Mover module and linear motor

A technology of linear motors and components, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problems of reducing the repeatability of motor positioning accuracy, damage to the insulation layer, and occupying space for coil windings, so as to ensure performance reliability and The effects of running stability, reducing the difficulty of assembly and manufacturing, and improving the compactness of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

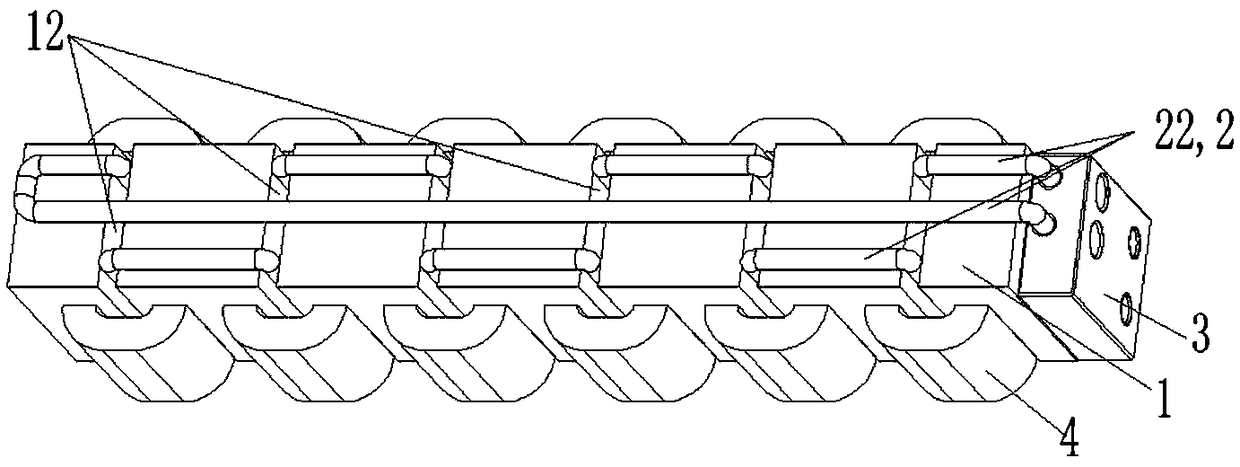

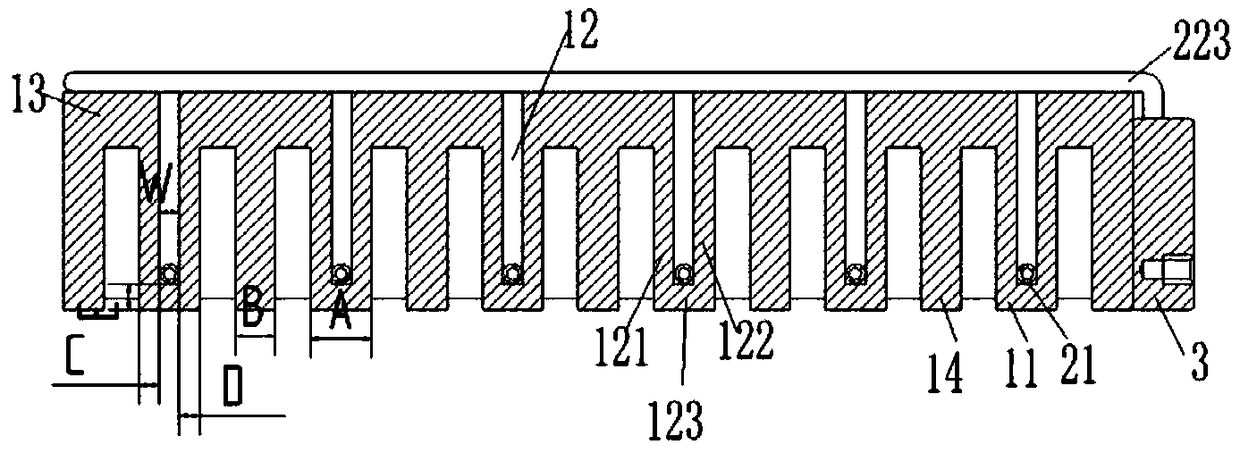

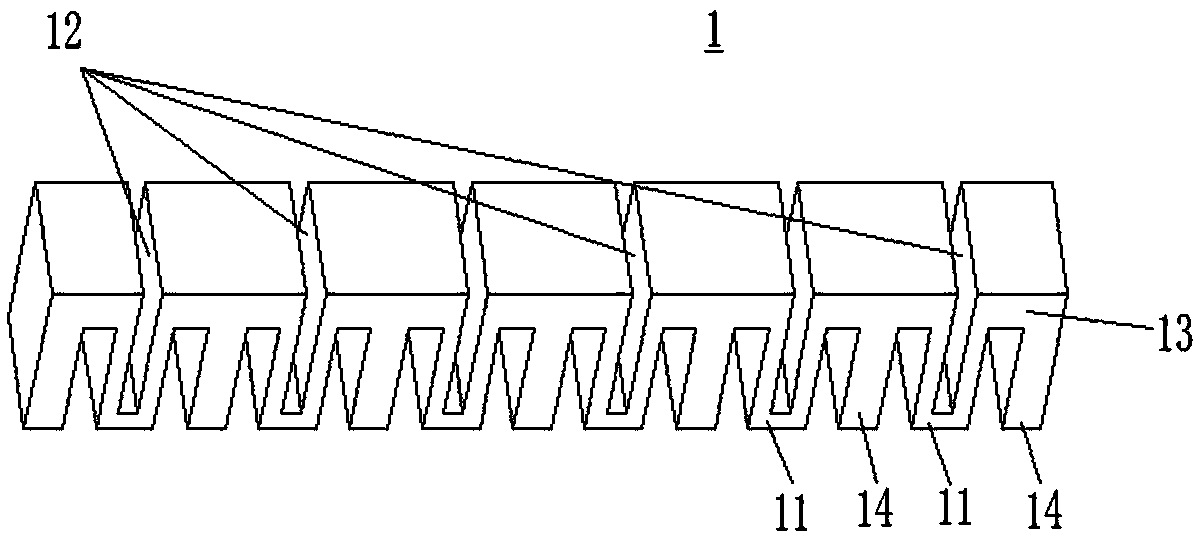

[0025] see Figures 1 to 6 As shown, according to an embodiment of the present invention, a mover assembly is provided, including a mover core 1, the mover core 1 has a first tooth portion 11, and the inner side of the first tooth portion 11 is configured to accommodate The tank 12 also includes a cooling pipeline 2 , and the cooling pipeline 2 includes a tooth pipe section 21 , and the tooth pipe section 21 is installed in the receiving tank 12 . In this technical solution, the cooling pipeline 2 relatively independent from the mover iron core 1 is used to cool the first tooth part 11 of the mover iron core and the coil winding 4 wound outside it in a targeted manner, which can greatly improve the The compact structure of the moving sub-assembly reduces the difficulty of assembly and manufacturing of the moving sub-assembly, effectively controls the temperature rise of the moving sub-assembly and even the linear motor, and is conducive to ensuring the performance reliability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com