Aluminum bar casting monitoring alarm device

A technology of monitoring and alarming, aluminum rods, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as hidden dangers of safety production photos, aluminum leakage from dummy heads, etc., to prevent safety accidents and prevent overflow. The effect of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

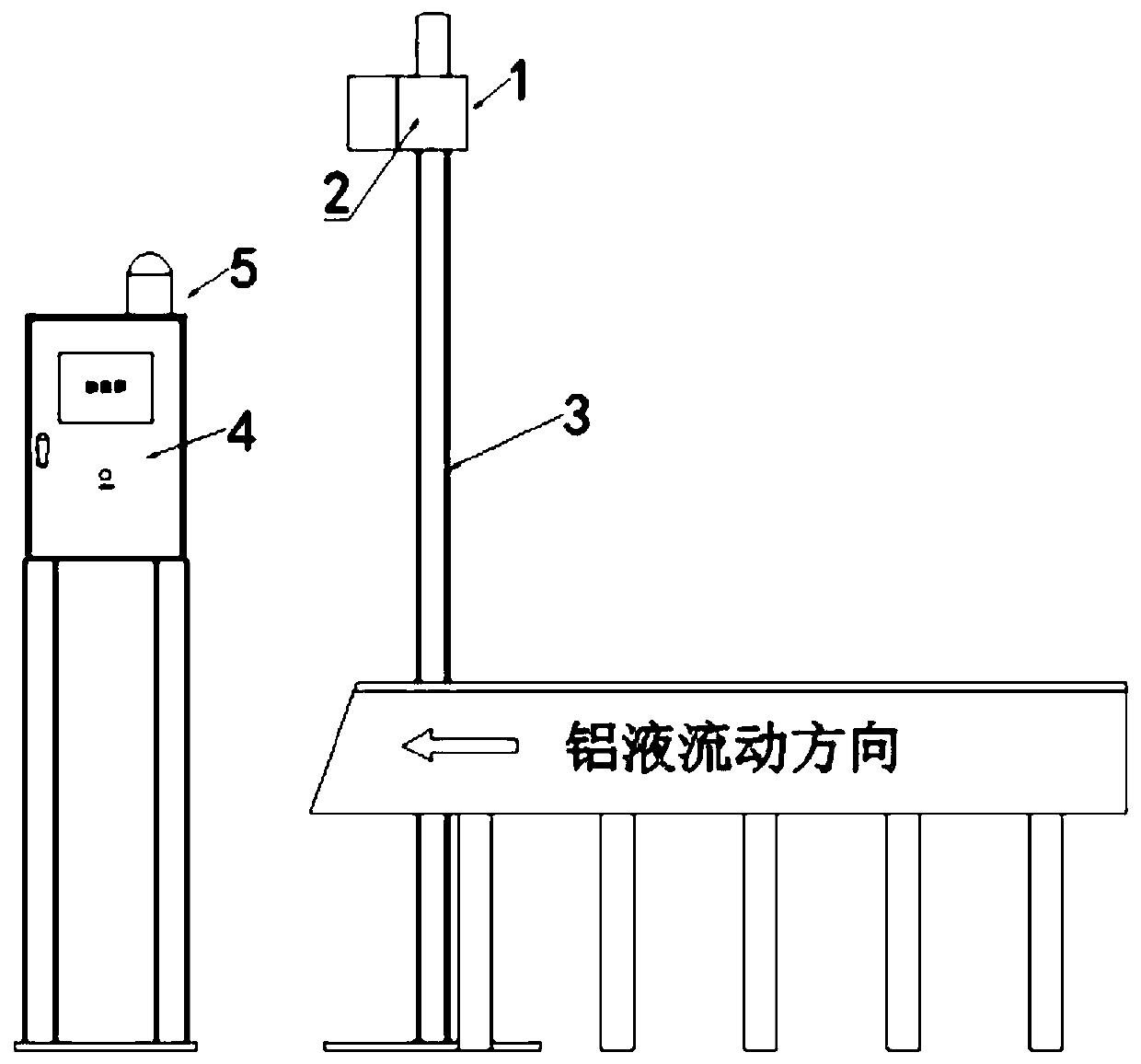

[0012] Such as figure 1 As shown, the aluminum rod casting monitoring and alarm device of the present invention is composed of a laser range finder installation box 1, a laser range finder 2, a laser range finder installation and fixing frame 3, a system control cabinet 4, and an acousto-optic alarm lamp 5; The instrument 2 is installed in the installation box 1 of the laser rangefinder, and the installation box 1 of the laser rangefinder is fixed on the installation frame 3 of the rangefinder. Installed at the entrance of the launder flowing into the casting mold plate, the laser range finder 2 is located above the launder, and the laser point is aligned with the middle of the launder.

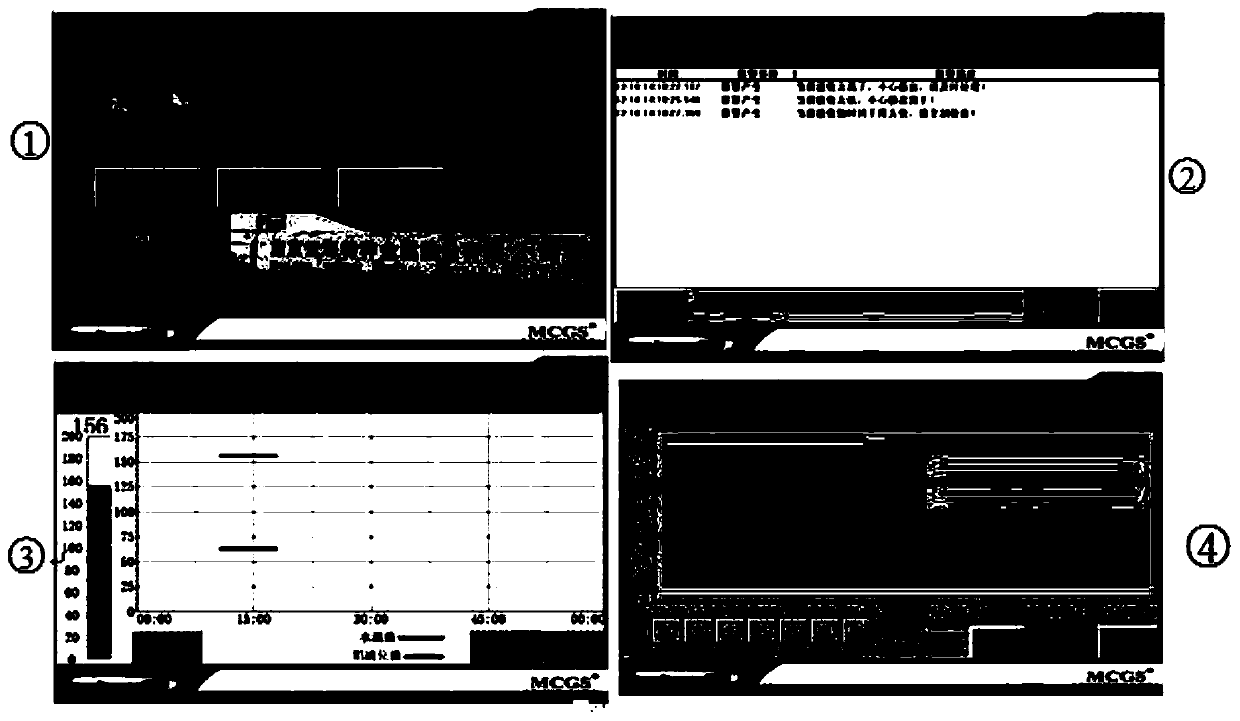

[0013] Such as figure 2 , the aluminum rod casting monitoring alarm device of the present invention, its touch screen system is characterized in that: No. 1 window is the main page...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com