Plastic mineral silica flaky dessicant and preparation method thereof

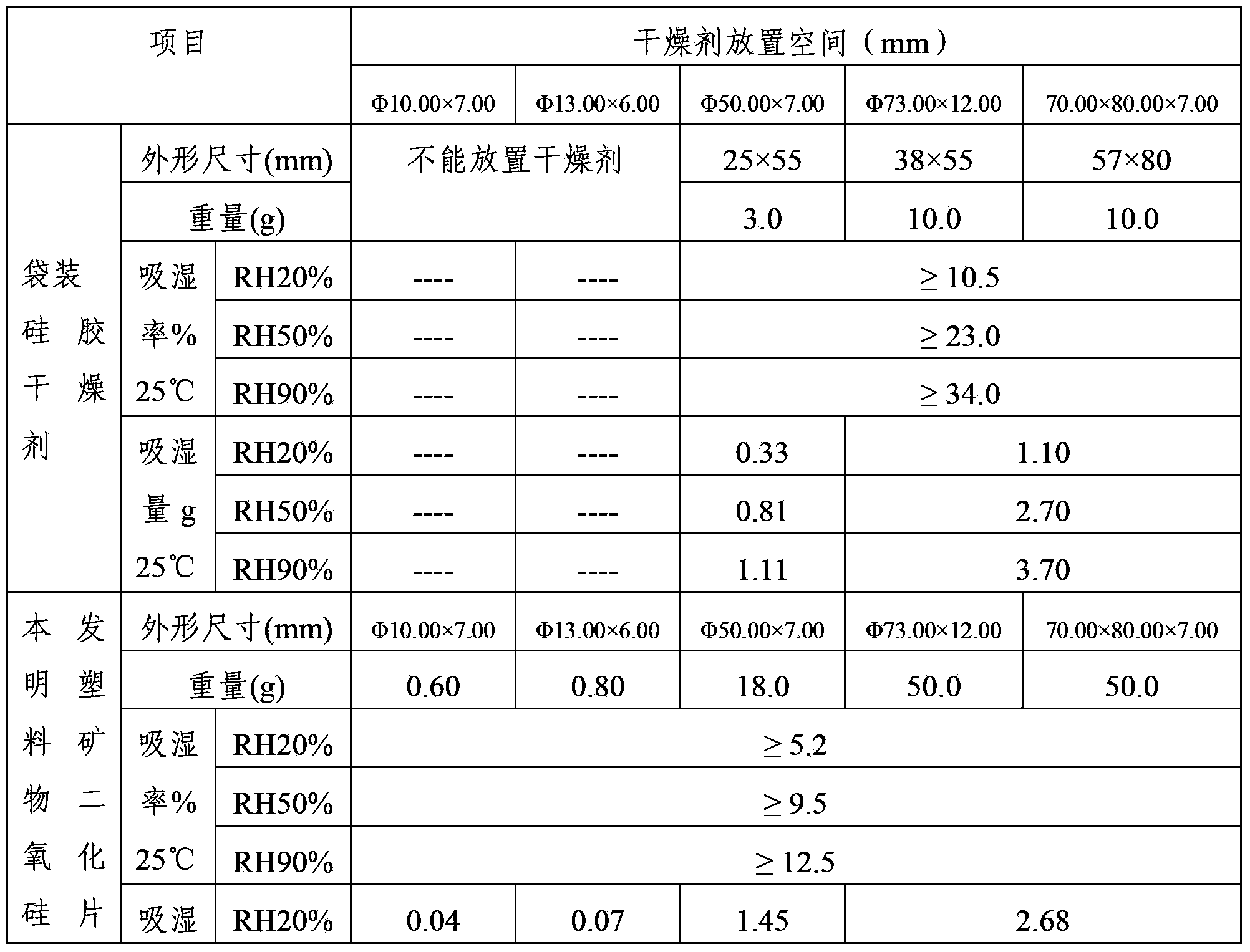

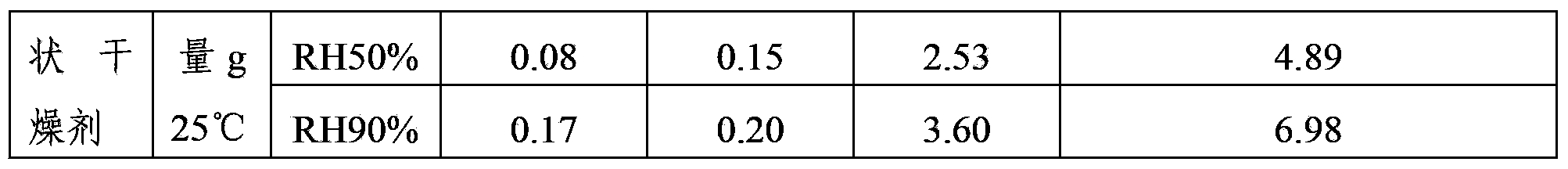

A technology of silica and desiccant, which is applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as inability to pack tightly, drop of bagged silica gel desiccant, and low absorption capacity, achieving huge Application prospect and economic value, effective space saving, high moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of mineral silica powder

[0040] Step 1: Natural Mineral Purification

[0041] Stir and soak 5 parts of montmorillonite ore soil with 80 parts of purified water for more than 50 hours, wait for it to fully expand, and sieve through 200 mesh or more to separate large particles of impurity ore soil.

[0042] Step Two: Wrap

[0043] Put 8 parts of the above-mentioned purified minerals and fine-pored (type A) silica powder (particle size above 400 mesh) into the flake machine, grind for more than 60 hours, and centrifuge the mixed material in a high-speed centrifuge (rotating speed of 2000 rpm above), remove the particles, and prepare the coating solution.

[0044] Step Three: Dry

[0045] Concentrate the prepared coating solution and dry it in vacuum to obtain mineral silica desiccant powder.

Embodiment 2

[0046] Embodiment 2: the preparation of mineral silica powder

[0047] Step 1: Natural Mineral Purification

[0048] Stir and soak 2 parts of montmorillonite ore soil and 3 parts of attapulgite clay with 100 parts of purified water for more than 50 hours, wait for them to fully expand, and then sieve through 200 mesh or more to separate large particles of impurity ore soil.

[0049] Step Two: Wrap

[0050] Put the above-mentioned purified minerals together with 3 parts of fine-pore (type A) silica gel powder (particle size: more than 400 mesh) and 2 parts of coarse-pore (type B) silica gel powder into the peeling machine, grind for more than 60 hours, and put The mixed material is centrifuged in a high-speed centrifuge (with a speed of more than 2000 rpm) to remove particulate matter and obtain a coating solution.

[0051] Step Three: Dry

[0052] Concentrate the obtained coating solution and dry it in a drying box to obtain mineral silica desiccant powder.

Embodiment 3

[0053] Embodiment 3: Preparation of Plastic Mineral Silica Flake Desiccant

[0054] The first step: material mixing

[0055] Mix 3 parts of natural mineral silica desiccant powder obtained in Example 1 with 1 part of low-density polyethylene (LDPE) plastic powder and 0.1 part of carboxymethylcellulose (CMC).

[0056] Step 2: Compression molding

[0057] The material mixed in the previous step is heated in a mold of corresponding specifications and sizes by a mechanical tablet press (at a temperature of 60 degrees), and pressed into blocks to obtain blocks;

[0058] Step Three: Dry

[0059] The aforesaid blocks are vacuum-dried to obtain a plastic mineral silicon dioxide flaky desiccant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com