Automatic opening machine for hazelnut

An opening machine, automatic technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of simple operation tools, backward processing methods, high labor density, etc., and achieves compact and reasonable overall structure, high opening rate of hazelnuts, and high production efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

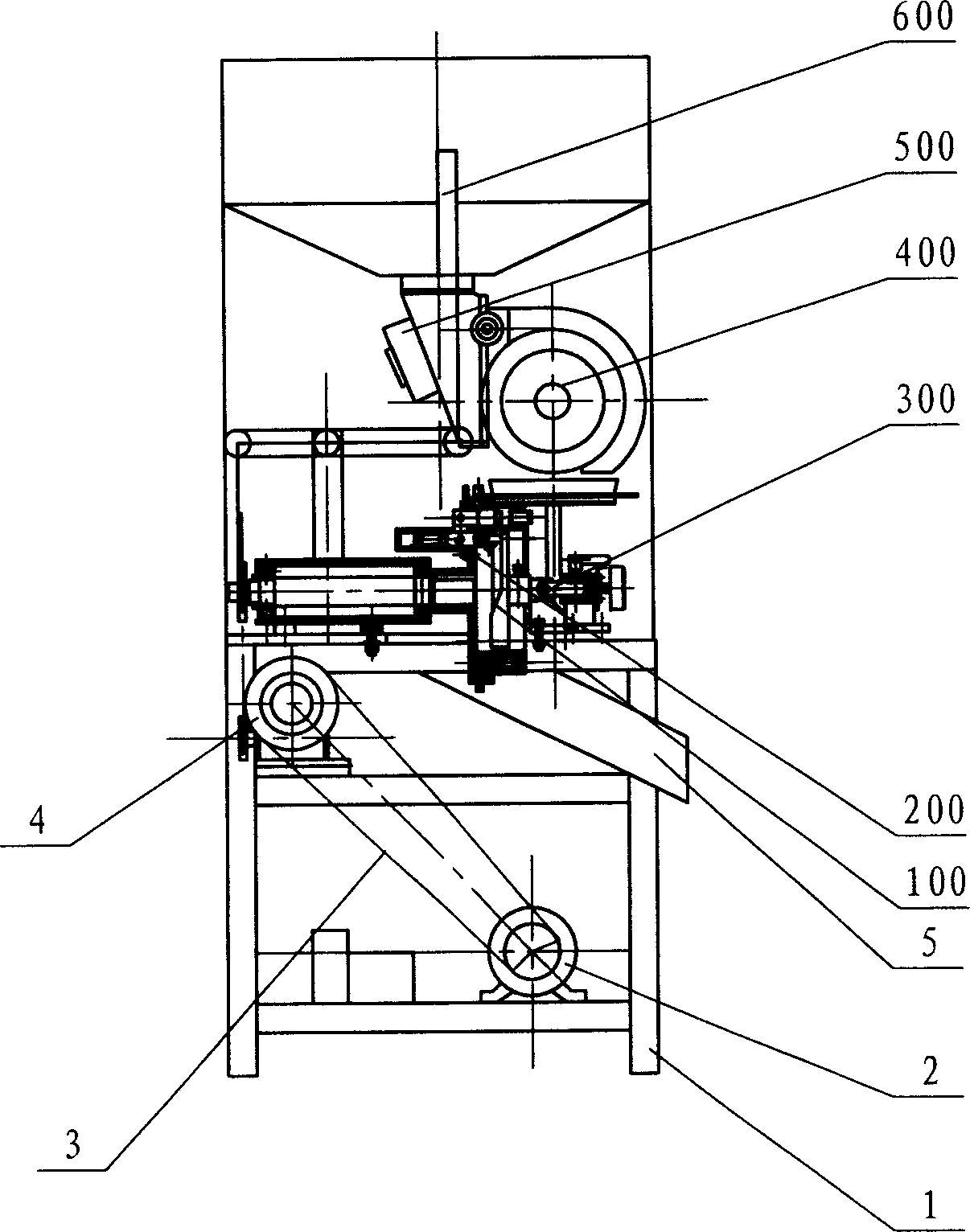

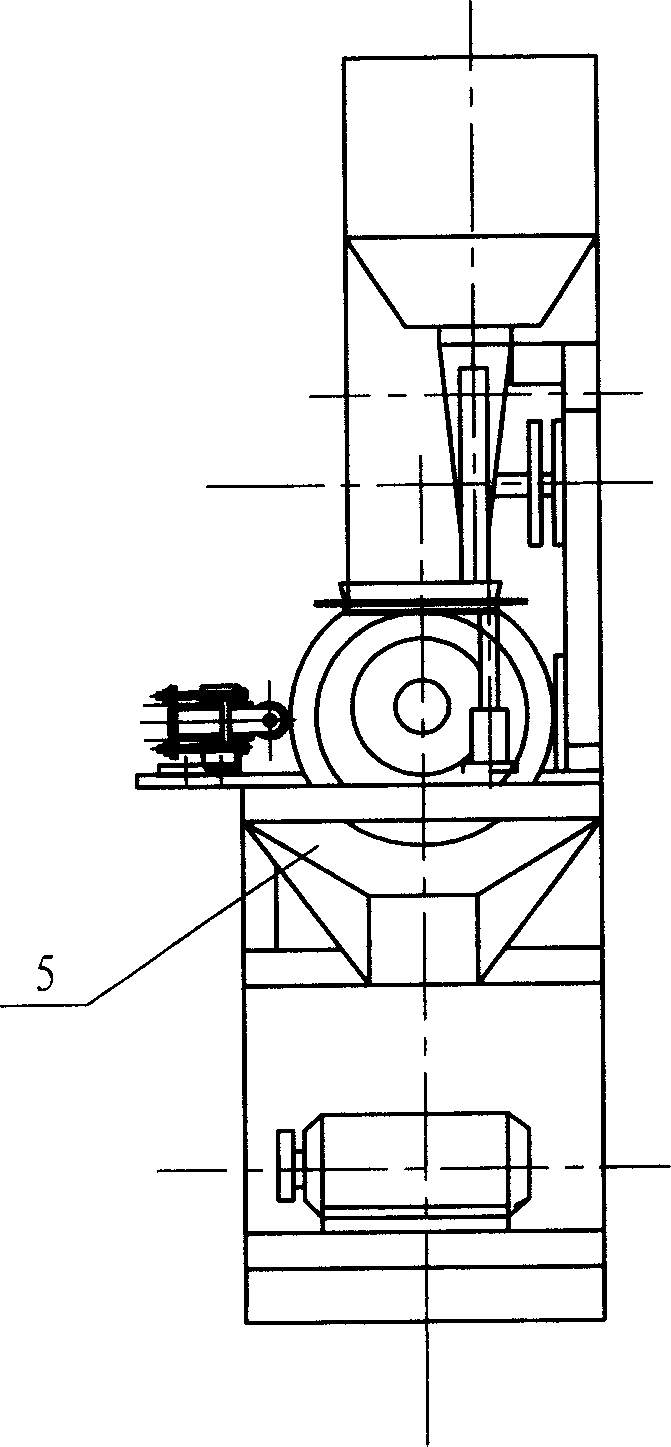

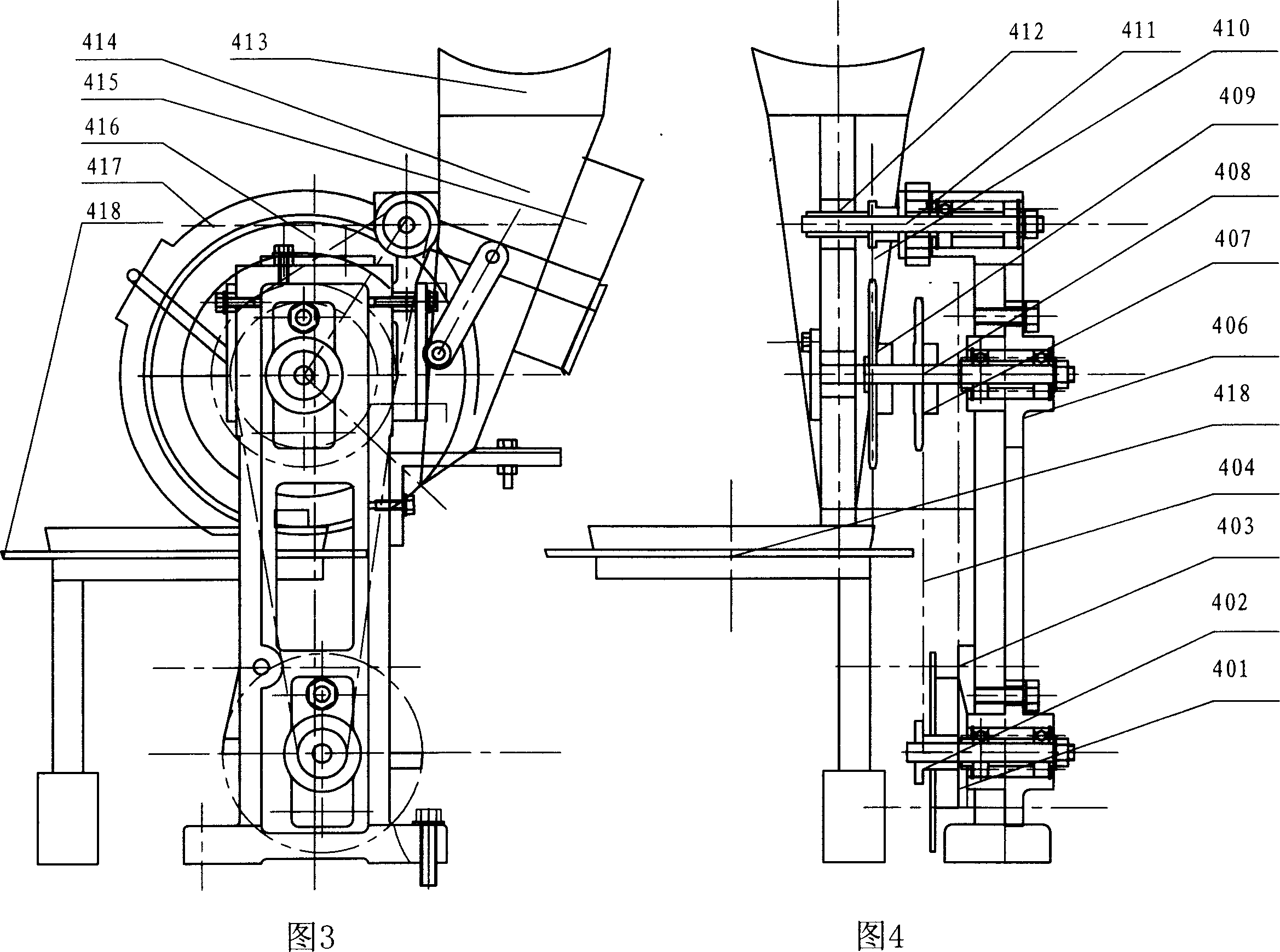

[0030] Depend on Figure 1-11 As shown, 1 in the figure is a frame, 2 is a motor, 4 is a reducer, and 100 in the figure is a wheel-type rotary extrusion device (the specific structure is defined by Figure 10 shown), 200 is an automatic compensator device (the specific structure is determined by Figure 10 shown), 300 is a double positioning locking device (the specific structure is determined by Figure 11 shown), 400 is the automatic feeding device for the circular dividing plate (the specific structure is shown in Figure 3-4), and 500 is the crankshaft feeding device (the specific structure is shown in Figure 3-4). Figure 7-8 shown), 600 is a crank-link feeder device (the specific structure is given by Image 6 shown). A storage box 413 and a conical feeder 414 are arranged on the upper part of the frame 1 from top to bottom, and a rotating circular dividing plate 416 with holes distributed along one side is vertically arranged at the discharge port at the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com