Accurate-positioning floating-type deburring and polishing device

A precise positioning and equipment technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of workpiece damage and prone to broken knives, and achieve the effects of improving production efficiency, reducing processing costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the scope of protection of the present invention.

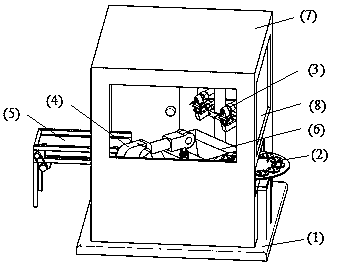

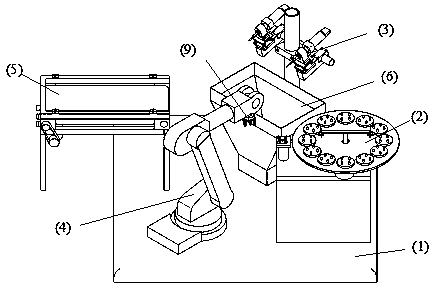

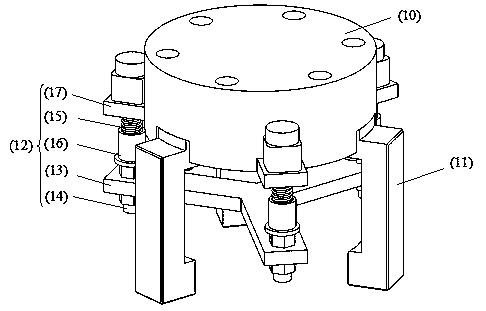

[0040] Such as Figure 1 to Figure 4 As shown, the present invention provides a precise positioning floating de-fronting grinding equipment, which is suitable for the de-fronting and grinding operation of various metal die castings, realizes precise positioning and multi-directional floating grinding, and has a high degree of automation, and one person can operate multiple sets equipment, high processing efficiency.

[0041]Specifically, a precision-positioned floating de-flashing and grinding device comprises a base 1, a carrying device 2, a de-flashing and grinding device 3, a robot mechanism 4, an output conveying device 5, a dust suction device 6 and a protective cover 7. The carrying device 2, the de-capping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com