Intermittent intelligent wine brewing system and wine brewing method

An intermittent, fermented grain technology, applied in the field of winemaking, can solve the problems of time-consuming and laborious, secondary pollution, uneven mixing, etc., and achieve the effects of easing the discharge, reducing the consumption of coal and improving the combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

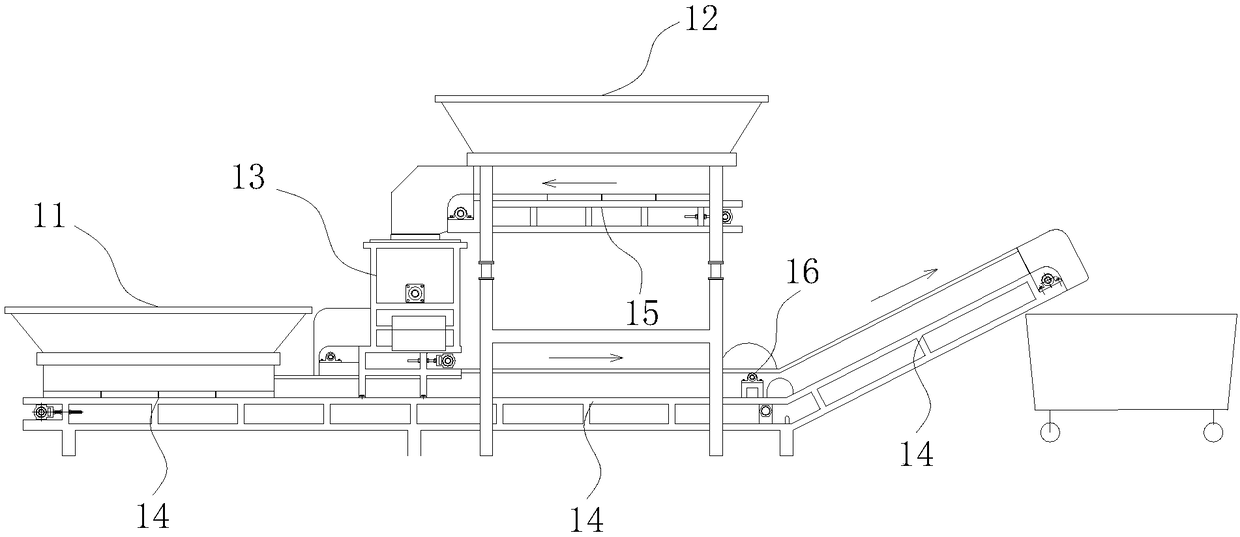

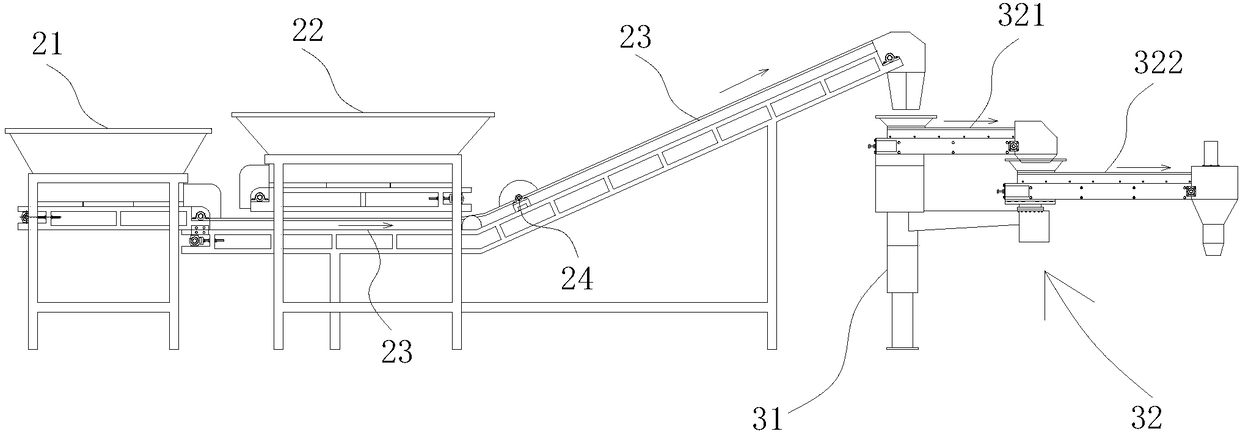

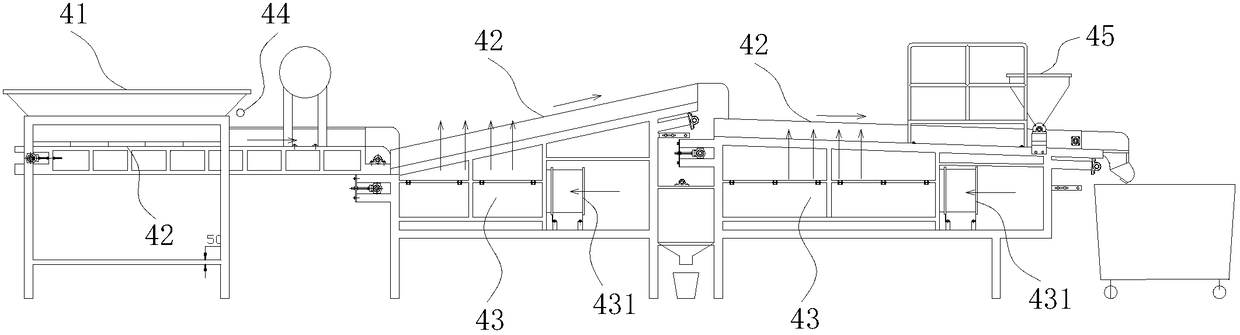

[0042] The intermittent intelligent brewing system of the present invention includes a first mixing unit, a second mixing unit, a retort unit, a co-fired steam supply unit, and a cooling unit for spreading fermented grains;

[0043] Such as figure 1 As shown: the first mixing unit includes a first wine unstrained spirits hopper 11, a grain hopper 12, a grain-water mixing device 13, a first conveyor belt 14 and a second conveyor belt 15, and the output of the grain hopper 12 falls on On the second conveyor belt 15, the discharge of the second conveyor belt 15 falls in the grain-water stirring device 13, and the discharge of the grain-water stirring device 13 and the first wine grain hopper 11 are respectively Fall evenly on the feeding end of described first conveyor belt 14. The first wine grain bucket 11 is used to hold wine grains, and the grain bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com