Dynamic membrane sewage direct filtering reactor based on different sewage qualities and operation method

A dynamic membrane and reactor technology, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, membrane technology, etc., can solve problems such as increased coagulant dosage, affecting process operation and maintenance, and increasing treatment costs , to achieve the effect of saving treatment cost, controlling membrane fouling, low cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

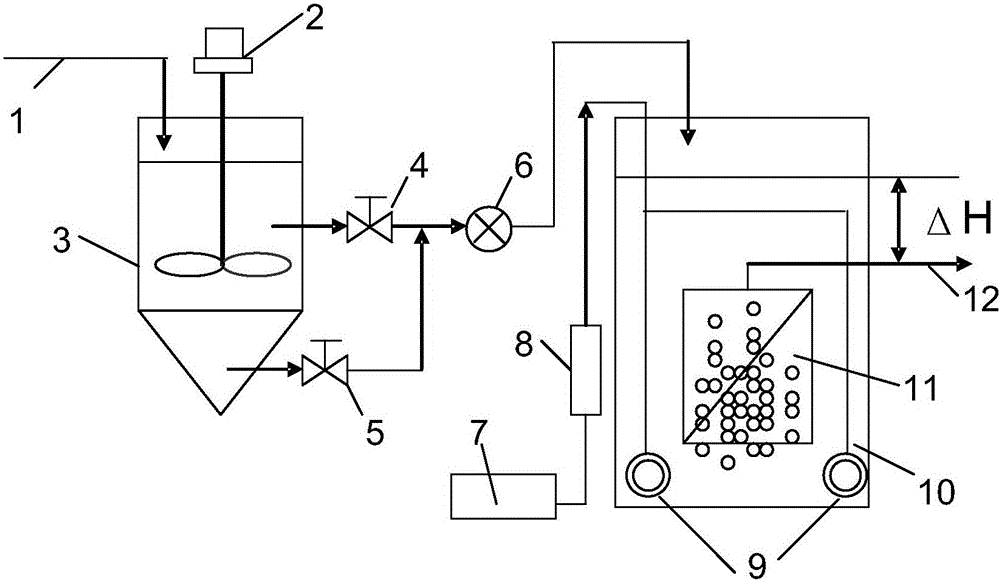

[0046] Such as figure 1 As shown, the high turbidity sewage (turbidity is 300-400NTU) is pumped into the sewage regulating tank 3 through the water inlet pipe 1, the stirring device 2 is started, the electric valve 4 is started (the electric valve 5 is closed), and the sewage is poured into the sewage through the lift pump 6 Dynamic membrane filtration reactor 10, now the aeration device 7 is opened, and the gas flow meter 8 is adjusted to a low aeration rate (1-2m 3 / m 2 h), the sewage passes through the dynamic membrane module 11, and flows to the outlet pipe 12 under the action of the water level pressure difference (10-10.5cm), and the initial produced water returns to the sewage regulating tank 3 due to high turbidity. Below 10NTU, the flux is at (20-80L / m 2 h). After the dynamic film is formed, adjust the gas flow meter 8 to a high aeration rate (4-6m 3 / m 2 h), continuously flush the surface of the membrane module, and the reactor runs stably for more than 6 hours. ...

Embodiment 2

[0048] Such as figure 1 As shown, the low turbidity sewage (turbidity is 70NTU) is pumped into the sewage regulating tank 3 from the water inlet pipe 1, the stirring device 2 is closed, the electric valve 5 is started (the electric valve 4 is closed), and the sedimentation sewage (the turbidity reaches 350-450NTU left and right) into the dynamic membrane filtration reactor 10 through the lifting pump 6, and now the aeration device 7 is opened, and the gas flow meter 8 is adjusted to a low aeration rate (1-2m 3 / m 2 h), the sewage passes through the dynamic membrane module 11, and flows to the outlet pipe 12 under the action of the water level pressure difference (10-10.5cm), and the initial produced water returns to the sewage regulating tank 3 due to the high turbidity. After 30-40 minutes of such circulation, the turbidity Below 10NTU, the flux is at (20-80L / m 2 h). After the dynamic film is formed, start the stirring device 2 to ensure that the sewage in the sewage regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com