Flexible heat pipe used for cooling surface of rotating shaft of high-speed motorized spindle

A high-speed motorized spindle and surface cooling technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of restricting the machining accuracy of CNC machine tools, lack of heat extraction methods, thermal deformation of rotating shafts, etc. Compact, low cost, and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

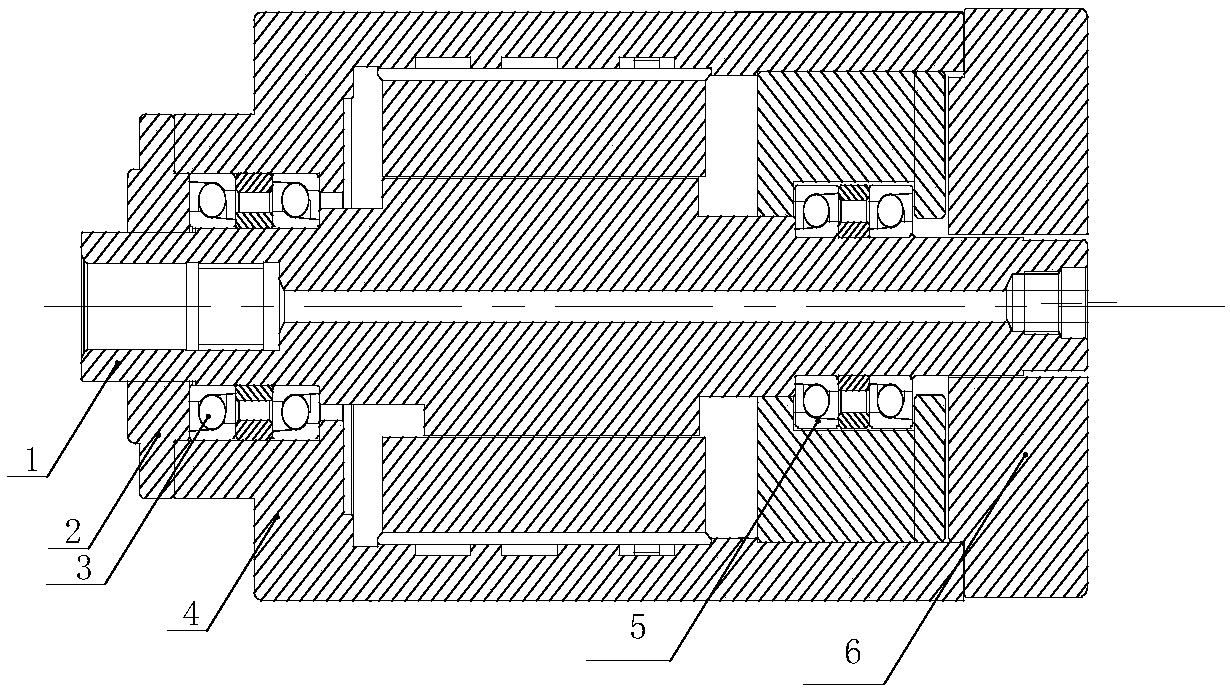

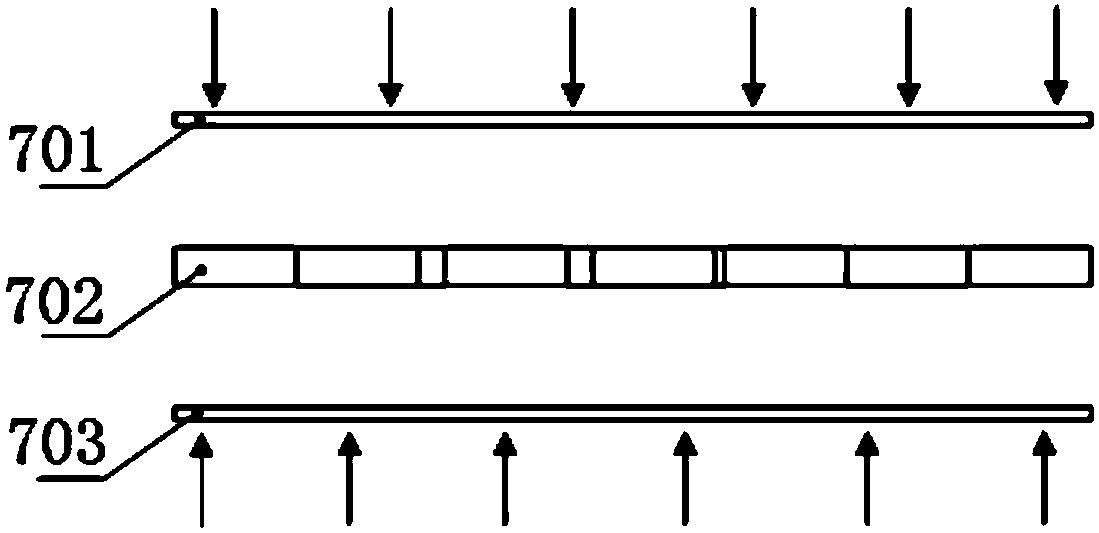

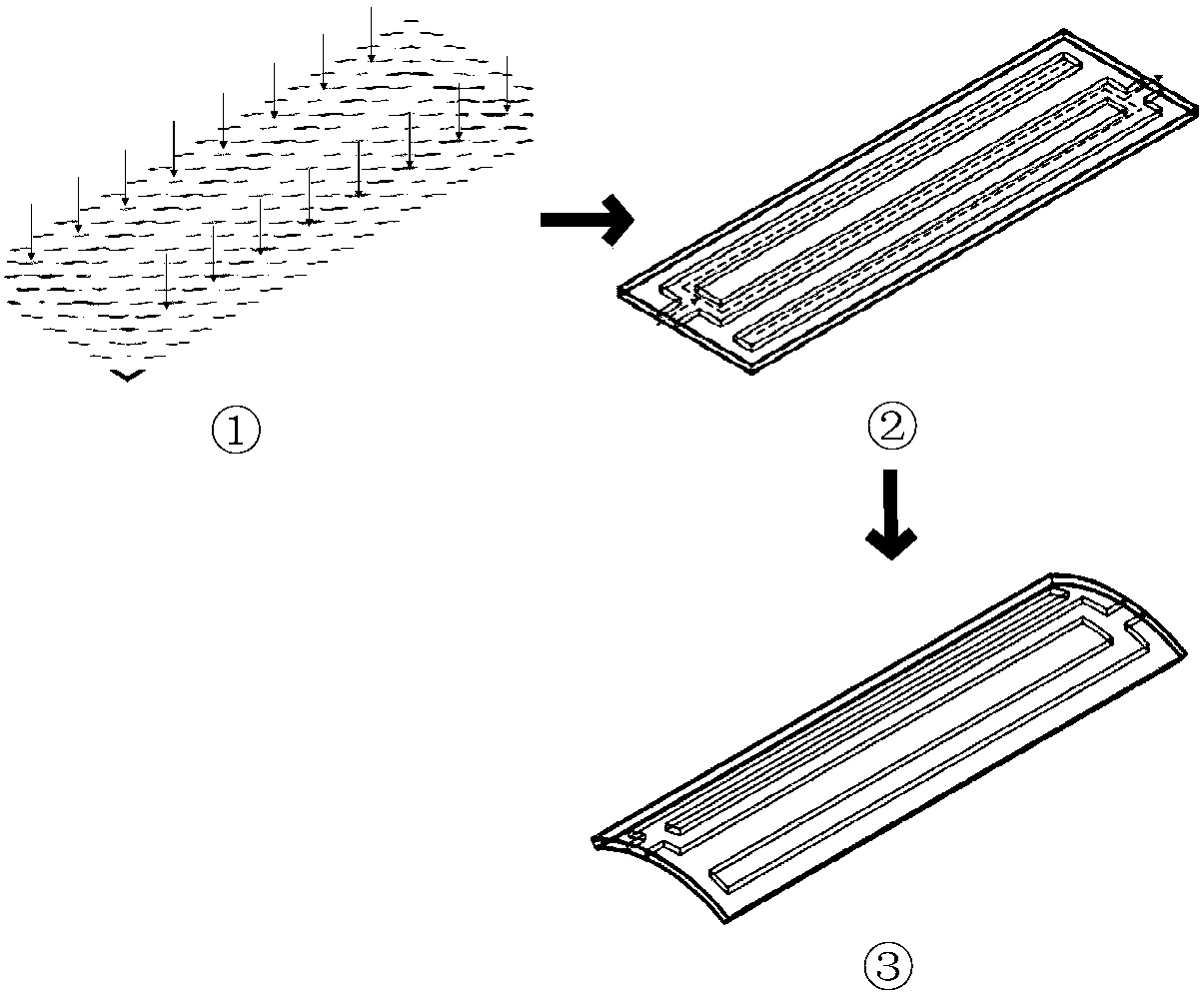

[0026] refer to figure 1 and figure 2 , a flexible heat pipe used for cooling the surface of the high-speed electric spindle shaft provided by the present invention. Firstly, the main components of the high-speed electric spindle are briefly introduced. The typical structure of the electric spindle mainly includes the rotating shaft 1. The front end cover 2 is used for sealing protection, the rear end of the rotating shaft 1 is matched with the rear bearing assembly 5, and the rear end cover 6 is used for sealing protection, the motor rotor is interference fit with the electric spindle shaft 1, and the motor stator is fixed with the electric spindle housing 4 together and are therefore not shown in the figure. When the electric spindle is running, due to factors such as frictional heat generation of the bearing, loss of the motor, and wind motors of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com