Mobile phone back cover capable of radiating

A technology for the back cover and body of a mobile phone, applied in the field of communication, can solve problems such as affecting the heat dissipation of mobile phones, and achieve the effects of avoiding excessive weight, good heat dissipation, and avoiding local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

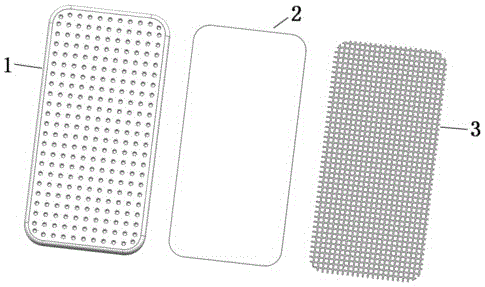

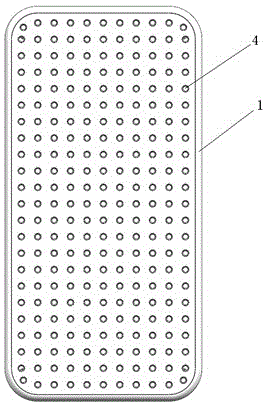

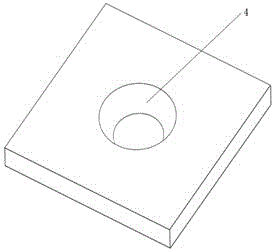

[0033] (1) The back cover body is made of aluminum alloy material, and the honeycomb-shaped small holes with a diameter of 1 mm and a draft angle of 10 degrees are set on the back cover body, and the distance between the centers of adjacent small holes is 2 mm.

[0034] (2) The ultrafiltration membrane is made of polyacrylonitrile (PAN), the thickness of the film is 300 microns, the diameter of the pores on the film is circular, and the diameter is 0.15 microns.

[0035] (3) Use 0.4mm thick and 1mm wide silver strips to weave into a silver screen with 16 meshes and 1 mm aperture. The area of the silver screen is 0.5 mm wider than the inner wall of the back cover body.

[0036] (4) Clean the inner surface of the back cover body first, then evenly apply 502 adhesive to the four corners of the inner surface of the back cover body and the corresponding parts of the ultrafiltration membrane, and then tightly bond the ultrafiltration membrane to the back cover body The inner surfa...

Embodiment 2

[0038] (1) Using a mold, the back cover body is processed by injection molding from a polycarbonate composition, and honeycomb-shaped small holes with a diameter of 1.5 mm and a draft angle of 5 degrees are formed on it, and the center-to-center distance between adjacent small holes is 3 mm;

[0039] (2) The ultrafiltration membrane is made of polyvinyl chloride (PVC), the thickness of the membrane is 0.3 mm, the diameter of the pores on the membrane is circular, and the diameter is 0.15 microns.

[0040] (3) Use 0.4mm thick and 2mm wide silver strips to weave into a 32-mesh drying net with an aperture of 0.5mm. The area of the drying net is 0.5mm wider than the inner wall of the back cover body.

[0041] (4) Pre-treat the four corners of the inner surface of the cleaned back cover body with a heat welding gun at a temperature of 240-270°C for 1-5 minutes; Apply polycarbonate solvent glue evenly on the parts, then tightly bond the ultrafiltration membrane to the inner surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Draft angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com