Separation and purification of gallic acid from suaeda salsa by SF-SMB

A technology of simulated moving bed and gallic acid, which is applied in the field of separation and purification of gallic acid in Suaeda salsa using a supercritical simulated moving bed chromatography system, which can solve the problems of expensive supercritical fluid chromatography equipment, unsatisfactory purification effect, and low purity. Achieve the effect of continuous automatic operation, excellent mass transfer performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

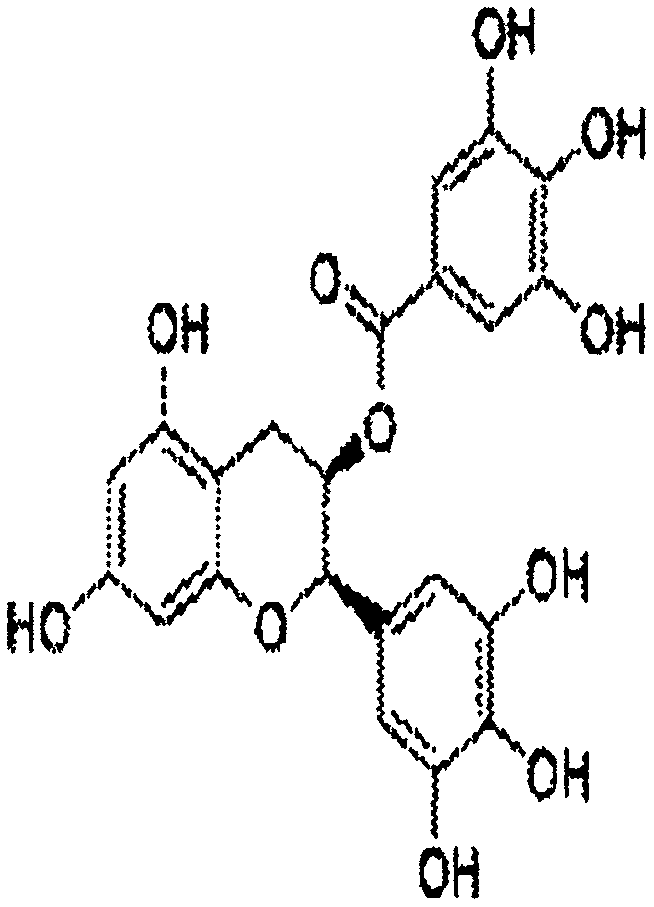

Image

Examples

Embodiment 1

[0035] 1.1 Screening of Suaeda salsa

[0036] Choose Suaeda salsa with moderate size, fresh color and no pests;

[0037] 1.2 Pretreatment of Suaeda salsa

[0038] (1) Cleaning treatment

[0039] Soak the Suaeda salsa in clean water and rinse until there is no dirt on the Suaeda salsa;

[0040] (2) Drying treatment

[0041] Spread the Suaeda salsa flat and place it in a well-ventilated environment for drying treatment, and dry it in an oven at 60°C for 2 hours; make the moisture on the surface of Suaeda salsa dry;

[0042] (3) Finished

[0043] Carry out greening under microwave, spread the Suaeda salsa leaf thickness 3 centimeters, 2kw microwave treatment 10 minutes;

[0044] (4) Smash

[0045] Pulverize the Suaeda salsa treated in a pulverizer at room temperature and pass through a 60-mesh sieve;

[0046] 1.3 Extraction of gallic acid and quercetin

[0047] Suaeda salsa gallic acid was extracted by ultrasonic-assisted hydroenzyme method, treated with compound enzyme: ...

Embodiment 2

[0054] 1.1 Screening of Suaeda salsa

[0055] Choose Suaeda salsa with moderate size, fresh color and no pests;

[0056] 1.2 Pretreatment of Suaeda salsa

[0057] (1) Cleaning treatment

[0058] Soak the Suaeda salsa in clean water and rinse until there is no dirt on the Suaeda salsa;

[0059] (2) Drying treatment

[0060] Spread the Suaeda salsa flat and place it in a well-ventilated environment for drying treatment, and dry it in an oven at 60°C for 2 hours; make the moisture on the surface of Suaeda salsa dry;

[0061] (3) Finished

[0062] Carry out greening under microwave, spread the Suaeda salsa leaf thickness 3 centimetres, the microwave treatment of 2kw 10 minutes.

[0063] (4) Smash

[0064] Pulverize the Suaeda salsa treated in a pulverizer at room temperature and pass through a 60-mesh sieve;

[0065] 1.3 Extraction of gallic acid and quercetin

[0066] Suaeda salsa gallic acid was extracted by ultrasonic-assisted hydroenzyme method, treated with compound e...

Embodiment 3

[0073] 1.1 Screening of Suaeda salsa

[0074] Choose Suaeda salsa with moderate size, fresh color and no pests;

[0075] 1.2 Pretreatment of Suaeda salsa

[0076] (1) Cleaning treatment

[0077] Soak the Suaeda salsa in clean water and rinse until there is no dirt on the Suaeda salsa;

[0078] (2) Drying treatment

[0079] Spread the Suaeda salsa flat and place it in a well-ventilated environment for drying treatment, and dry it in an oven at 60°C for 2 hours; make the moisture on the surface of Suaeda salsa dry;

[0080] (3) Finished

[0081] Carry out greening under microwave, spread the Suaeda salsa leaf thickness 3 centimeters, 2kw microwave treatment 10 minutes;

[0082] (4) Smash

[0083] Pulverize the Suaeda salsa treated in a pulverizer at room temperature and pass through a 60-mesh sieve;

[0084] 1.3 Extraction of gallic acid and quercetin

[0085] Suaeda salsa gallic acid was extracted by ultrasonic-assisted hydroenzyme method, treated with compound enzyme: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com