Electric vehicle-mounted complete closed switch reluctance motor

A switched reluctance motor, a closed technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems that affect the working efficiency and service life of the driving motor, the heat dissipation at the end of the stator winding is not good, and the working efficiency of the motor is reduced. , to achieve the effect of solving poor heat dissipation, large torque and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

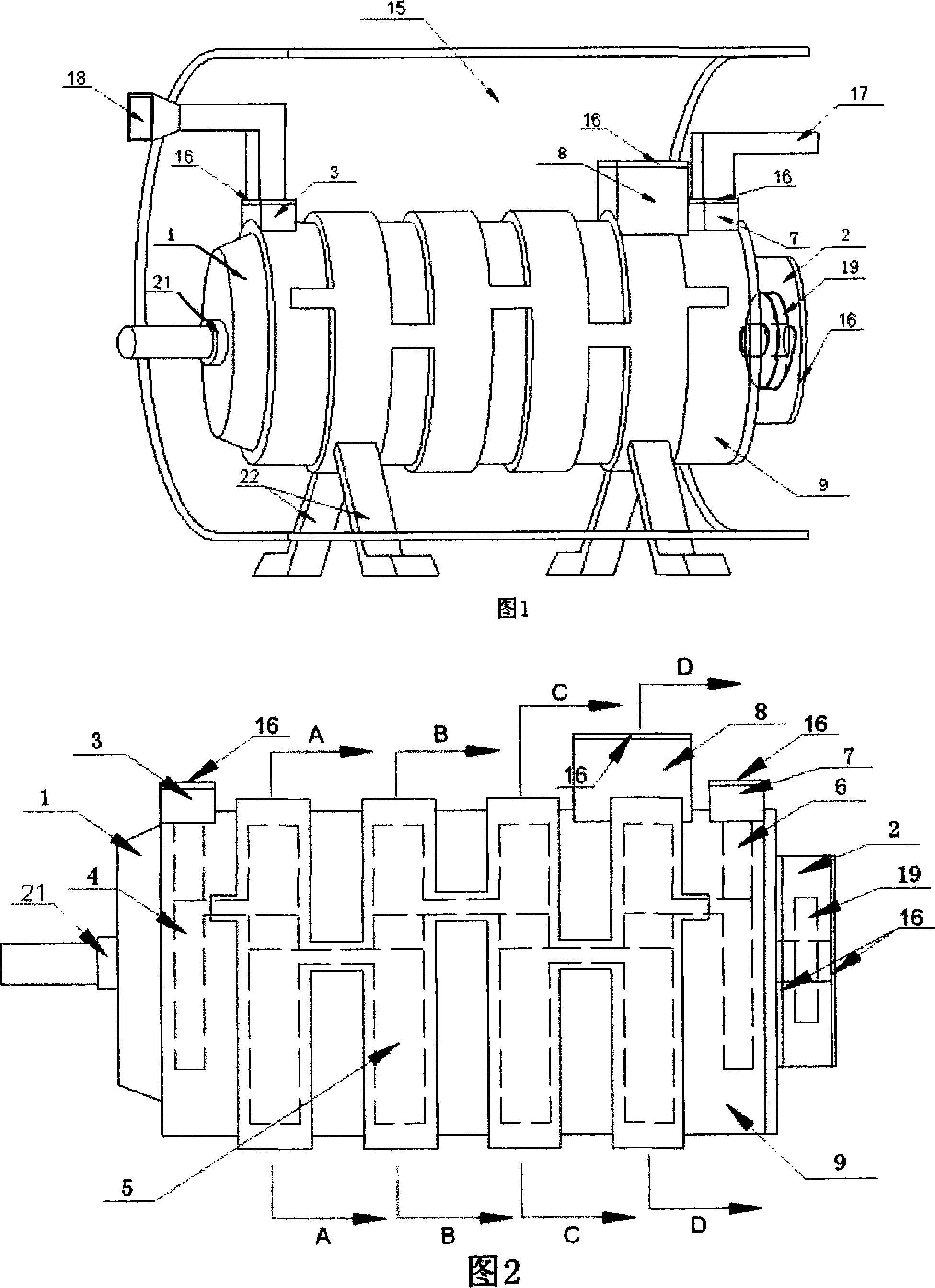

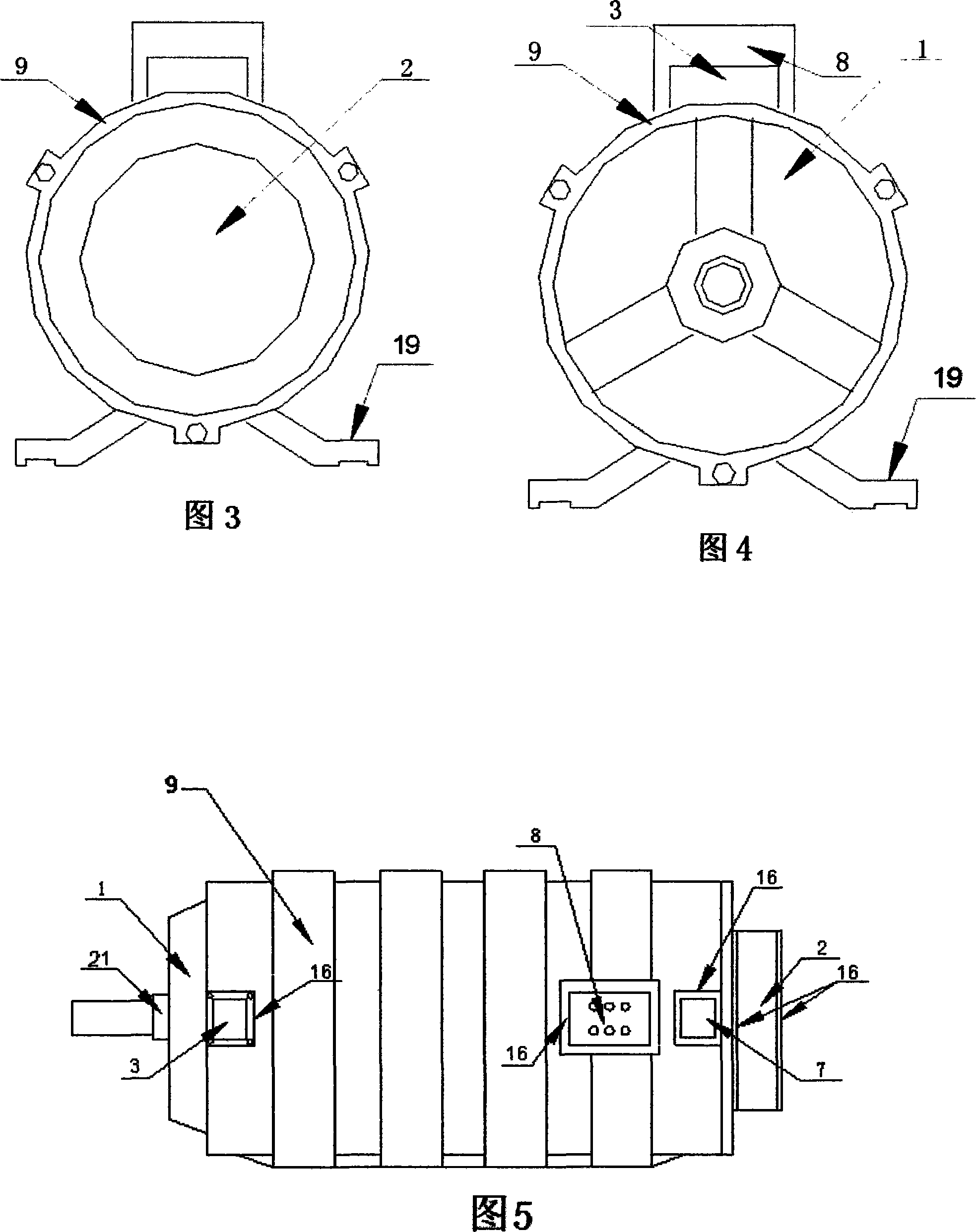

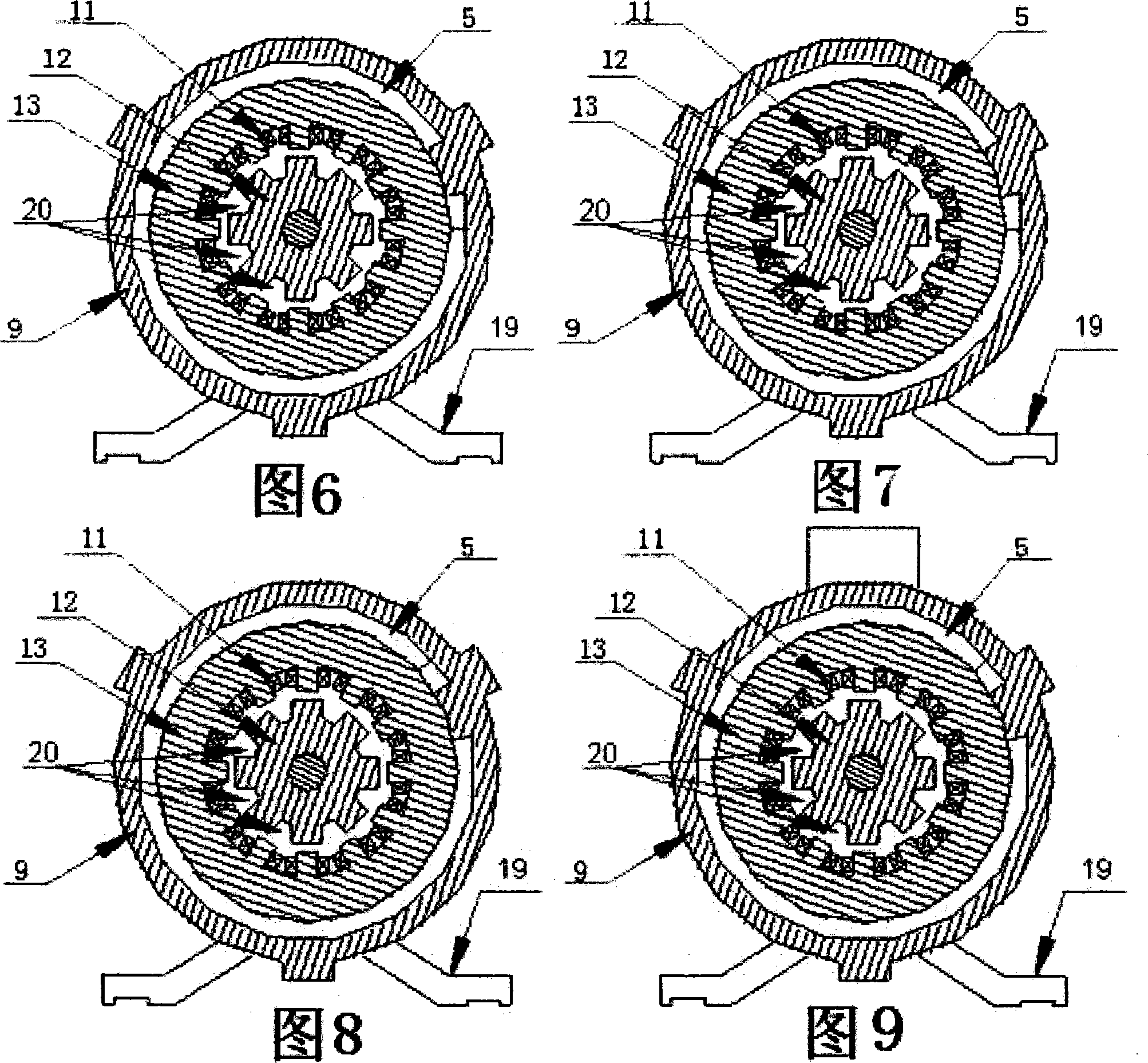

[0036] Describe according to accompanying drawing 1-19 below:

[0037] The electric vehicle fully enclosed switched reluctance motor includes front end cover 1, rear end cover 2, interfaces (3, 7, 23 and 24), cold air ring pipes 4 and 6, casing heat pipe 5, motor junction box 8, sealing machine Shell 9, B-type thermal wedge 10, stator winding 11, rotor 12, stator 13, A-type thermal wedge 14, windshield 15, waterproof rubber pad and sealing ring 16, cold air ducts 17 and 18, closed position sensor 19, The rotor is sealed with filling material 20 , waterproof ring 21 and frame 22 .

[0038] Air-cooled heat dissipation design of fully enclosed switched reluctance motor for electric vehicles:

[0039] Behind the switched reluctance motor, an arc-shaped windshield 15 facing the front of the vehicle is provided.

[0040] On the inner surface of the aluminum sealed casing 9, a spiral cooling chamber and casing heat pipes 5 are arranged.

[0041] The stator winding head 11 is desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com