River garbage automatic drifting separator

A technology for separators and garbage, applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve pollution, serious problems, etc., and achieve the effect of high separation cleanliness and fast efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

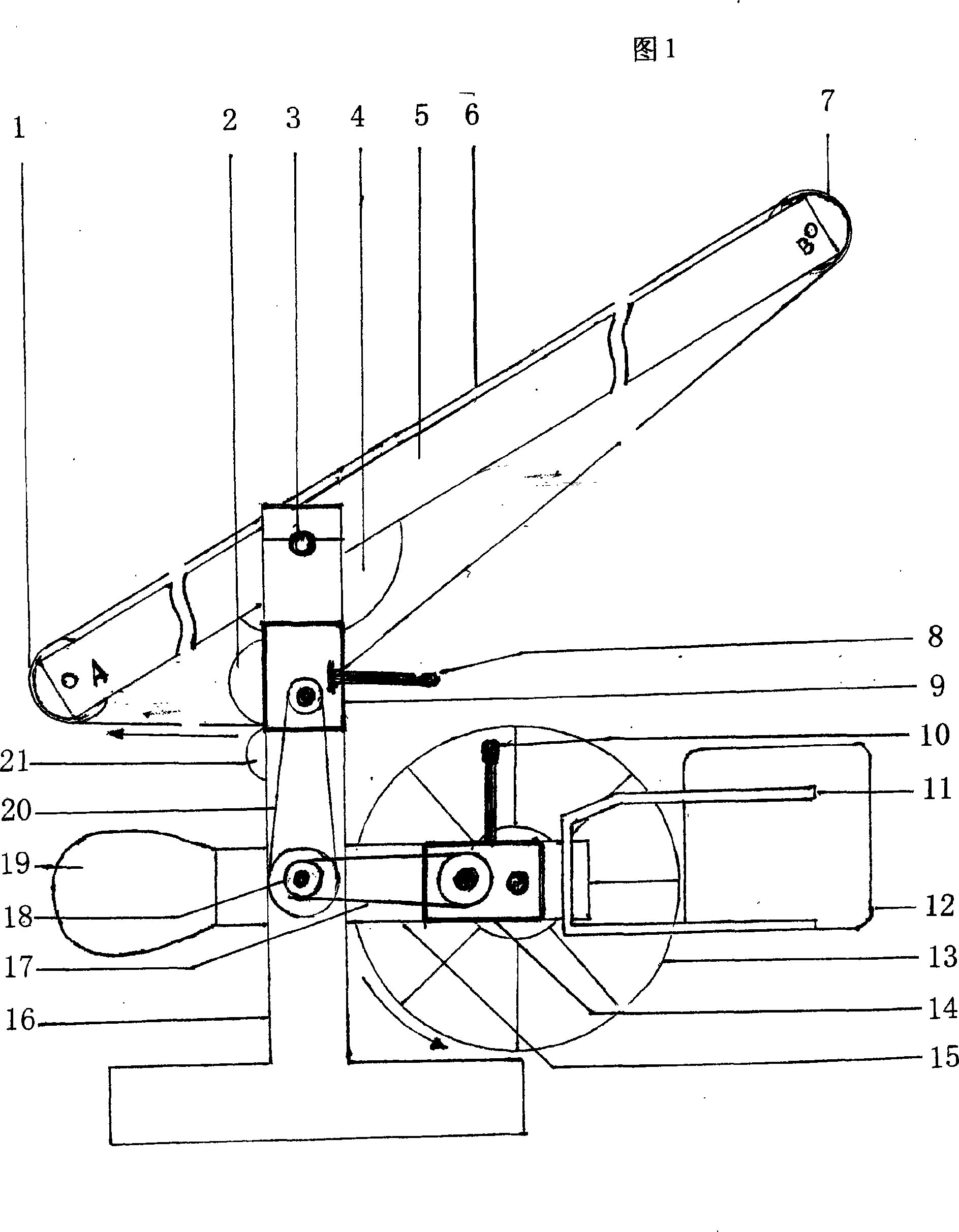

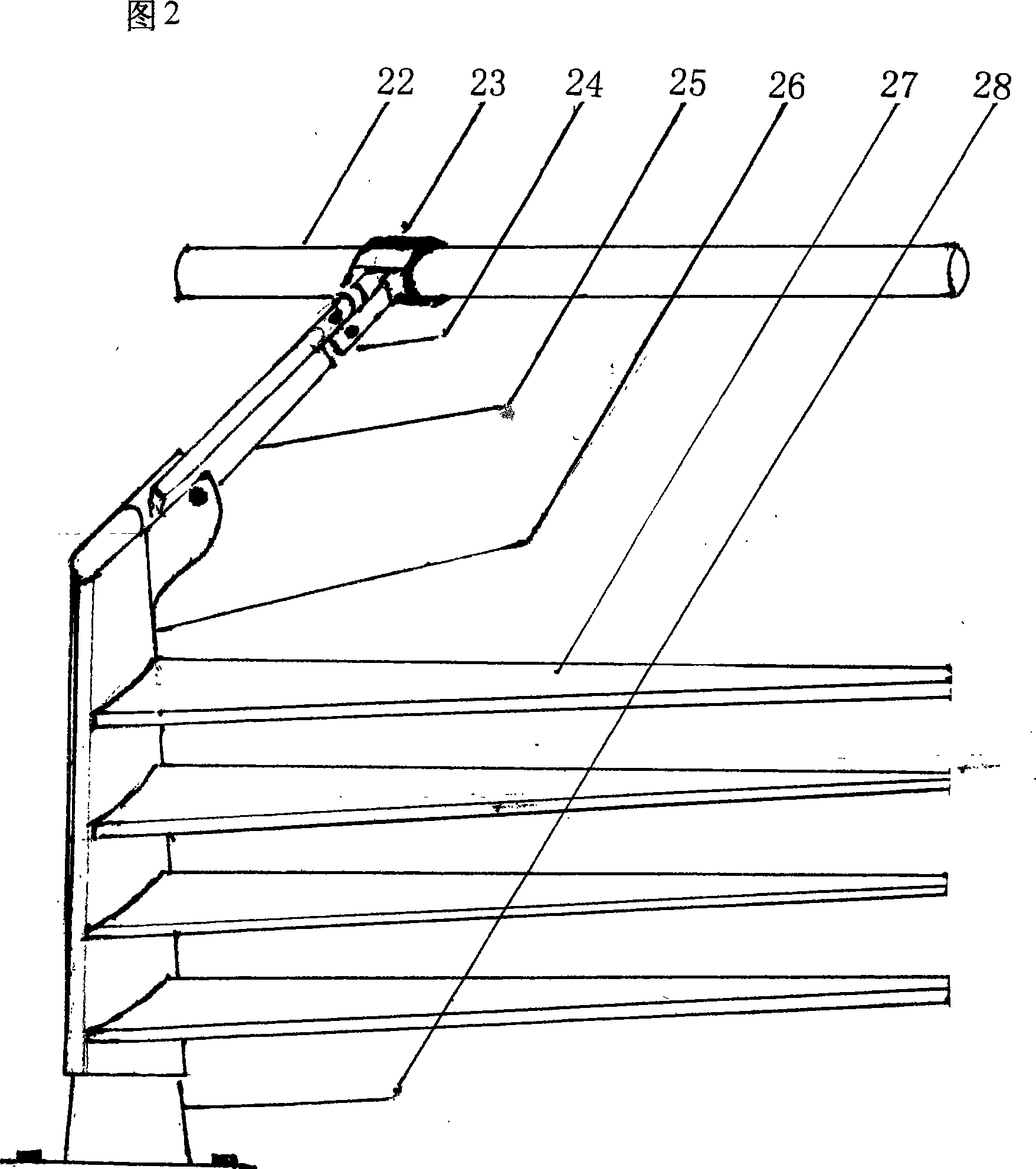

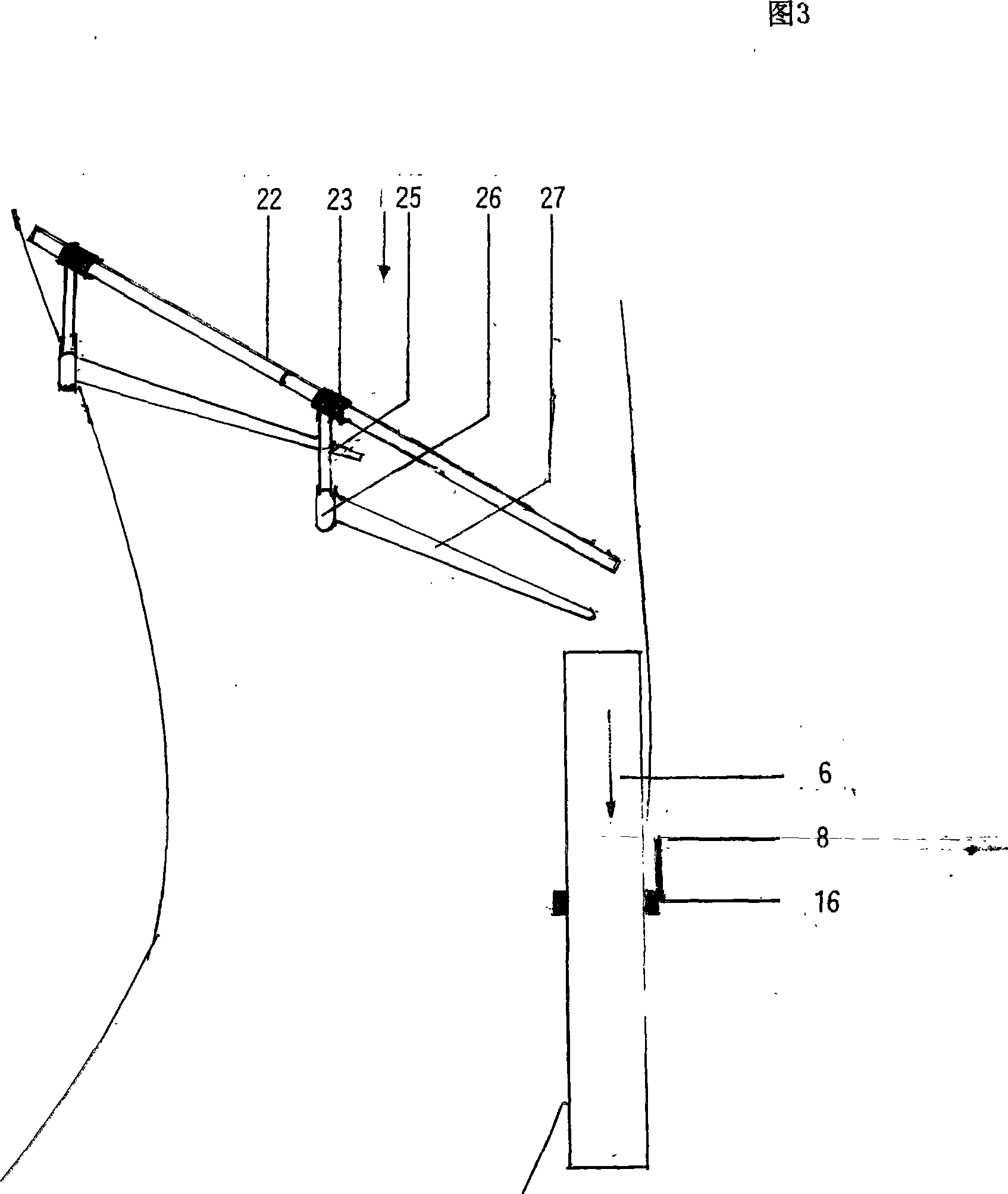

[0016] Illustrate implementation of the present invention below with reference to accompanying drawing

[0017] Axle 18 is arranged on column 16 to link horizontal frame 15 and column 16 together, and horizontal frame 15 can rotate flexibly on axis 18. One end of cross frame 15 has water wheel 13 to provide power for separator, and clutch 14 and transmission chain 17 are arranged on the axle of water wheel 13, can play the power effect of separation, transmission water wheel 13. The power transmission and separation between the water wheel 13 and the transmission chain 17 can be done through the operating lever 10 . There is buoyant tank 12 installed on the buoyant tank frame 11 at the back of waterwheel 13, and buoyant tank 12 can drive waterwheel 13 to float up and down together with the fluctuation of water level.

[0018] There is a balance bar 19 at the other end of the cross frame 15, and the balance rod 19 is to keep the balance between the two ends of the cross frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com