Method for preparing gasoline by double absorption and desorption of dry gas

An absorption-desorption and double-absorption technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc., can solve the problems of high difficulty in industrialization of dry gas to gasoline process, difficult control of reaction temperature, uneven distribution of ethylene concentration, etc., to achieve Solve the effect of difficult control of reaction temperature, increase of reaction temperature and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

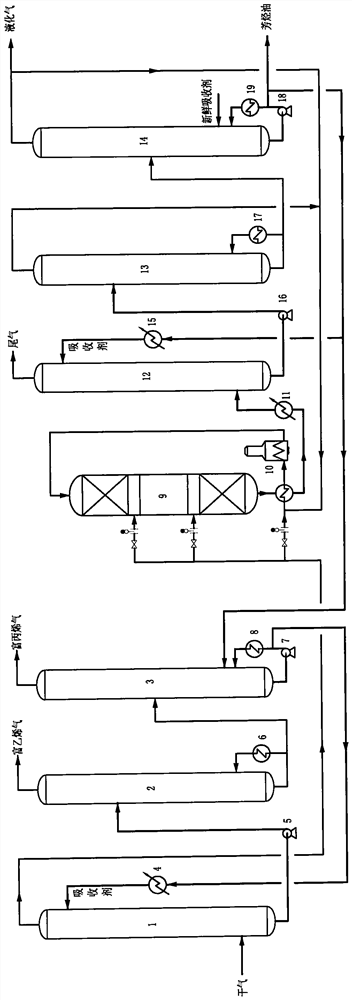

[0043] This example illustrates a process and effect of double absorption and desorption dry gas production of gasoline.

[0044] The process flow of this example is as follows figure 1 shown.

[0045] The MTP dry gas enters the dry gas absorption tower and contacts with the absorbent on the filler in countercurrent, and propylene and part of ethylene dissolve into the absorbent. The dry gas goes out from the top of the tower to the fixed-bed reactor, and the tower pressure is controlled by a regulating valve; the rich absorbent is boosted from the bottom of the tower to the deethylene tower through the bottom pump. The operating pressure of the dry gas absorption tower is 0.8MPa, the temperature at the top of the tower is 15°C, the temperature at the bottom of the tower is 19°C, the temperature of the absorbent is 10°C, and the pressure is 1.1MPa.

[0046] The rich absorbent enters the deethylene tower; the temperature of the tower kettle is controlled by a reboiler; the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com