Tobacco topping sprouting inhibition detection control system based on machine vision

A machine vision and detection system technology, applied in general control systems, control/adjustment systems, computer control, etc., can solve problems such as the inability of topping efficiency to meet the requirements of tobacco production and the immature tobacco topping technology, and achieve intelligent improvement. level, speed up the process of intelligentization, and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]The following specific embodiments are used to illustrate the present invention, but are not used to limit the scope of the present invention.

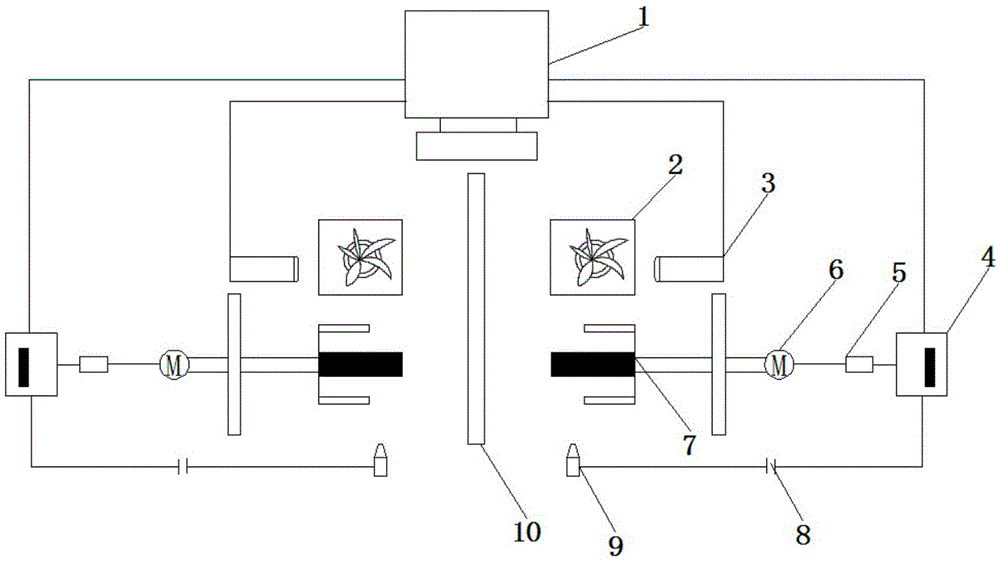

[0041] The control system hardware part involved in the present invention is all commercially available as industrial control machine, camera, single-chip microcomputer, stepper motor driver, stepper motor, electromagnetic valve; The industrial control machine used as the present embodiment is Suoqi T1217 industrial control machine, The camera model is an ordinary civilian camera with a resolution of 640*480, the single-chip microcomputer is 89C52R single-chip microcomputer, the stepping motor is 86BYGH450C-02 stepping motor, and the stepping motor driver is CF20611D driver. Various control modules involved in the present invention can be programmed according to the prior art, and keil software is used to complete the programming of related control programs to realize their control functions.

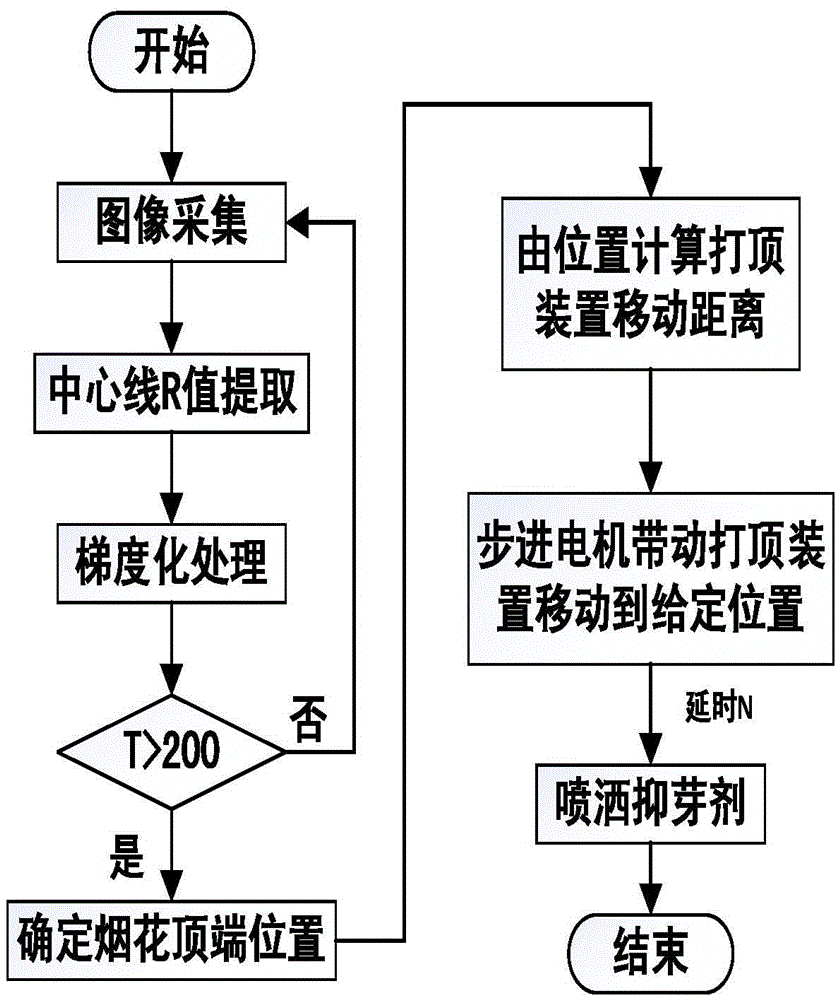

[0042] Such as figure 2 Shown is...

Embodiment 2

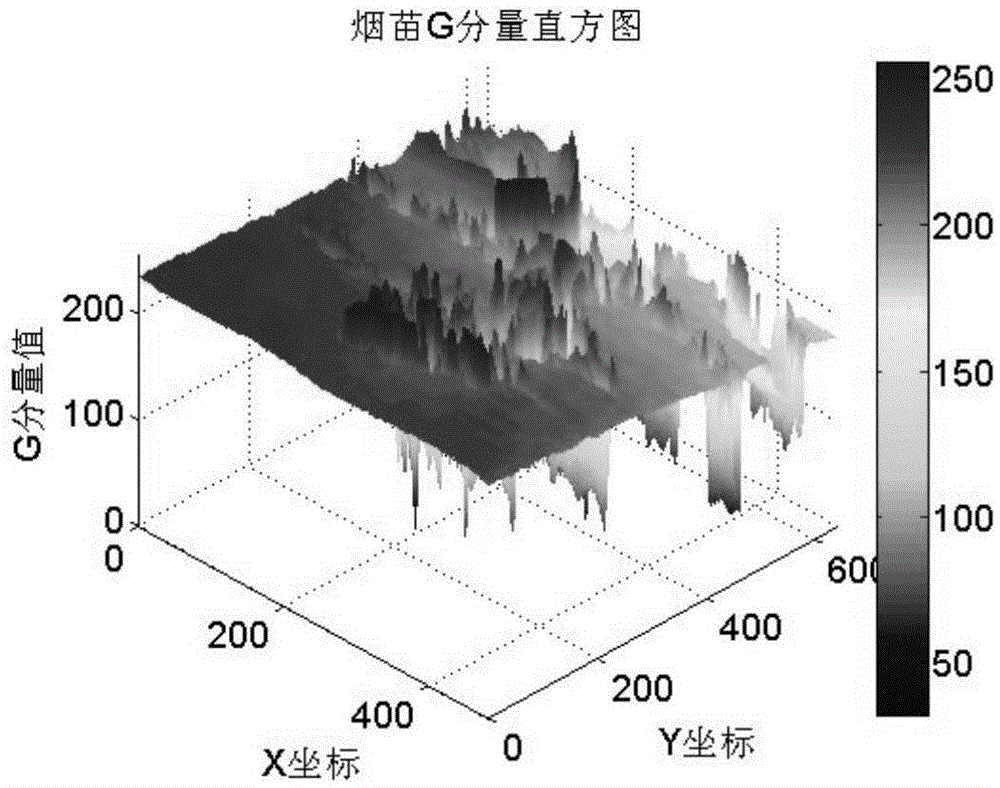

[0058] The R channel value and T>200 are selected as the verification basis for judging the presence of fireworks information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com