Large-scale high-precision gear compound grinding center

A compound grinding, high-precision technology, applied in the direction of grinding frame, grinding bed, grinding slide, etc., can solve the difficulties of workpiece lifting, clamping, calibration and detection, low equipment utilization rate, low production efficiency, etc. problems, to achieve the effect of reducing the number of machine tools and fixtures, reducing empty grinding time, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

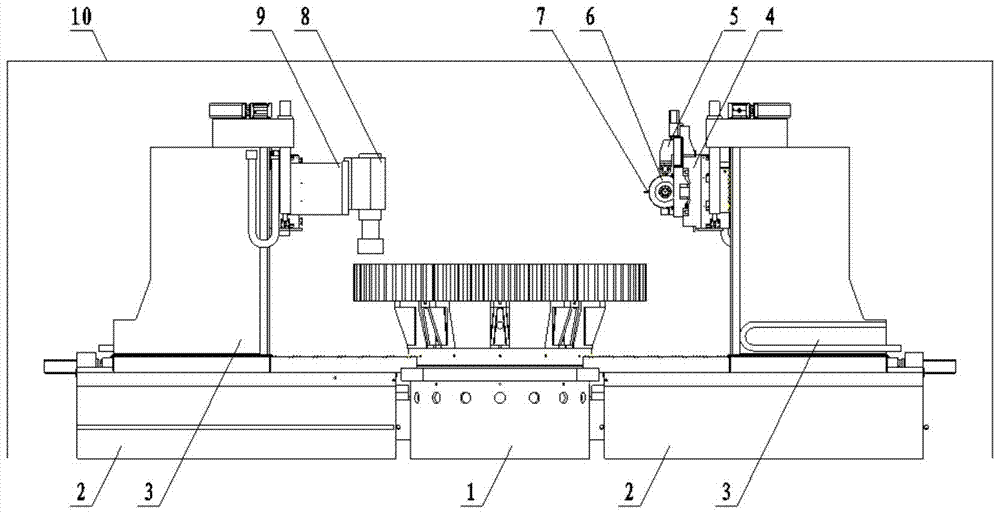

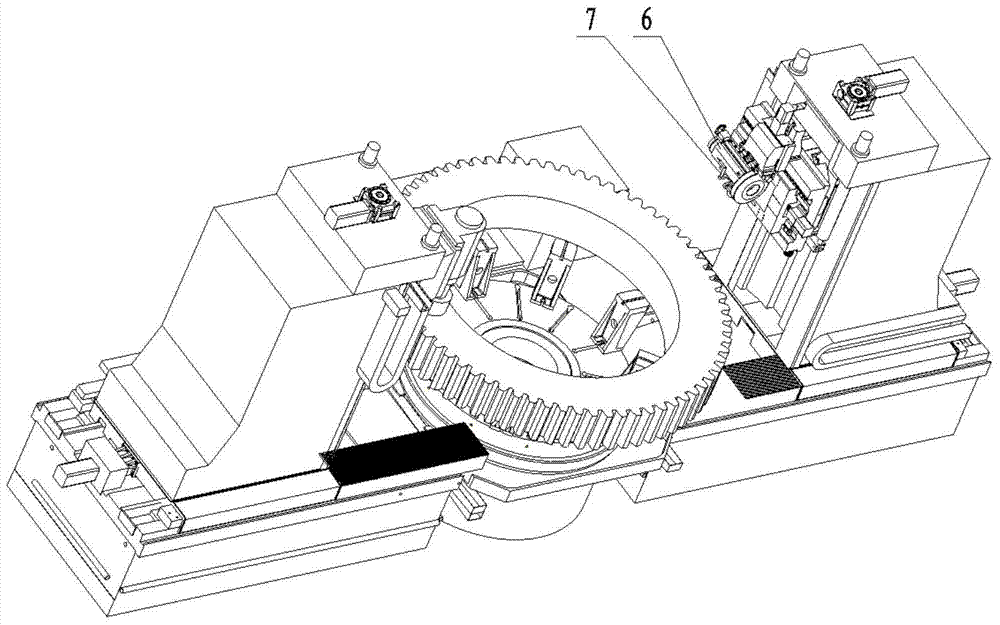

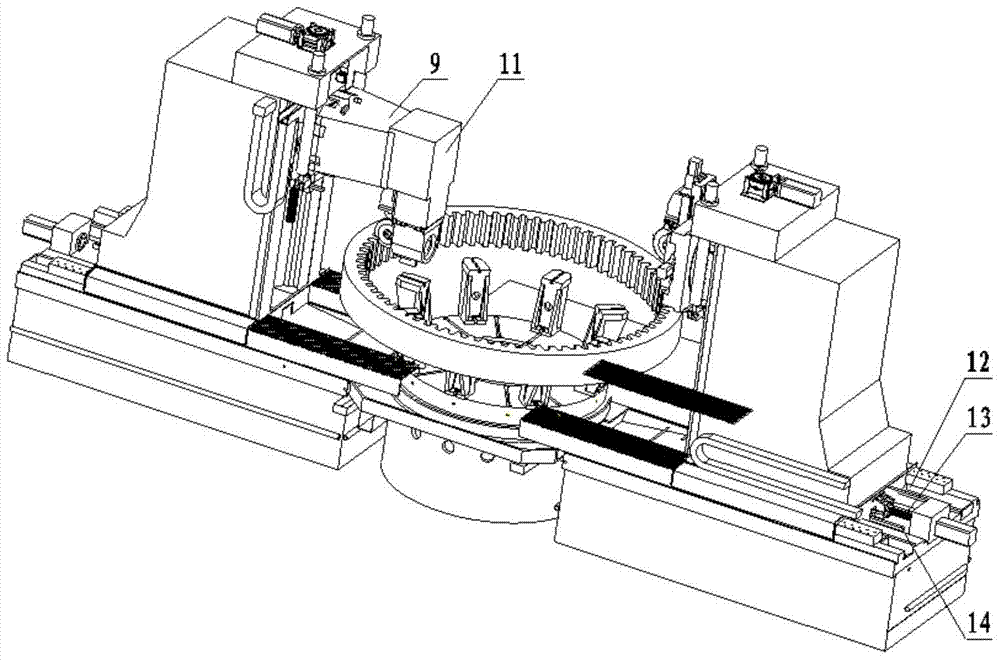

[0076] Such as Figure 1 to Figure 8 As shown, a large-scale, high-precision gear compound grinding center adopts a vertical structure and a symmetrical layout. The rotary table 1 is installed on the adjustment pad iron and connected with the foundation through anchor bolts. The external gear grinding function module is arranged on the right side of the rotary table, including bed 2, column 3, grinding wheel frame 4, grinding wheel dressing device 5, external gear grinding device 6, on-machine measuring device 7; internal gear, inner hole and The end face grinding function module is arranged on the left side of the rotary table, including bed 2, column 3, internal tooth grinding device 11, inner hole and end face grinding device 8. The large-scale, high-precision gear compound grinding center also includes an electrostatic mist absorption system 15, a grinding oil cooling and filtering system 16, and a machine tool safety system 17. This layout method has a compact structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com