On-line tracking and scanning automatic pick-up machine of leaf lard in slaughtered live pig

A swine suet, automatic technology, applied in slaughtering, slaughtering accessories, slaughtering devices and other directions, can solve the problems of carcass cross-contamination, high labor intensity, low work efficiency, etc., to avoid cross-contamination, meat hygiene and safety, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

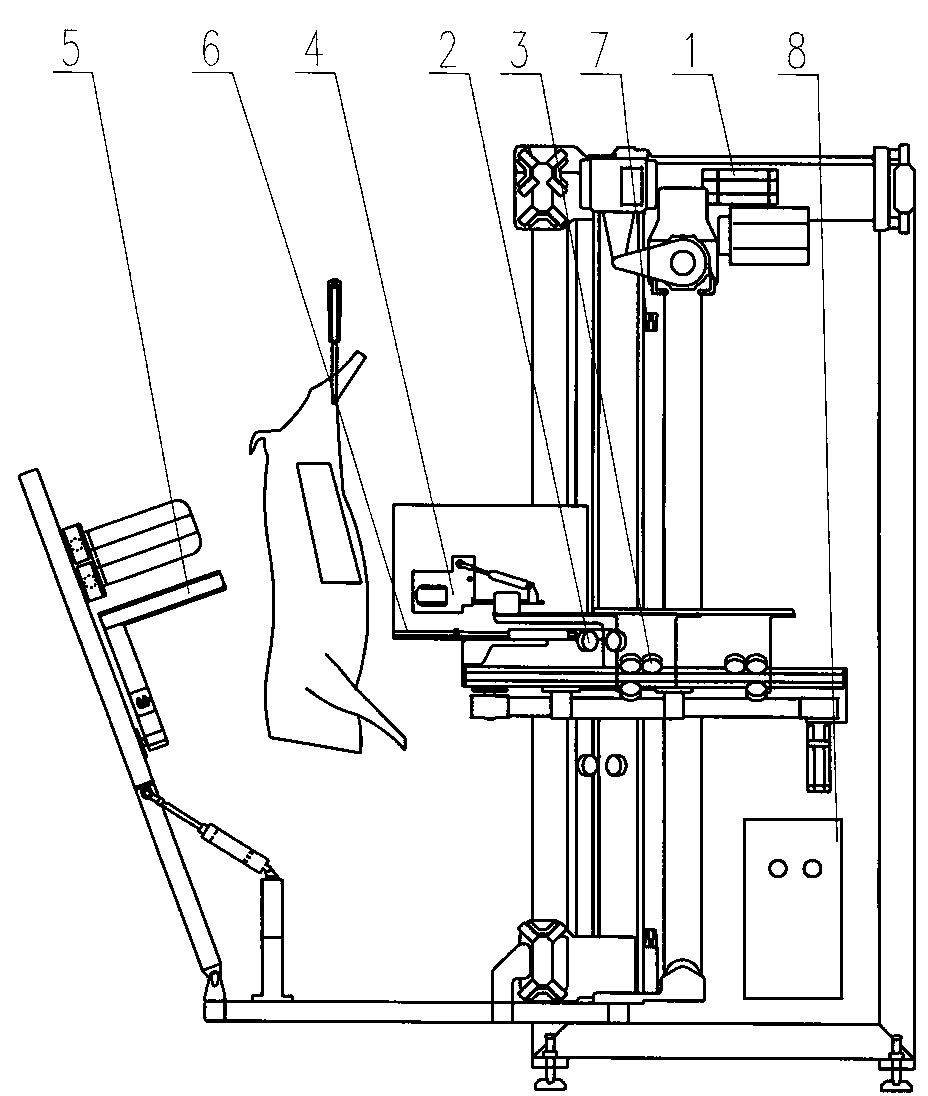

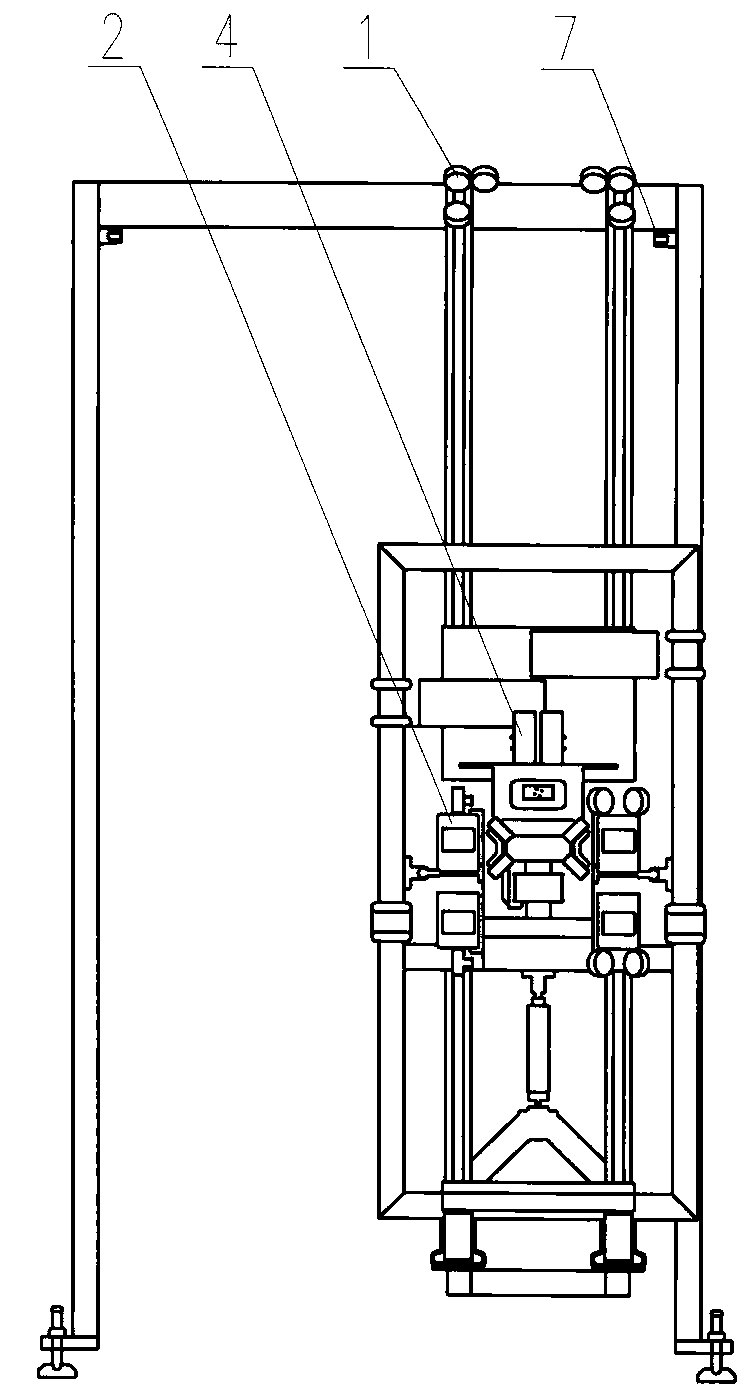

[0010] refer to figure 1 , 2 , the present invention on-line tracking scanning pig suet automatic picking machine in the body of slaughtered pigs, it is composed of parallel mover 1, lifter 2, longitudinal stretcher 3, picking arm 4, holding device 5, high-pressure spraying water device 6, Leakage protector 7 and electrical controller 8 are composed, servo motor reducer, synchronous belt, bracket and traversing track are respectively set on parallel mover 1, servo motor reducer is connected with driving synchronous belt pulley shaft through coupling, synchronous belt The wheel shaft is fixed by the bearing seat and the frame, the timing belt pulley is fixed on the other end of the frame, the timing belt bypasses the two timing pulleys, and the two sides are fixed with the bracket. material, the rollers are in contact with the track in an inclined direction, the parallel mover 1 moves horizontally on the traversing track, and the lifter 2 is respectively equipped with a liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com