Heat dissipation method of bearing having heat dissipation and lubrication functions

A heat dissipation method and bearing technology, which is applied in the direction of shafts and bearings, rotating bearings, bearings, etc., can solve the problems of bearing damage, cumbersome operation, and low efficiency, and achieve the effects of prolonging service life, controlling temperature rise, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

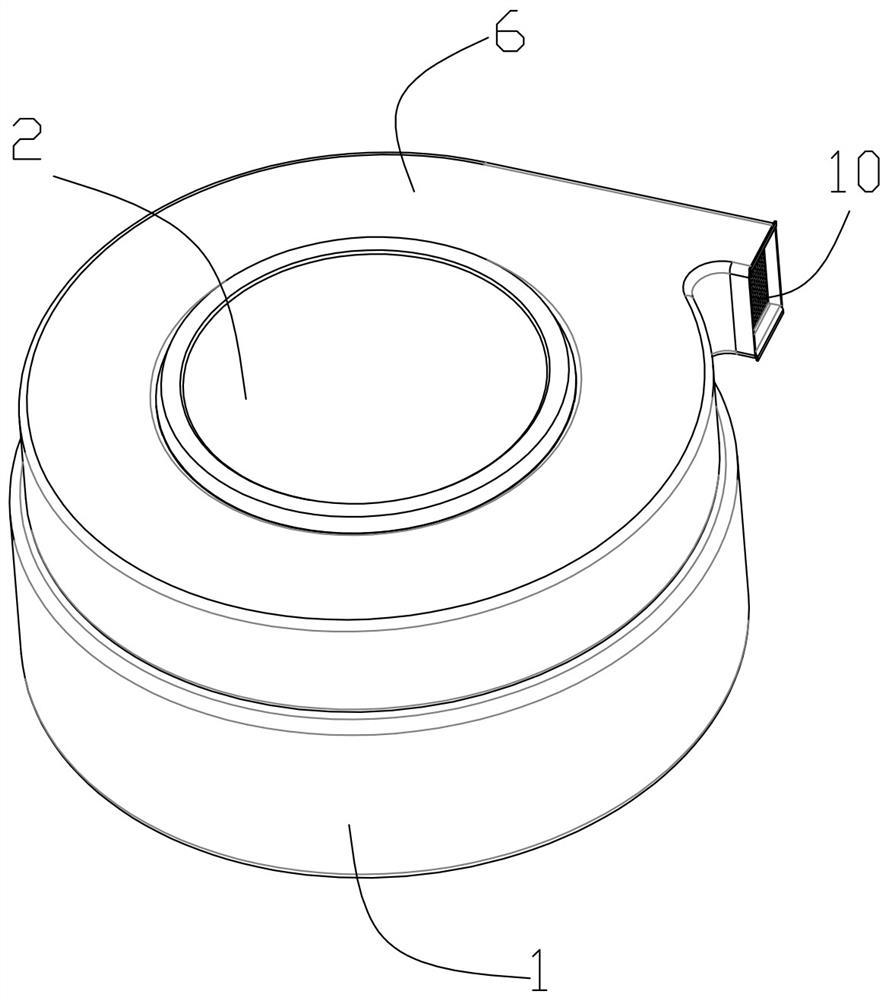

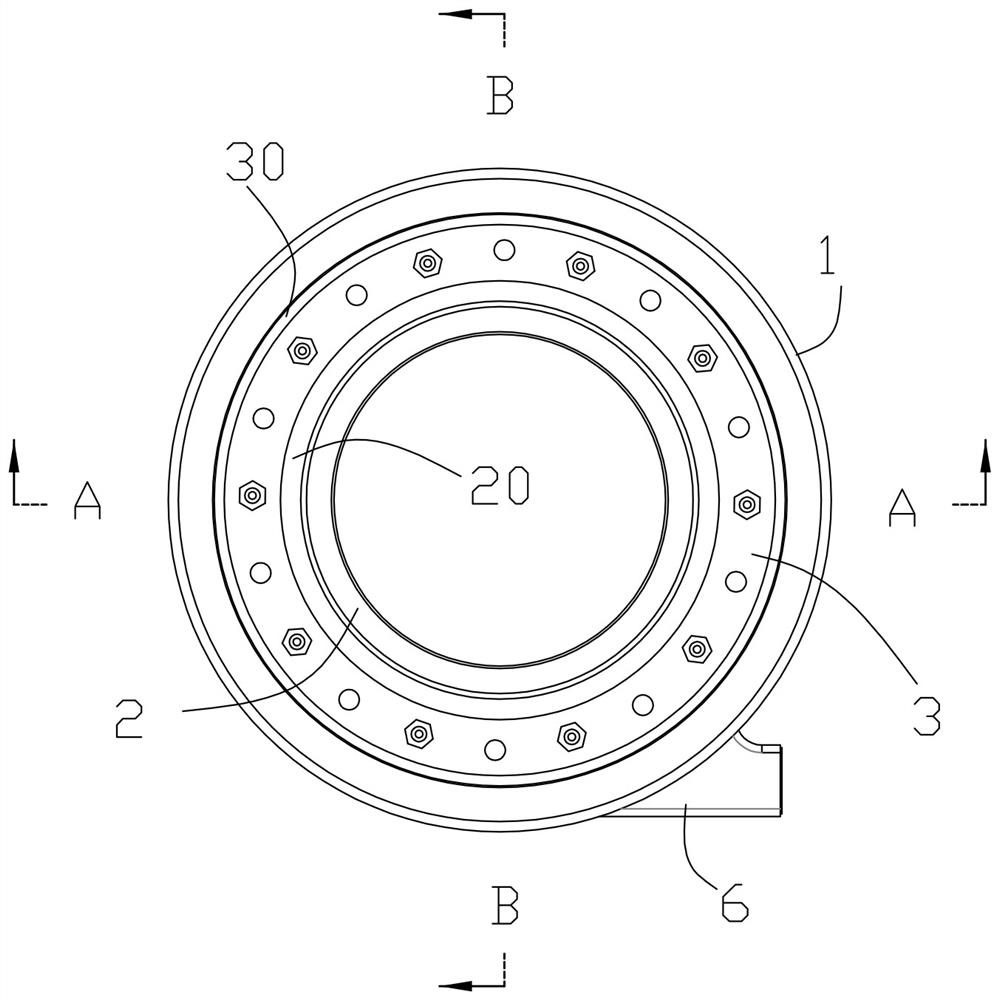

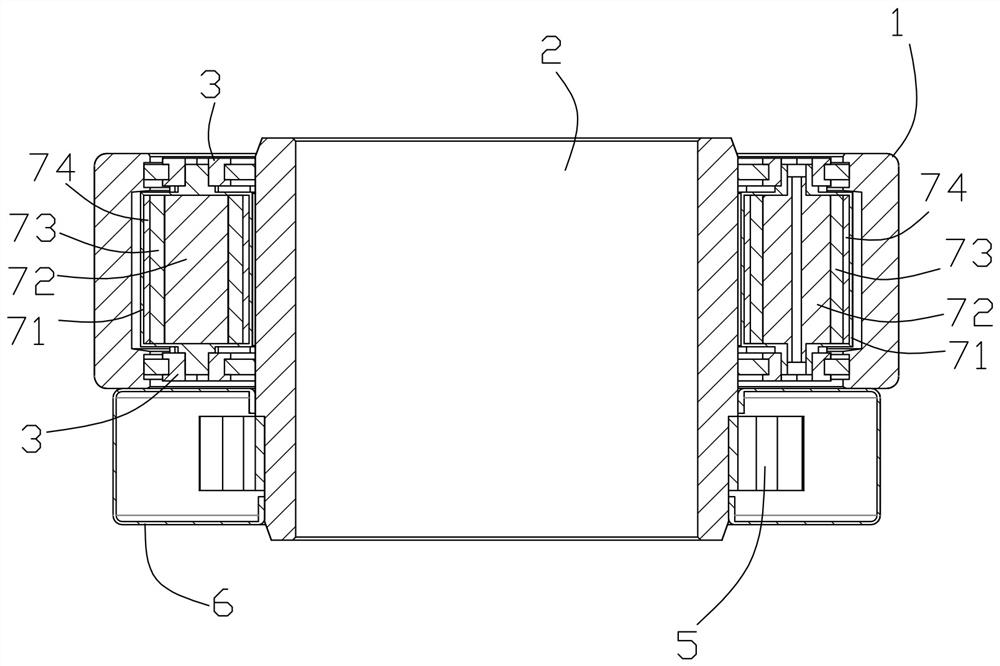

[0028] Such as Figure 1 to Figure 13 As shown, the heat dissipation method of a bearing with heat dissipation and lubrication functions described in this embodiment includes an outer ring 1, an inner ring 2 and a cage 3, and the cage 3 is arranged on the inner ring 2 and the outer ring 1 Between them, several rolling elements 4 are rotated at equal intervals on the cage 3, the length of the inner ring 2 is greater than that of the outer ring 1, and the inner and outer walls of the cage 3 correspond to the inner ring 2 and the outer ring respectively. 1 sealing fit, the free end of the inner ring 2 is fixedly covered with a compressor impeller 5, and also includes an airflow cover 6, the airflow cover 6 covers the compressor impeller 5 and is fixed on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com