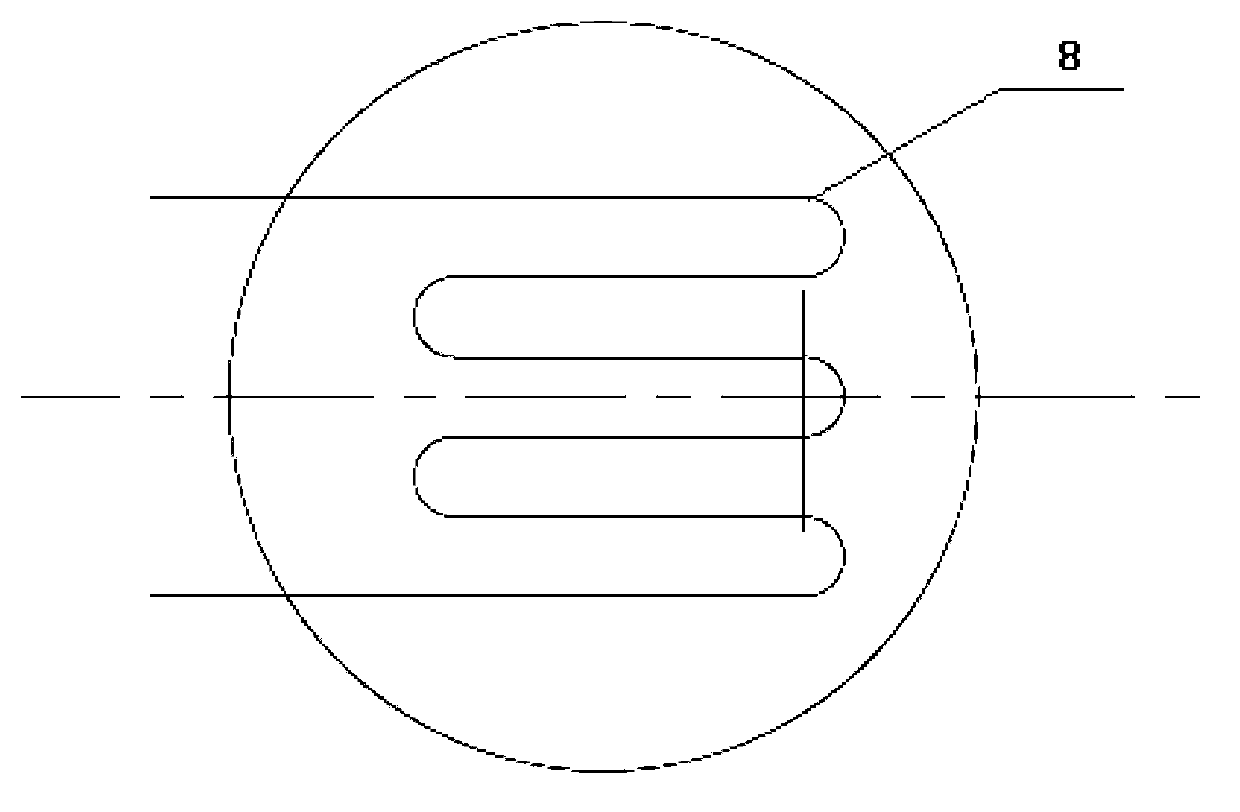

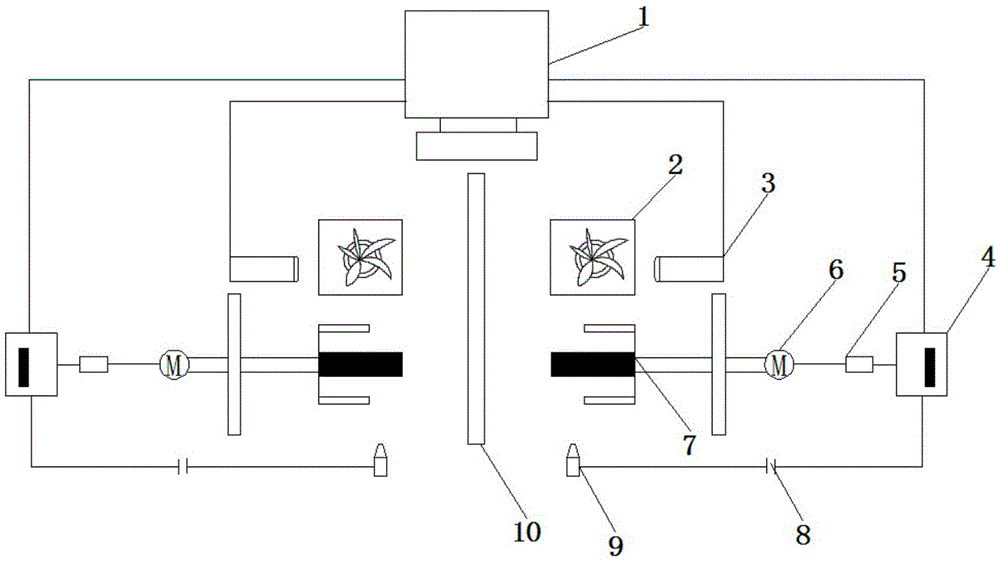

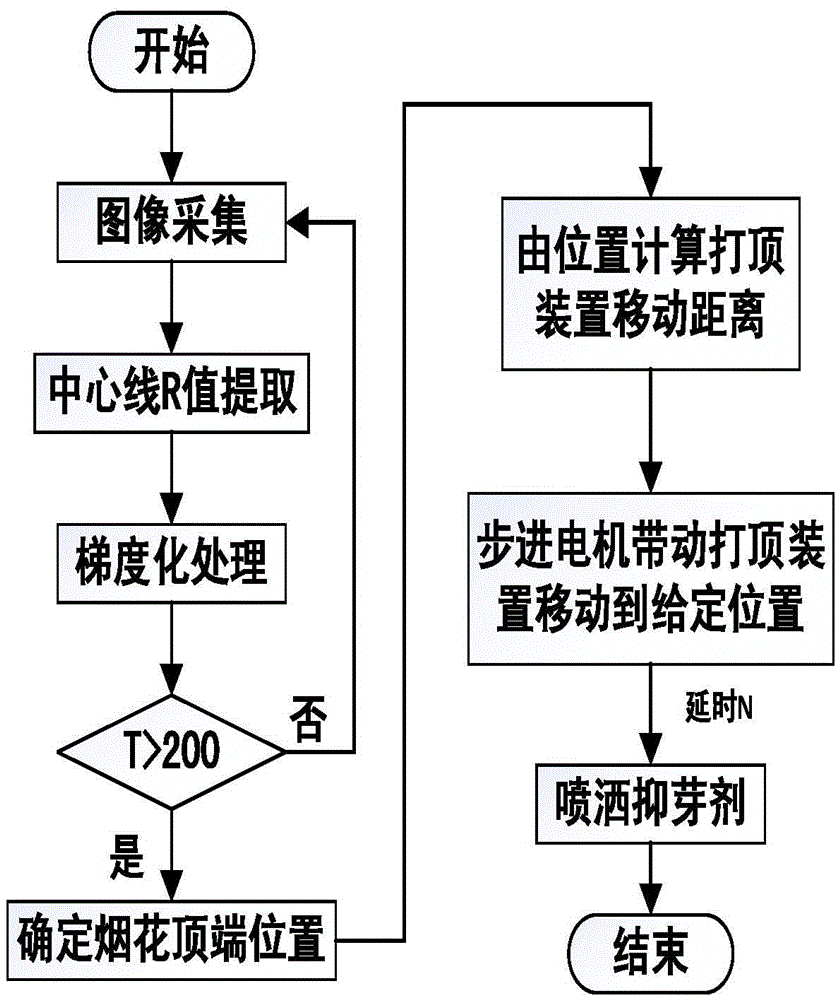

ActiveCN105549486AReal-time monitoring heightReduce the labor intensity of toppingProgramme controlComputer controlImaging processingMachine vision

The invention provides a tobacco topping sprouting inhibition detection control system based on machine vision. The system comprises a tobacco plant top position detection system and a topping sprouting inhibition control system. The tobacco plant top position detection system comprises an image collection module, an image processing module, and a tobacco plant top position positioning module. The image collection module comprises a camera and a background plate, and is used for collecting image information. The image processing module is used for the analysis of the image information collected by the image collection module, and enables the information to be transmitted to the tobacco plant top position positioning module. The tobacco plant top position positioning module achieves the positioning of the information of tobacco flowers, and determines a distance that the topping device needs to move. The system can quickly monitor the height of the top of a tobacco plant in real time, controls the topping device to complete the precise topping operation, reduces the topping labor intensity of tobacco, improves the topping efficiency of tobacco, and speeds up the intelligentization process of tobacco processing.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Automatic opening machine for hazelnut

InactiveCN1830333AContinuous automationCompact and reasonable structureHuskingHullingGear driveEngineering

An automatic opening machine for hazelnuts is composed of machine frame, motor and its speed reducer, raw material storage box, conic chute, rotary distributing disc, receiving tray, feeding tray, rotary wheel with single hazelnut falling holes, automatic shift compensator, cam with curved end face, locating-pressing unit, and chain-gear drive mechanism.

Owner:李忠文

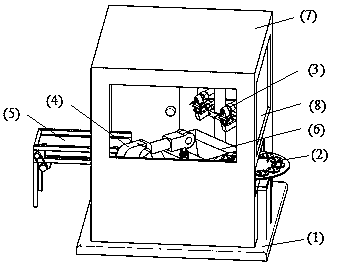

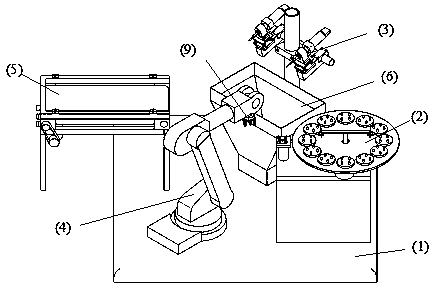

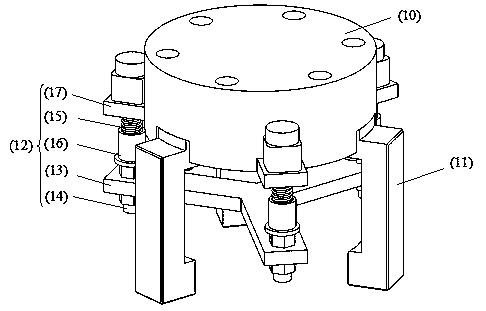

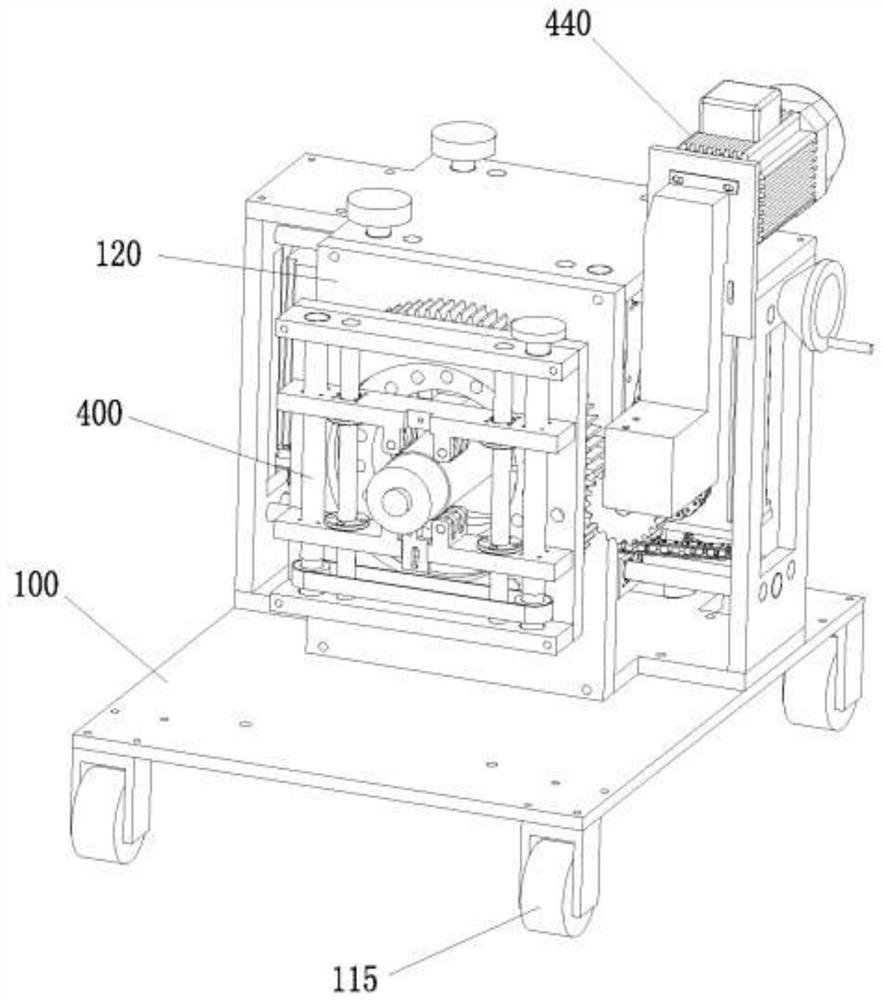

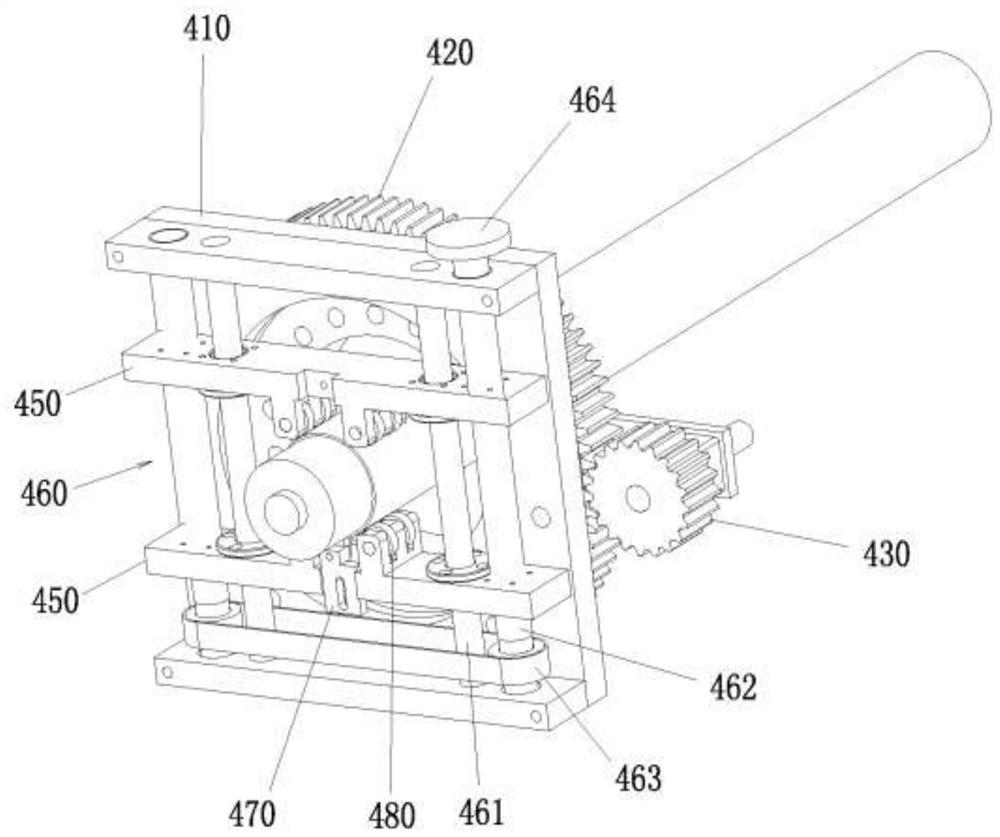

Accurate-positioning floating-type deburring and polishing device

InactiveCN108620976AContinuous automationIncrease productivityEdge grinding machinesGrinding carriagesDie castingEngineering

The invention provides an accurate-positioning floating-type deburring and polishing device. The accurate-positioning floating-type deburring and polishing device is characterized by comprising a carrying device, a deburring and polishing device, a robot mechanism, a discharging conveying device and a dust collection device. The robot mechanism grabs a to-be-deburred and to-be-polished die castingplaced on the carrying device, then the to-be-deburred and to-be-polished die casting is moved onto the deburring and polishing device so as to be polished, and afterwards, the polished die casting is conveyed to the discharging conveying device so as to be discharged. A flattening device is arranged at the tail end of a mechanical claw of the robot mechanism and is matched with a secondary positioning fixture arranged on the carrying device to make sure that the robot mechanism grabs castings at a fixed position; and meanwhile, the deburring and polishing device is provided with a floating assembly for achieving flexible contact between the castings and a polishing motor, so that burrs are prevented from being left while blade breakage and even casting damage caused by the non-retreatingproperty of the polishing motor are avoided, and accordingly, accurate-positioning floating-type deburring and polishing effects are achieved. By adoption of the accurate-positioning floating-type deburring and polishing device, full-automatic continuous deburring and polishing work can be achieved, the degree of automation is high, and one worker can operate multiple devices.

Owner:刘少军 +1

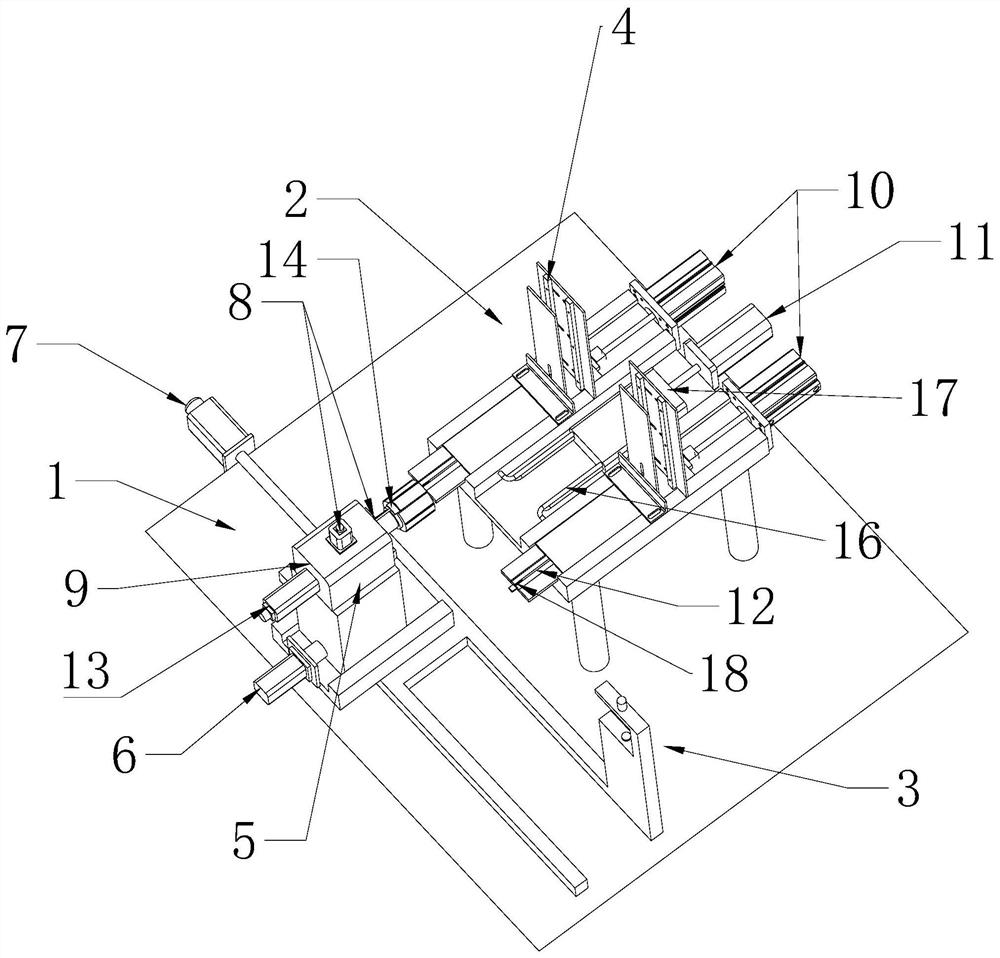

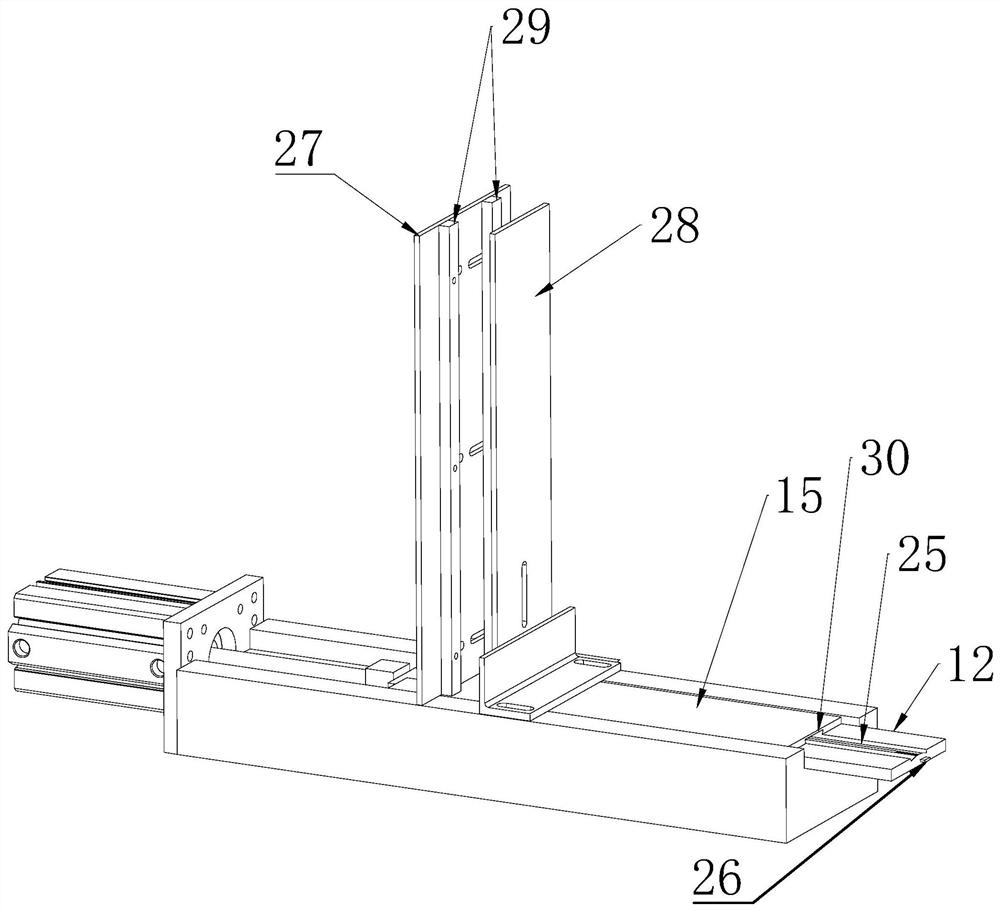

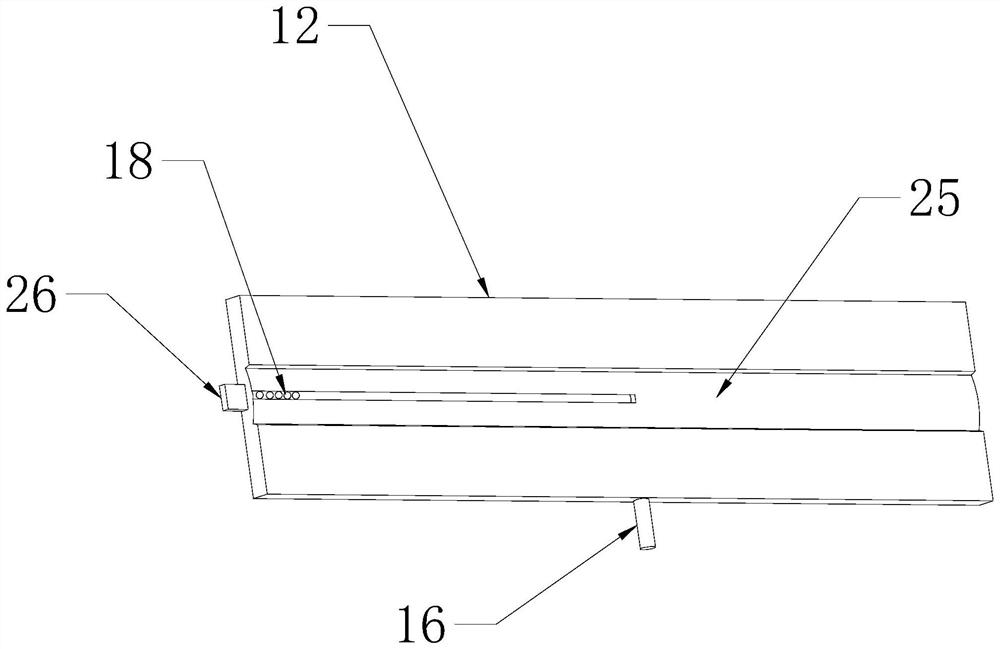

Rotor magnetic steel gluing assembly and detecting equipment

ActiveCN112688504AImprove assembly efficiencyHigh degree of automationManufacturing stator/rotor bodiesAdhesive glueEngineering

The invention discloses rotor magnetic steel gluing assembling and detecting equipment which comprises a rotor positioning mechanism, a magnetic steel pasting mechanism and a rotor detecting mechanism, the rotor positioning mechanism comprises a base, a longitudinal moving mechanism, a transverse moving mechanism, a rotor clamping mechanism and a rotor angle control mechanism, the rotor clamping mechanism is arranged on one side of the base, and the magnetic steel pasting mechanism is longitudinally arranged on one side of the rotor positioning mechanism. The rotor positioning mechanism, the magnetic steel pasting mechanism and the rotor detecting mechanism are combined, the automation degree is high, the rotor magnetic steel installation precision is ensured, and meanwhile the magnetic steel assembly efficiency is improved. The rotor angle control mechanism comprises a positioning rod, when the rotor angle rotates in place, a positioning plate is just inserted into a magnetic steel groove, the rotor rotation angle is controlled, and accurate guiding ensures that the magnetic steel is assembled in place. An automatic gluing mechanism comprises a glue guide screw rod and a glue extrusion mechanism, the glue guide screw rod is connected with the glue extrusion mechanism and a magnetic steel guide rail glue outlet, the bottom surface of the magnetic steel is uniformly coated with magnetic steel glue when the magnetic steel passes through the glue outlet, and continuous automatic operation is realized.

Owner:杭州微光技术有限公司

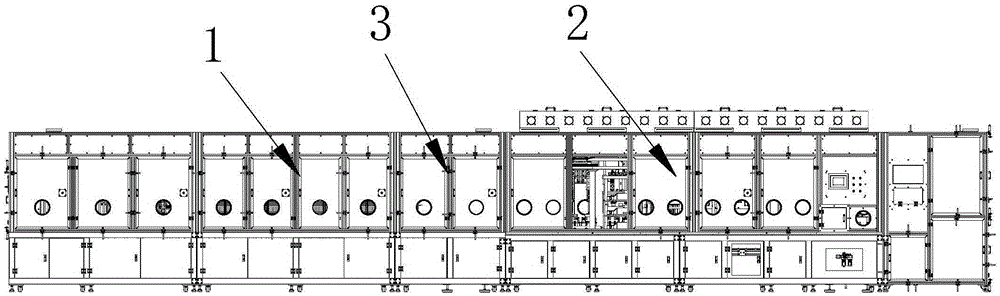

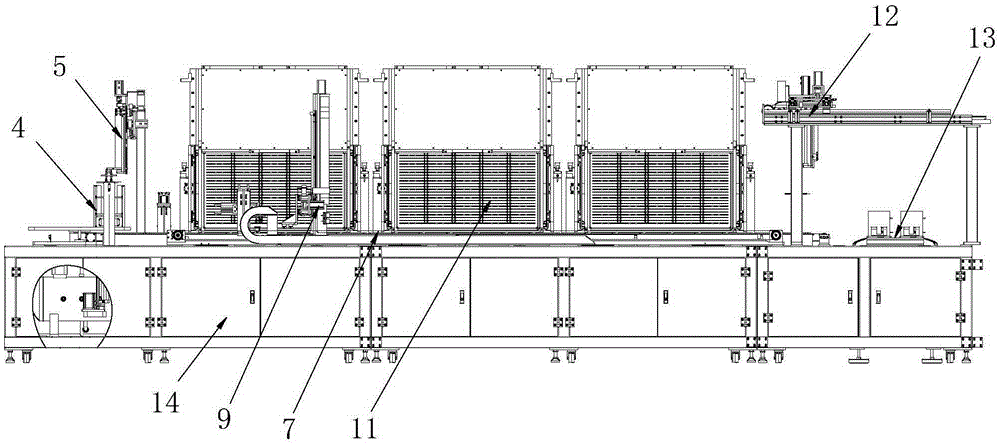

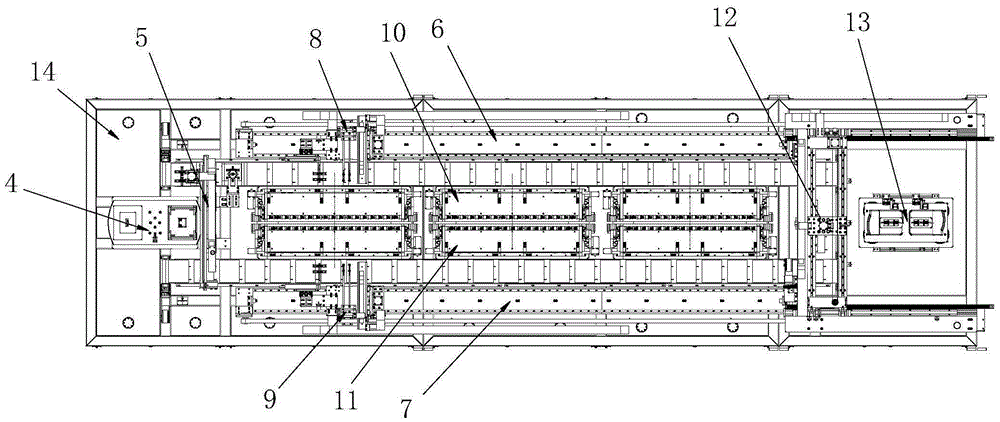

Vacuum baking and filling sealing machine for soft package battery

The invention relates to a vacuum baking and filling sealing machine for a soft package battery. The vacuum baking and filling sealing machine for the soft package battery comprises a vacuum baking part, a vacuum filling part and a sealing cover, wherein the vacuum baking part and the vacuum filling part are arranged in the sealing cover; the vacuum baking part comprises a first rack, a feeding mechanism, a distributing mechanism, a first feeding mechanism, a second feeding mechanism, a first oven group, a second oven group, a first battery core unloading and loading mechanism, a second battery core unloading and loading mechanism, a material shifting mechanism and a first weighing mechanism; and the vacuum filling part comprises a second rack, a first reclaiming mechanism, a material pushing mechanism, a material receiving mechanism, a vacuum filling mechanism, a vacuum standing mechanism, a first vacuum sealing mechanism, a second vacuum sealing mechanism, a battery core clamp circulating mechanism, a second reclaiming mechanism, a second weighing mechanism, a discharge mechanism and a battery box supply mechanism. The vacuum baking and filling sealing machine for the soft package battery is capable of carrying out operations of drying, filling, sealing and the like on a battery core in a vacuum sealing condition, so that manpower is saved; the production efficiency is high; the properties of the battery are kept; the maintenance cost is low; and the defective rate is low.

Owner:SHENZHEN XINPU AUTOMATIC EQUIP CO LTD

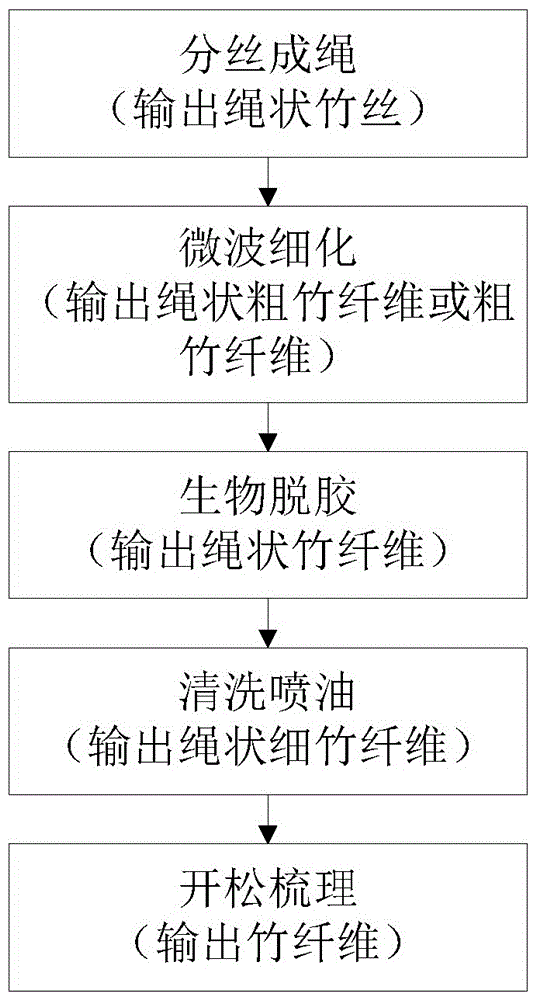

Bamboo fiber clean-production method

ActiveCN106676638AImprove production rateIncrease productivityVegetable materialMechanical fibre separationFiberEngineering

A bamboo fiber clean-production method comprises the following steps that bamboo pieces are separated into filaments, and the filaments are twisted into ropes to obtain rope-shaped bamboo filaments; the rope-shaped bamboo filaments are refined by adopting the modes of multiple cold-hot alternation and rolling and rubbing to obtain coarse rope-shaped bamboo filaments (can be directly put into a drying device and then made into coarse bamboo fiber for a composite material); the rope-shaped bamboo filaments undergo continuous biological degumming to obtain the rope-shaped bamboo filaments; the rope-shaped bamboo filaments are fed into a cleaning device for repeated cleaning, rolling and drying are performed, and then spraying-type oil supply is performed to obtain thin rope-shaped bamboo filaments; finally, the thin rope-shaped bamboo filaments are opened and carded to make bamboo fiber for a textile materials. The bamboo fiber clean-production method can achieve automatic and continuous processing, adopts no chemical, is clean, saves energy and is environmentally friendly.

Owner:张毅

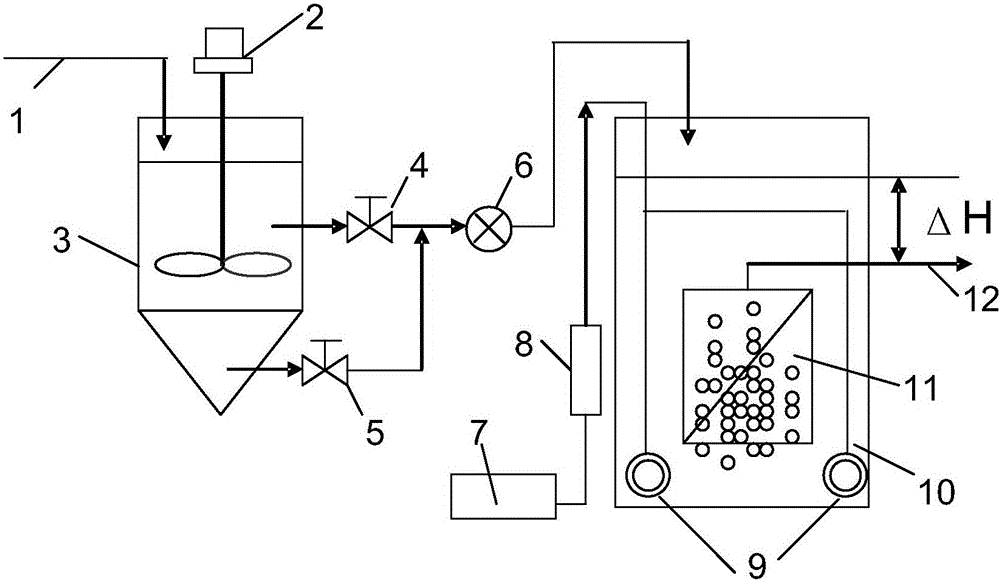

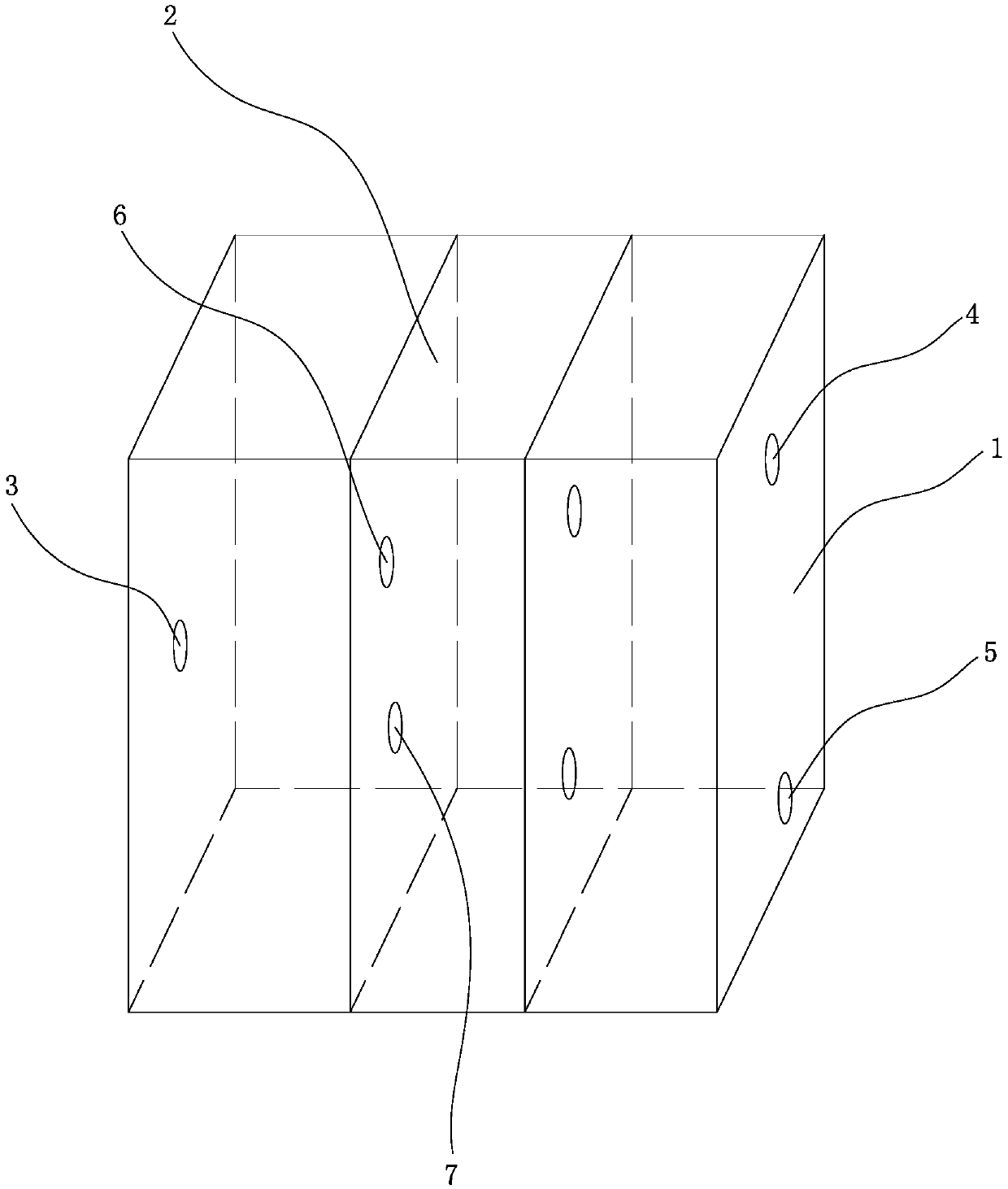

Dynamic membrane sewage direct filtering reactor based on different sewage qualities and operation method

ActiveCN106006847AReduce processing costsEasy to remove and replaceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisChemistryMunicipal sewage

The invention relates to a dynamic membrane sewage direct filtering reactor based on different sewage qualities and an operation method. According to the dynamic membrane sewage direct filtering reactor, a dynamic membrane is formed on the surface of a macropore membrane support material by virtue of inherent suspended solids in sewage, the dynamic membrane can be adopted for direct filtration and concentration on sewage, produced water can meet the standard of city sewage recycling landscape irrigation water, and a concentrated liquid can be discharged into a municipal pipe network or is further treated and recycled; on the basis of different contents of suspended solids in sewage, the operation method comprises the following steps: (1) under a high-turbidity raw water condition, powering on a stirring device in a sewage regulating pond, pumping the sewage into a dynamic membrane filtering reactor by using a lifting pump till the turbidity is less than 10 NTU to form a dynamic membrane, feeding back primary effluent to the sewage regulating pond, and carrying out normal operation to generate water; (2) under a low-turbidity raw water condition, powering off the stirring device in the sewage regulating pond, pumping settled sewage into the dynamic membrane filtering reactor by using the lifting pump so as to form the dynamic membrane in a manner the same as that of the process (1), after the dynamic membrane is formed, powering on the stirring device in the sewage regulating pond, and subsequently carrying out normal operation to generate water.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

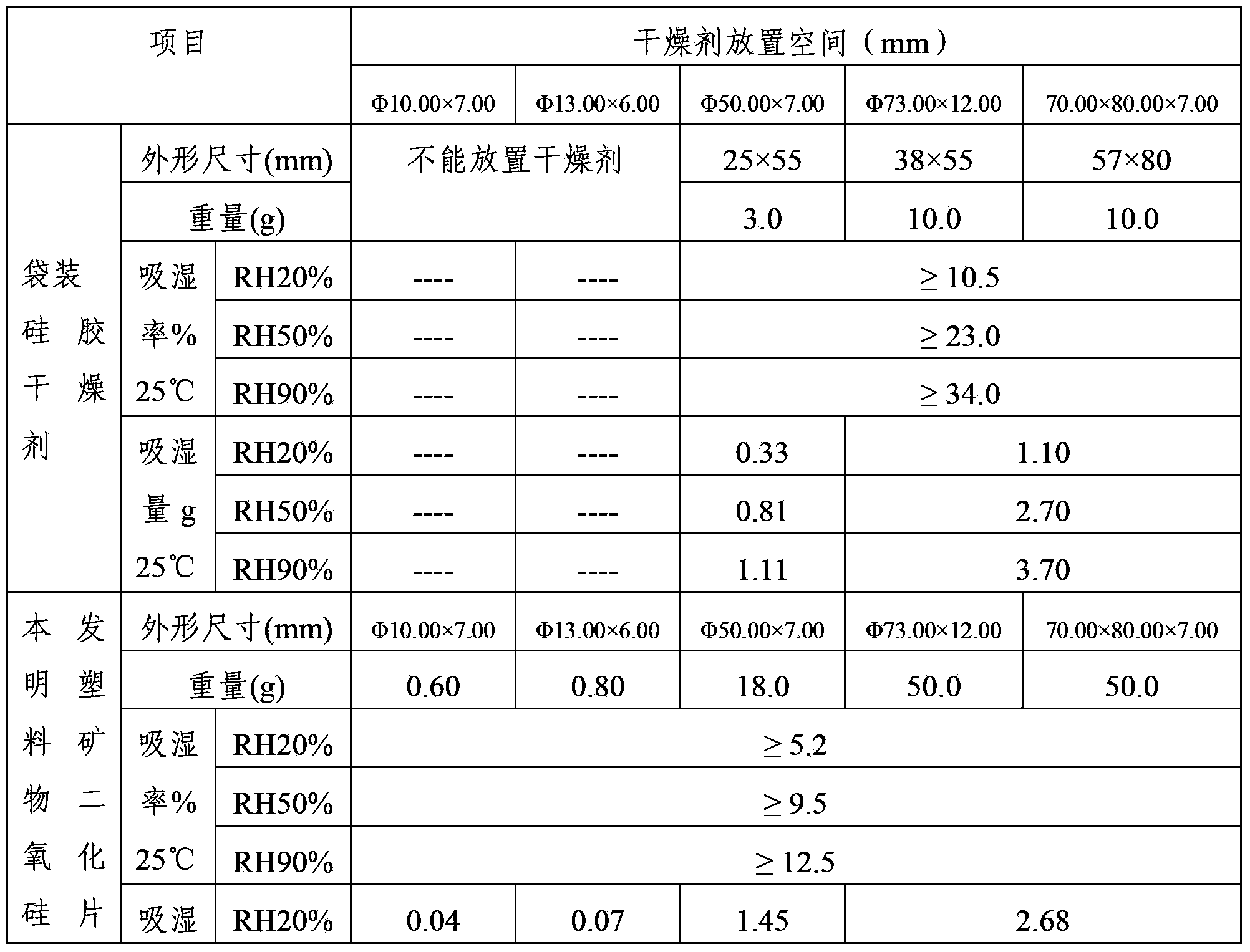

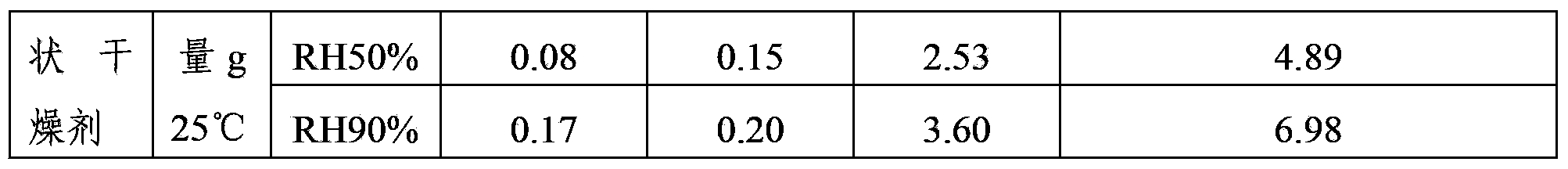

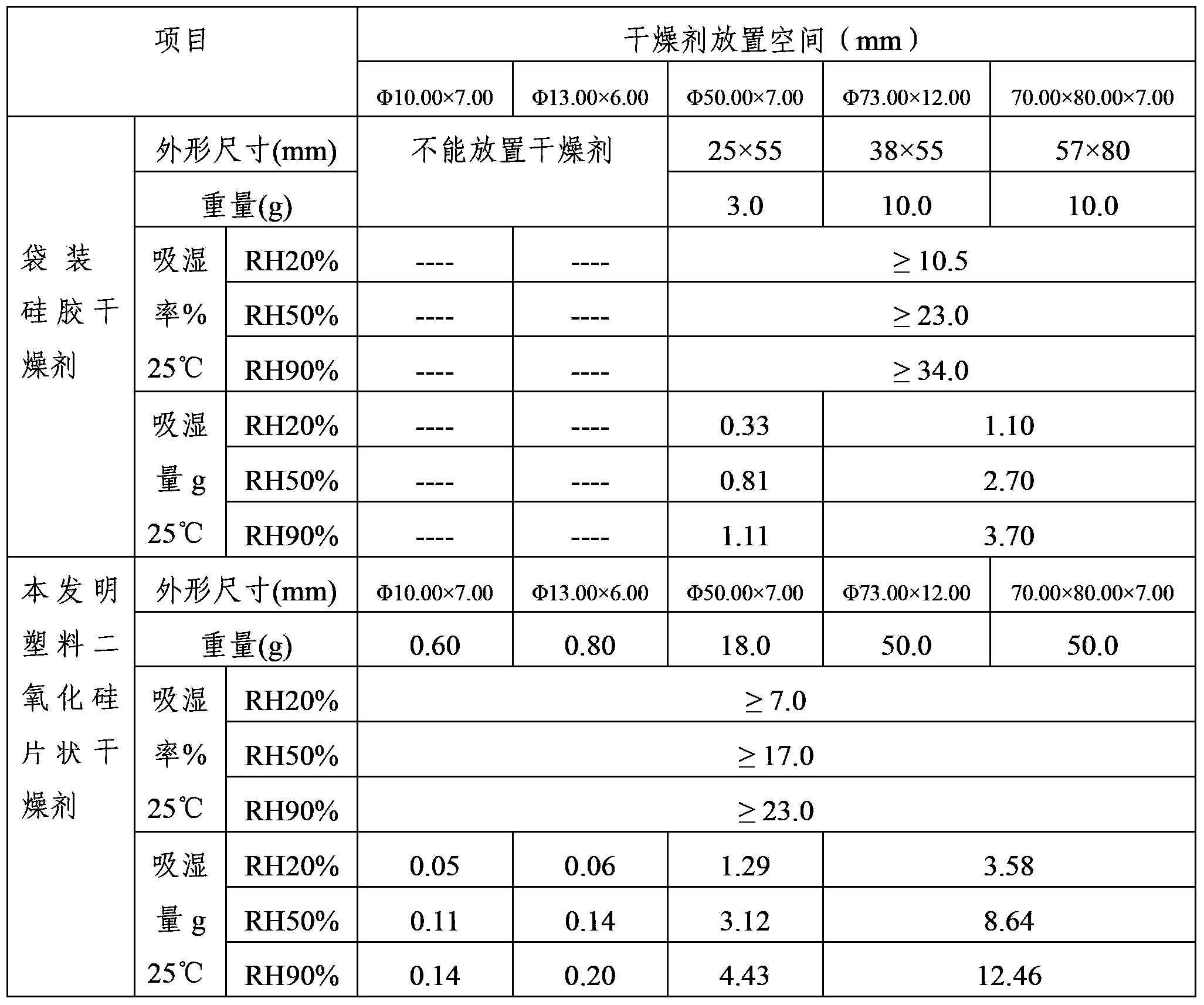

Plastic mineral silica flaky dessicant and preparation method thereof

ActiveCN103506067ASave effective spaceHigh moisture absorptionOther chemical processesDispersed particle separationDesiccantMaterials science

The invention relates to a plastic mineral silica flaky dessicant and a preparation method thereof. The plastic mineral silica flaky dessicant comprises the following components by weight percentage: 70-90% of mineral silica dessicant powder, 10-30% of high-molecule plastic, and 0-5% of auxiliary material. Compared with the prior art, the plastic mineral silica flaky dessicant can be more consistent with a space for placing the dessicant, can be directly used without packing, and is safe and environment-friendly; the quantity of dessicant placement in the space is increased greatly; in the same volume, the hygroscopic capacity is higher; automatic production can be achieved; and the dessicant has huge application prospect and economic value.

Owner:昆山威胜干燥剂研发中心有限公司

Manufacturing method of low-glue-consumption environmental-friendly concrete template

ActiveCN105773742ANo releaseImprove efficiencyOther plywood/veneer working apparatusCeramic shaping apparatusFiberCyclone

The invention relates to a manufacturing method of a low-glue-consumption environmental-friendly concrete template and belongs to the technical field of manufacturing wood-based panels. The process comprises the following steps of rotary cutting a short-cut wood into 1.5-2.5mm wood veneers, drying, regulating the moisture content to 2-10 percent, carrying out normal-pressure low-temperature plasma modification treatment on double sides of each veneer, atomizing an adhesive into particles with the diameter to be 40 microns through synergism of ultrasound and cyclone, spraying the particles on a tight side of each veneer, controlling the spreading quantity of a single-sided adhesive to be 10-80g / m<2>, vertically assembling the veneers mutually in the fiber texture directions of veneers at adjacent layers, then prepressing, hot pressing and covering a film to manufacture the low-glue-consumption environmental-friendly concrete template. According to the manufacturing method, the performances of a product accord with the national standard requirements, no free formaldehyde is released, in addition, the dosage of the adhesive is lowered by 30-70 percent compared with that in the traditional gluing manner, the quality of the product is dramatically promoted, and the production cost is obviously lowered; and in addition, the production process saves the energy and is environment-friendly, production equipment is simple and convenient in operation, the efficiency is high, the controllability is good, and continuous automation operation can be carried out.

Owner:NANJING FORESTRY UNIV

Flake plastic silicon oxide drying agent and preparation method thereof

ActiveCN103506091ASave effective spaceContinuous automationOther chemical processesDispersed particle separationPolymer scienceDesiccant

The invention relates to a flake plastic silicon oxide drying agent and a preparation method thereof. The flake plastic silicon oxide drying agent comprises the following components in percentage by weight: 50-90 percent of silicon oxide, 10-50 percent of high-molecule plastic and 0-5 percent of auxiliary material. Compared with the prior art, the flake plastic silicon oxide drying agent can be more consistent with a space for placing the drying agent, can be directly used without packing, and is safe and environmental friendly; moreover, the amount of drying agent placed in the space is greatly increased, and the moisture absorption capacity is higher under the same volume; the method can realize automatic production and has great application prospect and economic value.

Owner:昆山威胜干燥剂研发中心有限公司

Automatic stripping device and automatic stripping method for outer protective sleeve of power cable

ActiveCN113013792AImprove uniformityAvoid damageApparatus for removing/armouring cablesPower cableBraced frame

The invention provides an automatic stripping device and an automatic stripping method for an outer protective sleeve of a power cable. The automatic stripping device comprises a workbench, a feeding mechanism, a wire pressing mechanism and a rotary stripping mechanism, the workbench comprises a supporting frame and a fixing plate, and the feeding mechanism comprises two sets of feeding roll shafts. The two sets of feeding roll shafts are located at the two sides of a power cable respectively, the distance between the two sets of feeding roll shafts is adjustable, and at least one set of feeding roll shafts is provided with a driving mechanism. The wire pressing mechanism comprises two groups of wire pressing roll shafts, the two groups of wire pressing roll shafts are respectively positioned at the two sides of the power cable, and the distance between the two groups of wire pressing roll shafts is adjustable; the rotary peeling mechanism comprises a rotary frame, two centering pressing plates and a scraper, the rotary frame is rotationally connected with the fixed plate, the two centering pressing plates are arranged on the rotary frame in a sliding mode, and the scraper is arranged on the rotary frame or the centering pressing plates. According to the invention, a rotation and linear composite motion mode is adopted, the automatic separation of the outer protective sleeve of the power cable and the core wire is realized, and the stripping device and the stripping method have the advantages of good stripping quality and high efficiency.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

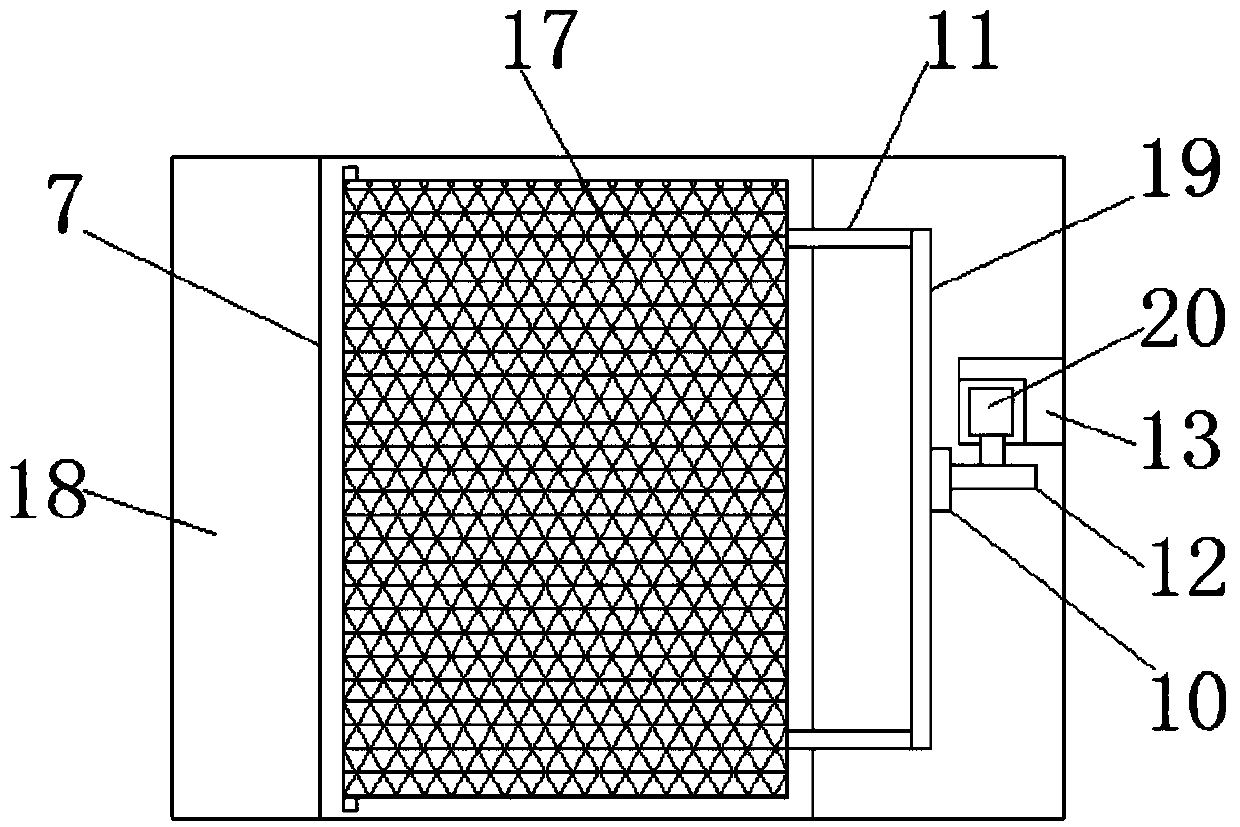

Intelligent quantitative watering machine for tobacco seedling

InactiveCN103548646AAvoid wastingSatisfied with the watering effectWatering devicesCultivating equipmentsWater storage tankAgriculture

The invention relates to an intelligent quantitative watering machine for the tobacco seedling. The intelligent quantitative watering machine for the tobacco seedling comprises a rack, a detection control system, a light box, an accumulator, a water storage tank, a solenoid valve, a water tank and a submersible pump, wherein the water tank is installed on the rack; the detection control system is packaged in a detection control box; the detection control box is fixedly arranged on a detection control system mounting hole on the top of the light box; a camera is fixedly arranged on a camera suspension bracket in the light box; the tail of the camera is connected with an ARM (Advanced RISC Machine) control panel via a data line; the light box is fixedly arranged on the tail part of the intelligent quantitative watering machine for the tobacco seedling via a light box suspension bracket; the water storage tank is installed on the tail part of the light box. According to the intelligent quantitative watering machine for the tobacco seedling, which is disclosed by the invention, the tobacco seedling position can be accurately detected by the machine visual technology, the solenoid valve can be controlled by a program in the ARM control panel and a relay control circuit to finish the watering operation of the tobacco seedling, the watering effect satisfies the agriculture requirement, and the continuous, efficient and automatic operation can be realized.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

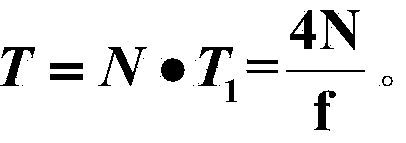

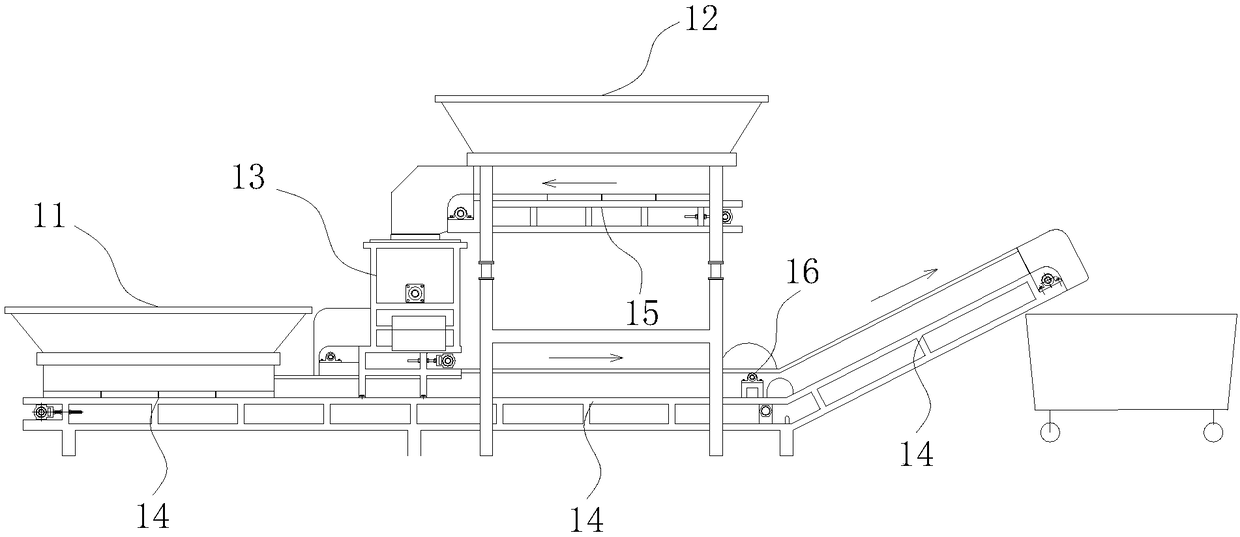

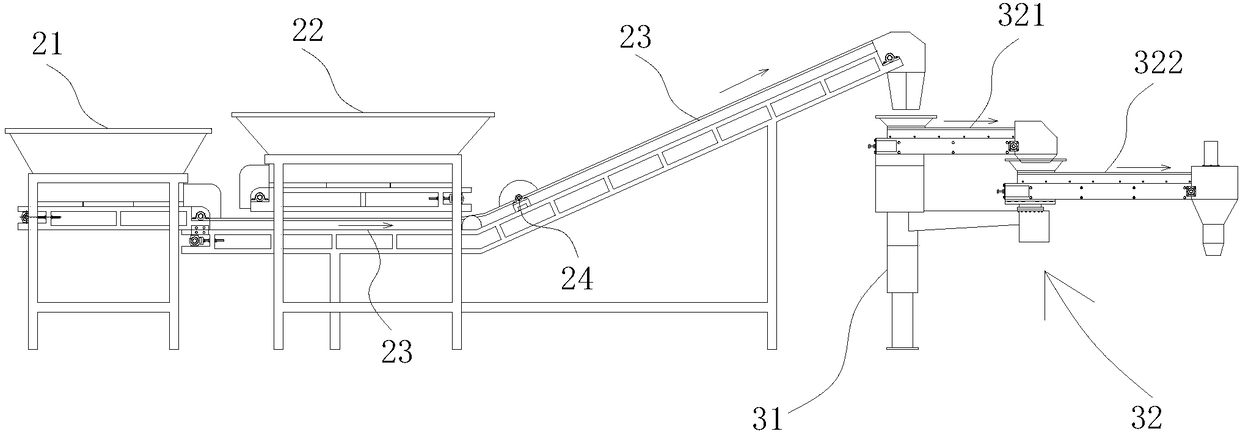

Intermittent intelligent wine brewing system and wine brewing method

InactiveCN108384699ALower installation heightAvoid uneven mixingAlcoholic beverage preparationCombustion chamberDistillation

The invention relates to an intermittent intelligent wine brewing system and a wine brewing method. The wine brewing system includes a first material stirring unit, a second material stirring unit, arice steamer storage unit, a mixed combustion vapor supply unit and a fermented grain airing and cooling unit; the first material stirring unit includes a fermented grain hopper, a grain hopper, a grain and water stirring device, a first conveyor belt and a second conveyor belt; the second material stirring unit includes a material mixing hopper, a bran hopper and a third conveyor belt; the rice steamer storage unit comprises a bracket and a spiral feeding mechanism for loading auxiliary materials into distillation rice steamers; the mixed combustion vapor supply unit includes a boiler for supplying vapor to the distillation rice steamers in which the auxiliary materials are stored; the boiler includes a combustion chamber composed of an upper layer bran husk combustion cavity, a middle layer marsh gas combustion cavity and a lower layer coal combustion cavity; the fermented grain airing and cooling unit includes a fermented grain hopper, a fourth conveyor belt and a blowing box. By means of the wine brewing system and the wine brewing method, not only can materials be uniformly blended, correspondingly the wine discharging amount is greatly increased, and the wine brewing qualityis ensured; moreover, continuous automatic operation can also be achieved, and the wine brewing efficiency is greatly improved.

Owner:ANHUI YINGJIA TRIBUTE WINE

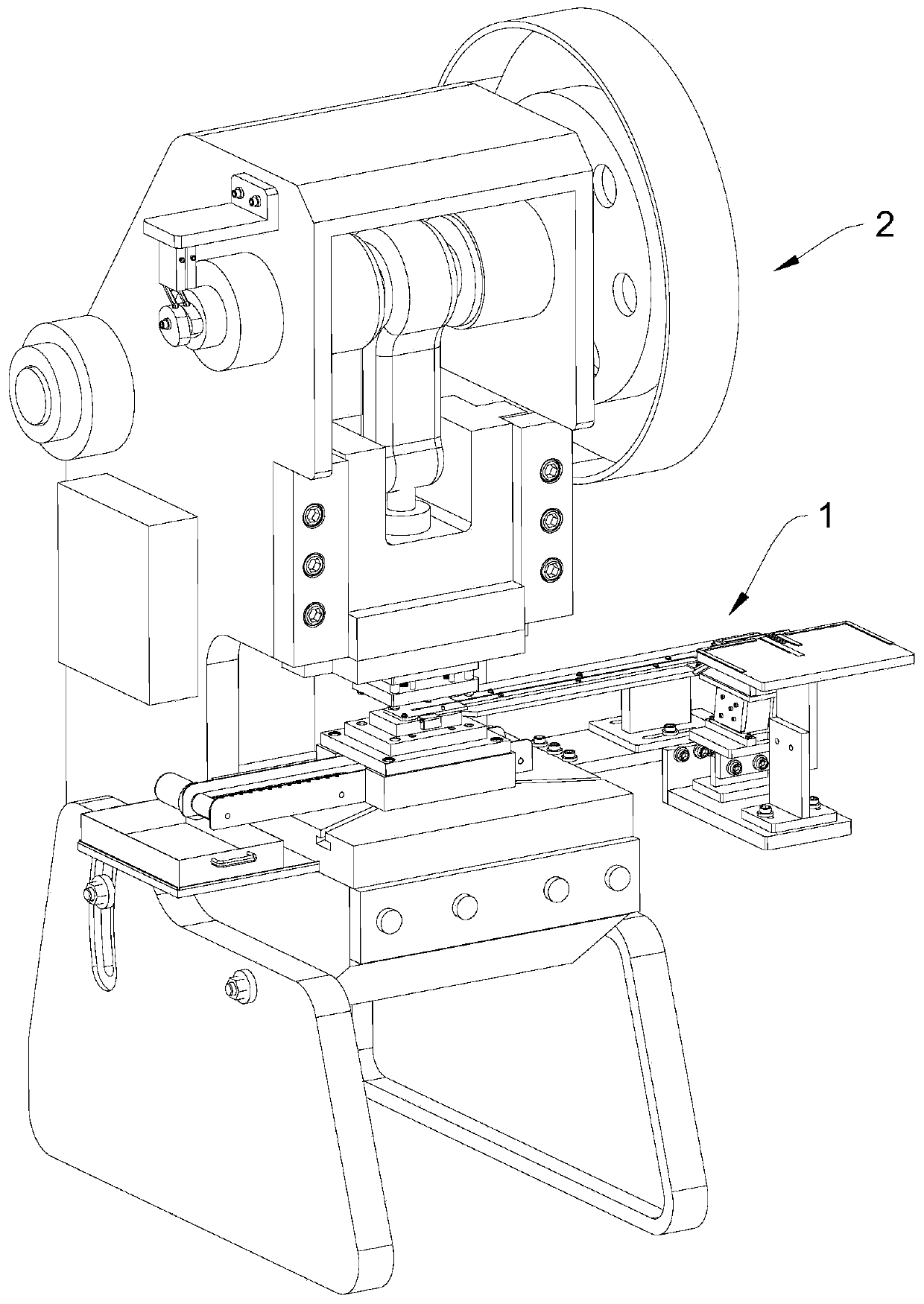

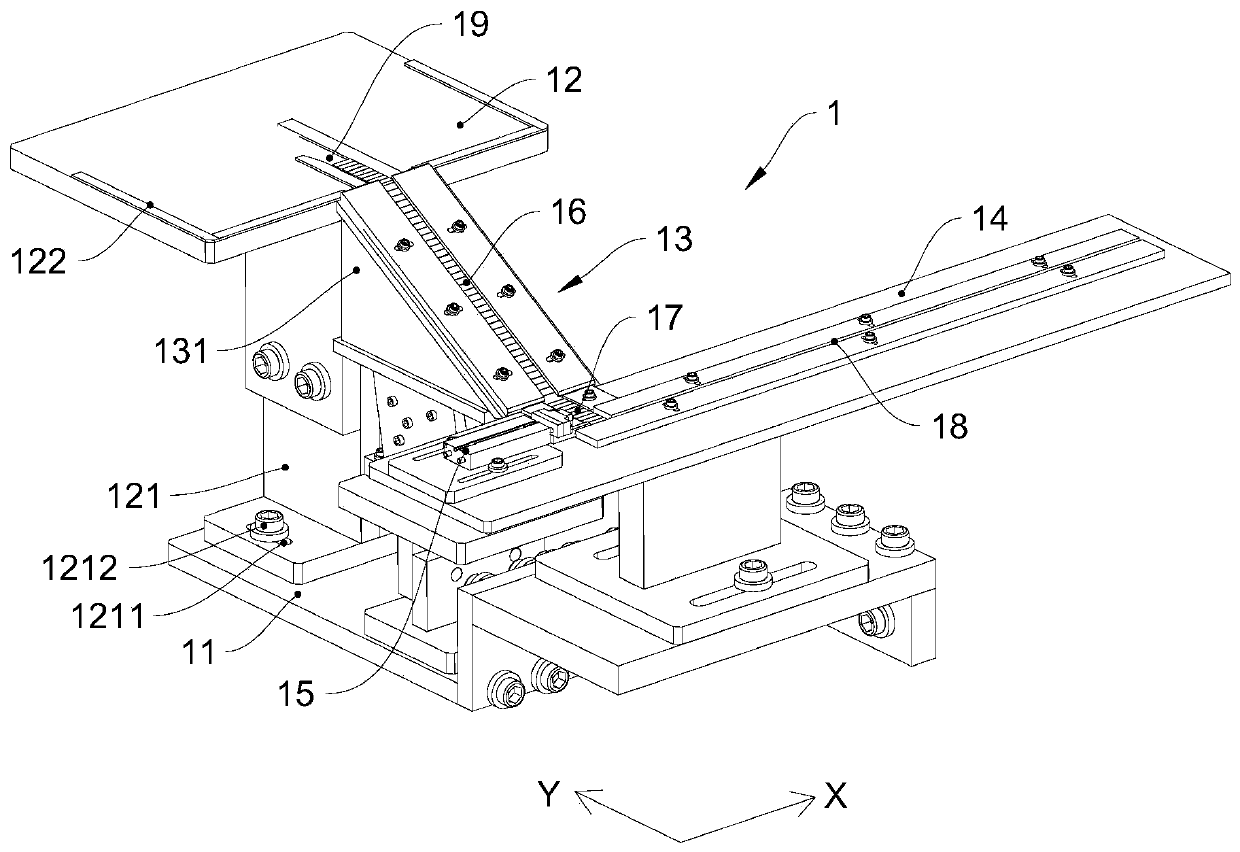

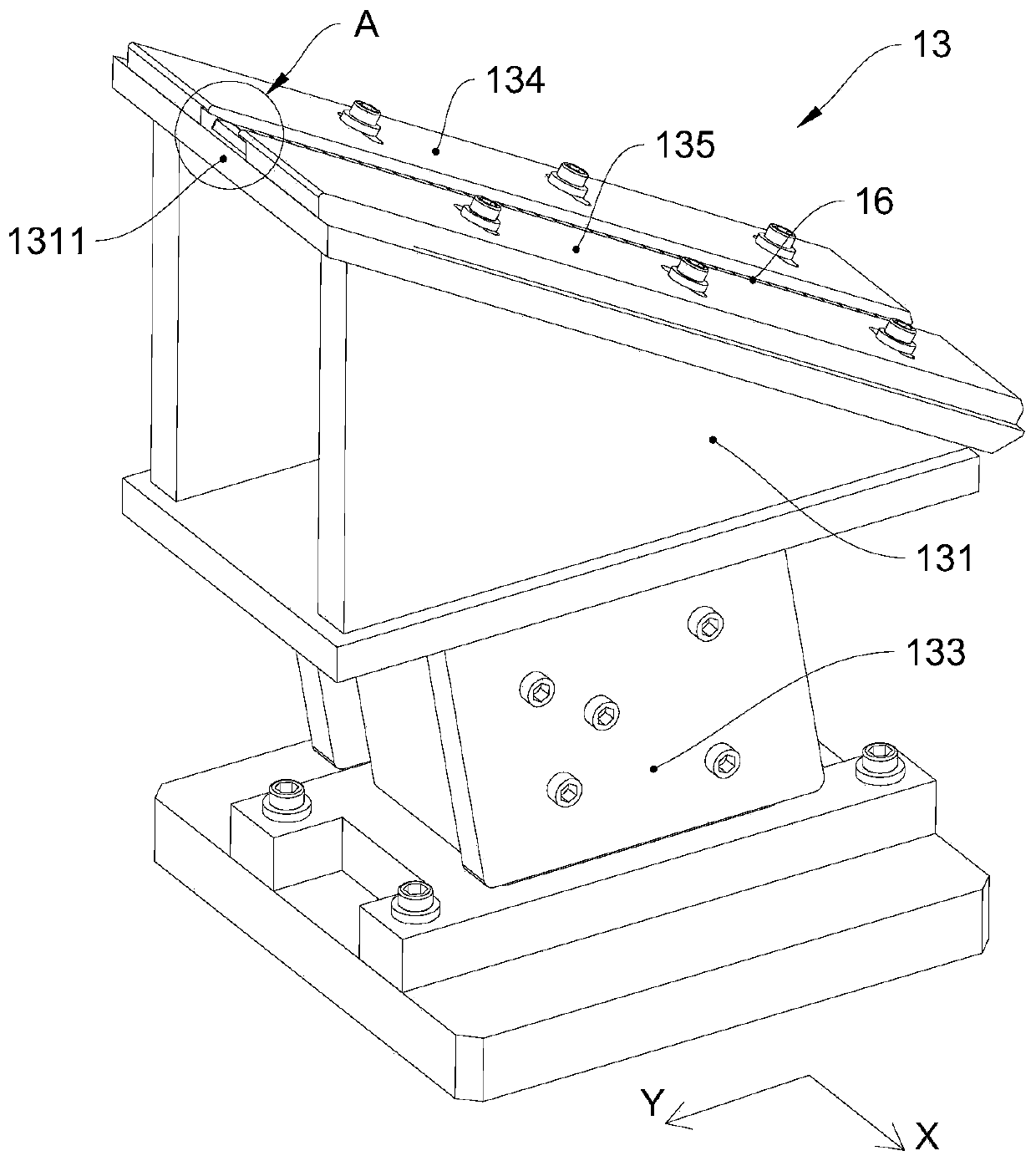

Semi-automatic stamping system

PendingCN110586736ASmooth transmissionImprove stamping efficiencyMetal-working feeding devicesCleaning using gasesSemi automaticEngineering

The invention provides a semi-automatic stamping system. The system comprises a feeding unit, a stamping unit and a control unit. The control unit is connected with the feeding unit and the stamping unit. The feeding unit comprises a discharging assembly, a pushing assembly and a loading platform. The discharging assembly is arranged on one side of the loading platform, the pushing assembly is arranged on the loading platform, the discharging assembly carries out discharging in the direction of the pushing assembly in a vibration manner, the pushing assembly is used for pushing materials to the direction of the stamping unit, the stamping unit comprises a stamping machine, a stamping mold, a blowing assembly and a material piece collecting assembly, a mold cavity is formed in the stampingmold in a penetrating manner, a puncher pin on the stamping machine is arranged over the mold cavity, the material piece collecting assembly is arranged below the mold cavity, and the blowing assemblyis arranged on the stamping mold. The stamping production efficiency and the loading stability can be obviously improved.

Owner:ZHUHAI FENGGU ELECTRONICS TECH CO LTD

Cleaning and drying device for surgical medical tool

InactiveCN110762952AWash thoroughlyImprove cleaning and drying efficiencyDrying gas arrangementsDrying machines with local agitationEngineeringSewage

The invention discloses a cleaning and drying device for a surgical medical tool. The device comprises a drying box with a box door, wherein one side of the drying box is provided with a sewage tank,a fan is fixed on one side of the top end of the drying box, a heating box is fixed on one side of the inner top wall of the drying box, a plurality of uniformly distributed heating wires are arrangedin the heating box, an air outlet of the fan is connected with an air guide pipe, the other end of the air guide pipe extends into the heating box, a cleaning cylinder is fixed in the center of the top of the drying box, a horizontally arranged first grid is arranged inside the drying box, the first grid is located below the cleaning cylinder, a discharging port is formed in the side wall of thebottom end of the cleaning cylinder, a cylinder is fixed on the inner wall of the side, away from the heating box, of the drying box, and the cylinder is located above the first grid. The cleaning anddrying device is reasonable in structure, ingenious in concept, continuous and automatic in cleaning and drying, good in cleaning effect, capable of saving manpower, and improving the cleaning and drying efficiency, high in practicability and suitable for popularization.

Owner:天津阿斯科雷生物科技有限公司

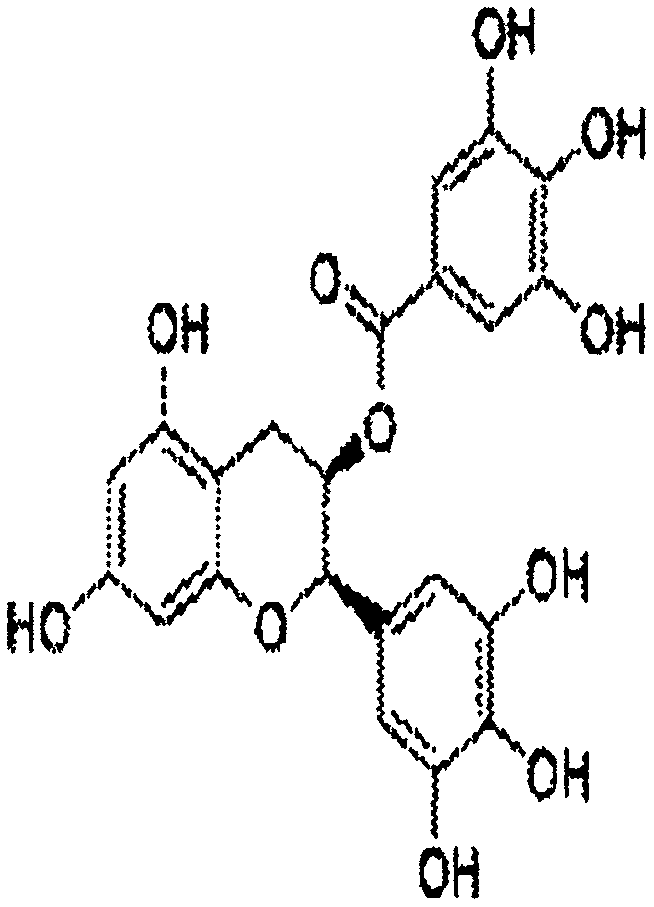

Separation and purification of gallic acid from suaeda salsa by SF-SMB

InactiveCN107903171AEasy solvent recoveryReduce energy consumptionBulk chemical productionCarboxylic compound separation/purificationSolventSimulated moving bed

The invention discloses separation and purification of gallic acid from suaeda salsa by SF-SMB, and relates to a method for separating and purifying the gallic acid from the suaeda salsa. In the wholeprocesses of extracting, separating and purifying the gallic acid from the suaeda salsa, water or ethanol which is environmentally-friendly to equipment and environments is taken as a solvent, and the solvent is conveniently recovered and the energy consumption is low; flavonoids constituents are not stable and easily oxidized, especially more susceptibly oxidized in high temperature environments, the separation and purification of the gallic acid from the suaeda salsa can be completed at room temperature by using an extraction method, the highest extraction temperature is controlled to be not higher than 70 DEG C, and conditions are relatively mild, thereby not affecting the extraction effect of flavonoids constituents, and further being beneficial to the stable existence of the flavonoids constituents; and by adopting the method of the invention, the continuity is enhanced, the purity of the gallic acid is high, the production cycle is shortened, and the cost is low.

Owner:BOHAI UNIV

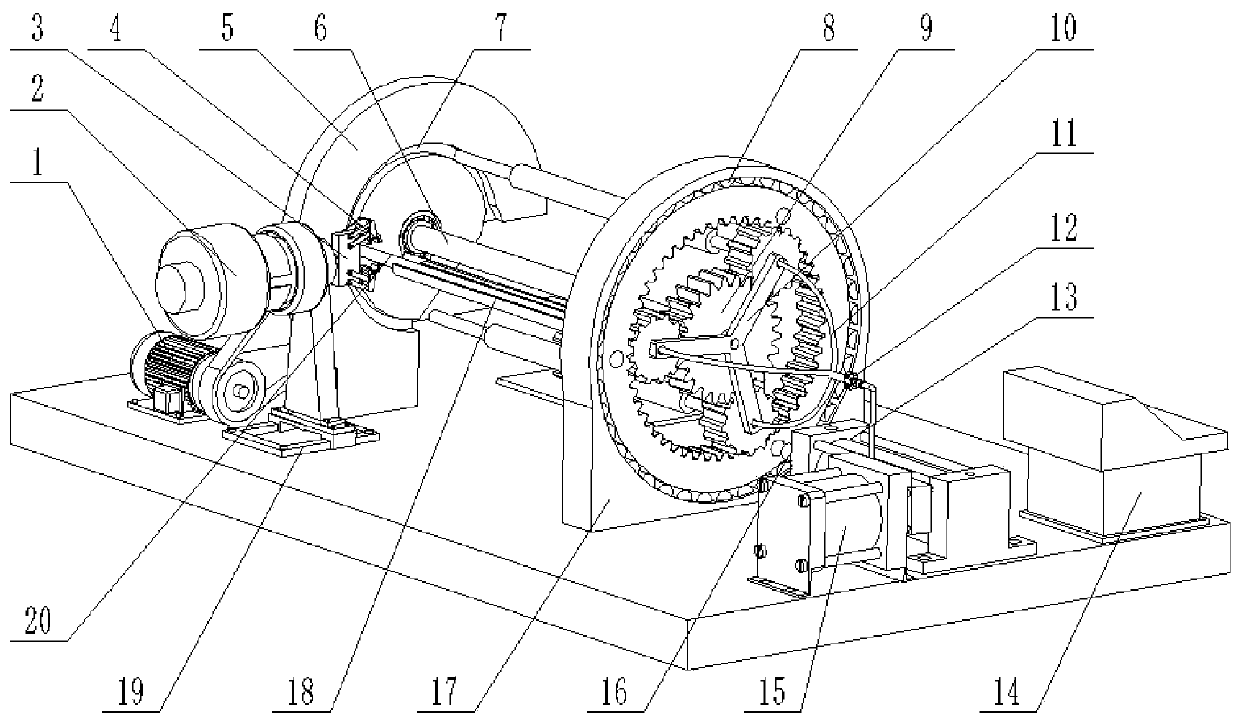

Net material automatic winding and coil unloading device

The invention discloses a net material automatic winding and coil unloading device. The device comprises a power device, a transmission device, a winding and coil unloading device and a control device, wherein the power device comprises an asynchronous motor, an air cylinder and an air pump, the transmission device comprises a planetary gear train, a central shaft, a sliding rail and a planetary gear support, the winding and coil unloading device comprises winding shafts, rotary clamps, a split-type radial sliding bearing, a pneumatic clamp, a horizontal guide rail, a coil unloading mechanicalarm unit, an air pipe, a rotary joint, an electromagnetic reversing valve and an electric air cylinder, and the control device comprises an electrical cabinet and a position sensor. According to thedevice, the planetary gear train structure is adopted, so that the central shaft and the three winding shafts are driven by one motor, and the production cost and the power loss are reduced; and during coil unloading, the rotary clamps in the winding shafts are loosened under the action of a hydraulic swinging cylinder, so that the tension of coils is reduced, a mechanical arm can directly unloada net material from vacancy of a left support, the purpose of automatic coil unloading is achieved, and the continuous and automatic production process is ensured.

Owner:BEIJING UNIV OF CHEM TECH

Pipe body punching device

InactiveCN106994480AContinuous automationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a pipe body punching device, which is used for punching holes at both ends of a pipe body. The punching device includes a support platform and a slope platform fixedly connected with the support platform. A first hole puncher and a second hole puncher are respectively provided at the joint, and a pneumatic conveying device is provided on the support platform to convey the pipe body upwards to the positions of the first hole puncher and the second hole puncher. A first guide bar and a second guide bar arranged parallel to each other are provided on the top, a first stop block is provided at the end of the first guide bar to block the pipe body, and at the end position of the second guide bar A second stop block is provided to block the pipe body, a first motor that drives the first stop block and the second stop block to rotate is provided in the ramp platform, and a position below the first guide bar is provided for The pipe body is conveyed to the first conveying block on the pneumatic conveying device, and a second conveying block for conveying the pipe body to the pneumatic conveying device is arranged at a position below the second guide slide bar.

Owner:TAIZHOU YUANDA HOME FURNITURE CO LTD

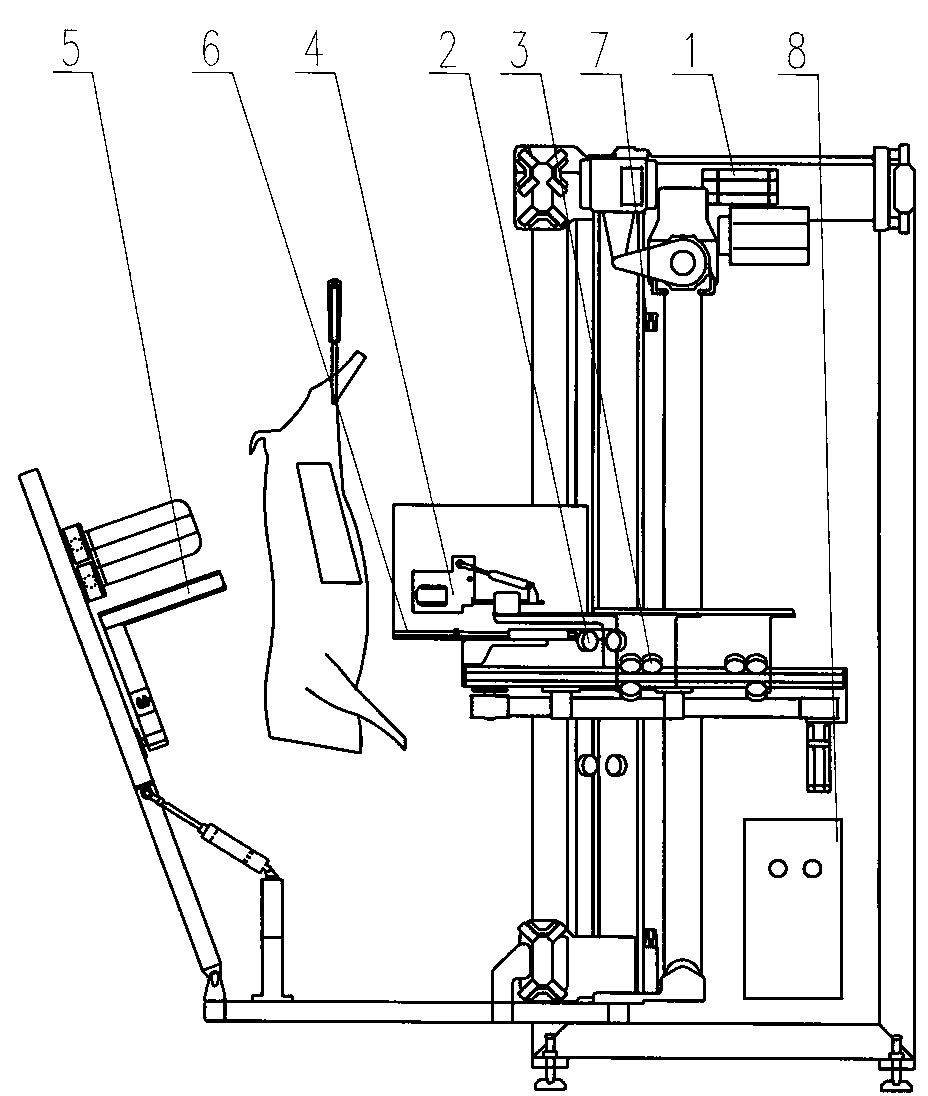

On-line tracking and scanning automatic pick-up machine of leaf lard in slaughtered live pig

ActiveCN104068093ATaste Quality Lean and FreshSimple structureSlaughtering accessoriesNumerical controlMotor speed

The invention relates to an on-line tracking and scanning automatic pick-up machine of leaf lard in a slaughtered live pig, in particular to processing equipment for automatic leaf lard pick-up of two split parts of the pig conveyed by a conveyer. The machine is characterized in that a lifting stand, a servo motor speed reducer, a lifting transmission shaft, an oblique guide wheel, a synchronous belt and a horizontal guide wheel are arranged on the parallel mover and the lifter respectively; a servo motor, a longitudinal moving rail and a synchronous belt are arranged on a longitudinal expansion piece respectively; a left support, a right support, a left arm, a right arm, a left clamping jaw, a right clamping jaw, a left air cylinder, a right air cylinder and an unfolding rack are arranged on a pick-up arm respectively; a left side plate, a right side plate, a machine base, a double outlet rod air cylinder and a double earring air cylinder are arranged on an enclasping device respectively; and an electric controller employs a PLC (programmable logic controller) for centralized control and numerical control. The machine has the effects that the machine is simple in structure, convenient to operate and high in production efficiency, operates continuously and automatically, saves manpower and time, requires no manual operation, avoids cross contamination, ensures meat hygiene and safety and is the slaughter processing equipment widely used for continuous and automatic leaf lard pick-up.

Owner:福瑞珂食品设备(济宁)有限公司

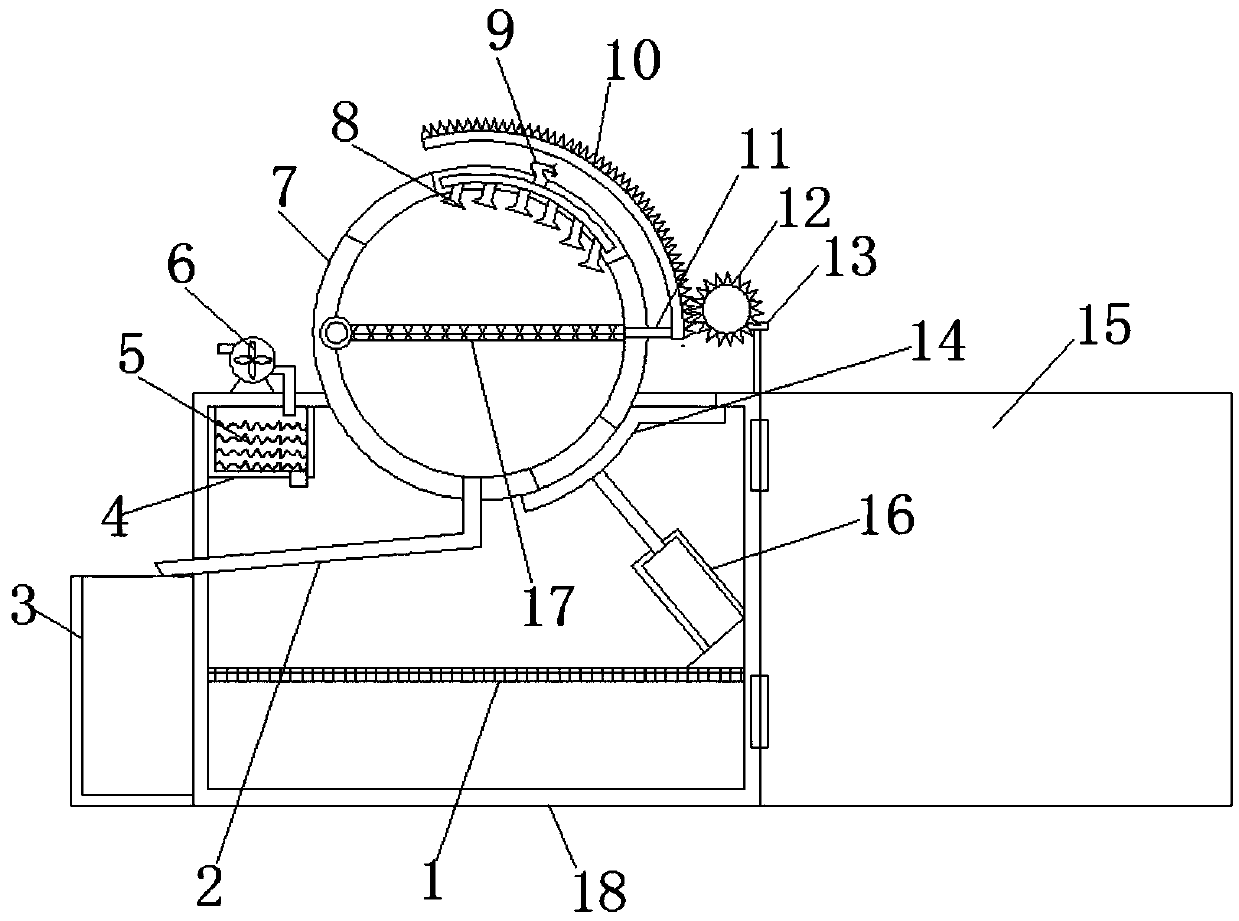

River garbage automatic drifting separator

The automatic river garbage floating and separating machine as one kind of river water environment tackling apparatus includes one frame, one rotating water mill, one floating tank, one separator, one control box for controlling the elevation of the separator, one row of flat rods for collecting the garbage in water, one row of floating rods for collecting floated garbage, and other parts. It is set in river, and under the action of water flow, it separates and collects garbage from water flow.

Owner:李德兴

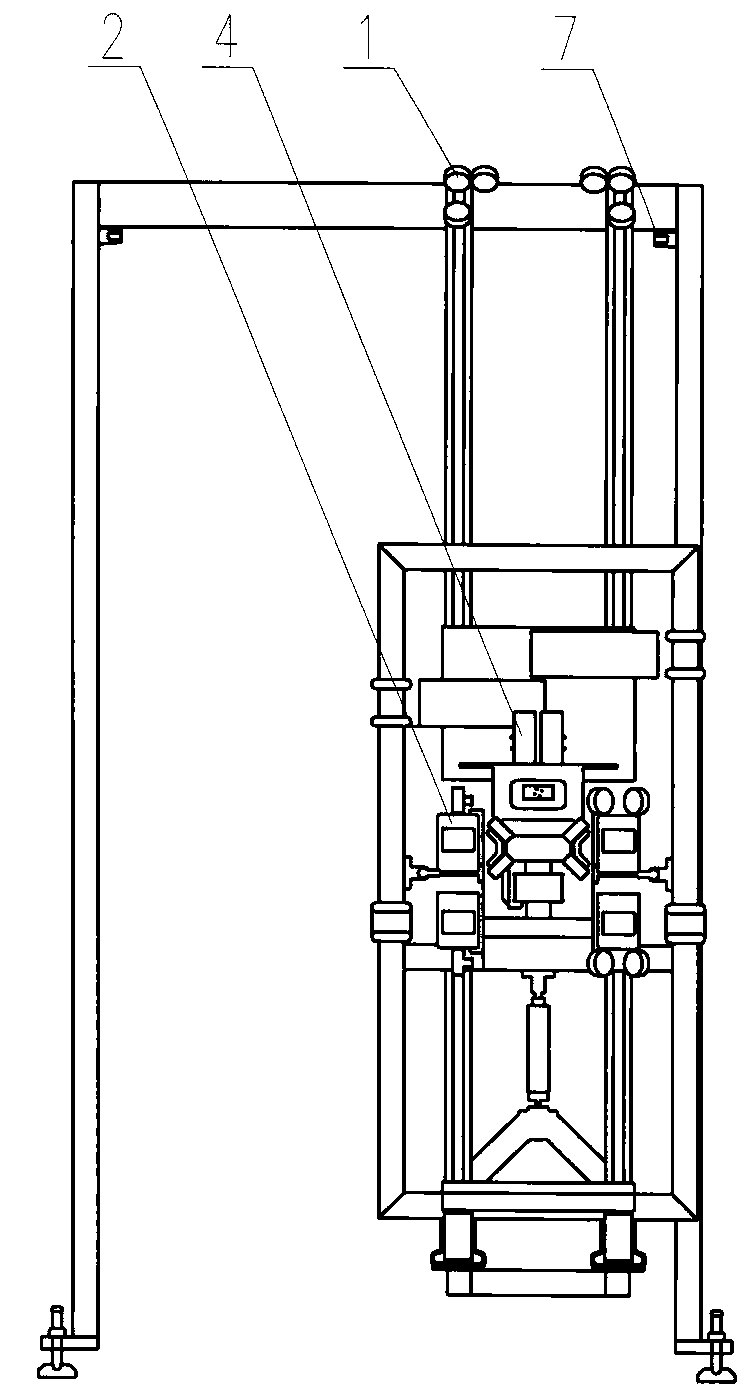

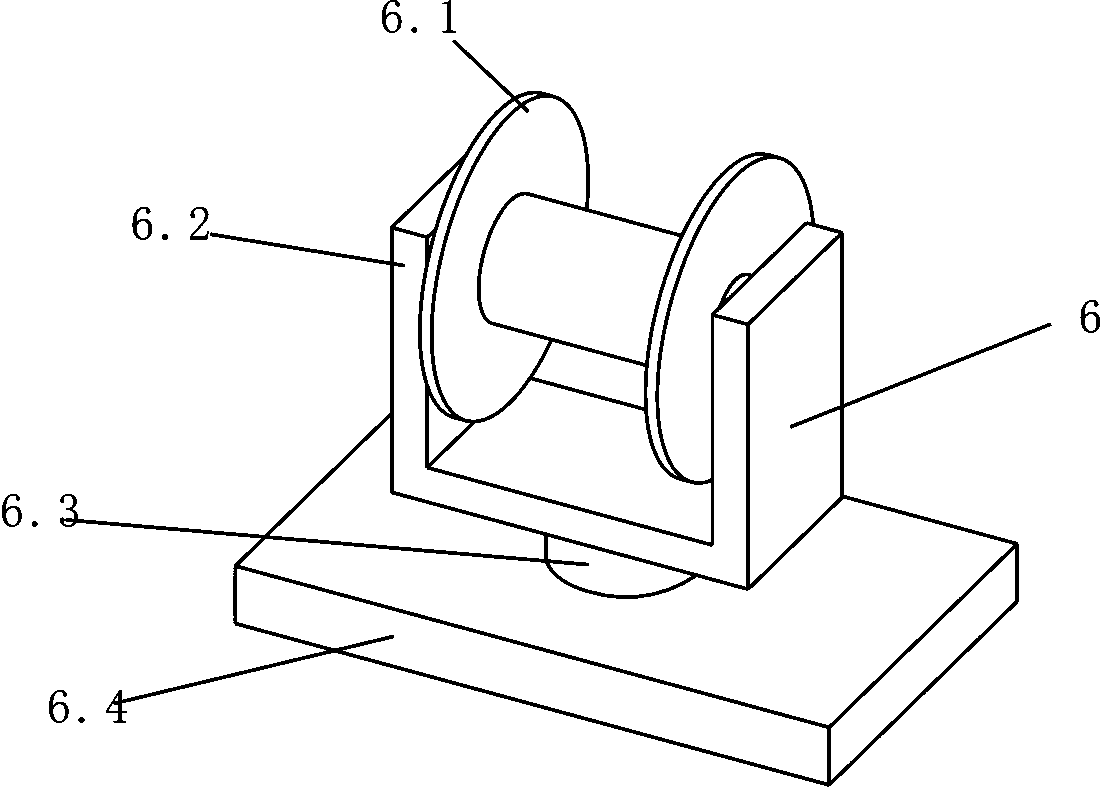

Method for manufacturing rotary optical fiber and rotary fiber winding device

The invention discloses a method for manufacturing a rotary optical fiber. The method comprises a step of manufacturing an optical fiber preform and a step of drawing the optical fiber preform, wherein in the step of drawing the optical fiber preform, a lower end of the rotary optical fiber is rotated along an axial direction of the optical fiber under fiber drawing, and rotation formed in the optical fiber is fixed in the cooling process. The rotary fiber winding device for manufacturing the rotary optical fiber comprises a fiber winding disc arranged in a fiber drawing tower and under the drawn optical fiber, wherein the fiber winding disc has a shape of a spool and is used for rotating with a drawn optical fiber as a rotating axis so as to drive the lower end of the optical fiber to rotate and for rotating with a central shaft of the fiber winding disc as a rotating axis so as to wind the optical fiber. By an ultralow double refraction optical fiber product manufactured by the process and equipment, because the rotation is not generated or cured in a drawing furnace, influence of the rotation in a high-temperature melting state on optical and mechanical properties is avoided, the manufactured ultralow double refraction optical fiber has long-term reliability and stability, and the using requirement of a sensing optical fiber in a harsh environment is met.

Owner:武汉长盈通光电技术股份有限公司

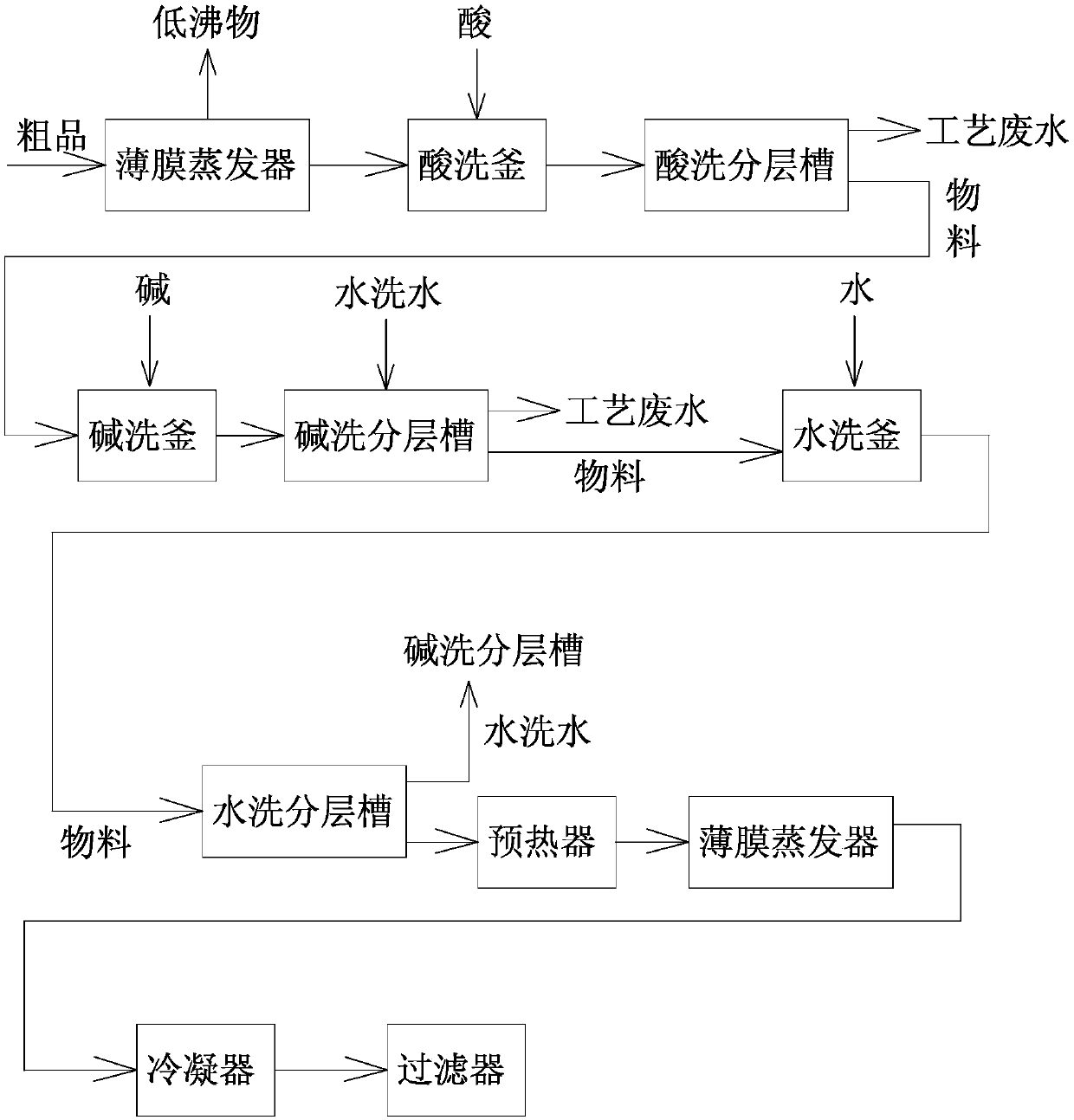

A kind of preparation method of high-purity phosphate flame retardant tris (2-chloropropyl) phosphate

ActiveCN106565773BRaise the ratioReduce the ratioPhosphorus organic compoundsAutomatic controlSecondary component

Owner:福建新安科技有限责任公司

Manufacturing method of low sizing amount environment-friendly plywood

ActiveCN105818225BImprove qualityReduce manufacturing costElectric wood treatmentWood treatment detailsFiberAdhesive

The invention relates to a method for manufacturing an environmentally friendly plywood with low sizing amount, and belongs to the technical field of wood-based panel manufacturing. The process is to cut wood sections into 1-3mm wooden veneers, dry them to adjust the moisture content to 2-15%, and carry out atmospheric pressure and low-temperature plasma modification treatment on both sides of the veneers. Through the synergistic effect of ultrasound and cyclone, the The adhesive is atomized into particles with a diameter of less than 40 μm and sprayed on the tight surface of the veneer. The amount of adhesive applied on one side is controlled at 10-80g / m2, and the fiber texture directions of adjacent layers of veneer are perpendicular to each other. Pressed to obtain low-sizing environment-friendly plywood. The performance of the product prepared by this method meets the requirements of the national standard for plywood, the amount of formaldehyde released reaches the requirements of E0 level, and the amount of adhesive is reduced by 30-70% compared with the amount of the traditional glue coating method, the product quality is significantly improved, and the production cost is significantly reduced. In addition, the production process of this method is energy-saving and environmentally friendly, and the production equipment is easy to operate, high in efficiency, good in controllability, and can be continuously automated.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com