Shell mold preparation method capable of preventing shrinkage porosity inside deep small hole

A deep hole, shell mold technology, applied in the field of investment casting, can solve the problems of inability to dissipate heat, shrinkage porosity, etc., and achieve the effect of solving the problem of poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a shell mold for preventing shrinkage inside a deep hole, comprising the following steps:

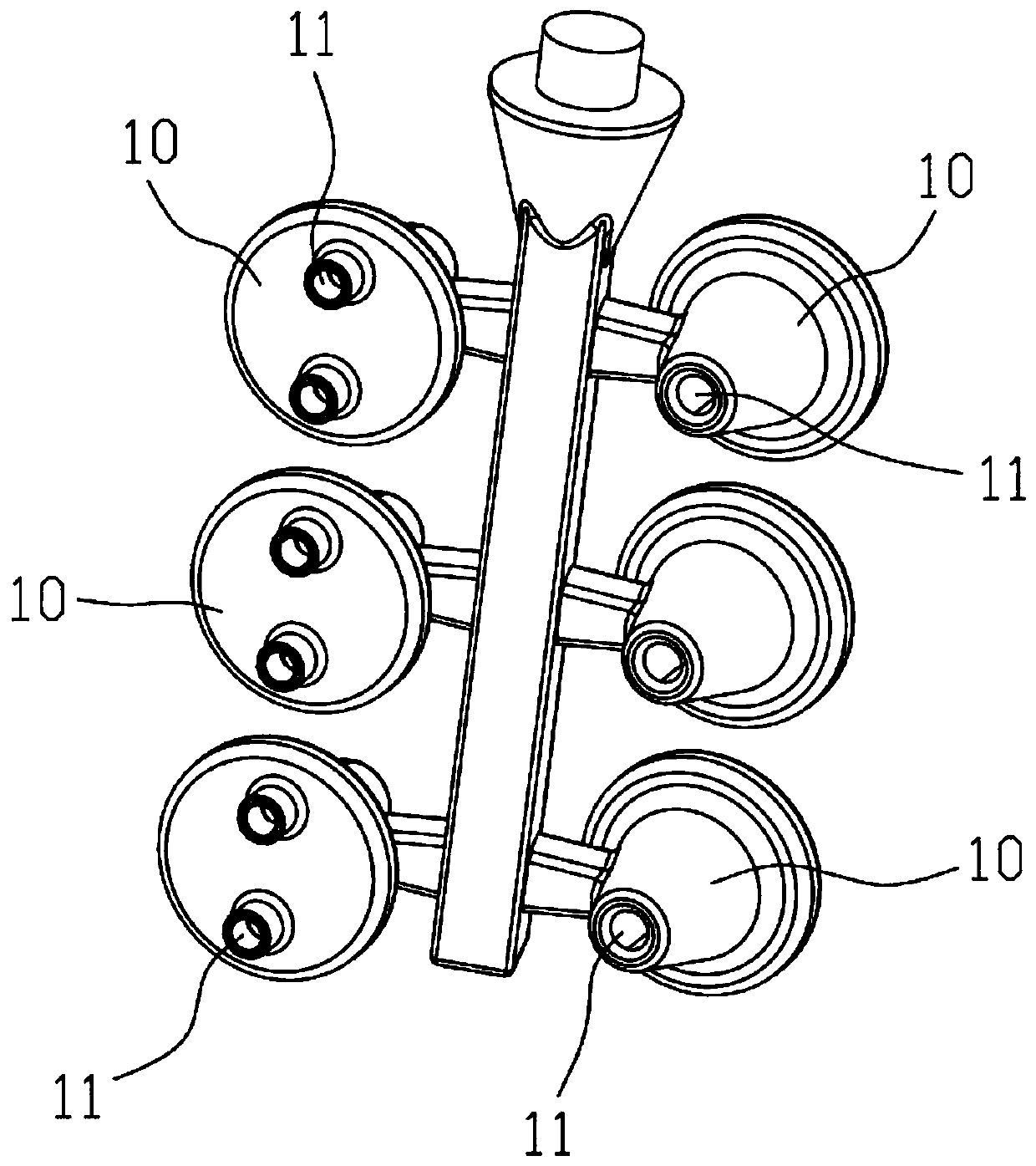

[0025] Pre-preparation of the shell mold 10: Prepare the wax mold, which has a through hole, first coat a layer of slurry and a layer of sand on the wax mold, one layer of slurry plus one layer of sand is the shell layer, use the above After making three layers of shells in the same way, add another layer of back layer slurry or sealing layer slurry; the main purpose of adding a back layer slurry or sealing layer slurry is to prevent the sand of the shell mold 10 from falling off;

[0026] A deep hole 11 with a diameter of φ5mm is formed on the above-mentioned pre-prepared shell mold 10;

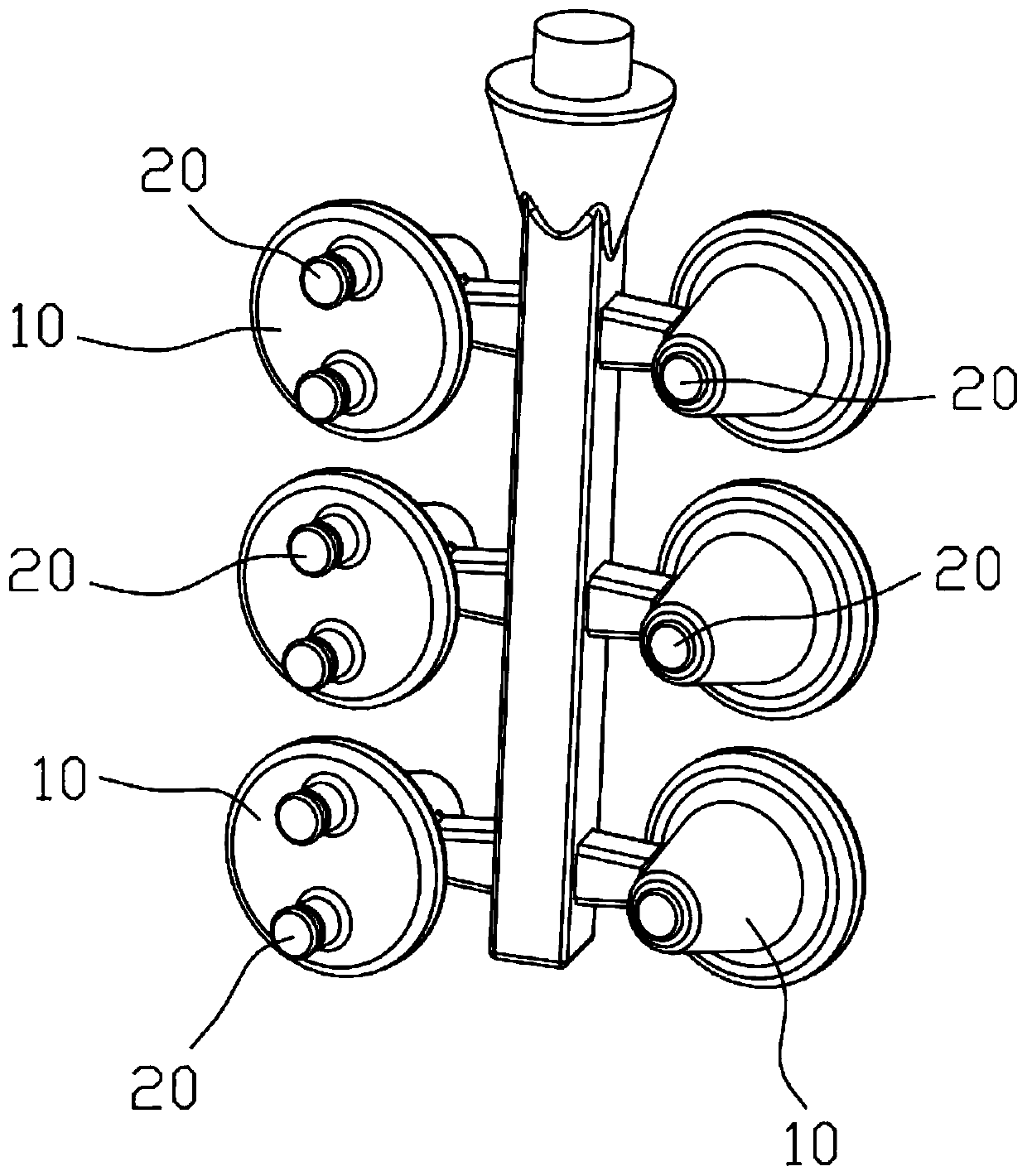

[0027] Drying the shell mold 10: Carry out drying treatment on the shell mold 10. When the deep small hole 11 is completely dried, block the deep small hole 11 with a wax block 20. The drying treatment adopts the air-drying method with constant temperature and humidity. T...

Embodiment 2

[0033] A method for preparing a shell mold for preventing shrinkage inside a deep hole, comprising the following steps:

[0034] Pre-preparation of the shell mold 10: First coat a layer of slurry and a layer of sand on the wax model in sequence, one layer of slurry plus one layer of sand is the shell layer, and after making 4 layers of shells in the same way as above, add another layer Layer back layer slurry or sealing layer slurry;

[0035] A deep hole 11 with a diameter of φ8mm is formed on the above-mentioned pre-prepared shell mold 10;

[0036] Drying the shell mold 10: Carry out drying treatment on the shell mold 10. When the deep small hole 11 is completely dried, block the deep small hole 11 with a wax block 20. The drying treatment adopts the air-drying method with constant temperature and humidity. The drying treatment time is 10h;

[0037] Continue to apply a layer of slurry and add a layer of sand to make the shell mold 10 until the shell mold 10 is completed;

...

Embodiment 3

[0041] A method for preparing a shell mold for preventing shrinkage inside a deep hole, comprising the following steps:

[0042] Pre-preparation of the shell mold 10: First coat a layer of slurry and a layer of sand on the wax mold in sequence, one layer of slurry plus one layer of sand is the shell layer, and after making the shell 5 layers in the same way as above, add another layer Layer back layer slurry or sealing layer slurry;

[0043] A deep hole 11 with a diameter of φ11mm is formed on the above-mentioned pre-prepared shell mold 10;

[0044] Drying the shell mold 10: Carry out drying treatment on the shell mold 10. When the deep small hole 11 is completely dried, block the deep small hole 11 with a wax block 20. The drying treatment adopts the air-drying method with constant temperature and humidity. The drying treatment time is 12h;

[0045] Continue to apply a layer of slurry and add a layer of sand to make the shell mold 10 until the shell mold 10 is completed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com