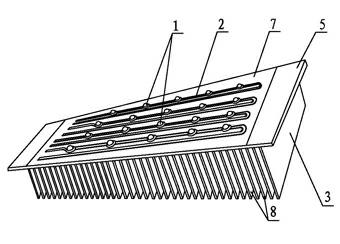

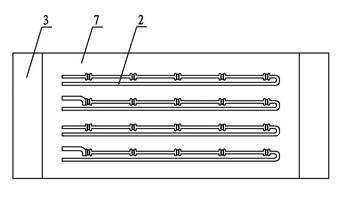

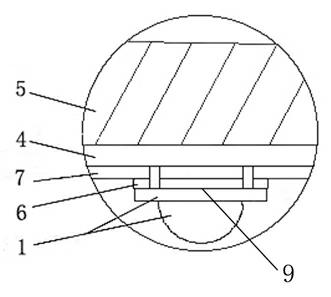

LED (light emitting diode) lamp with light weight and rapid heat dissipation and manufacturing method thereof

A technology of LED lamps and manufacturing methods, which is applied to lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting elements, etc., and can solve the problems of low LED arrangement density, low light intensity of equal surface area, and poor heat dissipation effect , to achieve the effect of improving heat dissipation, ensuring insulation performance, improving life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Use the following steps to manufacture LED street lights.

[0051] 1. Surface polishing: Use a cloth wheel and a soft polishing paste to polish the aluminum radiator to a mirror-like effect.

[0052] 2. Wax removal: Dilute the wax removal water to 2-4wt%, and rinse the aluminum radiator for 5-10 minutes at a temperature of 50-70°C.

[0053] 3. Perform one hot water wash and two running water washes.

[0054] 4. Degreasing: Dilute the alloy degreasing powder with water to 30-80g / l, and wash the aluminum radiator for 5-10 minutes at a temperature of 50-80°C.

[0055] 5. Perform one hot water wash and two running water washes.

[0056] 6. Aluminum radiator activation: use 50% volume ratio of nitric acid aqueous solution, soak at room temperature for 0.5-1 minute; then use a solution containing 80-120ml / l sulfuric acid and 70-100g / l ammonium persulfate, at room temperature , Soak the aluminum radiator for 0.5 to 1 minute.

[0057] 7. Two washes with running water.

[0...

Embodiment 2

[0077] Use the following steps to manufacture LED street lights.

[0078] 1. Surface polishing: Use a cloth wheel and a soft polishing paste to polish the aluminum radiator to a mirror-like effect.

[0079] 2. Wax removal: Dilute the wax removal water to 2-4wt%, and rinse the aluminum radiator for 5 minutes at a temperature of 70°C.

[0080] 3. Perform one hot water wash and two running water washes.

[0081] 4. Degreasing: Dilute the alloy degreasing powder with water to 30-80g / l, and rinse the aluminum radiator for 5 minutes at a temperature of 80°C.

[0082] 5. Perform one hot water wash and two running water washes.

[0083] 6. Aluminum radiator activation: use 50% volume ratio of nitric acid aqueous solution, soak at room temperature for 0.5 to 1 minute; then soak aluminum with a solution containing 120ml / l sulfuric acid and 100g / l ammonium persulfate at room temperature Heat sink for 0.5 minutes.

[0084] 7. Two washes with flowing water.

[0085] 8. Anodizing: for ...

Embodiment 3

[0100] Use the following steps to manufacture LED street lights.

[0101] 1. Surface polishing: Use a cloth wheel and a soft polishing paste to polish the aluminum radiator to a mirror-like effect.

[0102] 2. Wax removal: Dilute the wax removal water to 2-4wt%, and rinse the aluminum radiator for 10 minutes at a temperature of 50°C.

[0103] 3. Perform one hot water wash and two running water washes.

[0104] 4. Degreasing: Dilute the alloy degreasing powder with water to 30-80g / l, and wash the aluminum radiator for 10 minutes at a temperature of 50°C.

[0105] 5. Perform one hot water wash and two running water washes.

[0106]6. Aluminum radiator activation: use 50% volume ratio of nitric acid aqueous solution, soak at room temperature for 0.5 to 1 minute; then soak aluminum with a solution containing 80ml / l sulfuric acid and 70g / l ammonium persulfate at room temperature Cooler for 1 minute.

[0107] 7. Two washes with flowing water.

[0108] 8. Anodic oxidation: for p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com