Net material automatic winding and coil unloading device

A power device and net material technology, which is applied in the direction of coiling, transportation and packaging, thin material processing, etc., can solve the problems of labor cost, not suitable for high-speed small roll winding work, and cannot be used. Achieve the effect of saving production cost and power loss, reducing manual operation and use cost, and eliminating the need for secondary debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

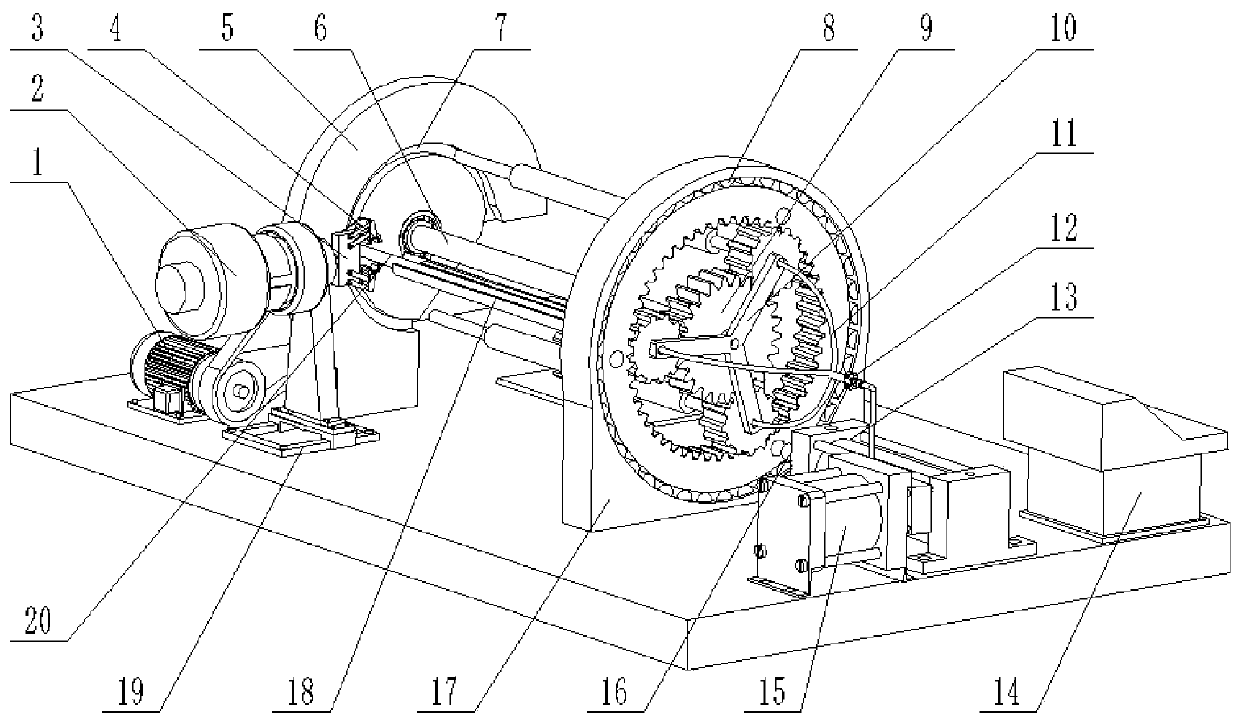

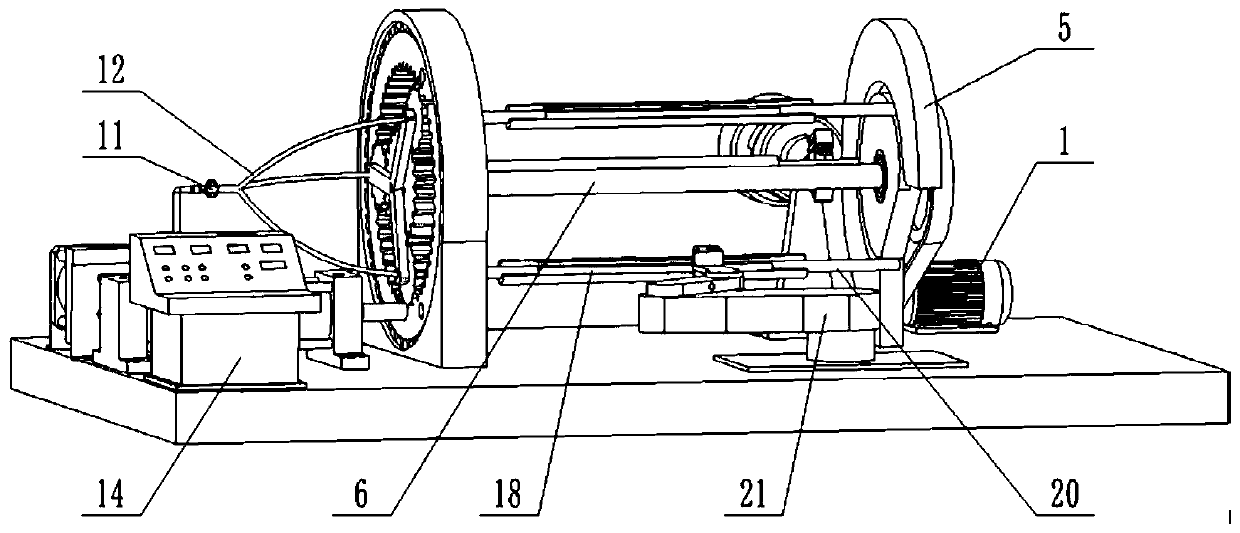

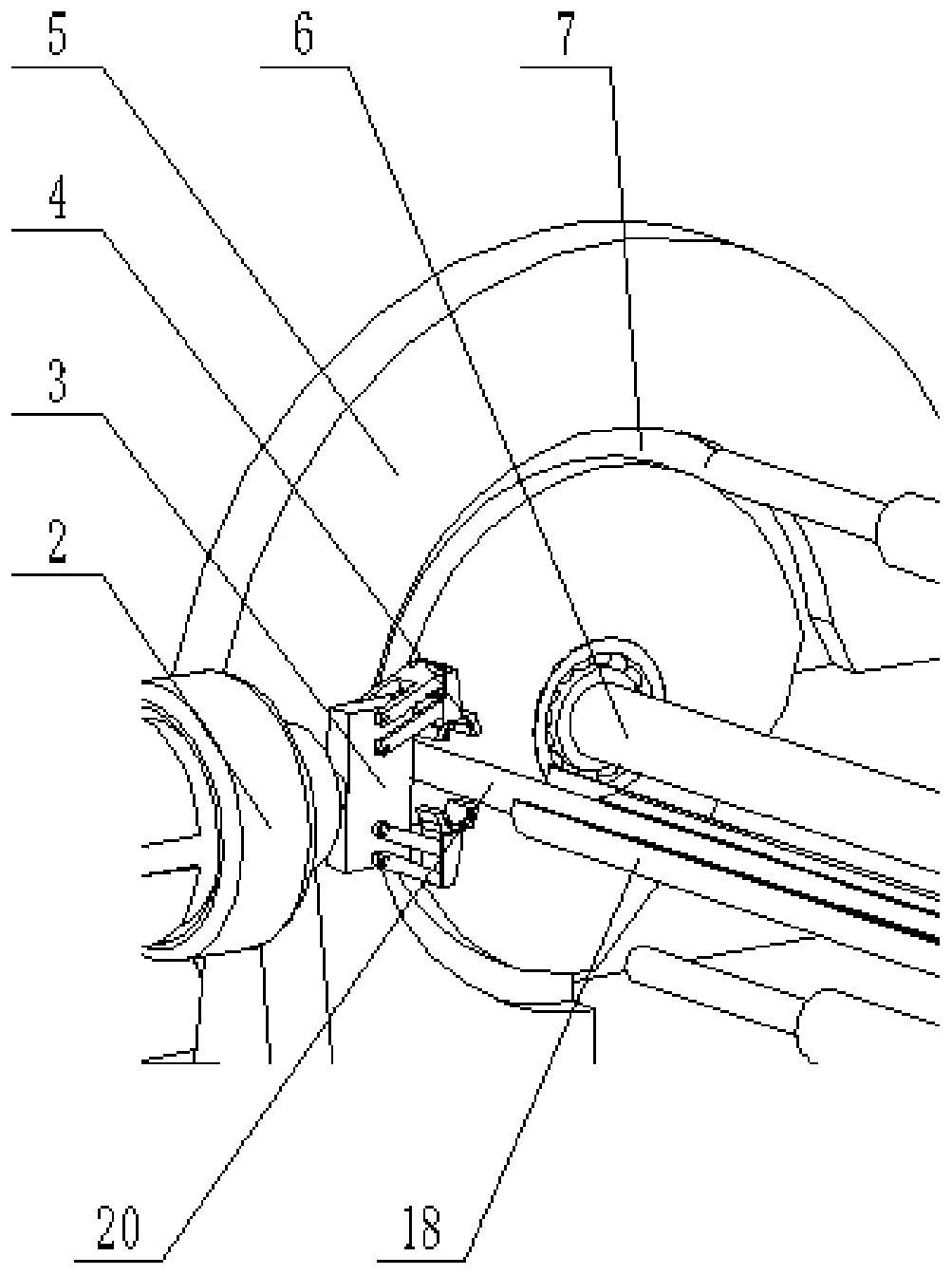

[0019] The present invention is an automatic rewinding and unwinding device for mesh materials, such as figure 1 and figure 2 As shown, including power device, transmission device, winding and unwinding device, and control device. The power device includes an asynchronous motor 1, a cylinder 2, and an air pump 15; the transmission device includes a planetary gear train 9, a central shaft 6, a sliding track 7, a planetary wheel support 10 and other transmission elements; the winding and unwinding device Including rewinding shaft 20, rotating fixture 18, split radial sliding bearing 4, pneumatic clamp 3, horizontal guide rail 19, unwinding mechanical arm unit 21, air pipe 11, rotary joint 12, electromagnetic reversing valve, other pneumatic components and Electric cylinder 13; the control device includes an electrical cabinet 14, a position sensor and other electrical components.

[0020] The power device includes an air cylinder 2 that provides power for the pneumatic clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com