High-speed high-precision motorized spindle for lathe, material clamping method and material loosening mechanism

A technology of clamping mechanism and electric spindle, applied in clamping, metal processing mechanical parts, supports, etc., can solve problems such as affecting processing quality and large vibration, improve production quality and processing efficiency, improve service life, and optimize the overall The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the examples.

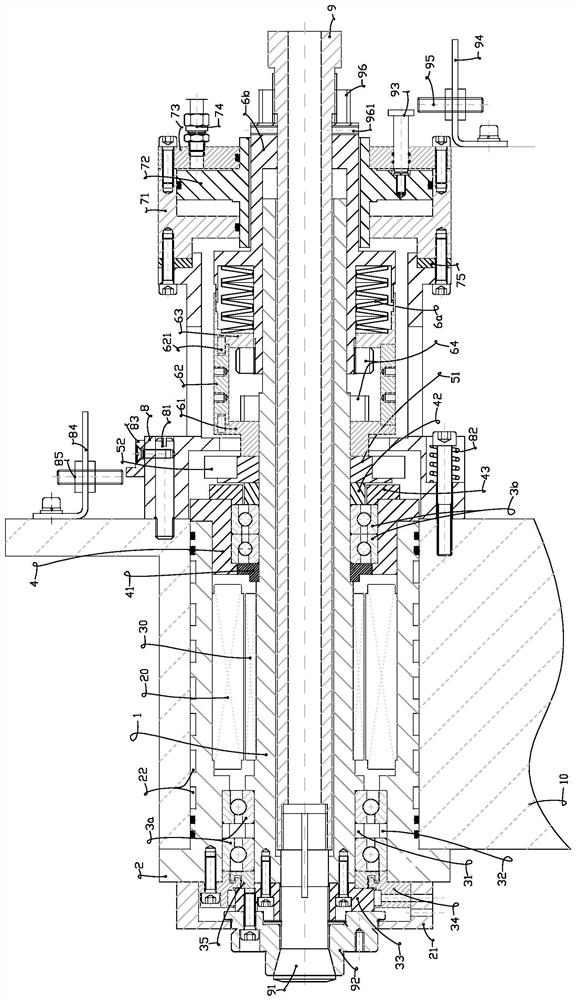

[0059] Such as figure 1 A high-speed and high-precision electric spindle for a lathe is shown, including a spindle seat 10, a spindle core 1, a (motor) stator 20 and a (motor) rotor 30 associated with the spindle core 1, and a spindle sleeve Barrel 2, pull rod 9, collet 91, adapter 92, clamping mechanism and loosening mechanism.

[0060] The stator 20 is fixed on the inner wall of the main shaft sleeve 2 , and the rotor 30 is arranged outside the main shaft core 1 . The stator 20 and the rotor 30 are respectively installed in the middle positions of the main shaft sleeve 2 and the main shaft core 1 . The stator 20 and the rotor 30 are driven by an external driver, that is, the electro-spindle is driven to rotate through electromagnetic induction to provide rotational power for it.

[0061] With the help of the solution of this patent, the formed electric spindle device can choos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com