Determination method of lead screw preload based on thermal error and temperature rise weighting

A preload, thermal error technology, applied in metal processing equipment, metal processing mechanical parts, electrical program control, etc., can solve the problem of shortening the service life, without considering the influence of the lead screw preload thermal error bearing temperature rise, acceleration Bearing wear and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] Taking the X-axis of a certain type of vertical machining center as an example, the embodiment of the present invention will be described in detail. The X-axis stroke of the machining center is 0~-500mm, and the maximum feed speed is 32000mm / min.

[0045] The first step, the thermal behavior test of the feed shaft under typical working conditions

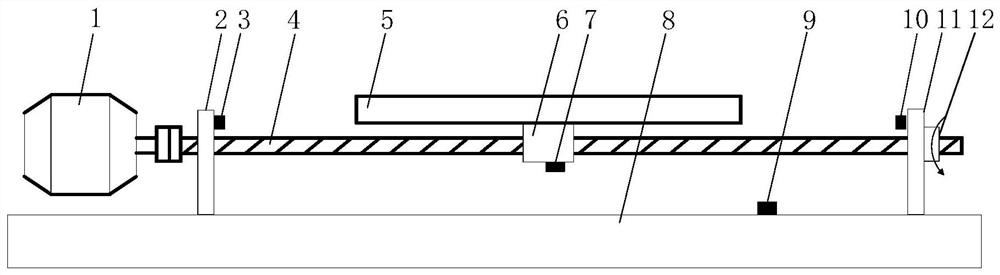

[0046]The first temperature sensor 3 is arranged on the front bearing 2 of the feed system, the second temperature sensor 7 is arranged on the nut 6, the third temperature sensor 10 is arranged on the rear bearing 11 of the feed system, and the fourth temperature sensor 9 is arranged On the bed 8 near the leading screw.

[0047] The machining center under test is for the consumer electronics industry, and the typical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com