Barrel-hammer-following circulating water cooling system

A circulating water cooling and barrel hammer technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as leakage, inability to change water chamber capacity and heat dissipation efficiency, and inability to replenish cooling water in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

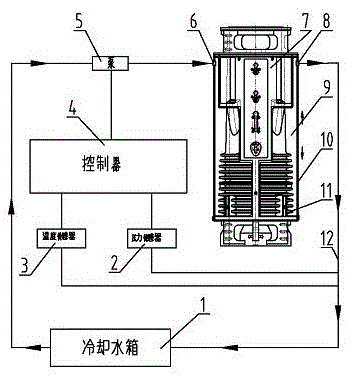

[0024] exist figure 1 In the shown cylinder-hammer accompanying circulating water cooling system, the lower cylinder block 7 has a cylindrical structure, and a water cavity outer wall 10 is sleeved outside the lower cylinder block 7; a closed cooling water cavity is formed between the lower cylinder block 7 and the water cavity outer wall 10 9. A water inlet 6 and a water outlet 8 for circulating cooling water in and out are provided on the outer wall 10 of the water cavity, and the water inlet 6 and the water outlet 8 communicate with the cooling water cavity 1 . Between the water inlet 6 and the outlet water 8 of the cooling water chamber 1 , a cooling water tank 1 and a circulating pump group 5 are connected in series through a cooling water pipe 12 . In this embodiment, the circulating pump group 5 only includes one water pump, which is a centrifugal pump, and the cooling water pipe 12 is a common flexible water pipe capable of withstanding pressure.

[0025] When working...

Embodiment 2

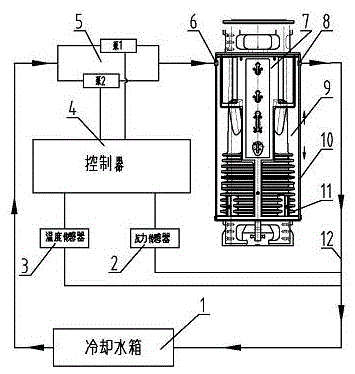

[0028] like figure 2 As shown, this example is the same except that the circulating pump set is different from the above-mentioned embodiment. In this embodiment, the circulating pump group 5 includes two water pumps in parallel with each other. According to the water temperature and water pressure at the water outlet, the two water pumps can work simultaneously, or either one can work alone or alternately.

Embodiment 3

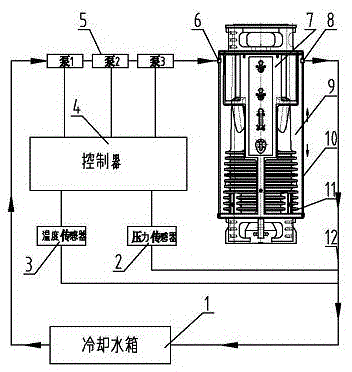

[0030] like image 3 As shown, this embodiment is the same except that the circulating pump group is different from that of Embodiment 1. In this embodiment, the circulating pump group includes three water pumps connected in series with each other, and each water pump is electrically connected to the controller 4 in phase. Similarly, in this embodiment, the number of pumps connected in series is not limited to three, but may also be two, four or more, that is, the number of pumps connected in series is at least two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com