Monitoring tray for tower crane

A pallet and tower crane technology, applied to cranes, etc., can solve problems such as no function and use value, inconsistent quality of whereabouts scheduling, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

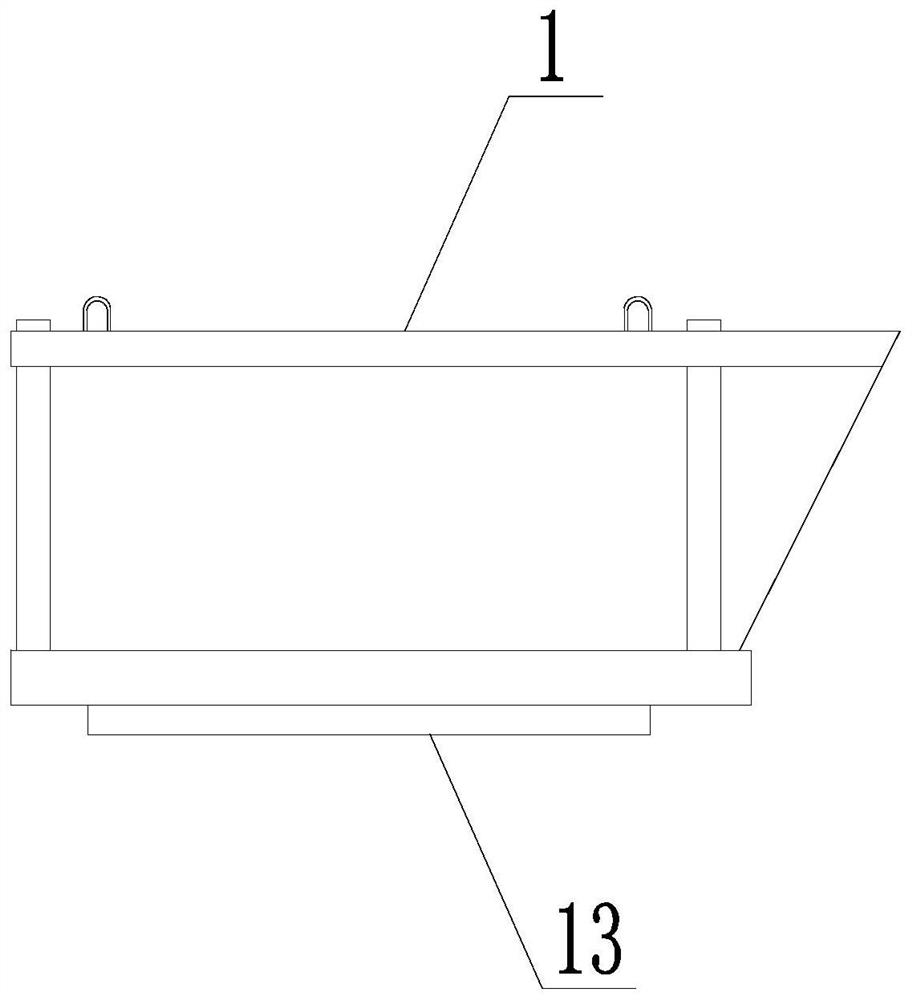

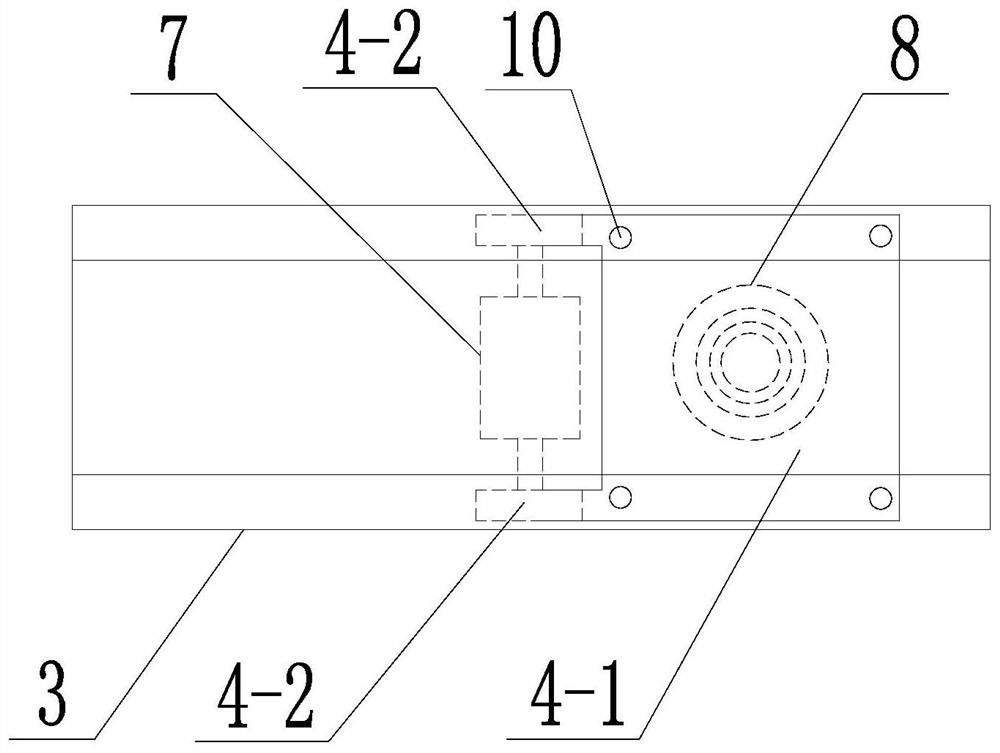

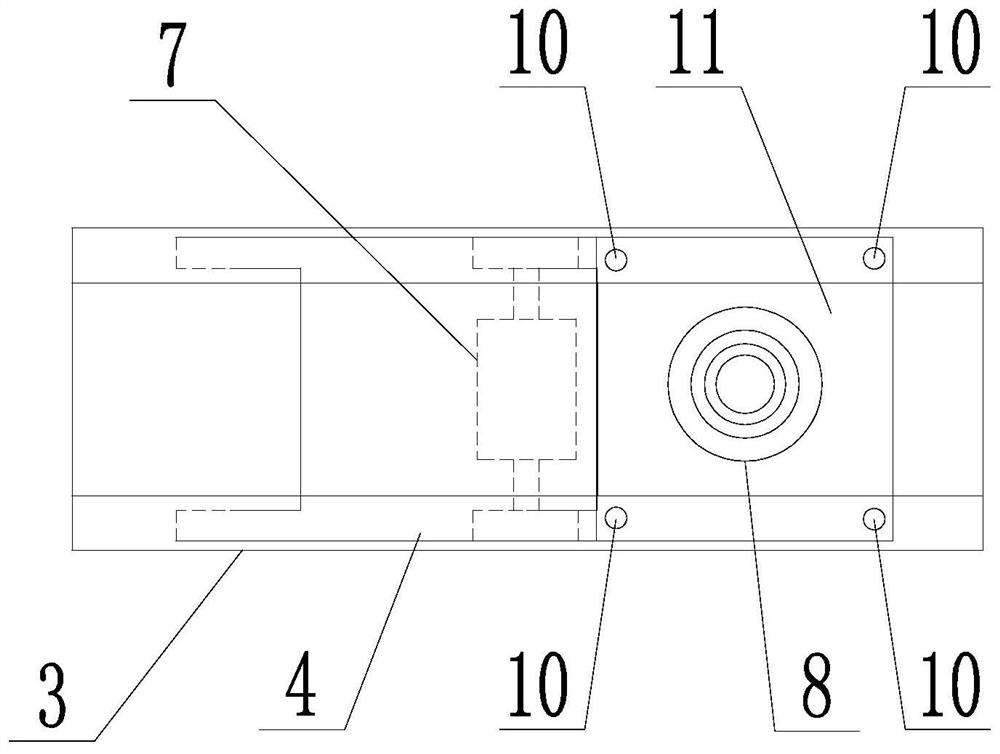

[0035] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 9 and Figure 11 Describe this embodiment, this specific embodiment adopts the following technical solutions: this embodiment includes a tray body 1 and a monitoring assembly, and the monitoring assembly includes several monitoring units 2, and several monitoring units 2 are arranged on the tray body 1 Each monitoring unit 2 includes a housing 3, a first shield assembly, a camera 8, a controller 9 and a plurality of photosensitive sensors 10, the first shield assembly includes a cover plate 4, a rack 5, a gear 6 and a motor 7, The shell 3 is a box body and its bottom is processed with an opening 11 matching the first blocking assembly, the cover plate 4 is arranged at the opening 11, the motor 7 is fixedly installed in the shell 3, the output shaft of the motor 7 is sleeved with a gear 6, The upper end of the rack 5 meshes with the gear 6, the lo...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment is a further limitation of Embodiment 1, and the motor 7 is a biaxial motor.

[0039] In this embodiment, the motor 7 is an existing product.

[0040]In this embodiment, the motor 7 is preferably a small two-axis motor. Correspondingly, the motor 7 is correspondingly provided with two gears 6, and each gear 6 is correspondingly provided with two racks 5, and the two racks 5 are arranged on the cover plate 4 in parallel. both sides of the upper end.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or Embodiment 2. In this embodiment, the cover plate 4 is a rectangular plate.

[0042] In this embodiment, in order to save the weight of the cover plate 4 and facilitate operation, another structural form of the cover plate 4 is as follows:

[0043] The cover plate 4 includes a main board body 4-1 and two sub-board bodies 4-2, and the two sub-board bodies 4-2 are arranged side by side at one end of the main board body 4-1, and the two sub-board bodies 4-2 are strip-shaped As for the board body, each sub-board body 4-2 is correspondingly provided with a rack 5, and each sub-board body 4-2 is fixedly connected with its corresponding rack 5.

[0044] In this embodiment, the number of cover plates 4 is two, that is, the two first shielding components cooperate with each other to realize the operation process of quickly shielding or exposing the camera 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com