Precision machine tool spindle cooling system and centralized heat dissipation method based on heat conduction channel

A technology of precision machine tools and heat dissipation methods, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of limited cooling efficiency, increased difficulty and cost, and achieve temperature rise and thermal deformation, improve The effect of heat dissipation intensity and good engineering application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention will be further described:

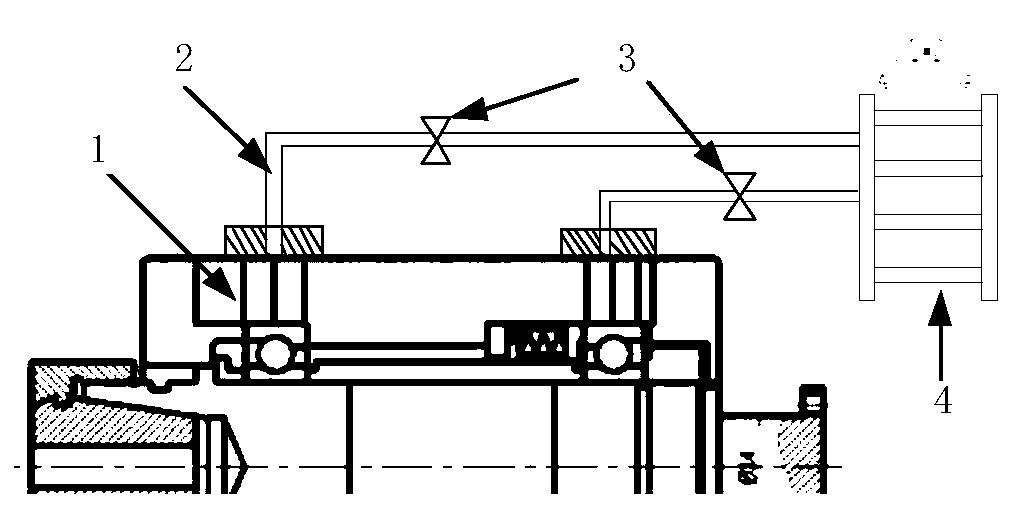

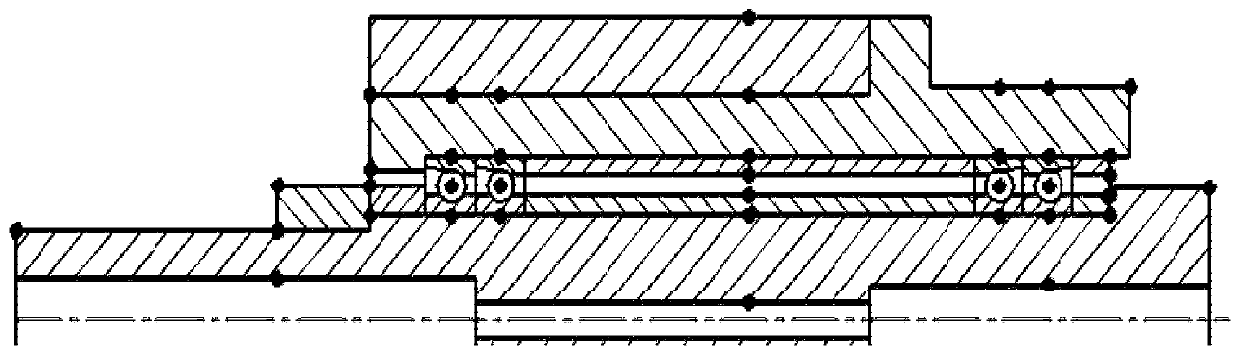

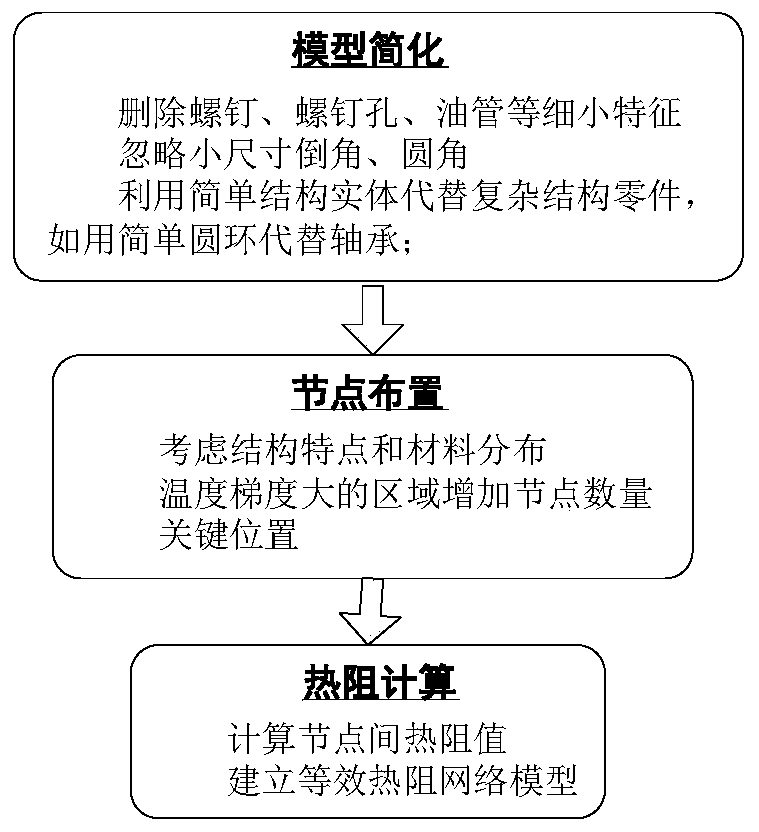

[0045] Such as figure 1 As shown, a precision machine tool spindle cooling system based on heat conduction passages of the present invention includes heat conduction passages 1 , cooling pipes 2 , valves 3 and cooling devices 4 . The heat conduction channel 1 is constructed along the radial direction according to the temperature field distribution at the bearings at both ends of the mechanical spindle. The basic principle of construction is that the heat conduction channel 1 must be constructed at the place with the highest temperature at both ends of the mechanical spindle. The higher the temperature, the denser the arrangement of the heat conduction channels. The number of is proportional to the temperature at the bearing, and the specific arrangement can be determined by formula (3) and the basic basis of the specific arrangement.

[0046] The basic basis for the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com