A kind of preparation method of high-purity phosphate flame retardant tris (2-chloropropyl) phosphate

A technology of tris and chloropropyl phosphates, applied in chemical instruments and methods, phosphorus organic compounds, compounds of elements of Group 5/15 of the periodic table, etc., can solve the problem of unstable product quality, affecting product yield, and long contact time. and other problems, to achieve the effect of light product smell, short reaction time and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 5000L reactor, 600kg of the last batch of materials was left at the bottom, and 2600kg of phosphorus oxychloride was put in. After adding 6kg of phosphorus trichloride, 6kg of pyrophosphoryl chloride, and 7kg of aluminum trichloride, propylene oxide was passed again, and the temperature was Control the flow at 50-100kg / h at 35-40°C (initial stage of reaction); control at 100-300kg / h at temperature at 45-50°C (middle stage of reaction); control at 300-400kg at temperature at 50-55°C / h (late stage of reaction). At the end of the reaction, when the temperature drops by 3°C / min, the automatic chain will automatically close the propylene oxide feed valve, keep it warm for 1 hour, and test the acid value ≤ 0.3, which is qualified, and put into the crude product tundish.

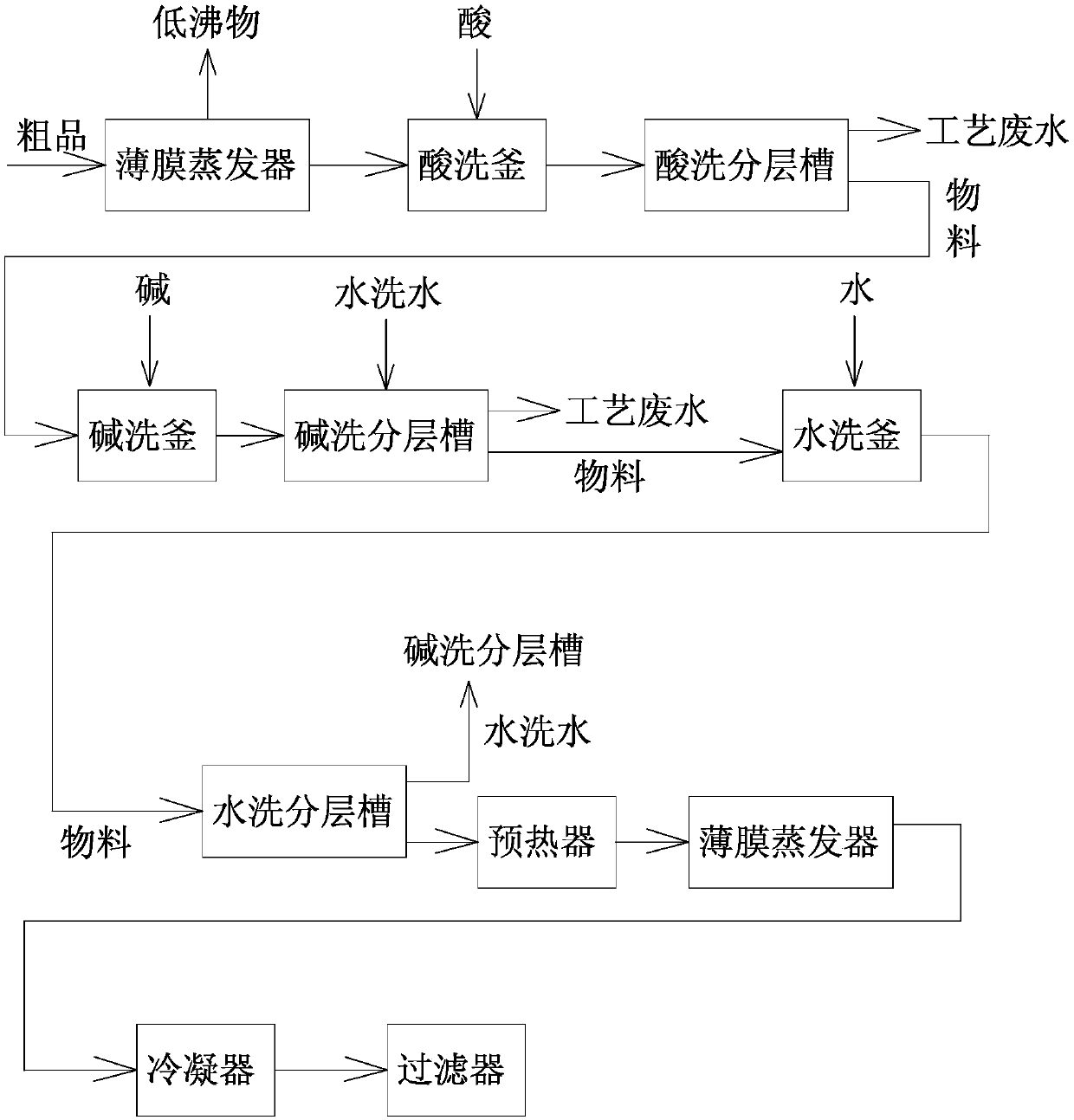

[0029] Such as figure 1As shown, put 5.5 tons of crude product intermediate tank into the caustic washing kettle, turn on the stirring, start to heat up and turn on the vacuum, the temperature rises t...

Embodiment 2

[0033] 5000L reactor, keep 600kg of the last batch of material, put in 2600kg of phosphorus oxychloride, add 12kg of phosphorus trichloride, 7kg of aluminum trichloride, then pass through propylene oxide, the temperature is 20-40℃, the flow rate Control at 50-80kg / h (initial stage of reaction); temperature at 45-55°C, flow control at 100-200kg / h (middle stage of reaction); temperature at 60-65°C, flow control at 300-400kg / h (late reaction ). At the end of the reaction, when the temperature drops by 0.1°C / min, the automatic chain will automatically close the propylene oxide feed valve, keep it warm for 1 hour, and test the acid value ≤ 1, which is qualified, and put into the crude product tundish.

[0034] Such as figure 1 As shown, put 5.5 tons of crude product intermediate tank into the caustic washing kettle, turn on the stirring, start to heat up and turn on the vacuum, the temperature rises to 70-80°C, pull the vacuum for 10-30min, then add 1.5 tons of washing water, add ...

Embodiment 3

[0038] The difference with Example 2 is the preparation of the crude product: 5000L reactor, the last batch of material left 600kg at the bottom, dropped into 2600kg of phosphorus oxychloride, added 12kg of pyrophosphoryl chloride, 7kg of aluminum trichloride, and then passed Propylene oxide, temperature at 50-60°C, flow control at 50-120kg / h (initial stage of reaction); temperature at 60-70°C, flow control at 100-250kg / h (middle stage of reaction); temperature at 70-80°C , the flow rate is controlled at 300-400kg / h (late stage of reaction). At the end of the reaction, when the temperature drops by 0.1°C / min, the automatic chain will automatically close the propylene oxide feed valve, keep it warm for 1 hour, and test the acid value ≤ 1, which is qualified, and put into the crude product tundish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com