Patents

Literature

132results about How to "Small working area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

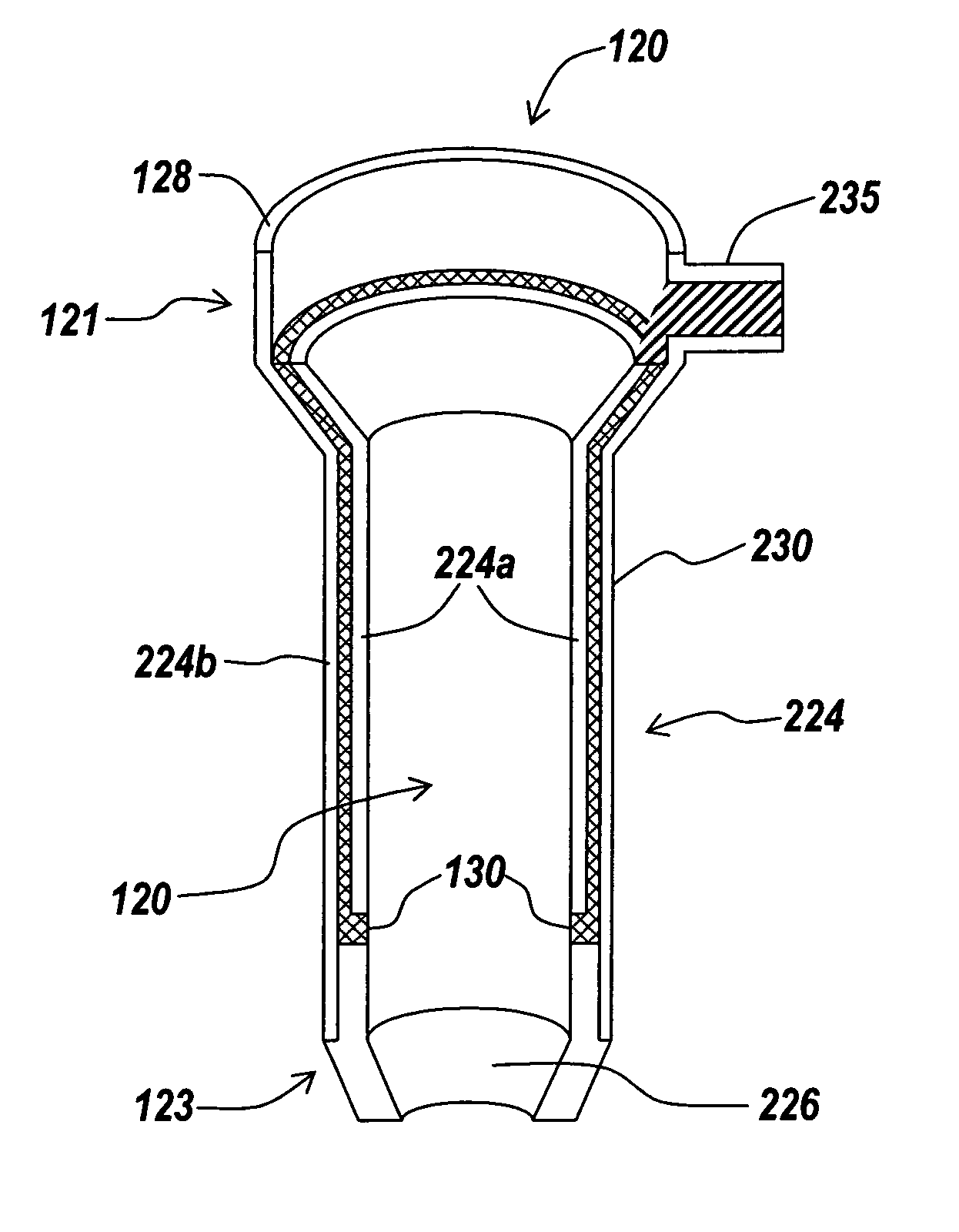

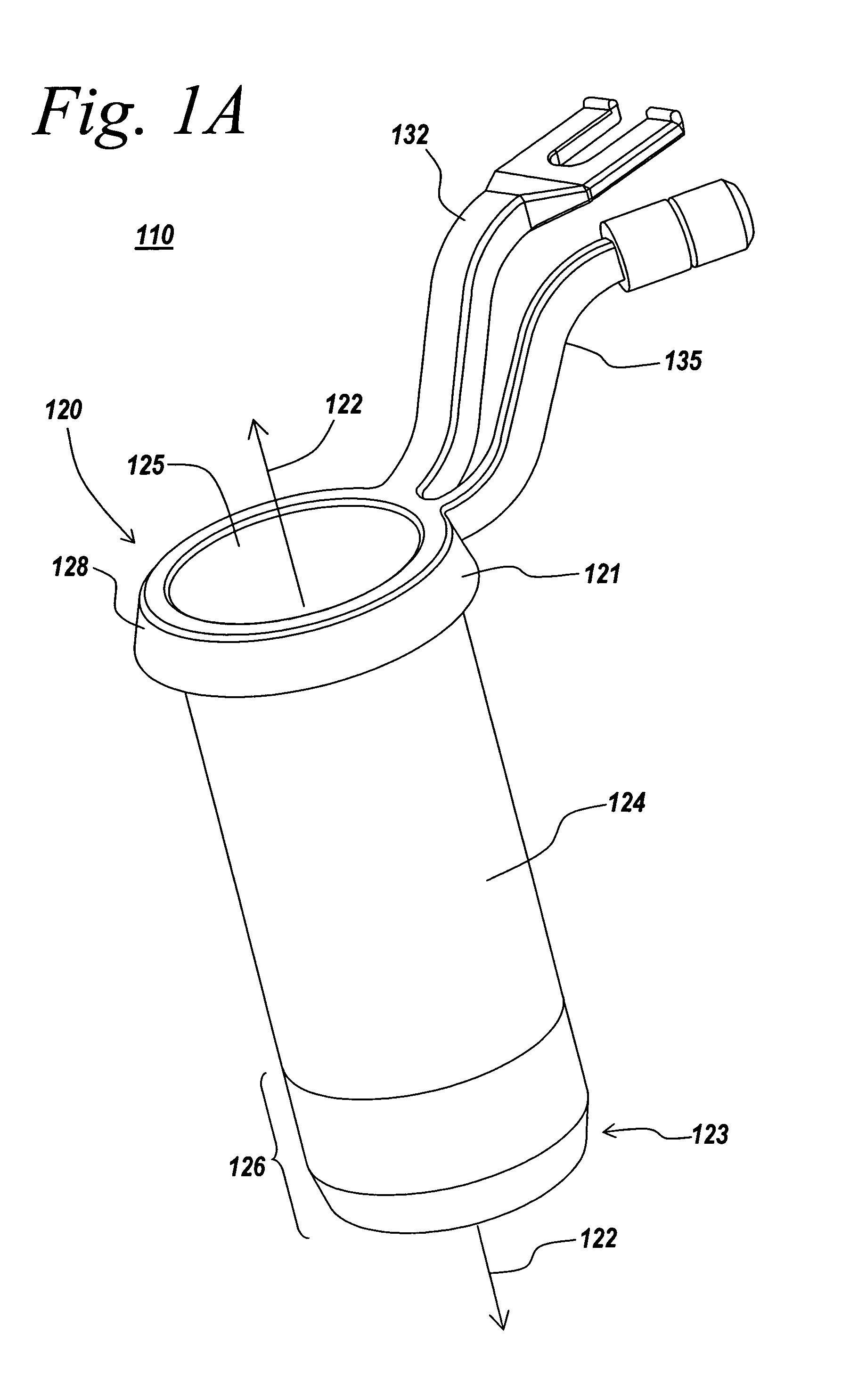

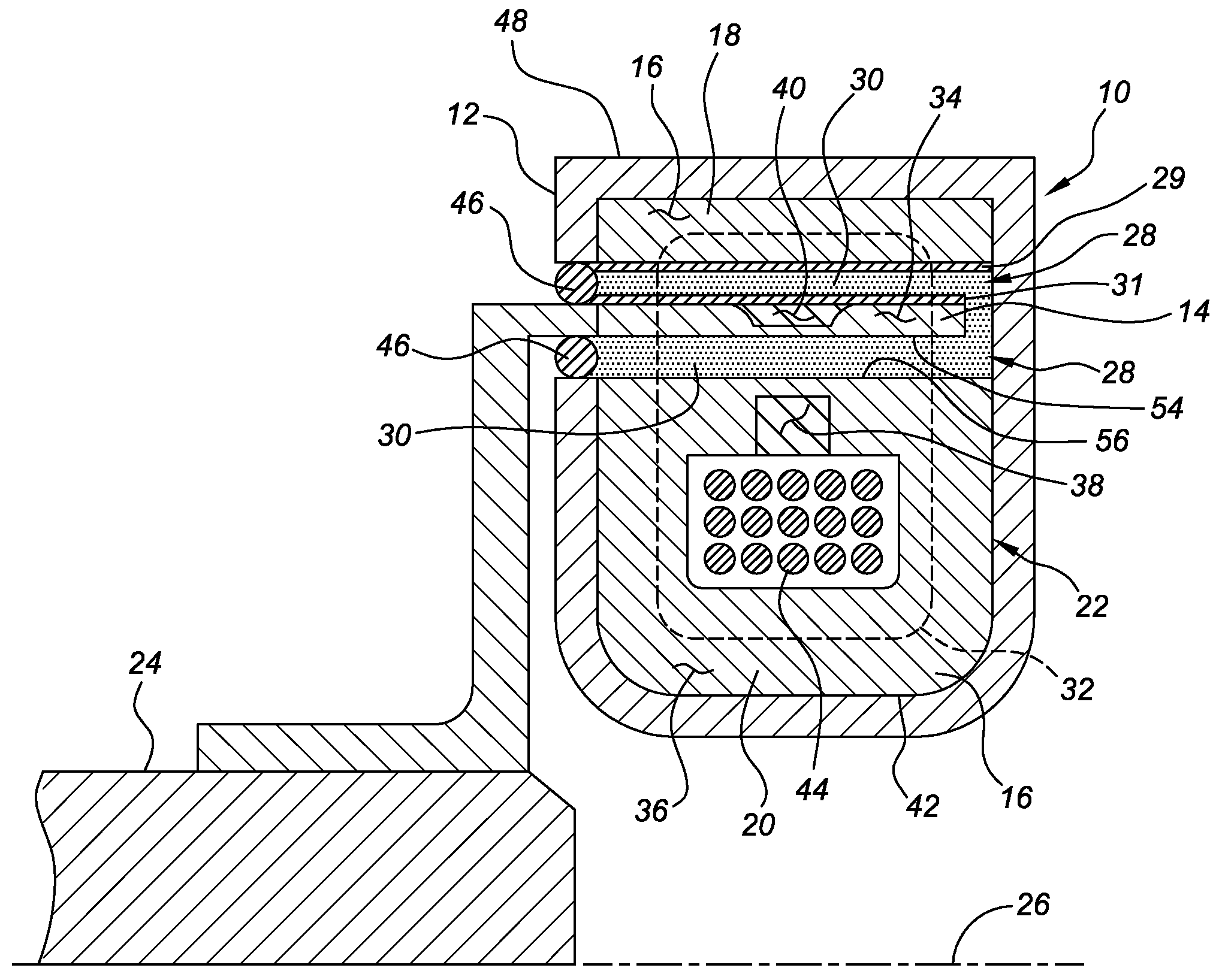

Illuminated surgical access system including a surgical access device and integrated light emitter

ActiveUS20070276191A1Small working areaConvenient lightingCannulasLaproscopesSurgical siteLight transmission

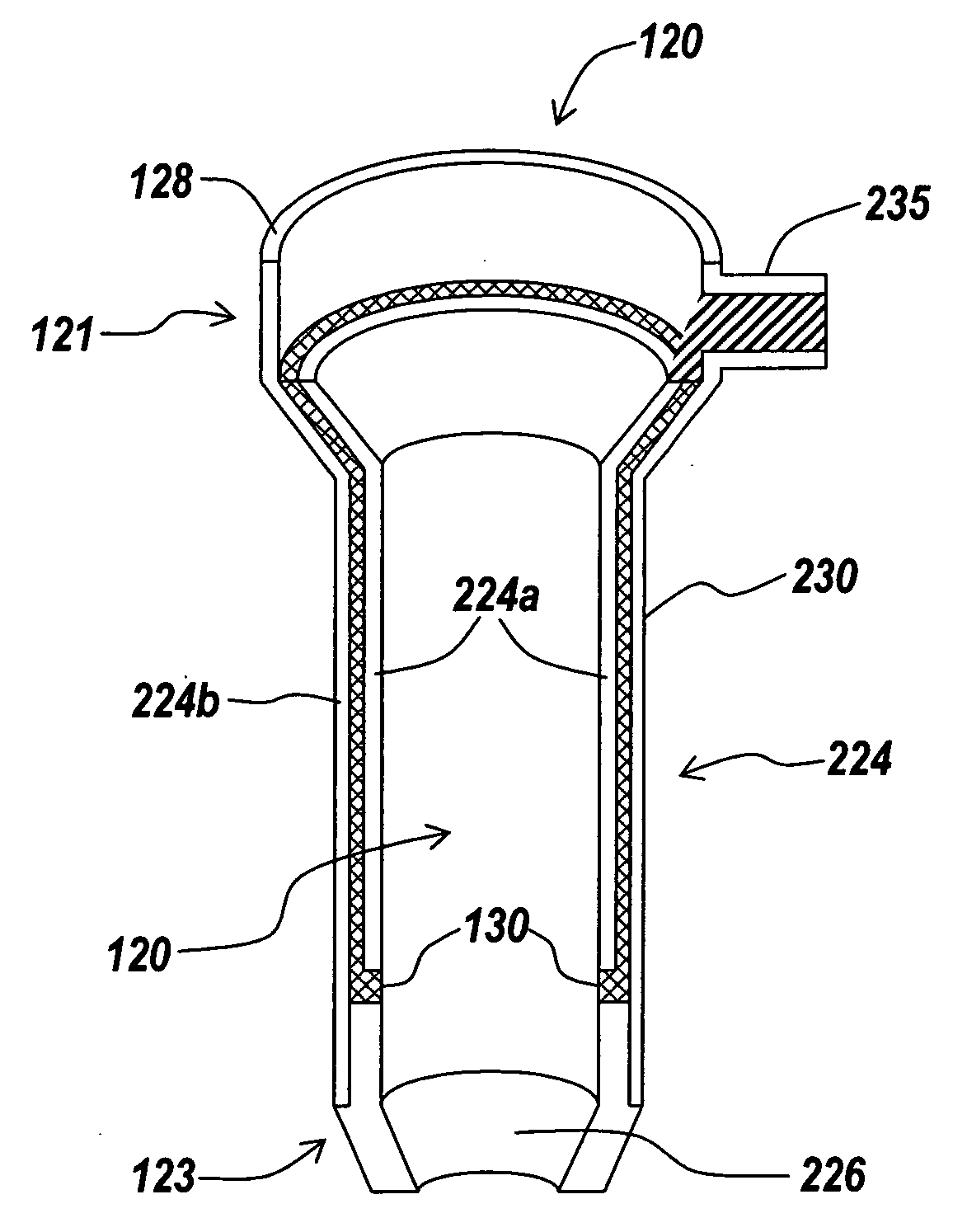

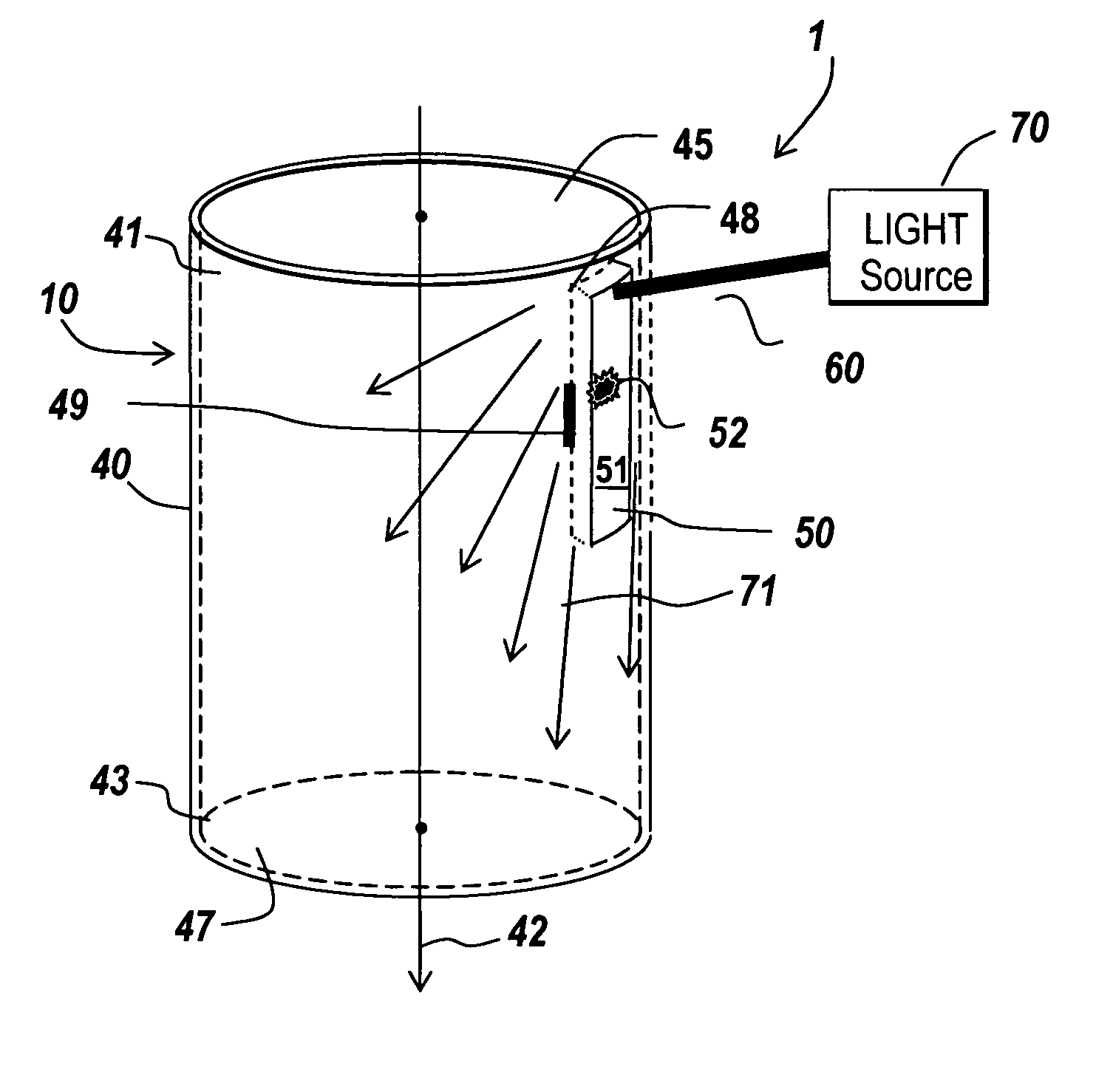

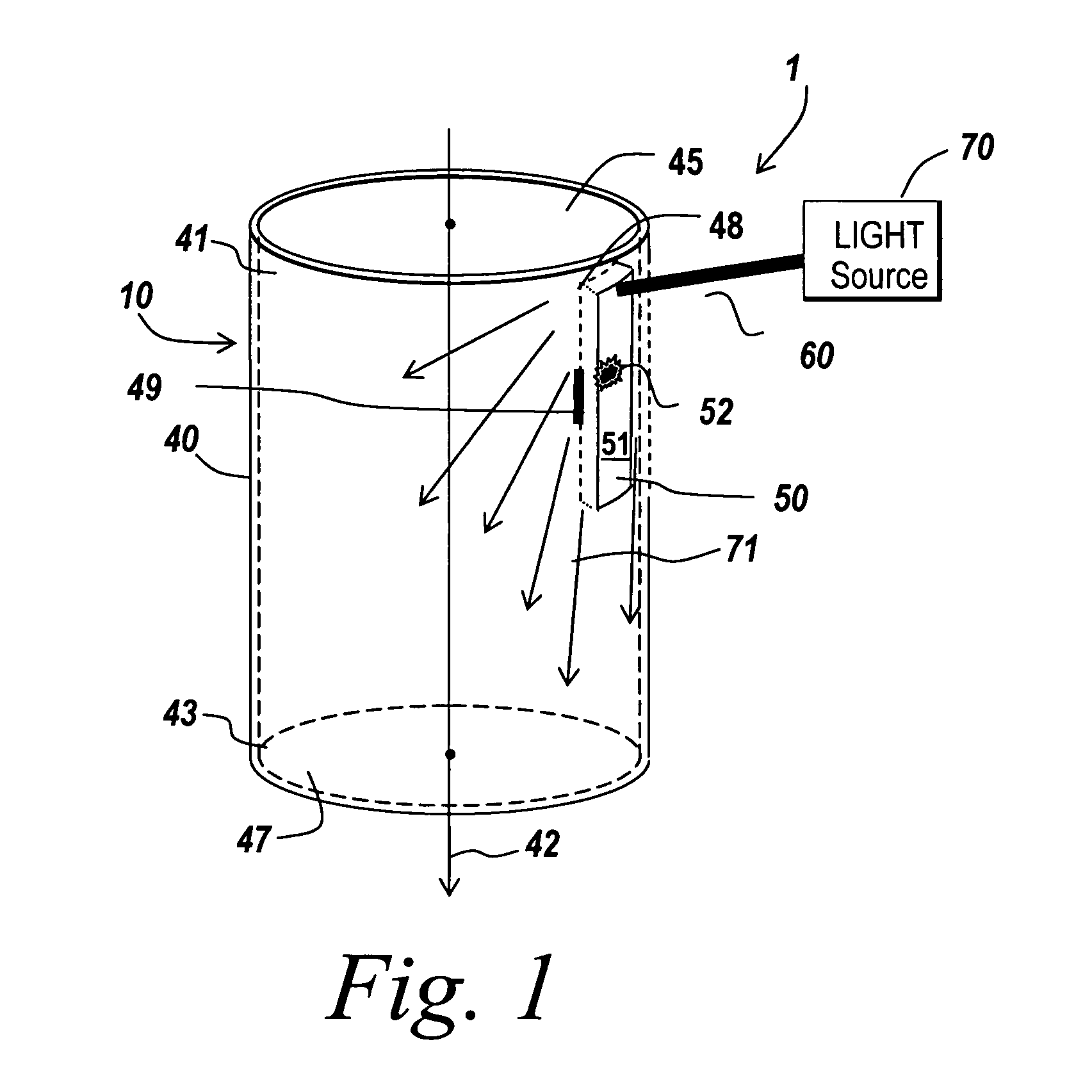

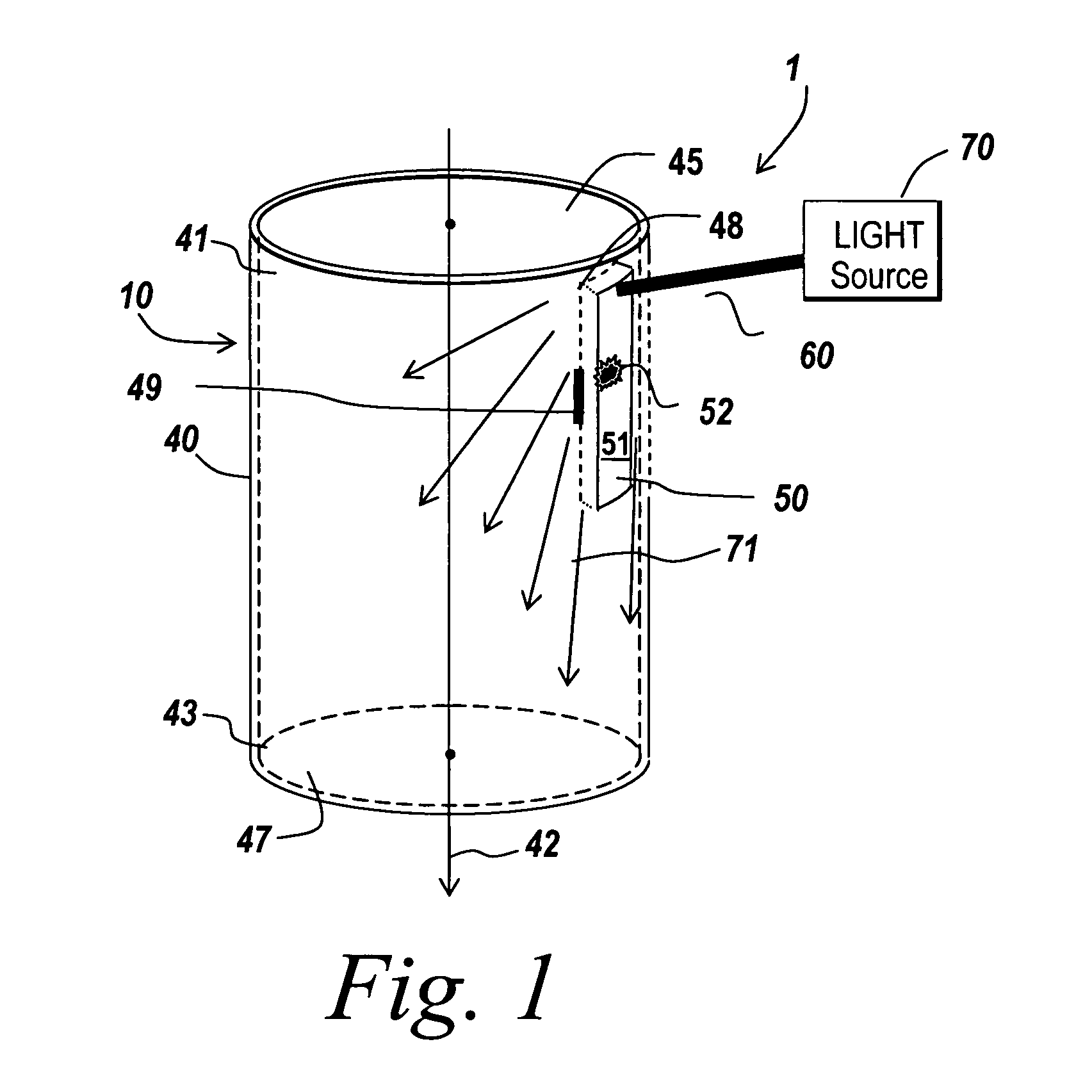

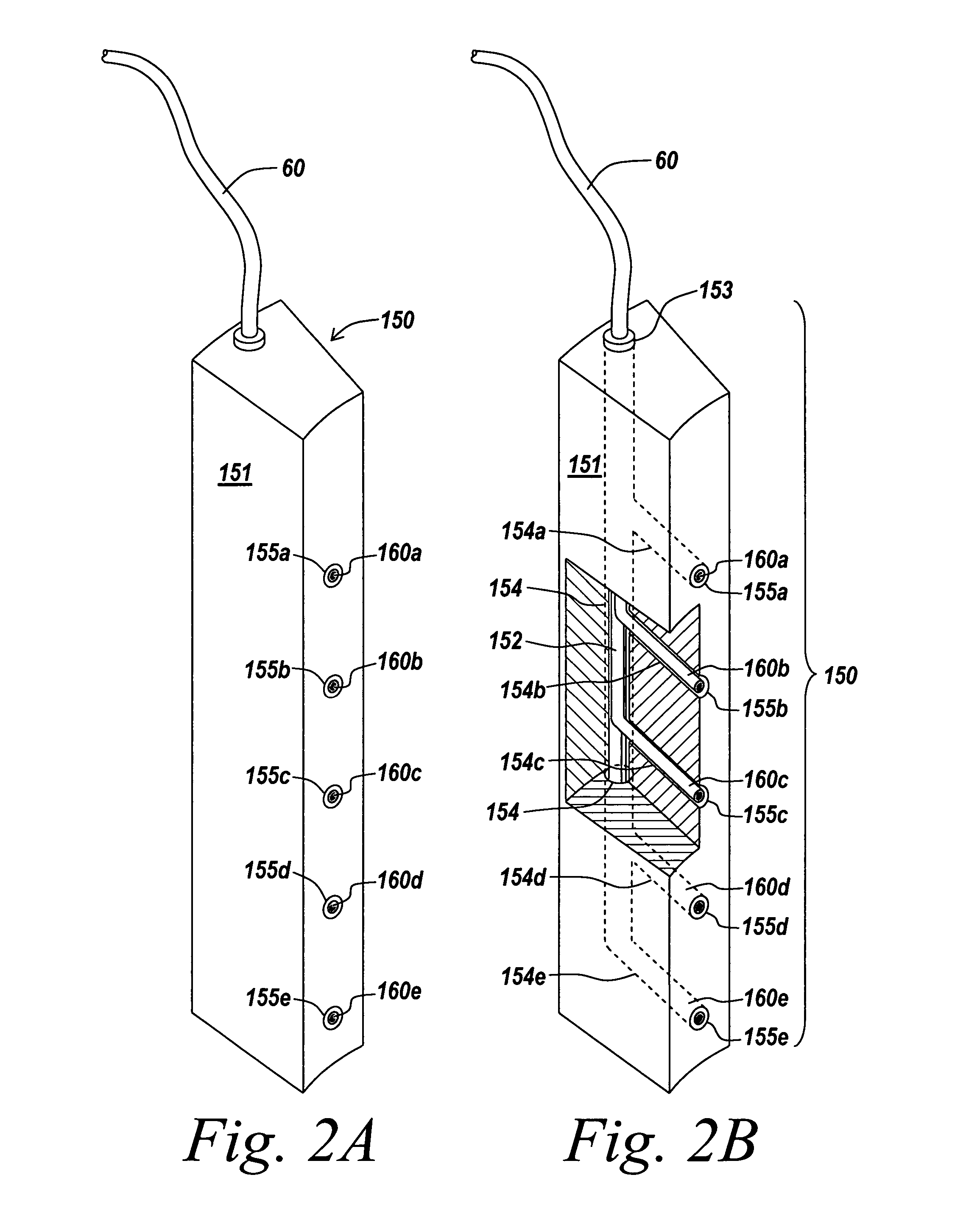

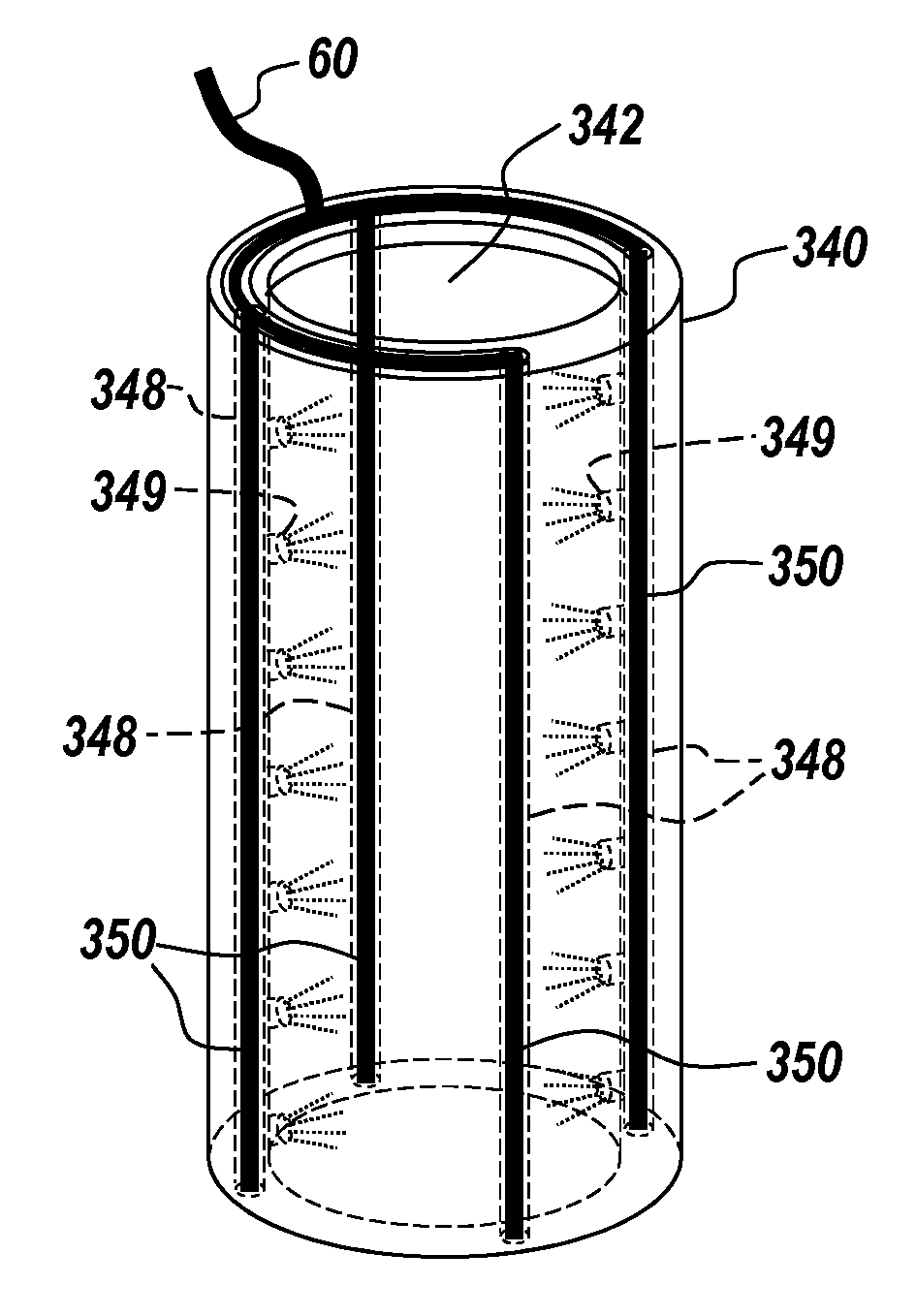

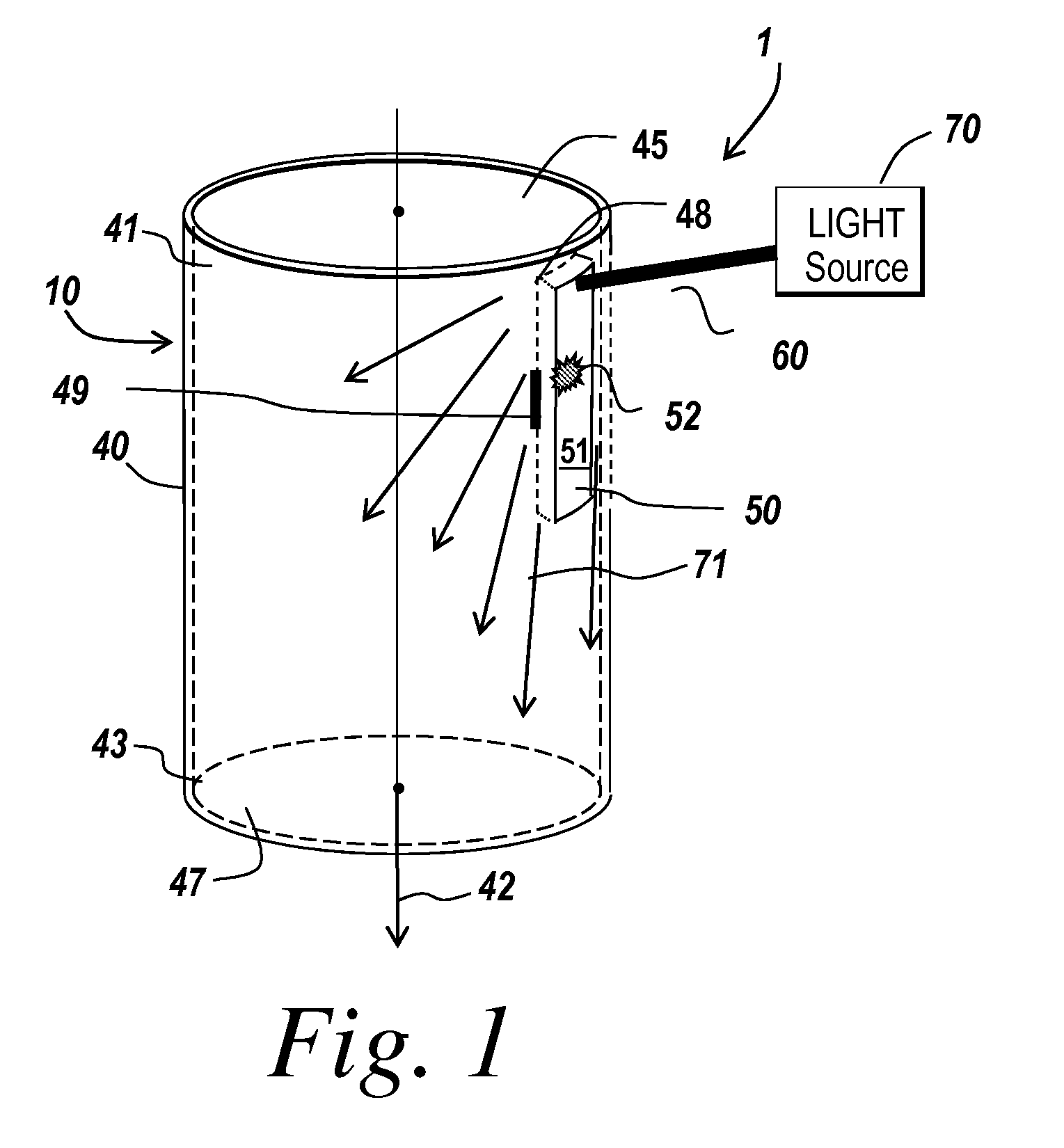

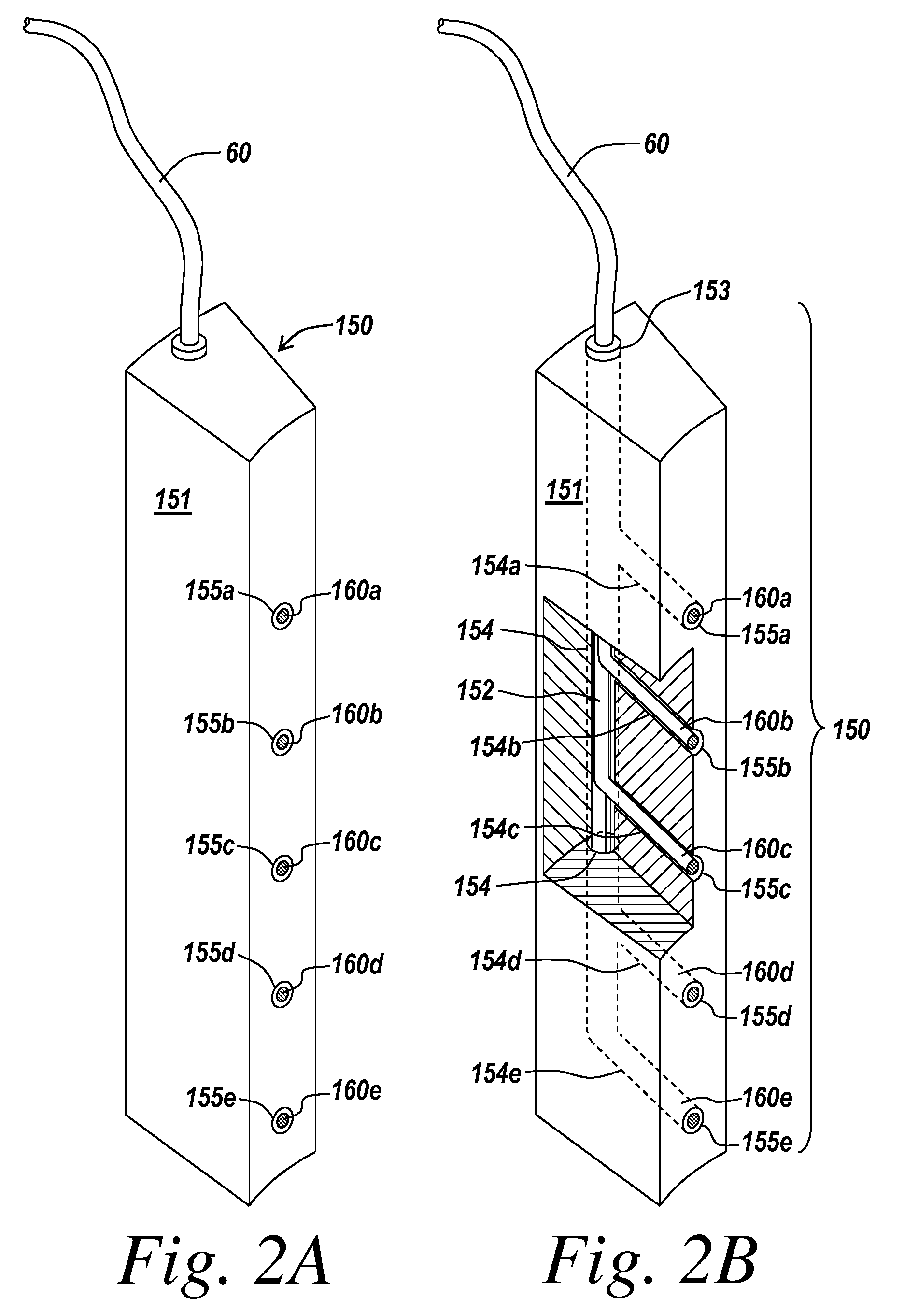

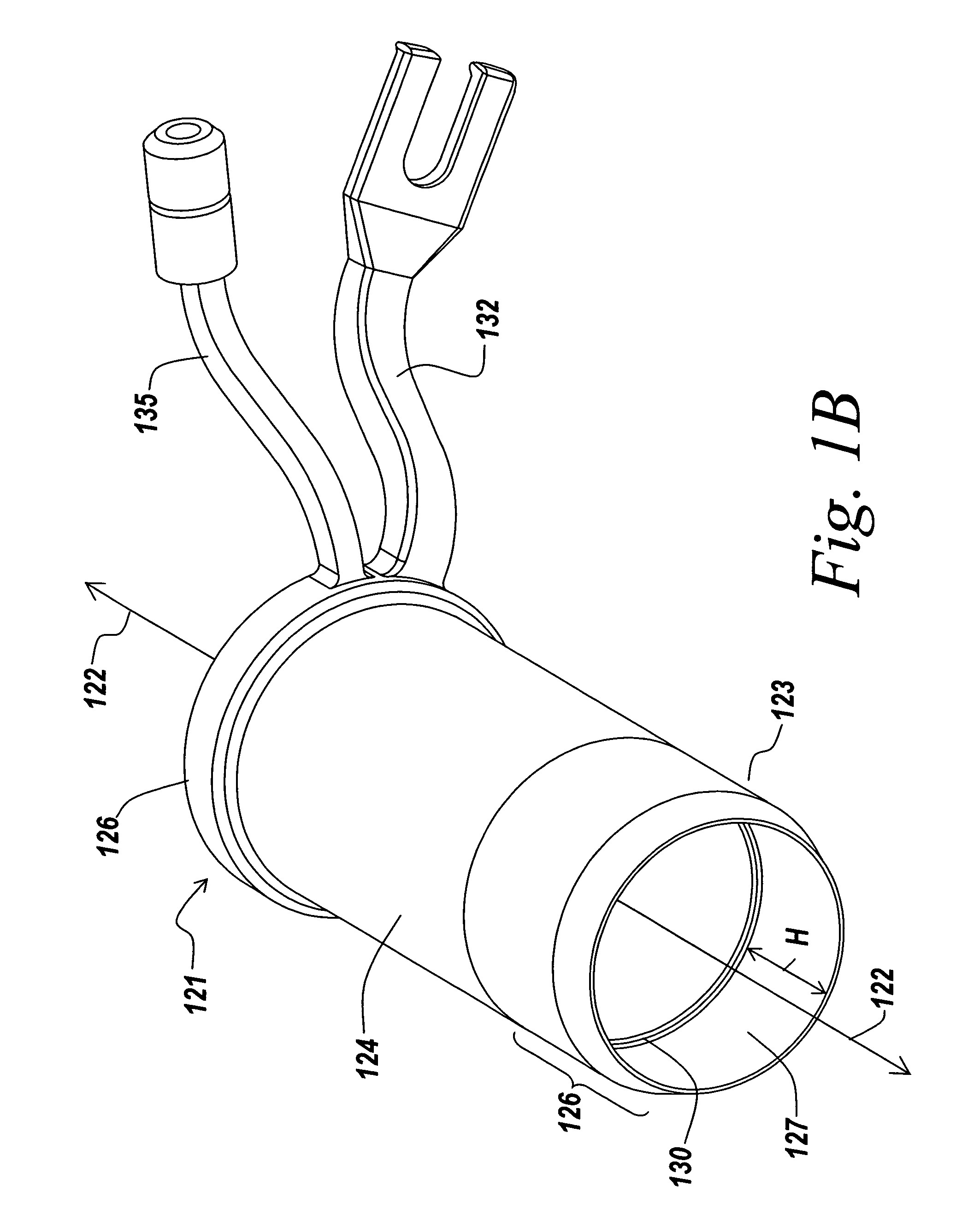

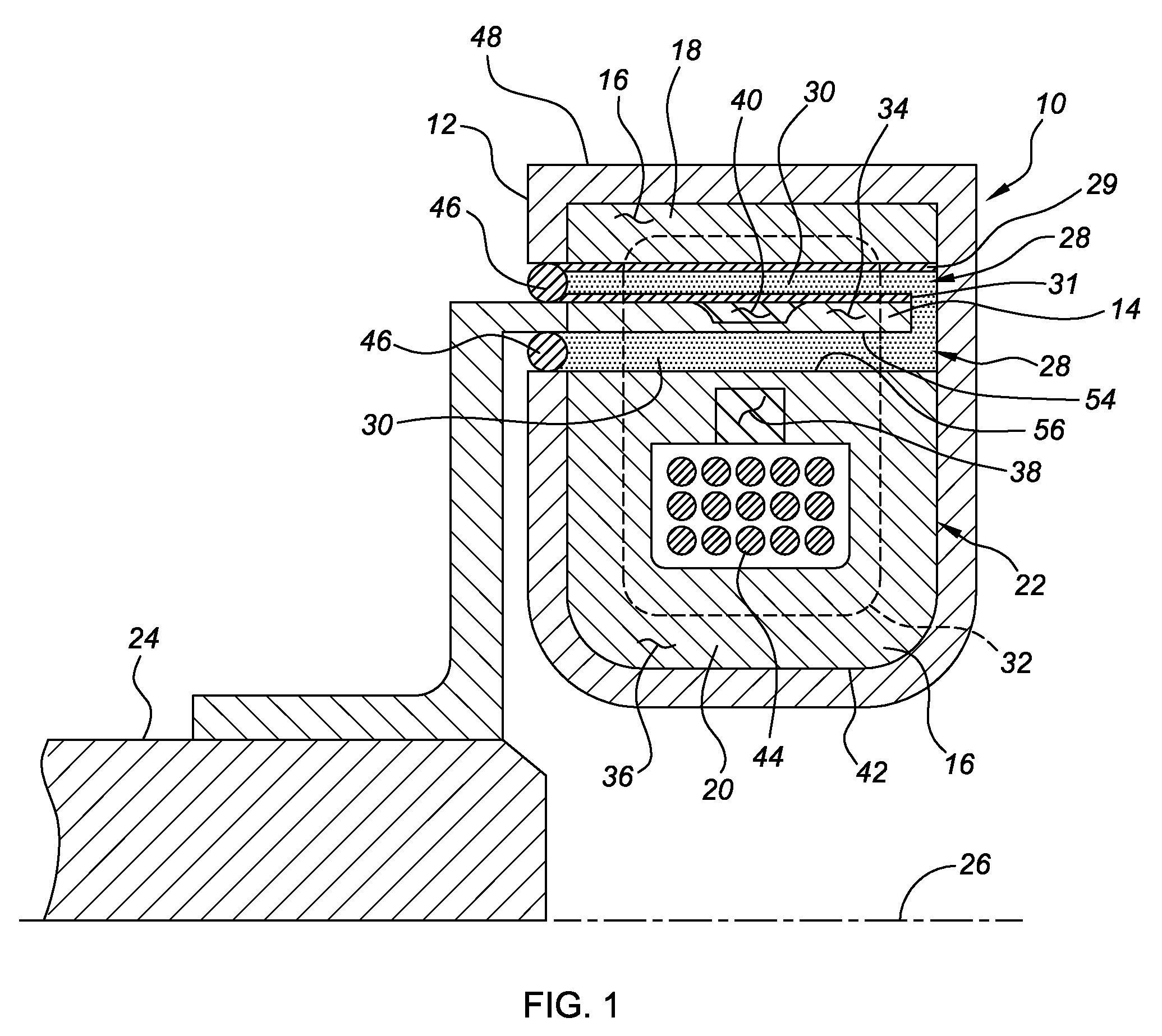

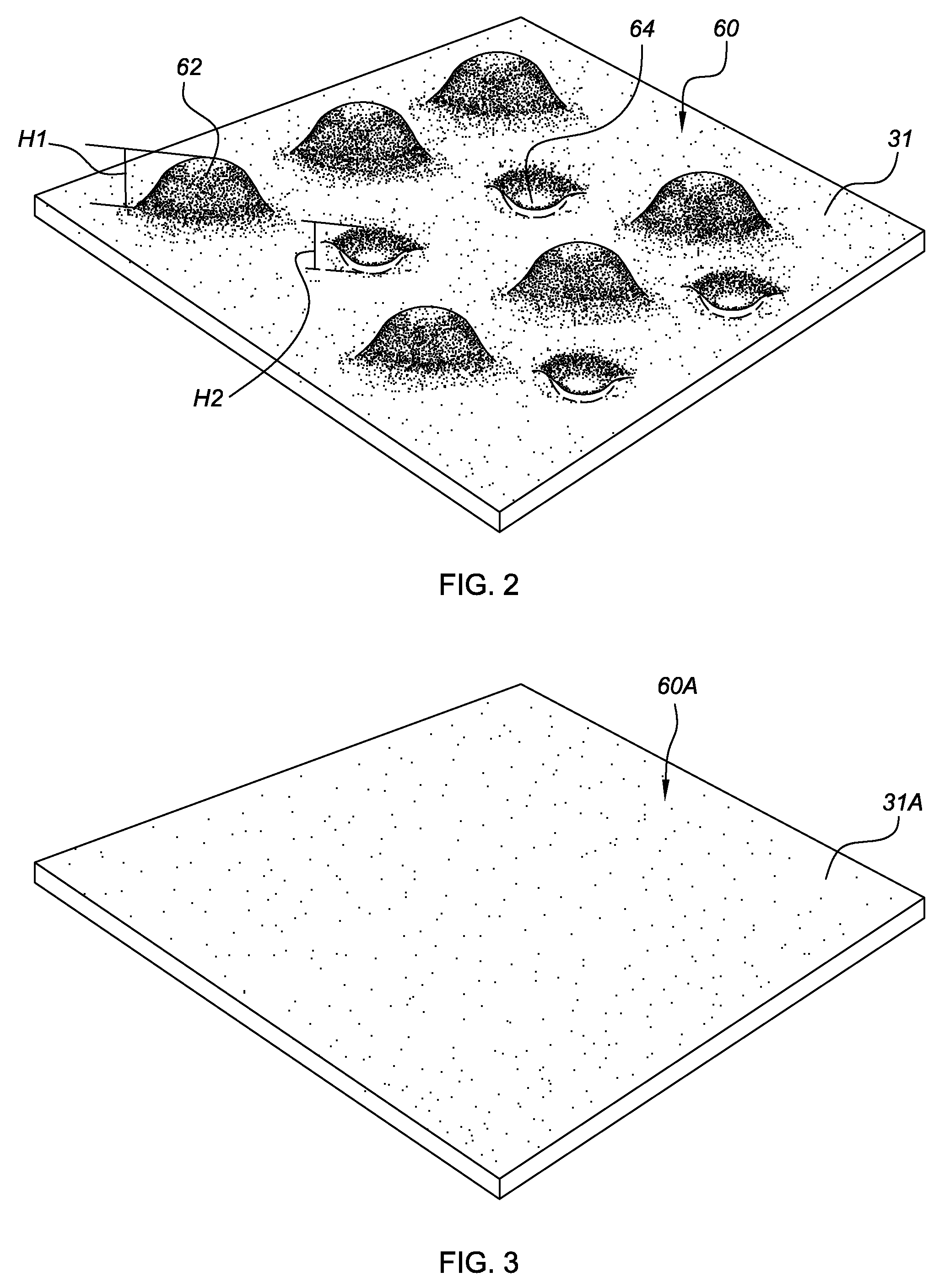

A surgical access system for providing access to a surgical site in a patient includes a surgical access device defining a working channel for accessing a surgical site and an integrated light emitter for illuminating the surgical site. The light emitter is integrated in proximity to a distal end of the surgical access device. In some embodiments, the light emitter is offset from the distal end. In certain embodiments, the integrated light emitter includes a light transmission medium for transmitting light from a proximal end of the access device to the distal end.

Owner:DEPUY SYNTHES PROD INC

Illuminated surgical access system including a surgical access device and coupled light emitter

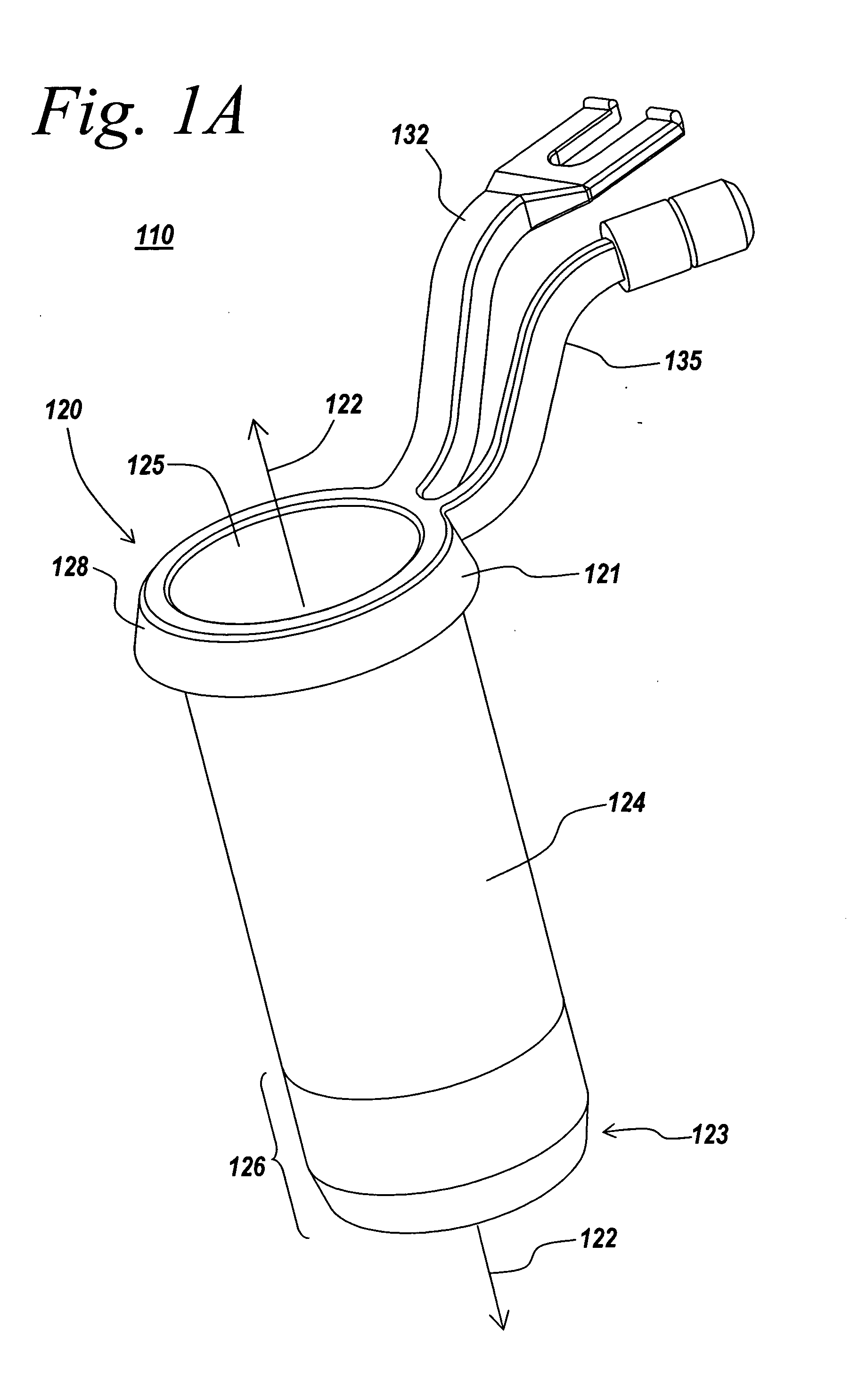

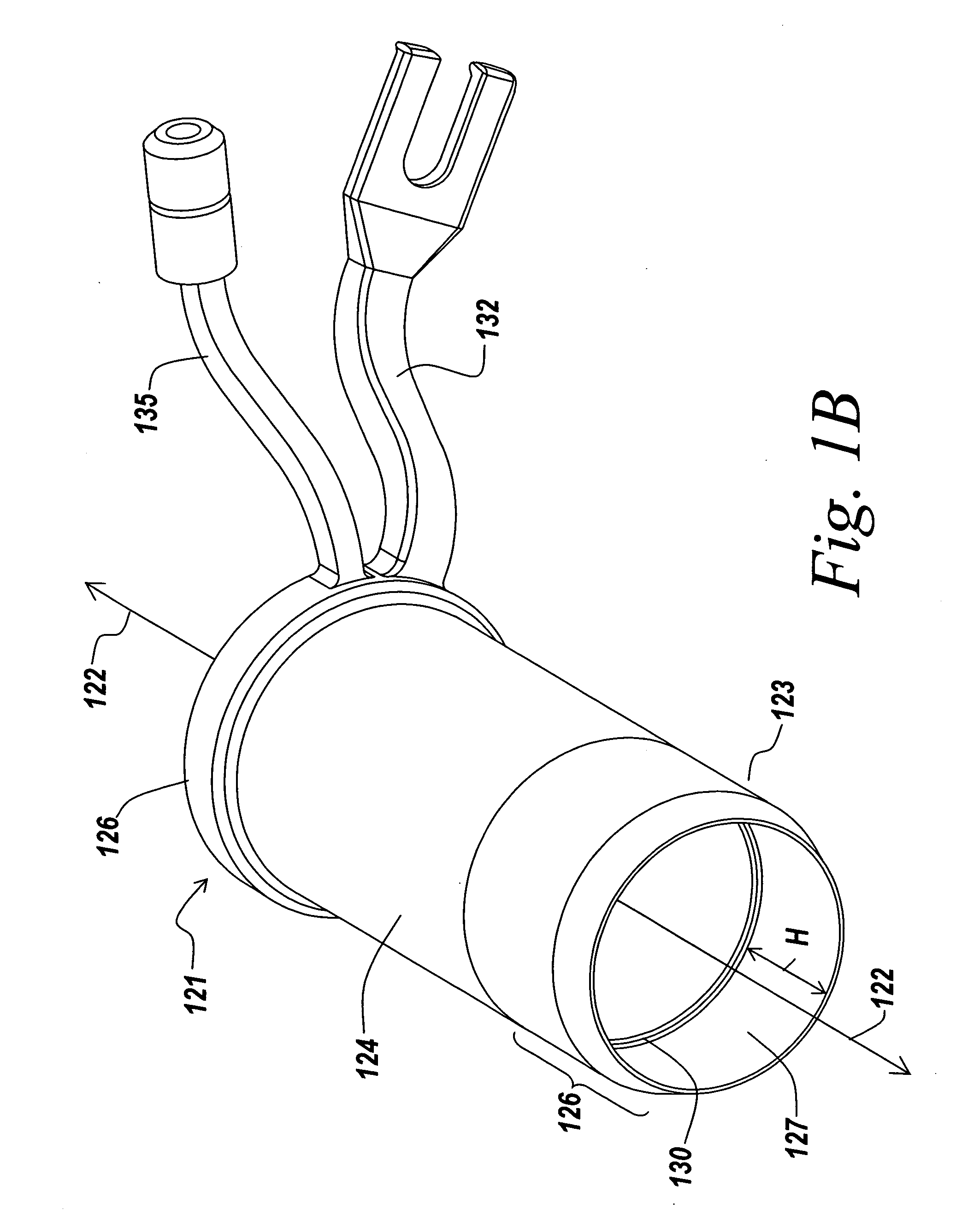

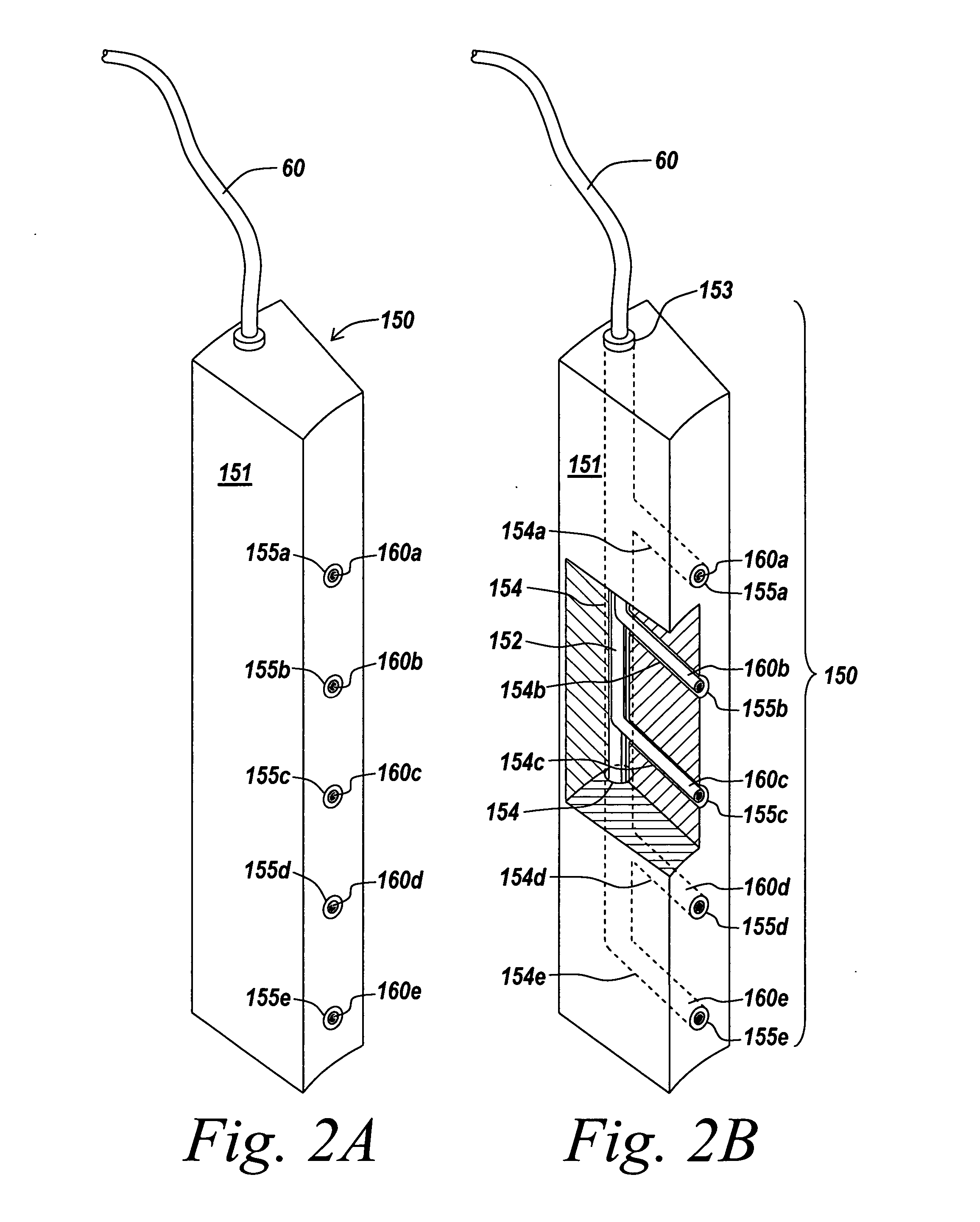

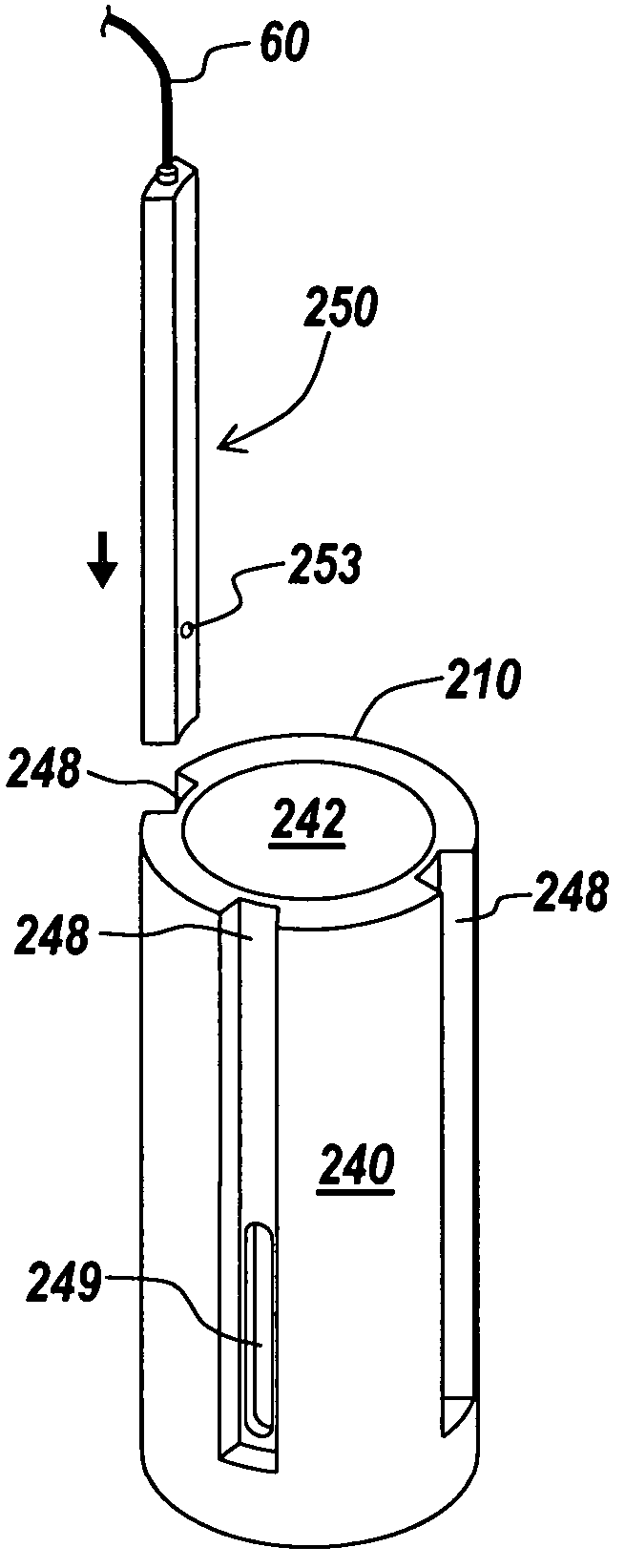

A surgical access system for providing access to a surgical site in a patient includes a surgical access device defining a port and a light emitter coupled to the surgical access device for illuminating the port. The light emitter preferably comprises an elongated shaft having a light transmitting element housed therein, which emits light transmitted to the elongated shaft from a light source. The elongated shaft is configured to be inserted in an elongated channel in the access device. The elongated channel has or forms a window for transmitting light emitted by the light emitter into the interior of the access device.

Owner:DEPUY SYNTHES PROD INC

Illuminated surgical access system including a surgical access device and coupled light emitter

ActiveUS7874982B2Small working areaConvenient lightingBronchoscopesLaryngoscopesSurgical siteSurgical device

A surgical access system for providing access to a surgical site in a patient includes a surgical access device defining a port and a light emitter coupled to the surgical access device for illuminating the port. The light emitter preferably comprises an elongated shaft having a light transmitting element housed therein, which emits light transmitted to the elongated shaft from a light source. The elongated shaft is configured to be inserted in an elongated channel in the access device. The elongated channel has or forms a window for transmitting light emitted by the light emitter into the interior of the access device.

Owner:DEPUY SYNTHES PROD INC

Illuminated surgical access system including a surgical access device and coupled light emitter

ActiveUS20110021882A1Small working areaConvenient lightingCannulasEndoscopesSurgical siteSurgical access

A surgical access system for providing access to a surgical site in a patient includes a surgical access device defining a port and a light emitter coupled to the surgical access device for illuminating the port. The light emitter preferably comprises an elongated shaft having a light transmitting element housed therein, which emits light transmitted to the elongated shaft from a light source. The elongated shaft is configured to be inserted in an elongated channel in the access device. The elongated channel has or forms a window for transmitting light emitted by the light emitter into the interior of the access device.

Owner:DEPUY SYNTHES PROD INC

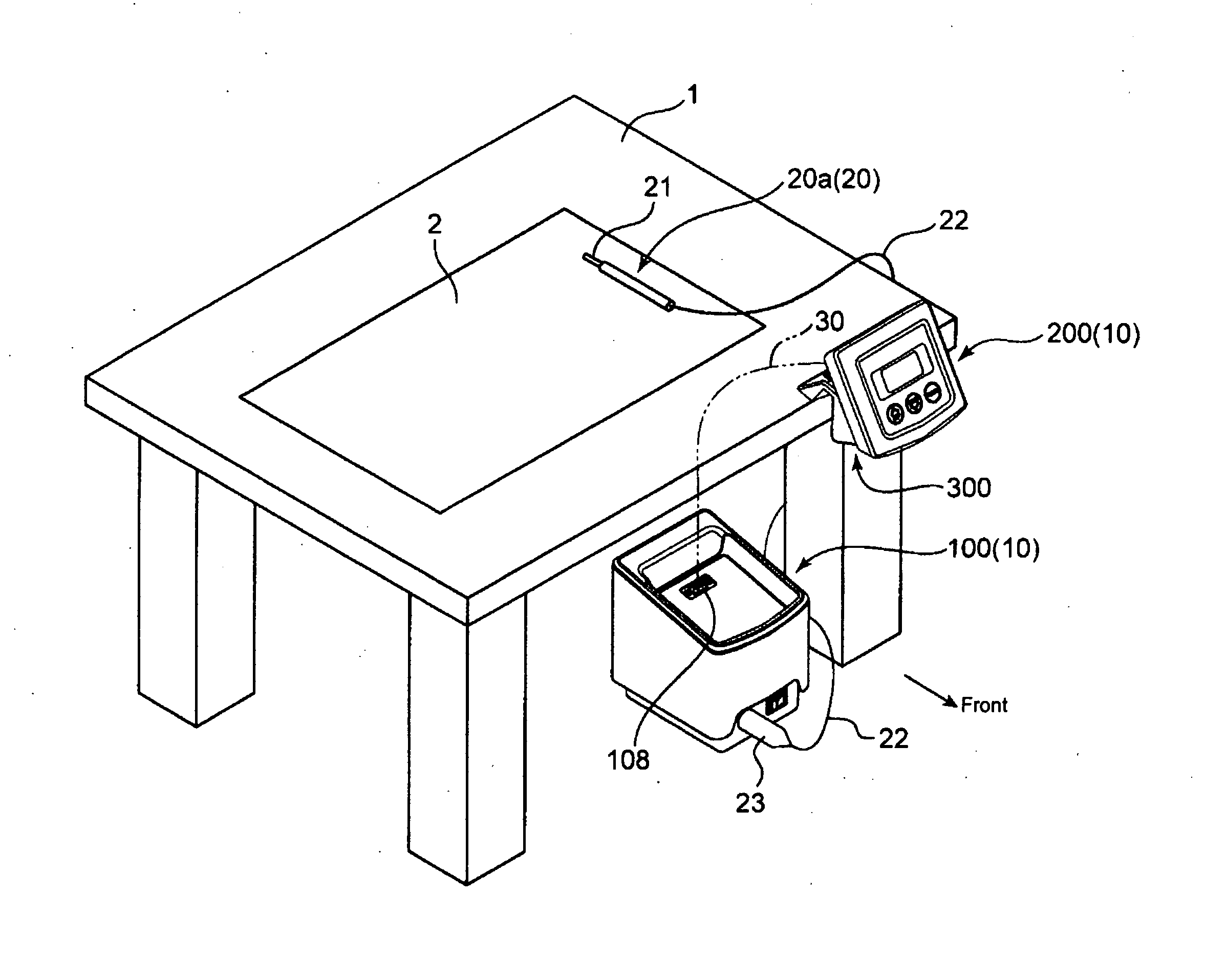

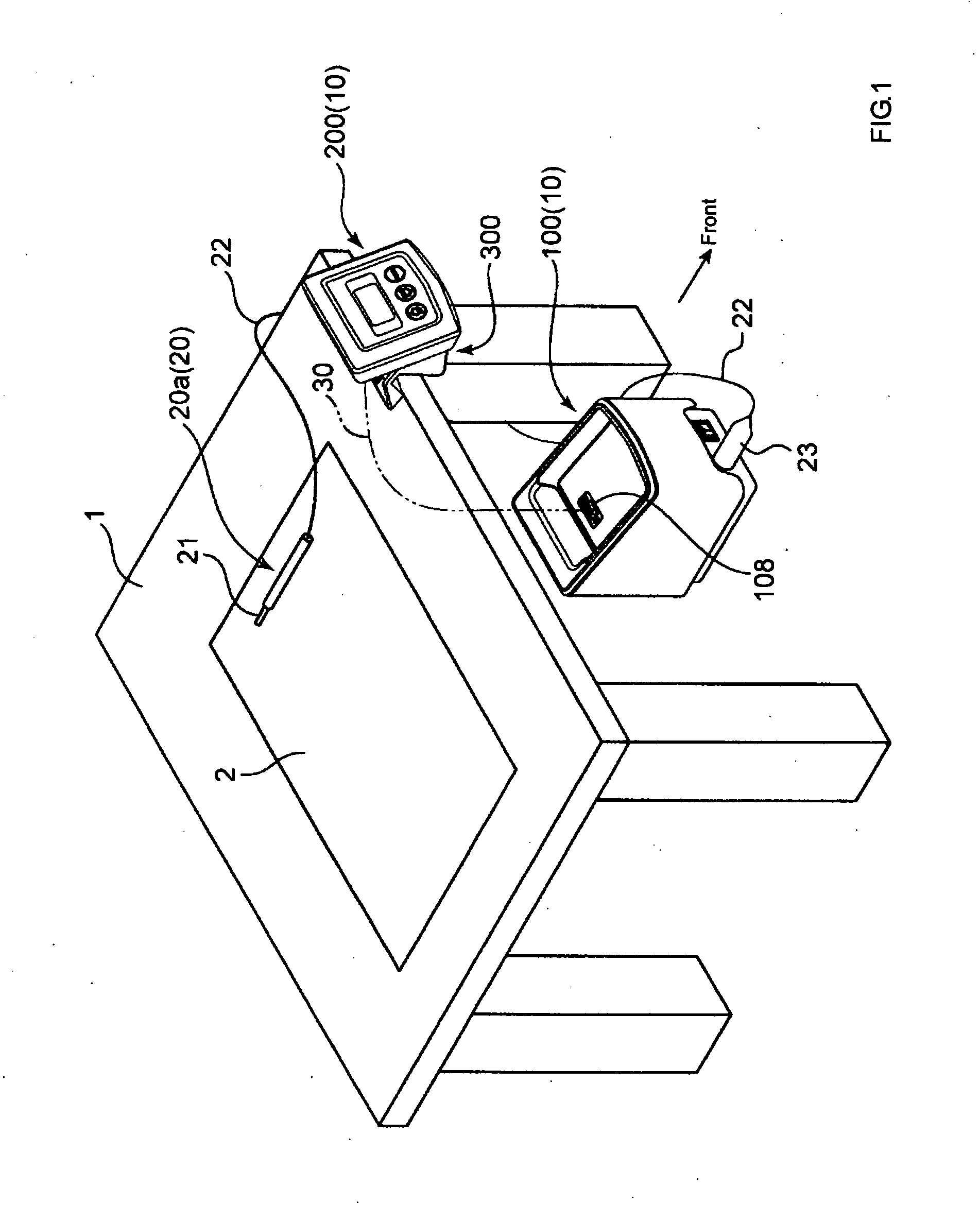

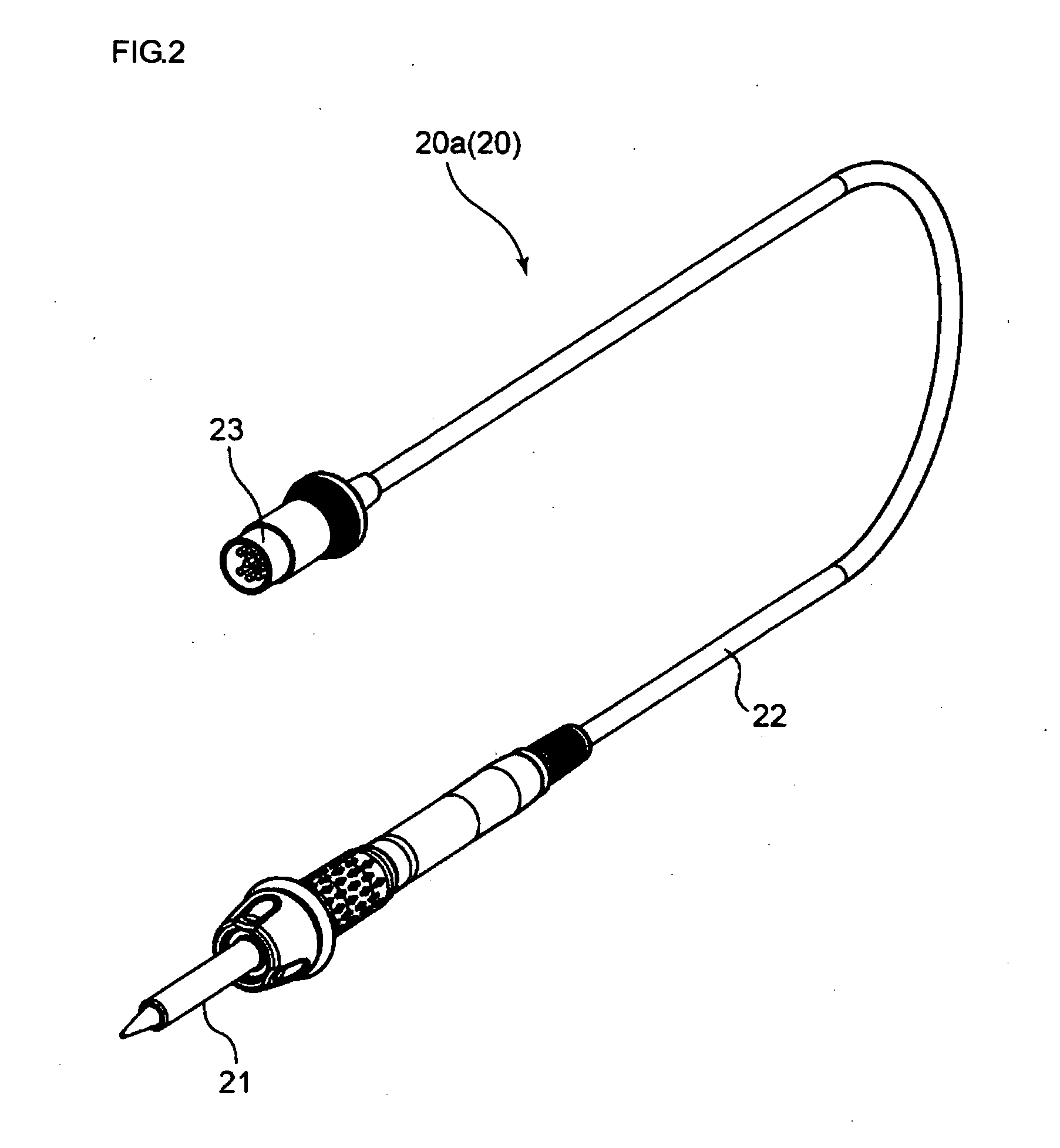

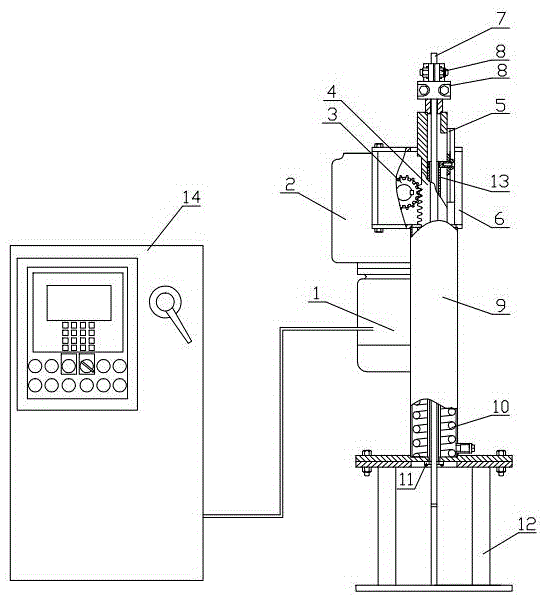

Soldering System Power Supply Unit, Control Unit, Administration Device, and Power Supply-and-Control Device

ActiveUS20150246404A1Improve convenienceSmall working areaComputer controlArc welding apparatusSolderingControl unit

The present invention is intended to ease the control and management of soldering devices, and enhance convenience. In accordance with the intention of the invention, a system includes a power supply unit having a connecting cable to be connected to soldering devices, a power supply portion supplying power to the soldering devices through the connecting cable, a power supply control portion to control the power supply from the power supply portion based on a temperature setting signal T(s) set in advance and a control unit that may be physically separated from the power supply unit but which inputs the temperature setting signal T(s) to the power supply control portion of the power supply unit.

Owner:HAKKO CO LTD

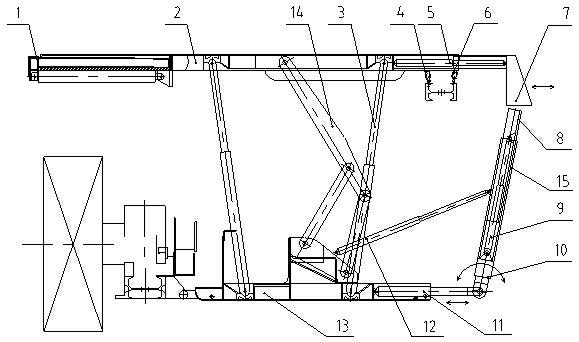

Automatic tamper type waste filling hydraulic support

InactiveCN102135006AGood topping effectSmooth connectionMaterial fill-upMine roof supportsGround subsidenceCut and fill

The invention discloses an automatic tamper type waste filling hydraulic support which comprises a base and a top beam, wherein the base and the top beam are connected by uprights, the front end of the top beam is provided with a forepole, the rear end of the top beam is provided with a scraper conveyor and further connected with an internally-telescopic extrusion scraping plate by a retractable jack which is arranged horizontally; the rear side of the base is provided with the extrusion scraping plate by a first and a second extrusion jacks, and the first extrusion jack is horizontally arranged. The automatic tamper type waste filling hydraulic support solves the problems that conventional cut and fill hydraulic support equipment can not ensure top filling of filler and has poor tamper intensity; in addition, the automatic tamper type waste filling hydraulic support realizes the high-strength supporting for a gob roof by virtue of waste fillers, effectively eliminates the defect of ground subsidence, realizes safe recovery for part of permanent coal pillars, corner coals and coal under buildings on the premise of not destroying factories and relocating villages, and improves the recovery of the coal resources. The invention is also suitable for various solid fillers such as coal ash, river sand, loess and the like.

Owner:HENAN POLYTECHNIC UNIV

Illuminated surgical access system including a surgical access device and integrated light emitter

ActiveUS8430813B2Small working areaConvenient lightingCannulasEndoscopesSurgical siteSurgical device

A surgical access system for providing access to a surgical site in a patient includes a surgical access device defining a working channel for accessing a surgical site and an integrated light emitter for illuminating the surgical site. The light emitter is integrated in proximity to a distal end of the surgical access device. In some embodiments, the light emitter is offset from the distal end. In certain embodiments, the integrated light emitter includes a light transmission medium for transmitting light from a proximal end of the access device to the distal end.

Owner:DEPUY SYNTHES PROD INC

Designing method of fish-friendly axial flow pump based on fish survival rate prediction

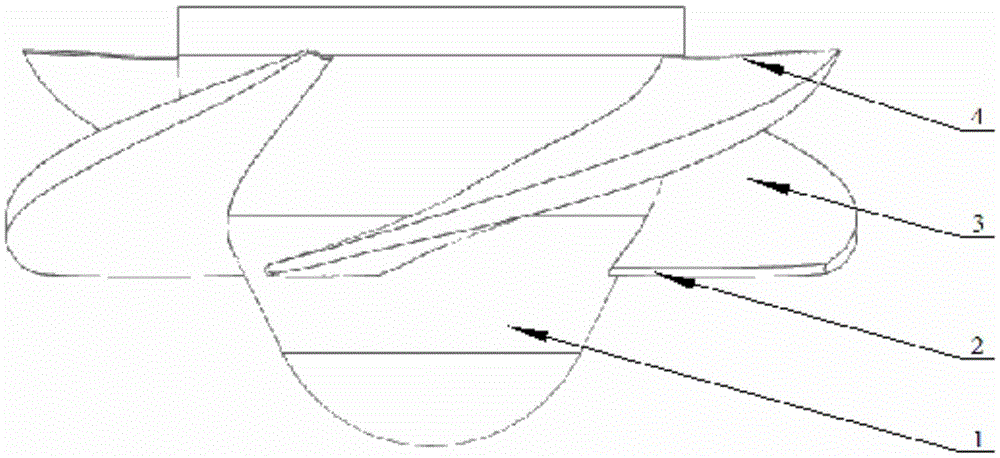

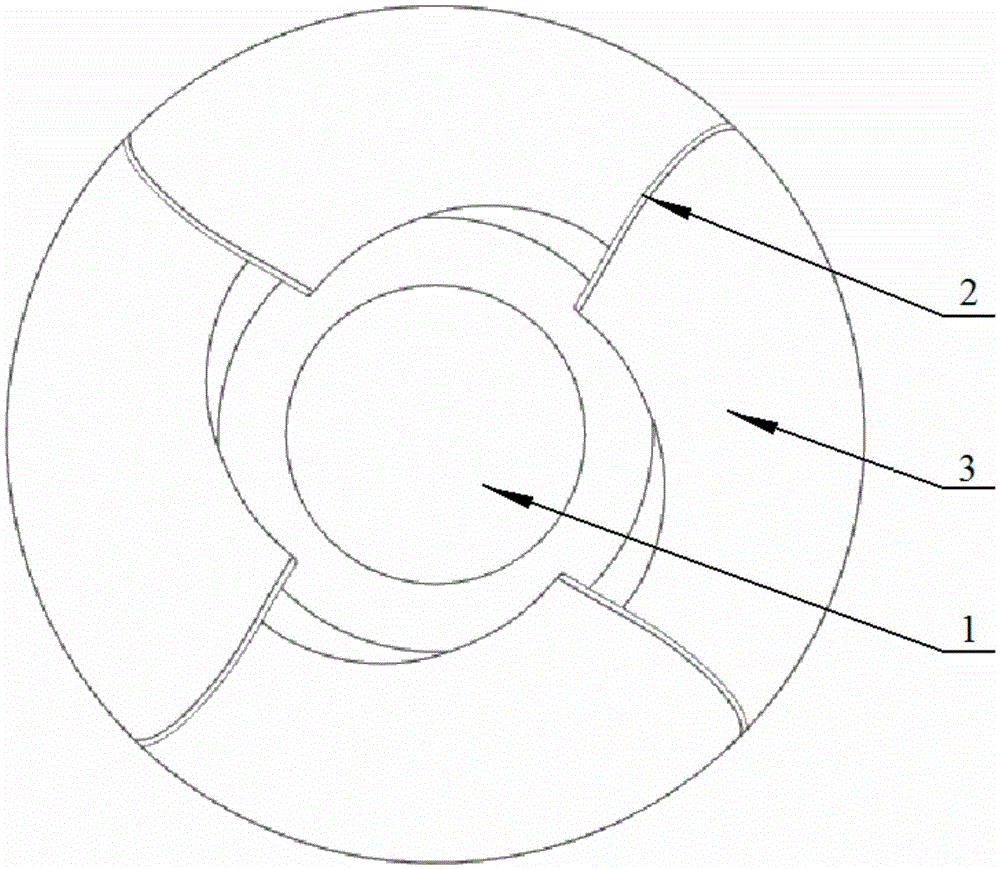

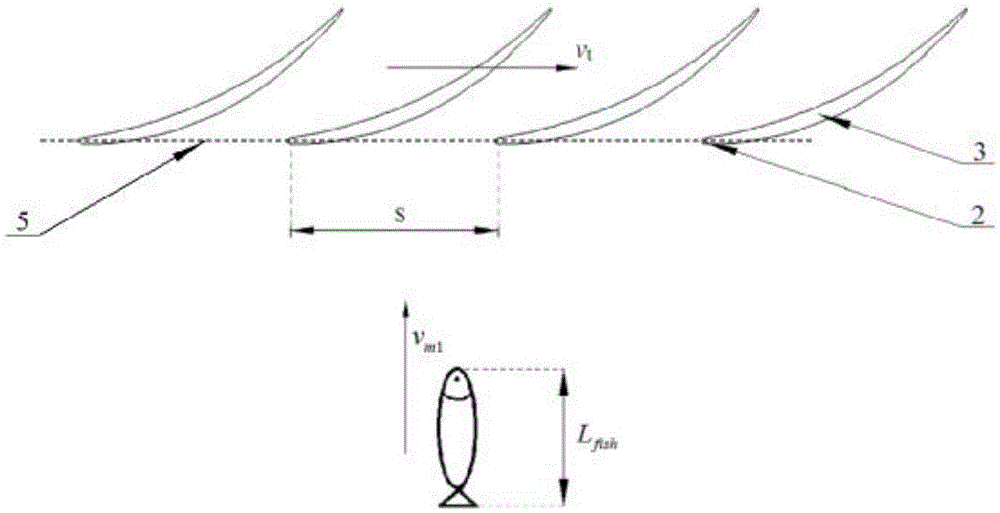

InactiveCN105626573AImprove survival rateReduce the probability of impactPump componentsPumpsAxial-flow pumpMathematical model

The invention provides a designing method of a fish-friendly axial flow pump based on fish survival rate prediction. A relation between a pump design parameter and the fish passing survival rate is predicted by adopting a mathematical model, and thus a fish-friendly design of an axial flow pump is guided. The mathematical model is mainly composed of the blade leading edge impact probability and the impact death rate; the impact probability is a ratio of the time that fishes pass through the cross section of passage of the blade leading edge and the time needed by an impeller rotating around a blade pitch; the impact death rate is relevant to the impact velocity, the fish length and the thickness of the blade leading edge; and the impact velocity adoptsa velocity component of a vertical leading edge. The fish-friendly axial flow pump design comprises the following steps: lowering the blade leading edge impact probability by adopting two blade impellers, lowering the impact death rate by adopting the blade leading edge with linear sweepforward protraction, and ensuring good hydraulic performance by virtue of airfoil parameter design. According to the designing method, a fish survival rate prediction model is high in goodness of fit to an experiment value, and the fish-friendly axial flow pump designed by guidance can greatly lower the fish death rate.

Owner:JIANGSU UNIV

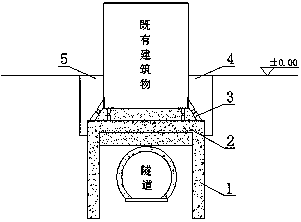

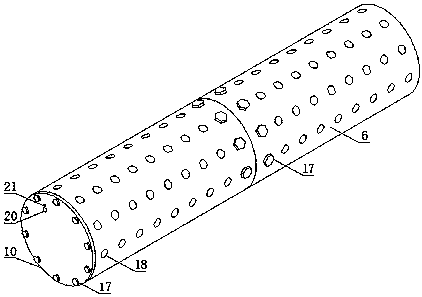

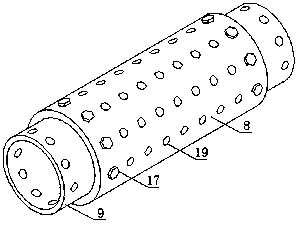

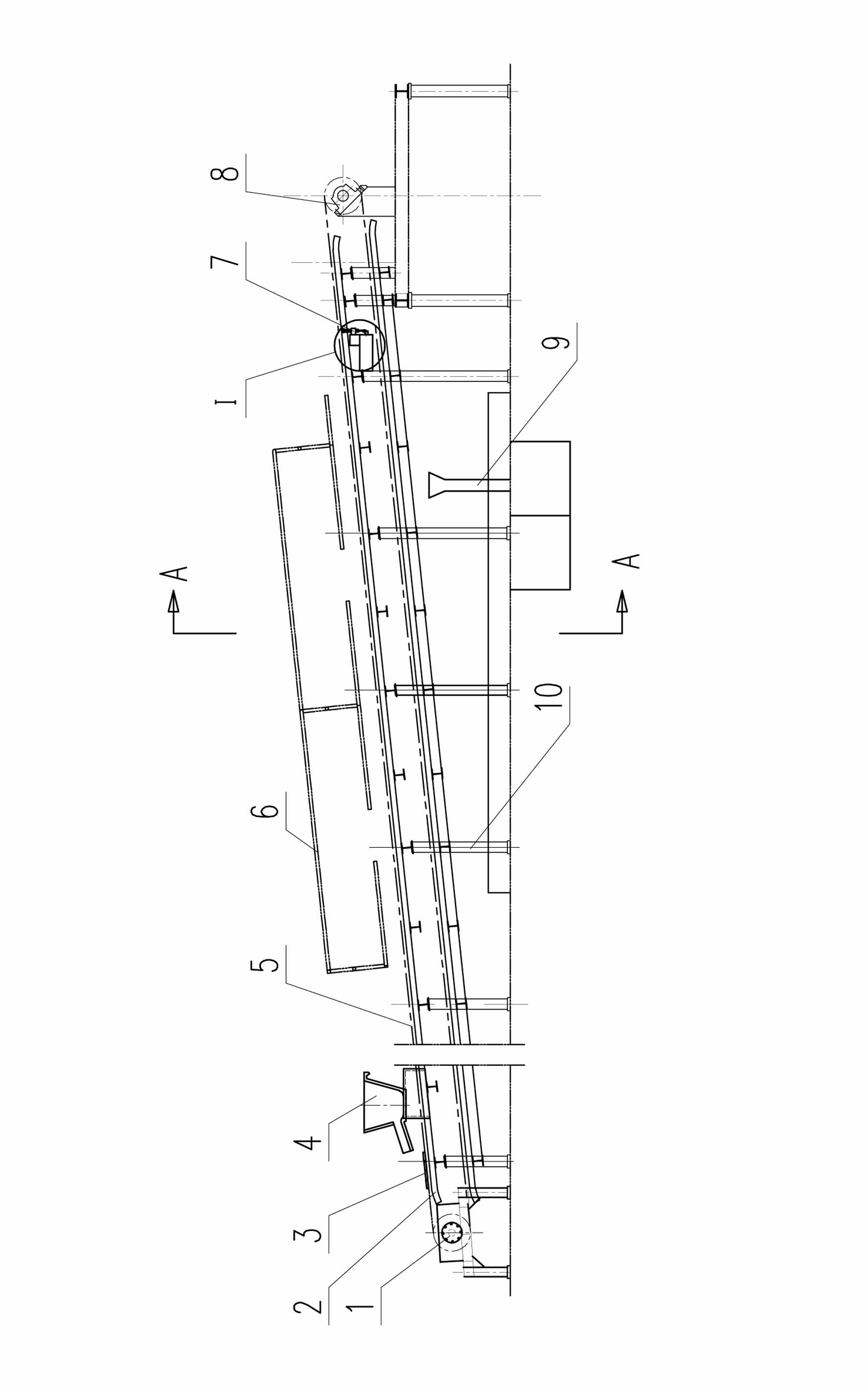

Tunnel support structure passing underneath existing building and construction method

ActiveCN108119149AAvoid leaningImprove stabilityUnderground chambersTunnel liningSheet steelReinforced concrete

The invention provides a tunnel support structure passing underneath an existing building and a construction method, and belongs to the field of tunnel engineering support. The structure is composed of load bearing anti-slide piles, a concrete filled steel tube beam and telescopic devices; the load bearing anti-slide piles are reinforced concrete piles; slurry-permeating steel pipes are connectedin sequence in a working well to form an exosmic steel pipe to be pushed to a receiving well, in this way, auxiliary pipes are connected in sequence and inserted into the exosmic steel pipe, the two ends of the exosmic steel pipe are blocked by means of circular steel plates, grouting is conducted in a gap of the steel pipes through a grouting hole, after the strength is met, the circular steel plates at the grouting ends and the auxiliary steel pipes are removed, concrete is poured into the exosmic steel pipe, and the concrete filled steel tube beam is formed; the end, provided with angle iron, of each telescopic device is connected with the bottom of the building through an expansion bolt, the other end of each telescopic device is welded to the exosmic steel pipe, reserved steel bars onthe tops of the load bearing anti-slide piles are inserted into holes formed in the two ends of the concrete filled steel tube beam, and the tunnel support structure is formed through grouting. The structure is simple in principle, reasonable in stress and capable of reducing the working space.

Owner:甘肃智广地质工程勘察设计有限公司

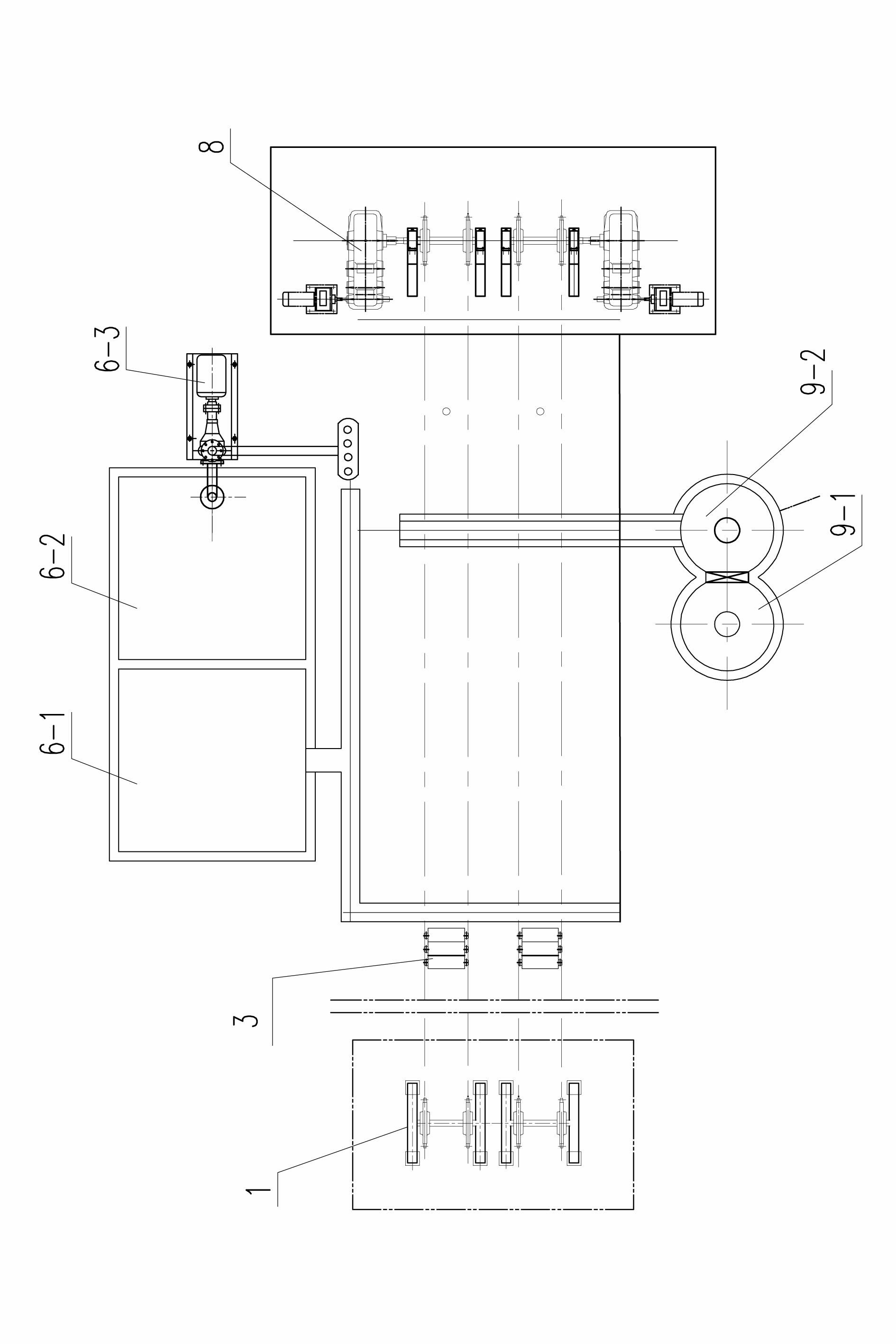

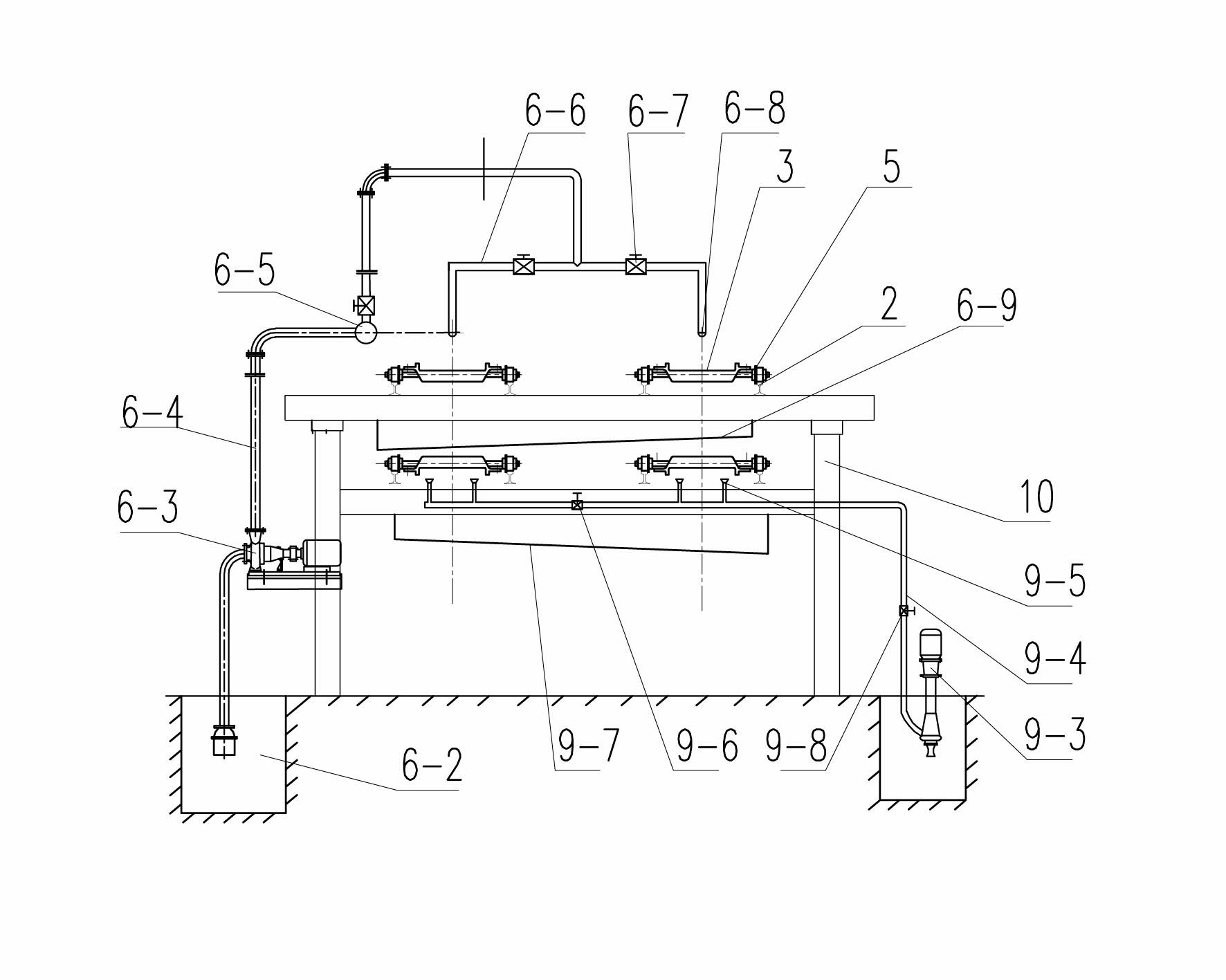

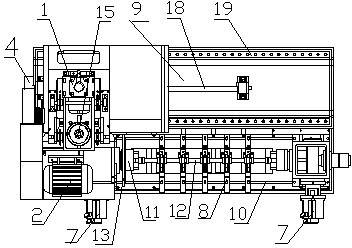

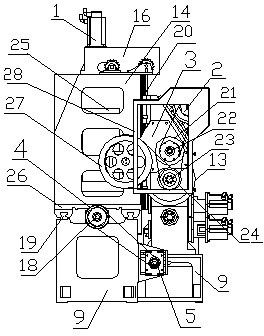

Iron alloy grain casting machine

The invention belongs to the technical field of pig casting machines for continuously producing casting pigs, and in particular relates to an iron alloy grain casting machine, which consists of a chain type slope conveyor, a grain casting die, a slurry spraying mechanism, a water cooling mechanism, a shocking device, an iron alloy liquid pouring insulation chute, a finished grain casting product receiving hopper and an electric control device, wherein the chain type slope conveyer consists of a conveyor frame, a chain inclined rail, a conveyor driving device, a conveyor tensioning and rotating device, and an annular roller chain; the slurry spraying mechanism consists of a stirring device, a slurry spraying stirring tank, a slurry spraying tank, a coating slurry sprayer and a slurry return groove; the water cooling mechanism consists of a water sedimentation tank, a water cooling tank connected with the water sedimentation tank through a water connecting pipe, a cold water sprayer and a water return groove; and the shocking device consists of a shocking bracket, a shocking driving device, an eccentric block, a fixed pin roll, a connecting rod, a reciprocating rod, a guide sleeve, a spring and a contact. The iron alloy grain casting machine completes a series of work procedures such as pouring, cooling, demolding and collecting iron alloy grains at one time and reduces labor intensity and production cost.

Owner:LIAONING DINGSHIDA METALLURGICAL EQUIP MFG +1

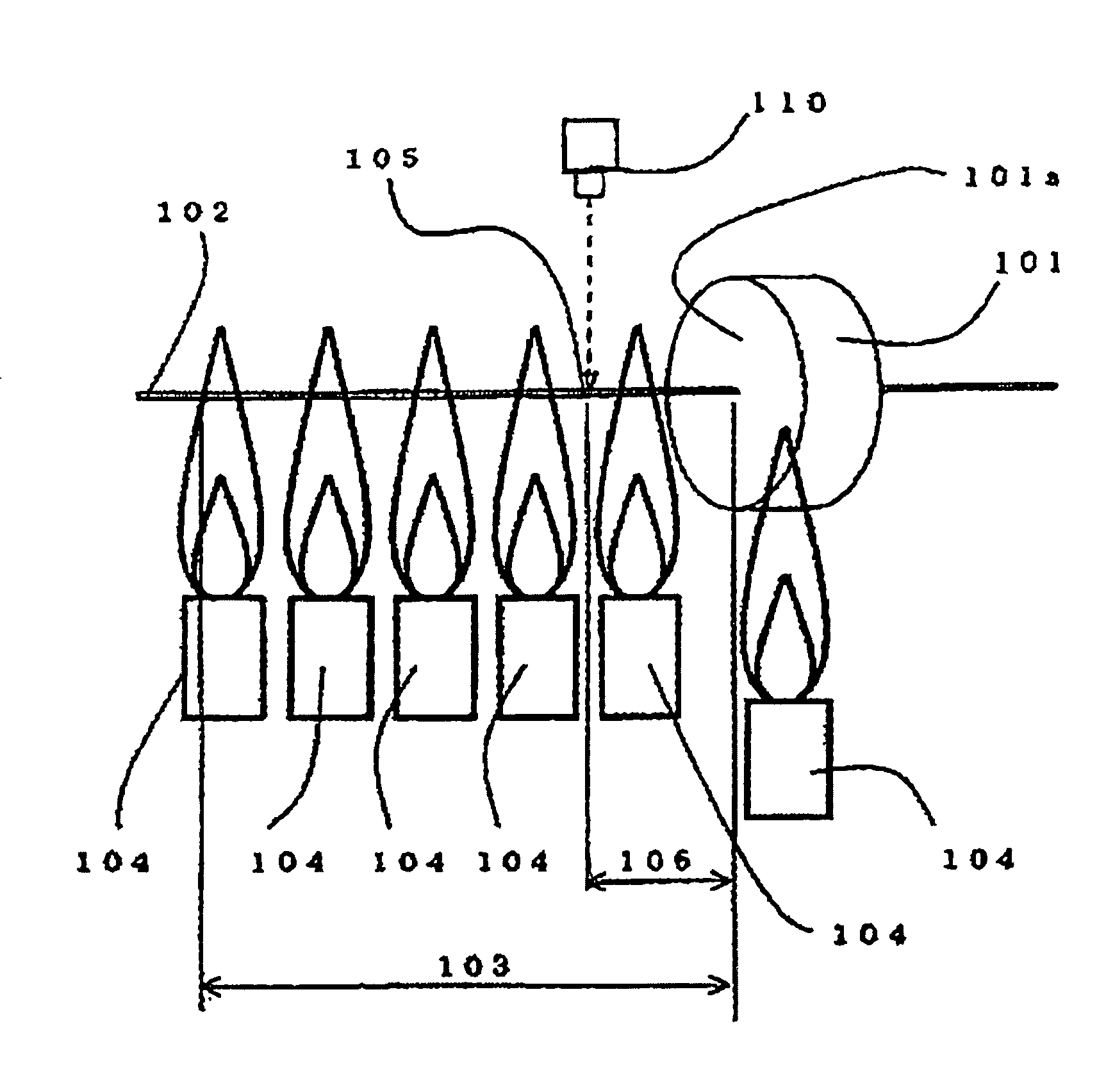

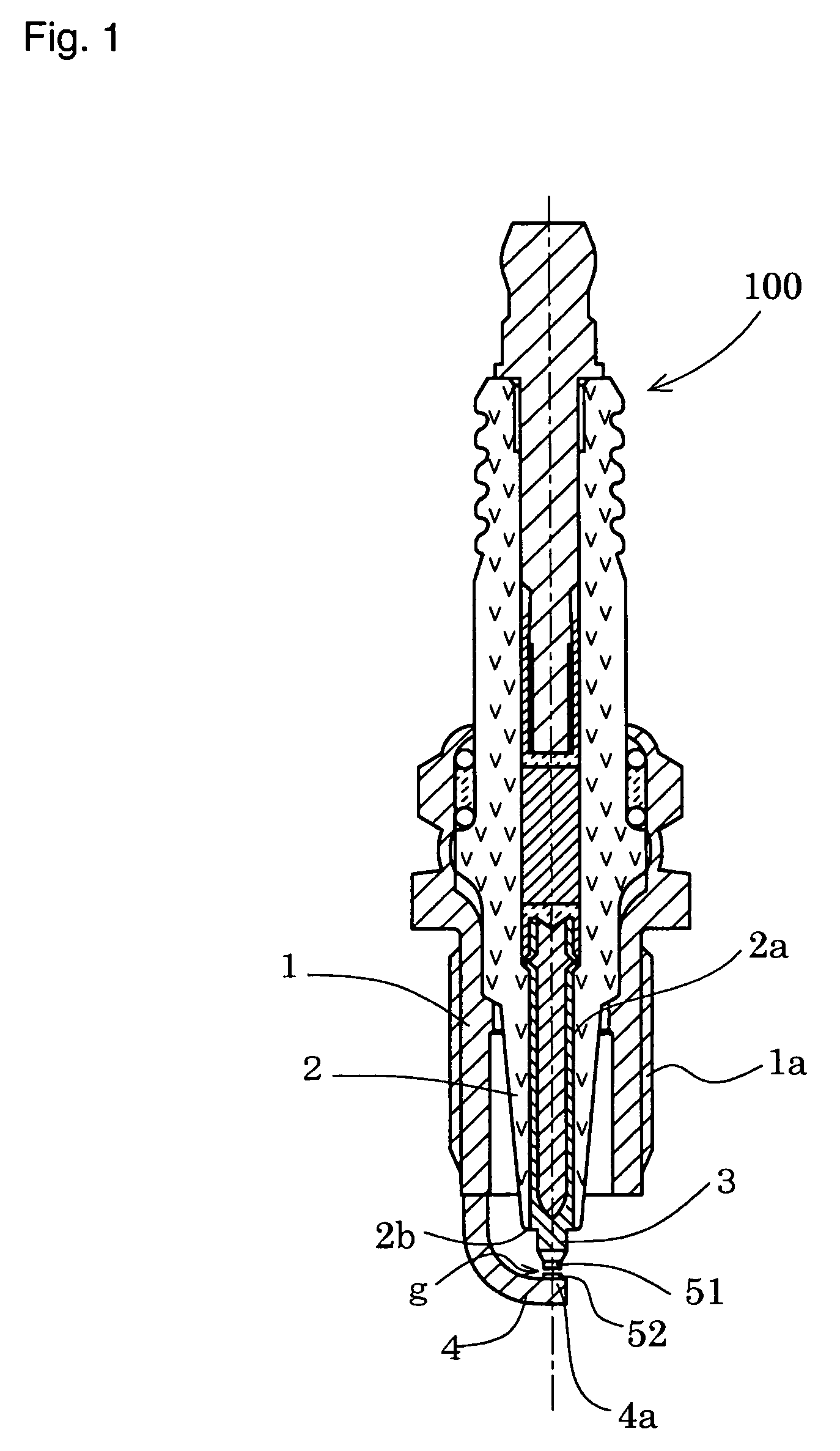

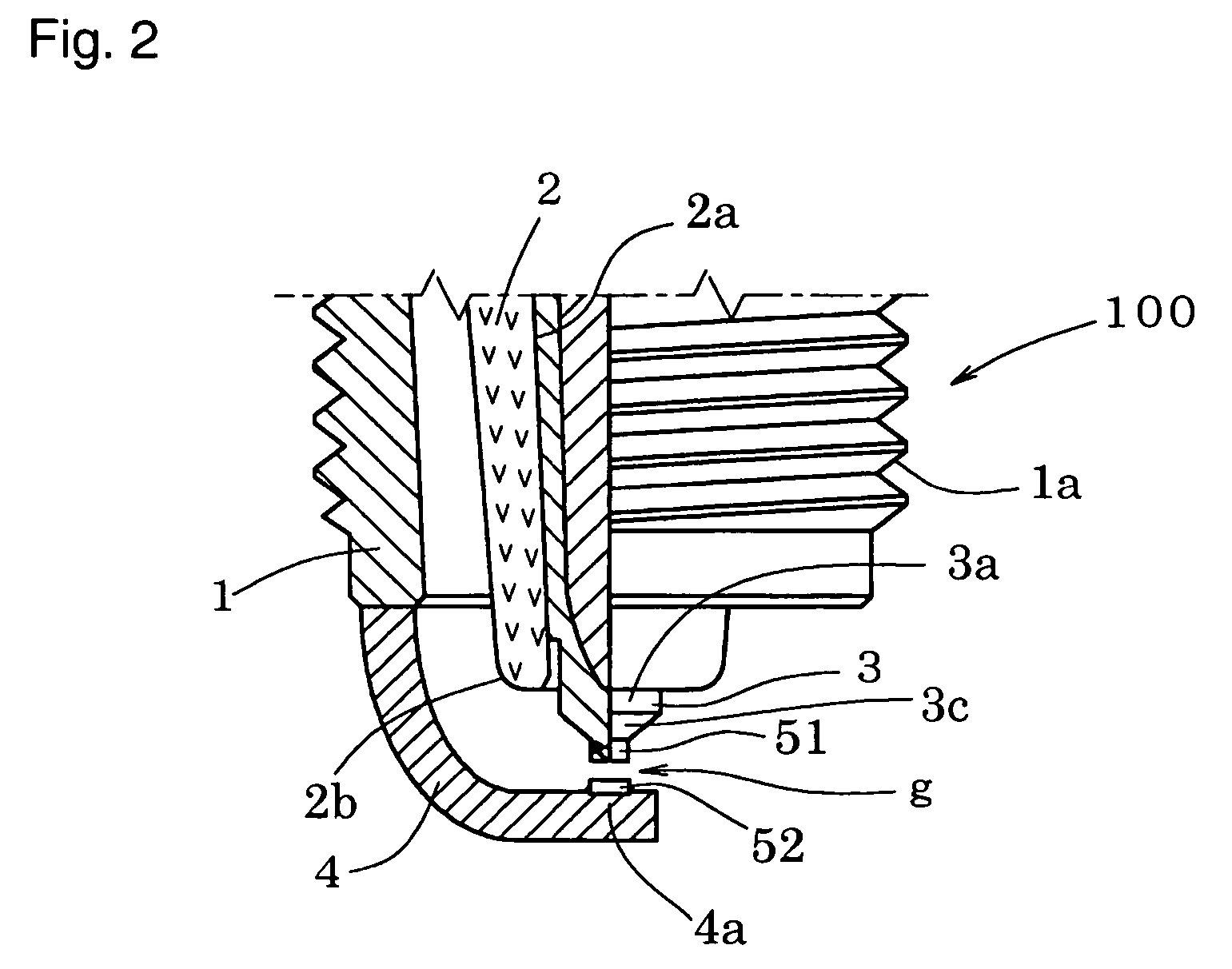

Method for manufacturing noble metal electric discharge chips for spark plugs

ActiveUS7131191B2Suppress oxidation volatilityRemarkable effectContact member manufacturingSpark gapsIridiumPlatinum

In a wire drawing process for forming a wire rod containing iridium as a main component and which further contains nickel and at least one of platinum, rhodium and ruthenium, and having a cross-sectional area of not smaller than 0.05 mm2 and not larger than 1.2 mm2. The worked material is continuously heated red hot and / or white hot in a heating region 103 extending up to 60 mm from the work inserting surface 101a of a die 101 in a direction opposite that in which the work 102 moves, the work being heated to a temperature of 1000 to 1150° C. at a temperature measuring position 105 which is removed from the work inserting surface 101a by 20 mm. Furthermore, the temperature in the region 106 extending from the temperature measuring position 105 to the work inserting surface 101a is set to not lower than 1000° C., and the wire drawing rate is set to 300 to 1600 mm / min.

Owner:NGK SPARK PLUG CO LTD

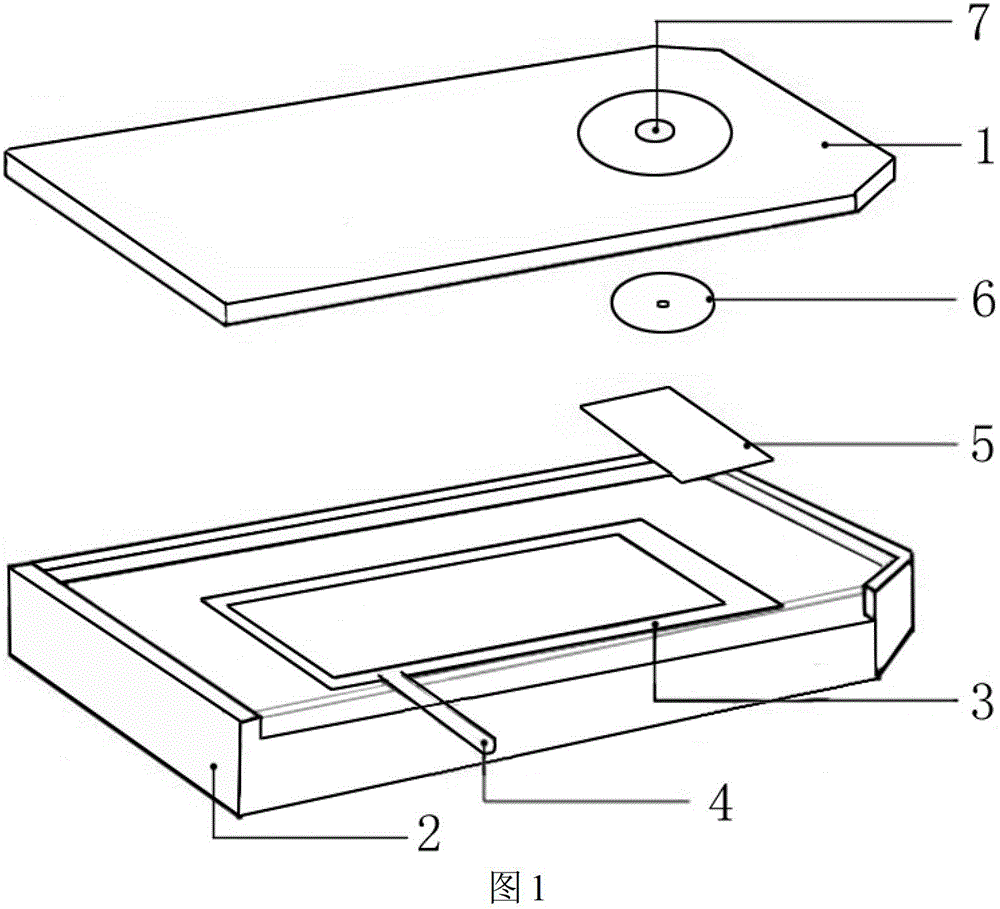

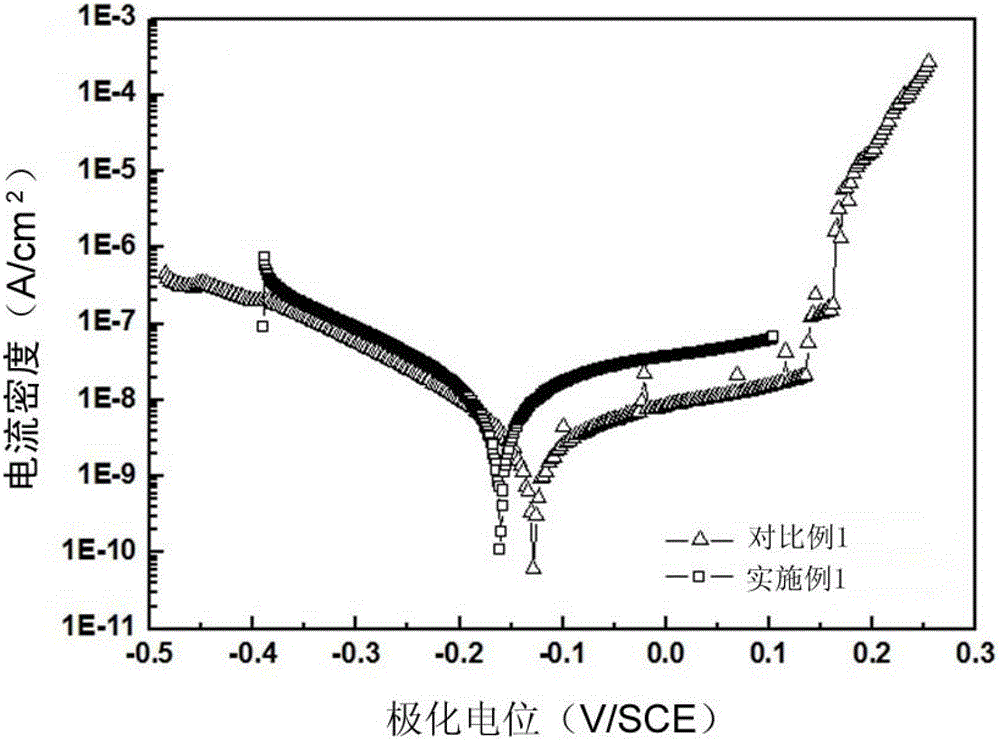

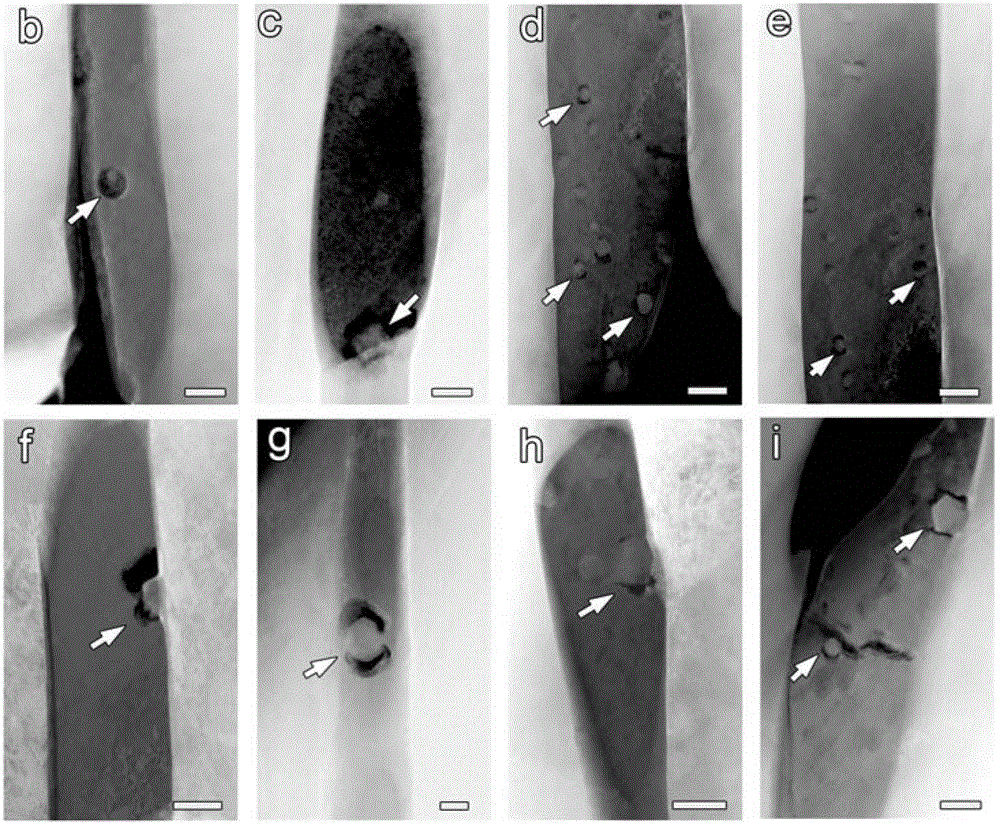

Apparatus for studying electrochemical behavior of material corrosion, and in-situ TEM method thereof

InactiveCN104007149ARealize Correspondence ObservationSmall working areaPreparing sample for investigationMaterial electrochemical variablesIn situ studyAluminium

The invention discloses an apparatus for studying electrochemical behavior of material corrosion, and an in-situ TEM method thereof, and belongs to the research field of corrosion electrochemistry behaviors. The apparatus comprises an upper plastic shell, a lower plastic shell, a platinum sheet and an aluminium conductive wire. The upper plastic shell is provided with a hole having a diameter of 2 mm; an upper surface of the lower plastic shell is embedded with the platinum sheet; the platinum sheet is connected to one end of the aluminium conductive wire; the other end of the aluminium conductive wire extends to the outer part of the lower plastic shell; the platinum sheet is provided with a pad, a TEM sample and the upper plastic shell in sequence; and the TEM sample contacts with electrolyte out of the apparatus through the hole on the upper plastic shell. The TEM sample is encapsulated in to an electrode by using the apparatus; then test of an electrochemical curve is carried out in the electrolyte to obtain electrochemical information; and the sample after the test is observed and characterized by TEM. The method can realize in-situ study of structural evolution in an electrochemical corrosion process in small size, thereby realizing corresponding observation of the electrochemical information and the structural evolution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

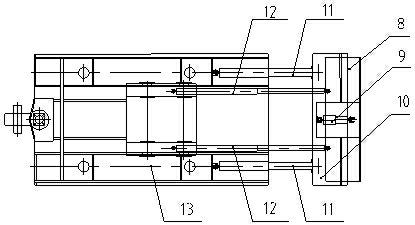

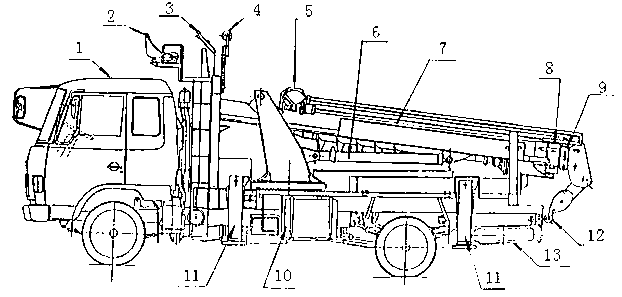

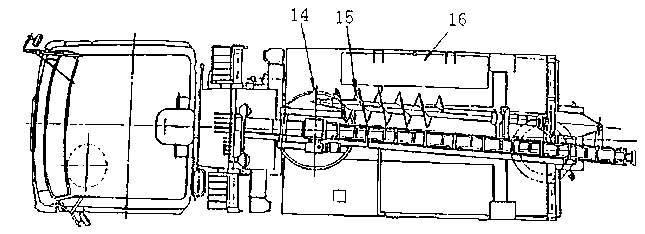

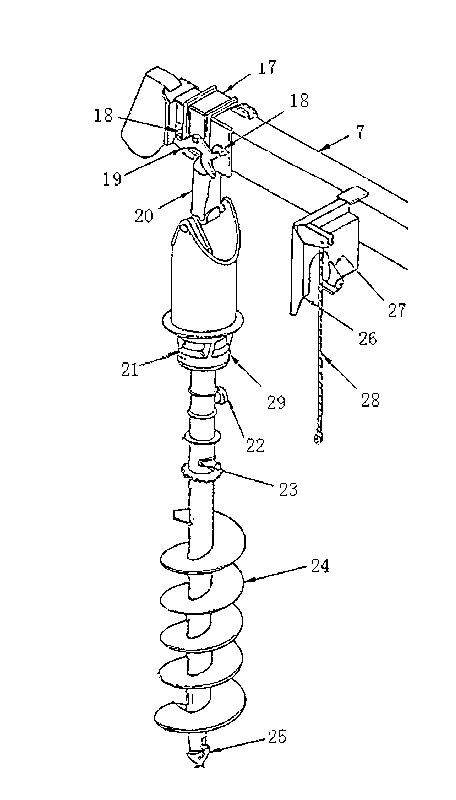

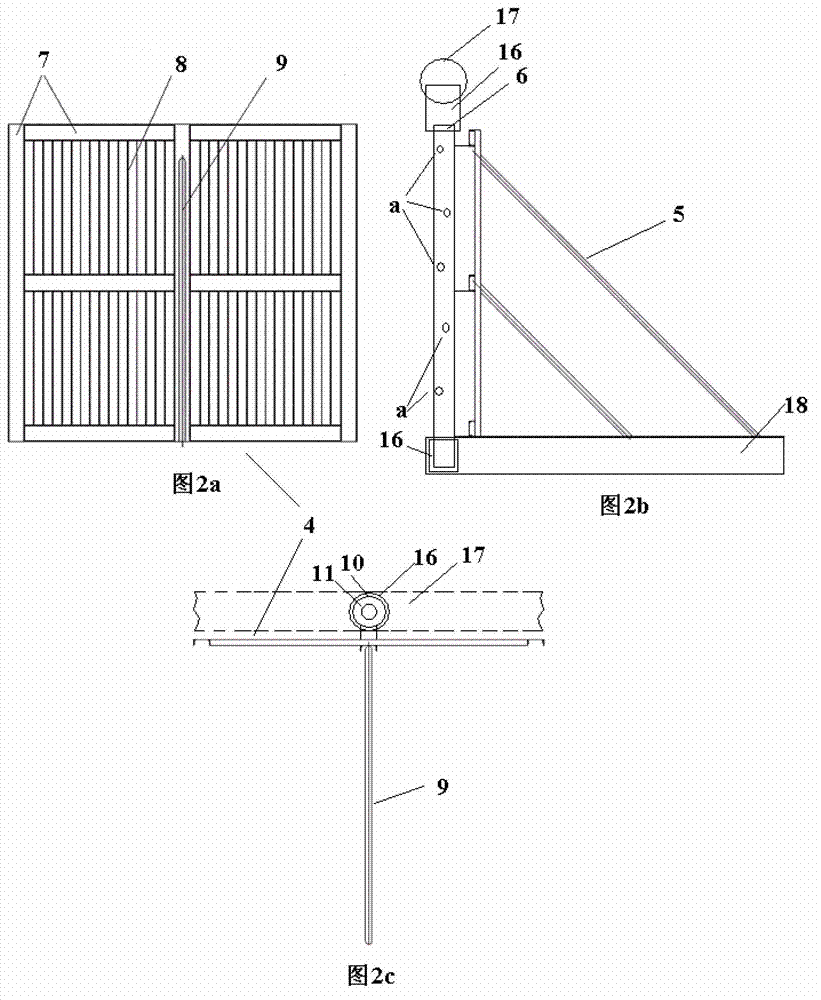

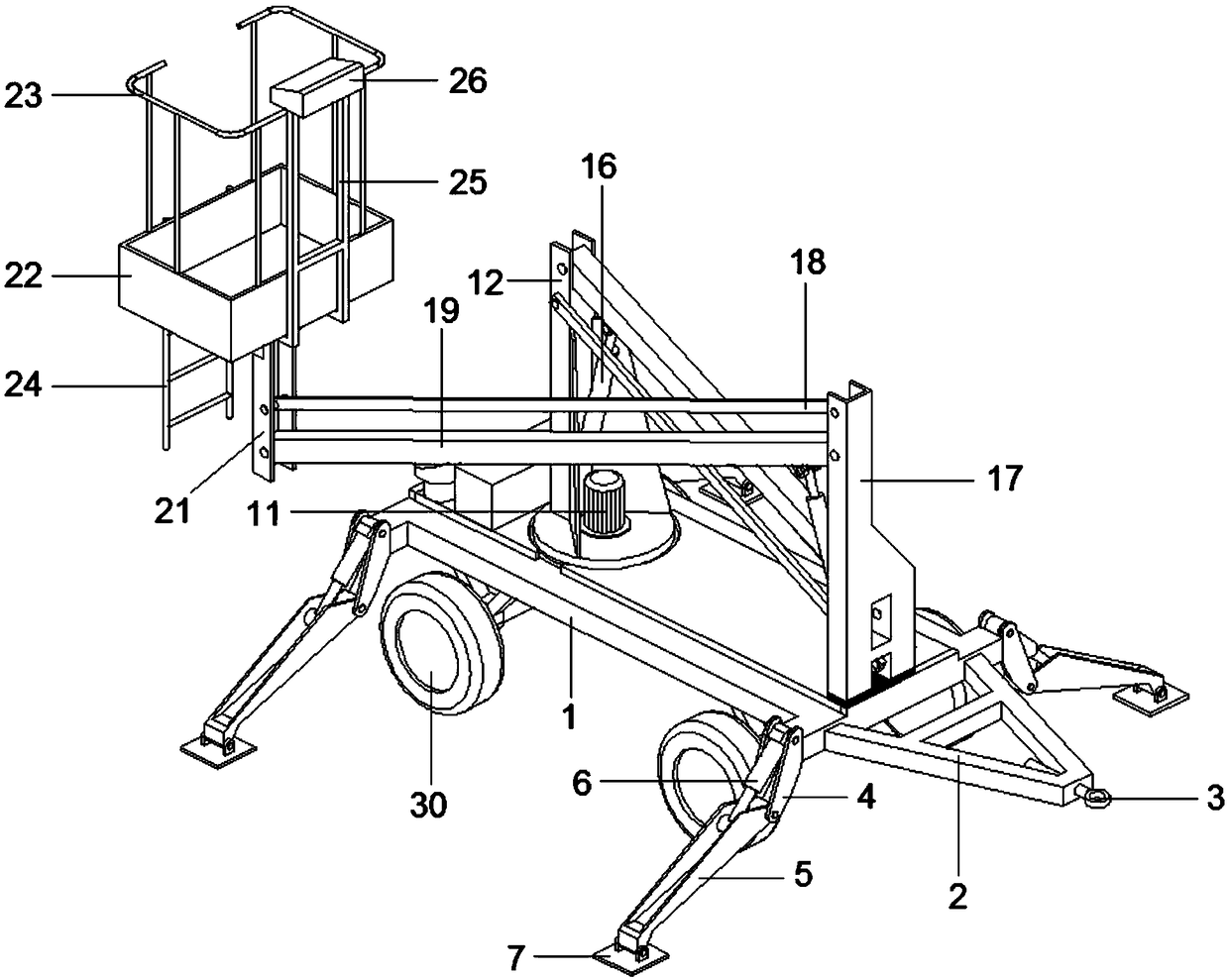

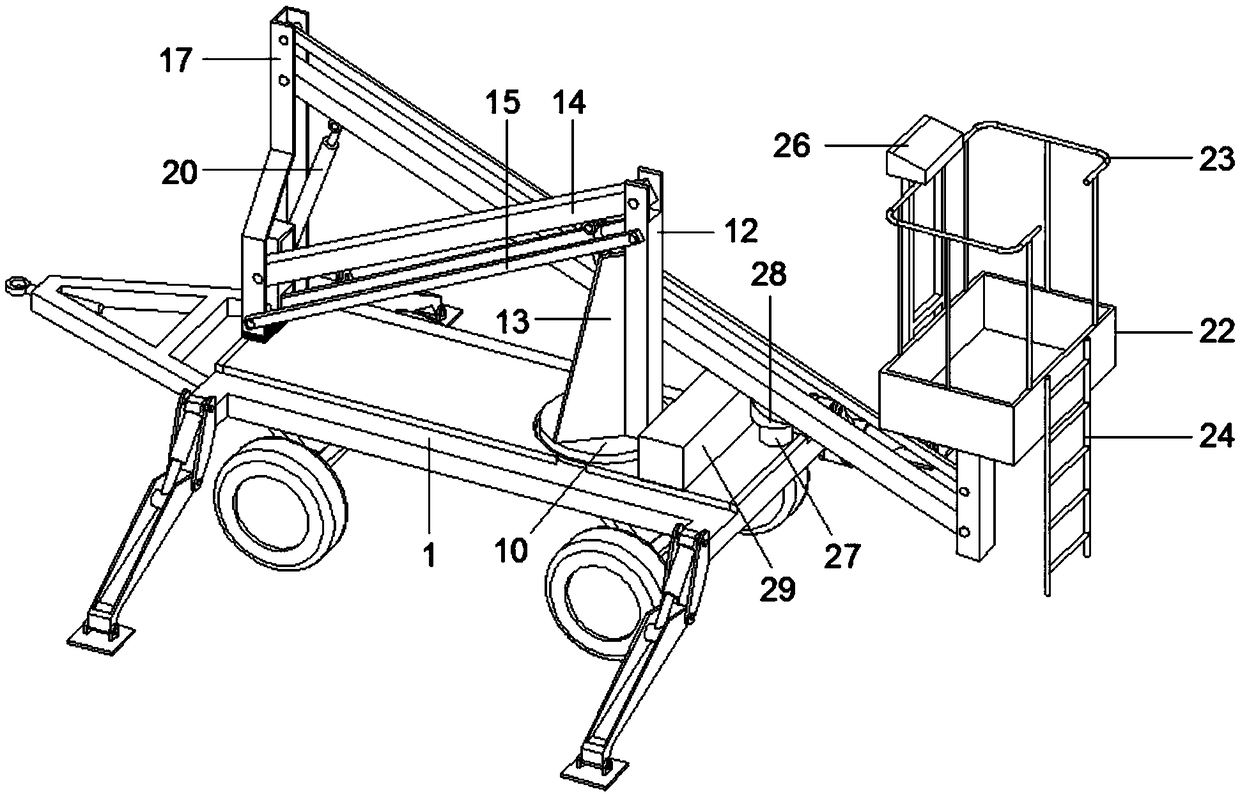

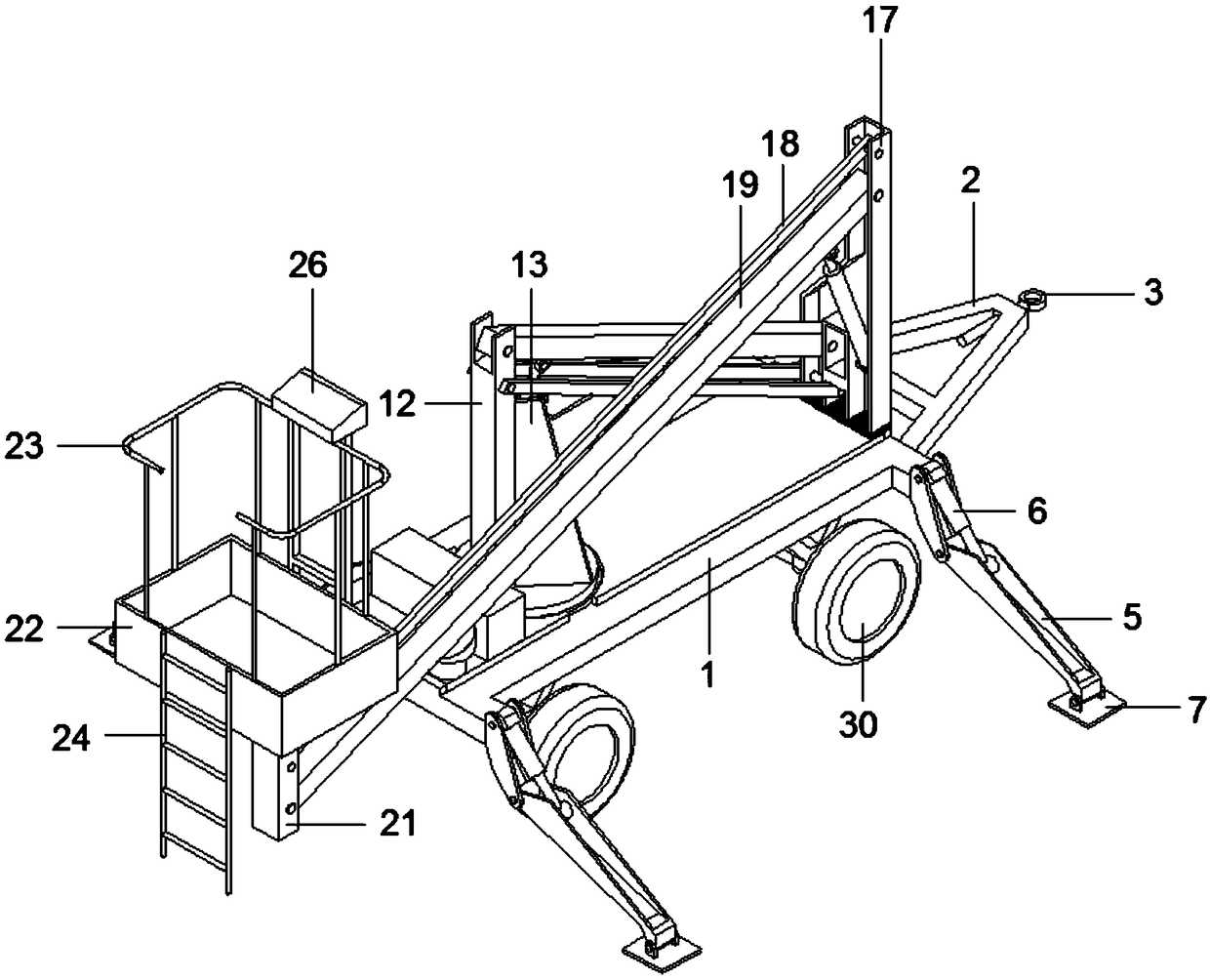

Hole-drilling pole-erecting vehicle

The invention relates to a hole-drilling pole-erecting vehicle which comprises a head and a body. An operating seat is arranged at a joint of the front end of the body and the head, an operating rod and an operating lamp are arranged right in front of the operating seat, a cycling platform is fixed in the middle of the front end of the body and connected with a rising and falling device through a lifting-on device to control an outer hanging rod, an inner hanging rod is socketed inside the outer hanging rod, a screw drill supporting portion is arranged on the inner hanging rod, a screw drill device and a hanging hook device are arranged on the screw drill supporting portion, an actuating oil tank is arranged on the side face of the body, supporting legs are arranged around the bottom of the body, and a containing box is arranged on one side of the upper portion of the body. An advanced process and excellent materials are adopted to design and manufacture the hole-drilling pole-erecting vehicle, so that the hole-drilling pole-erecting vehicle is reliable in quality, good in pole erecting effect, suitable for hillside fields, sandy fields and hard fields, small in operating area and free of green belt damaging and is ideal mechanical equipment for drilling and erecting wire poles, road lamp poles and telecom optical cable concrete poles.

Owner:山东华源索具有限公司

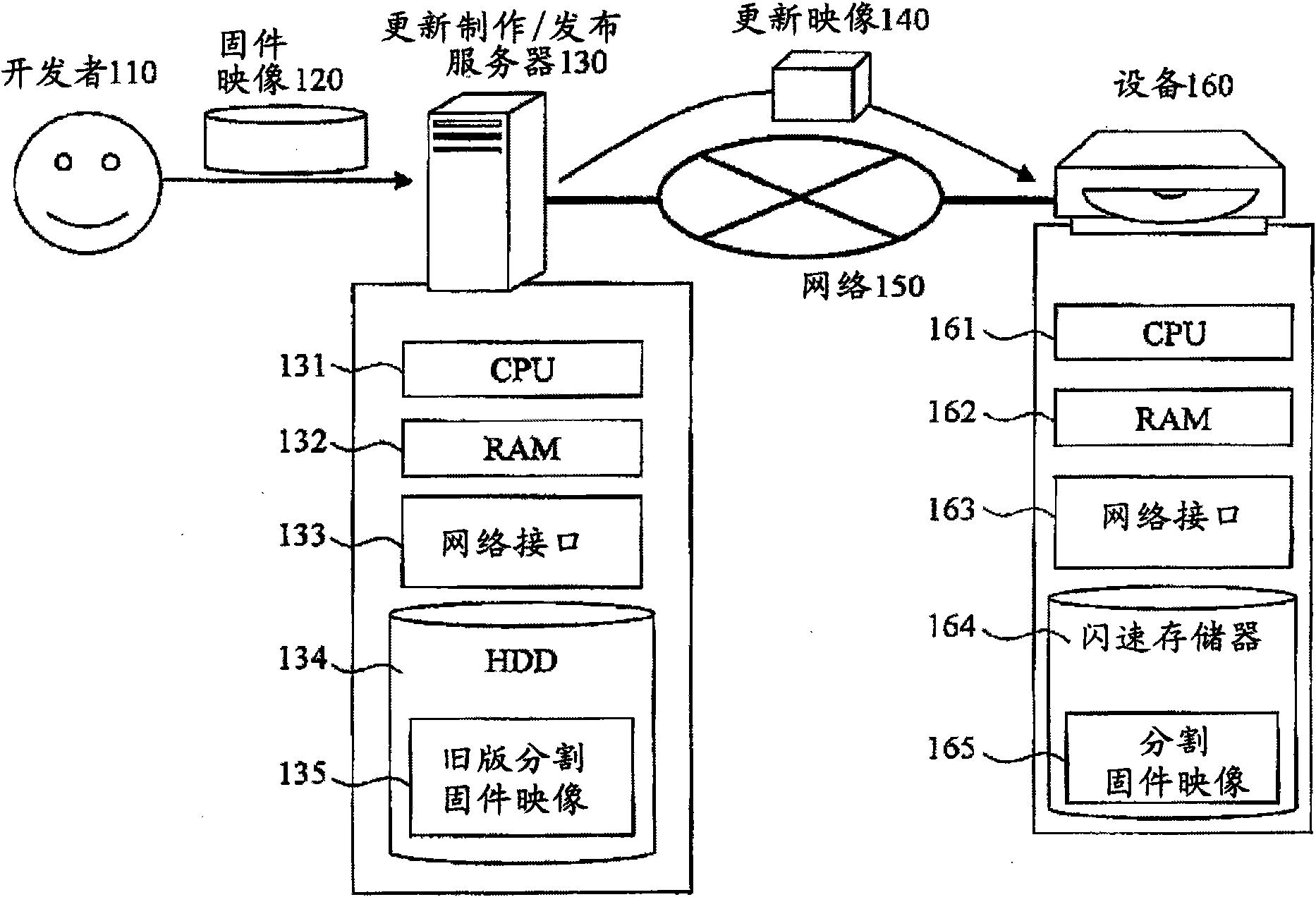

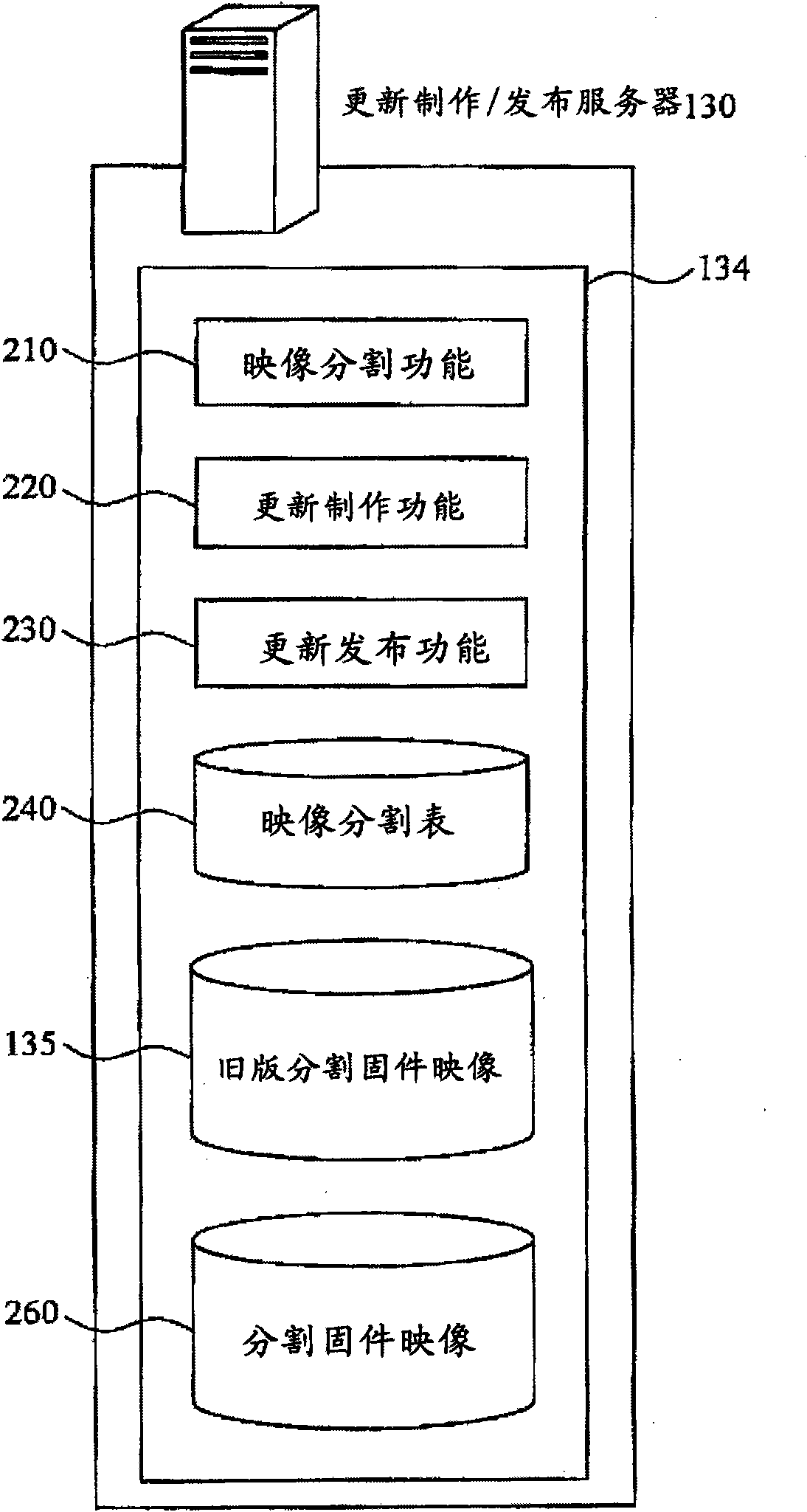

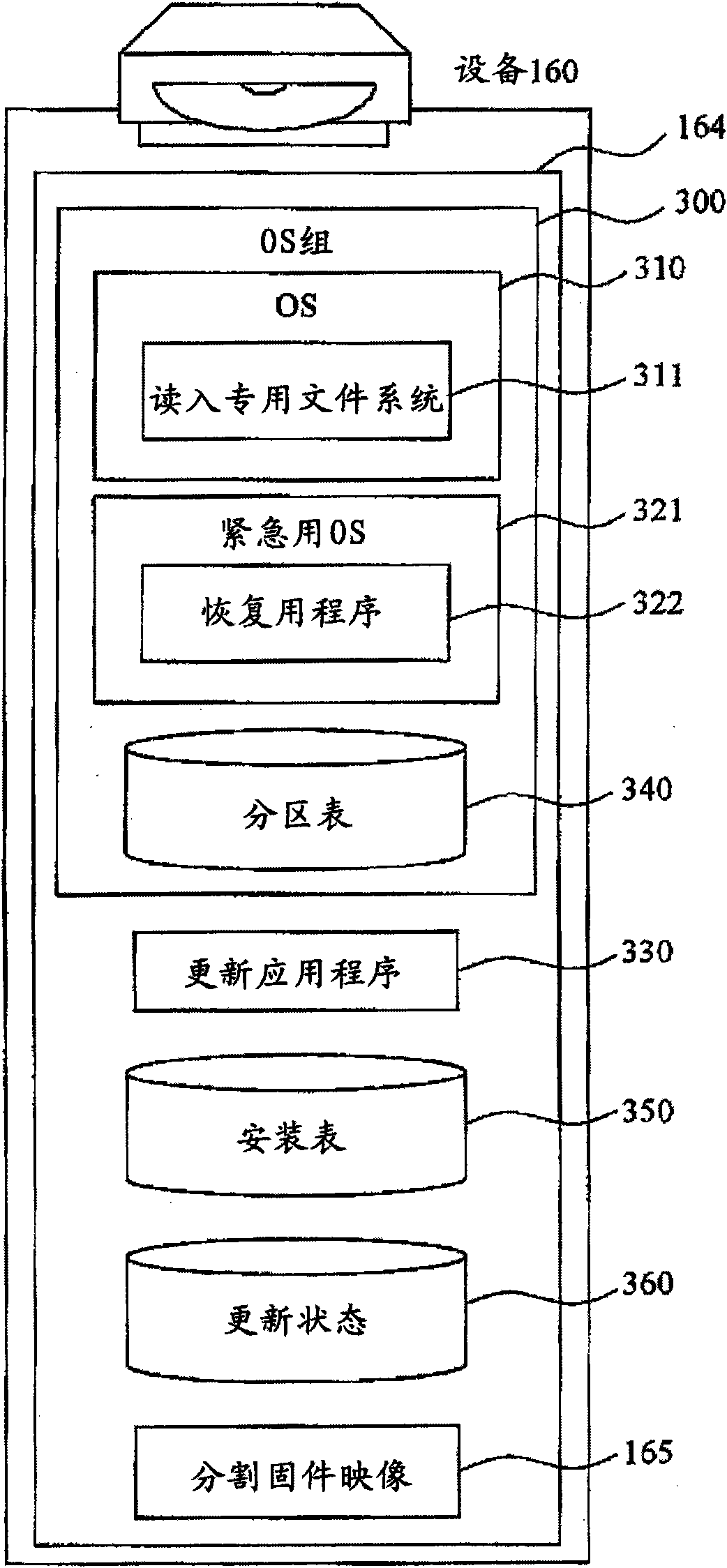

Firmware updating system, firmware delivering server, firmware incorporating device, and program

InactiveCN102132259ASmall working areaShort working hoursError detection/correctionSoftware deploymentNetwork packetFile system

Provided is a firmware updating technique wherein: working area is small; working time is short; updating can be resumed even in the event of power interruption; and file systems that do not support writing are supported. An update creating / delivering server divides the firmware images of old and new versions; extracts differences between the divided firmware images of the old and new versions; creates an updated package; and delivers the updated package to an incorporating device. On the other hand, the incorporating device applies the updated package to the divided firmware images of the old version (currently-used, existing firmware images).

Owner:HITACHI SOFTWARE ENG

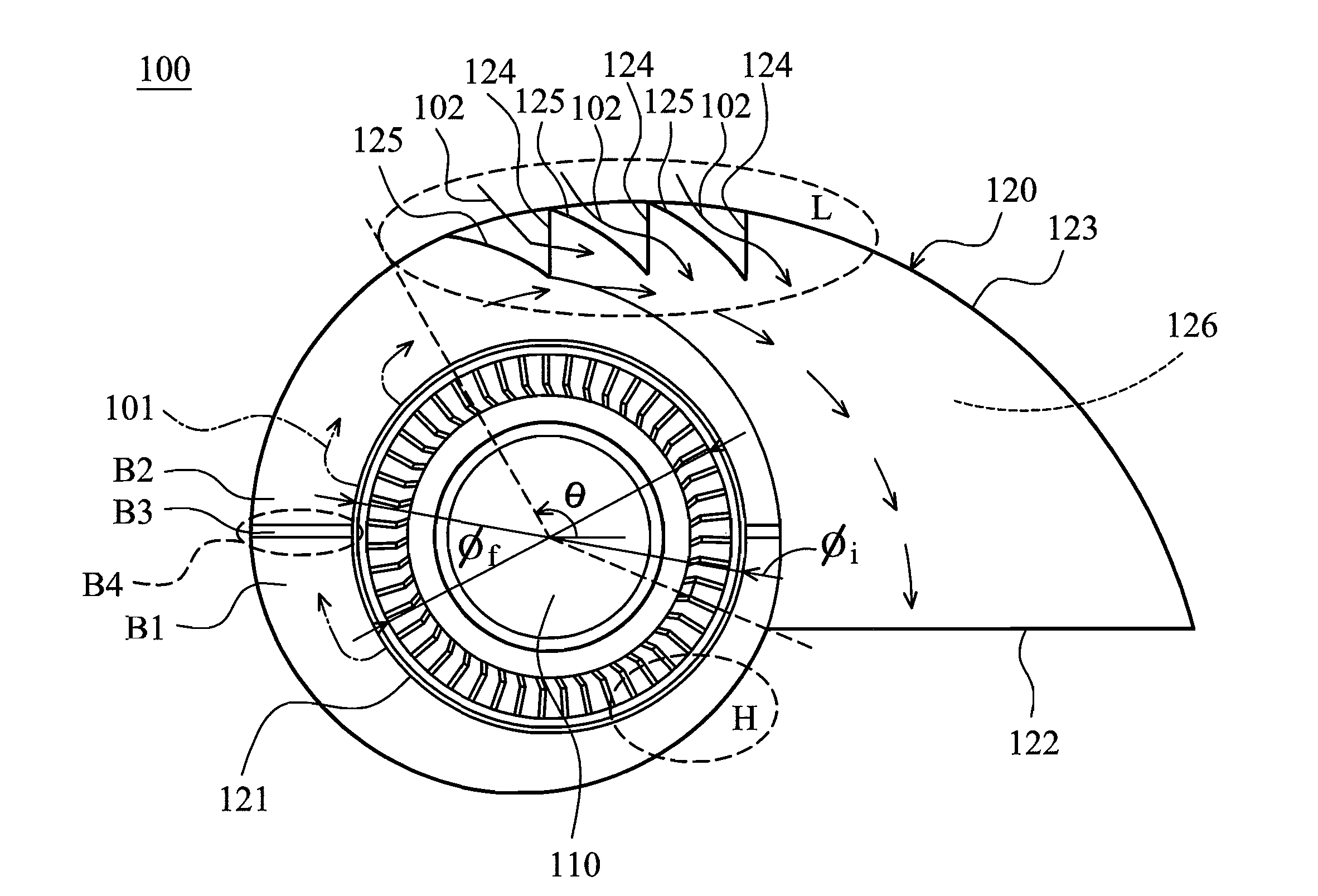

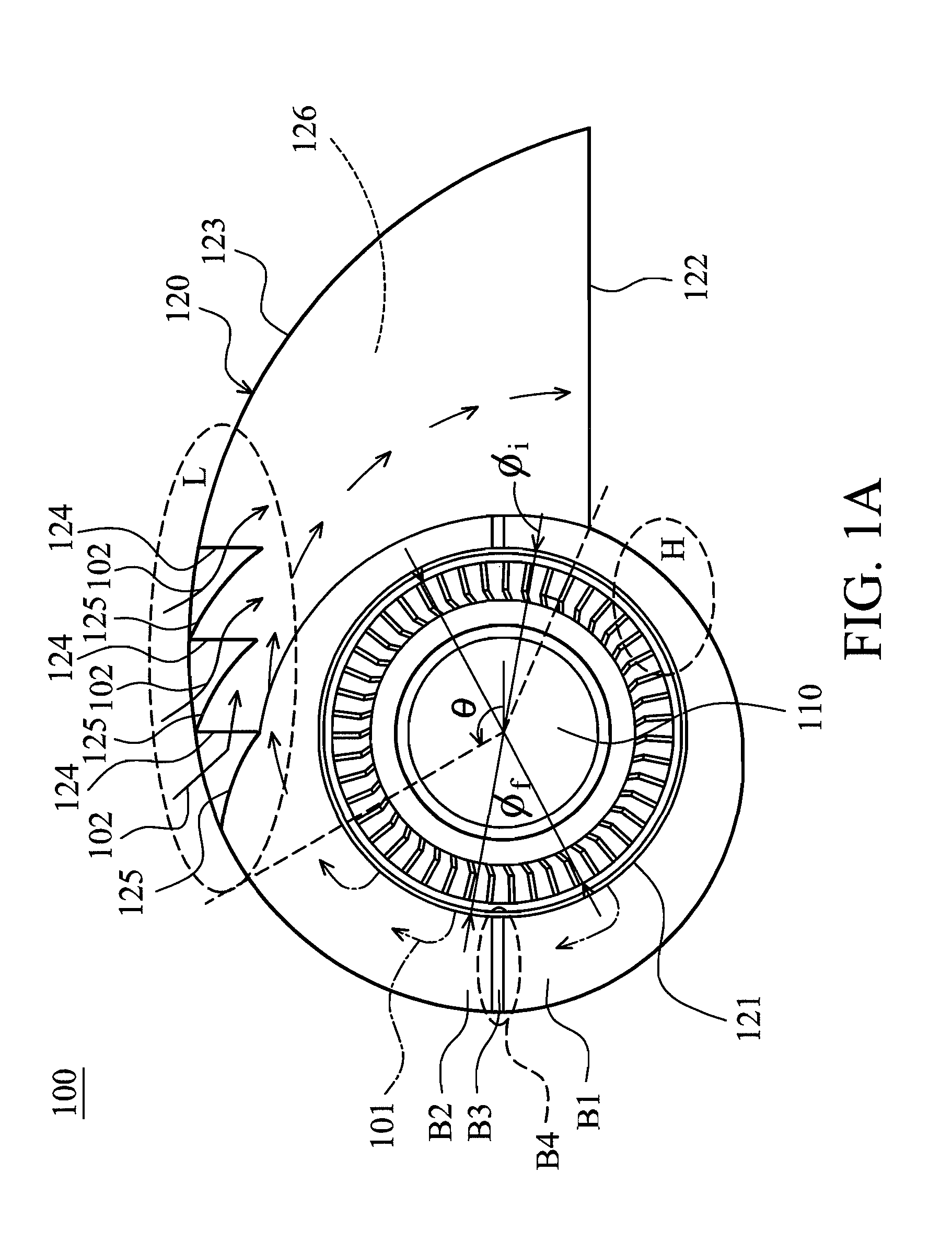

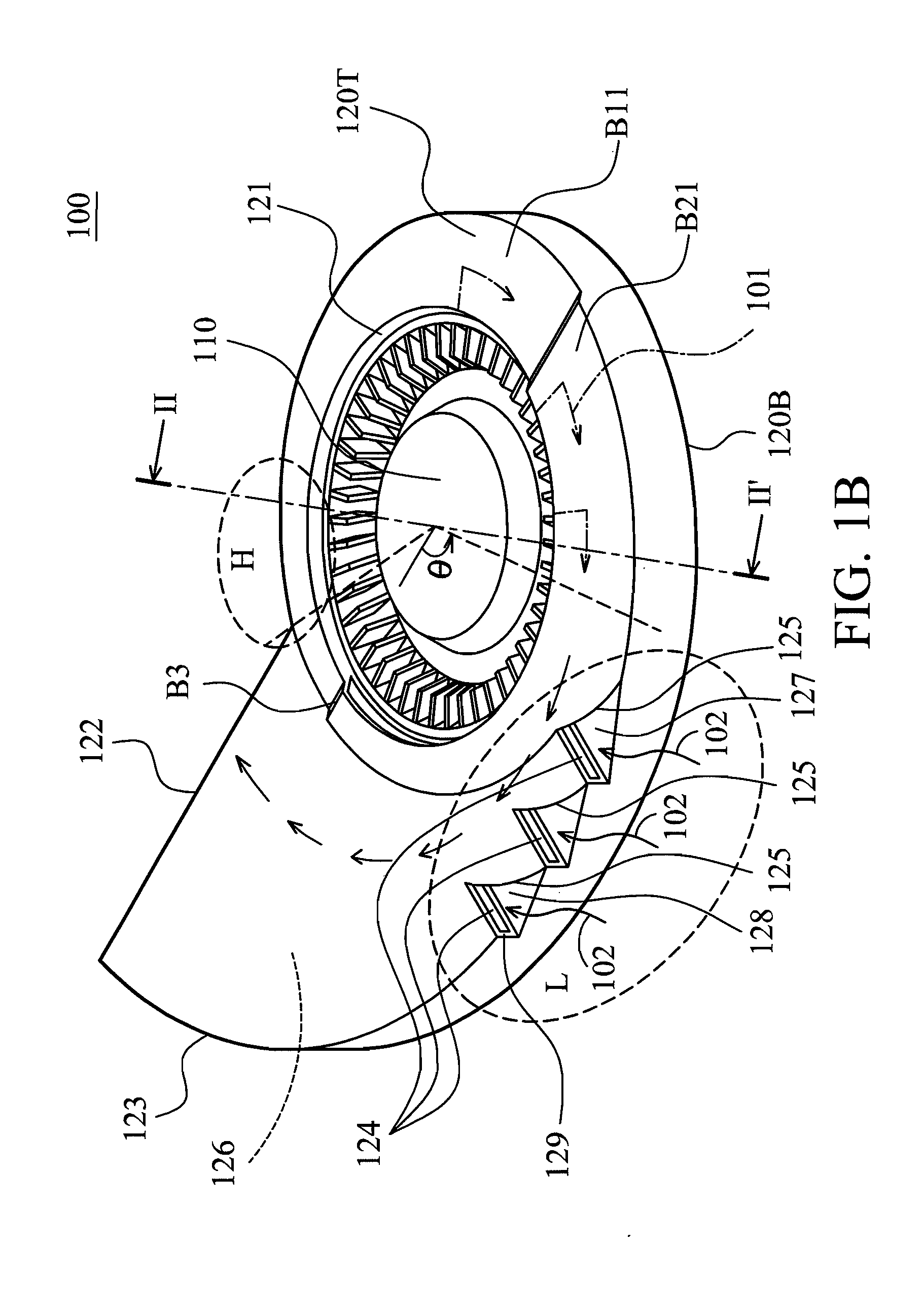

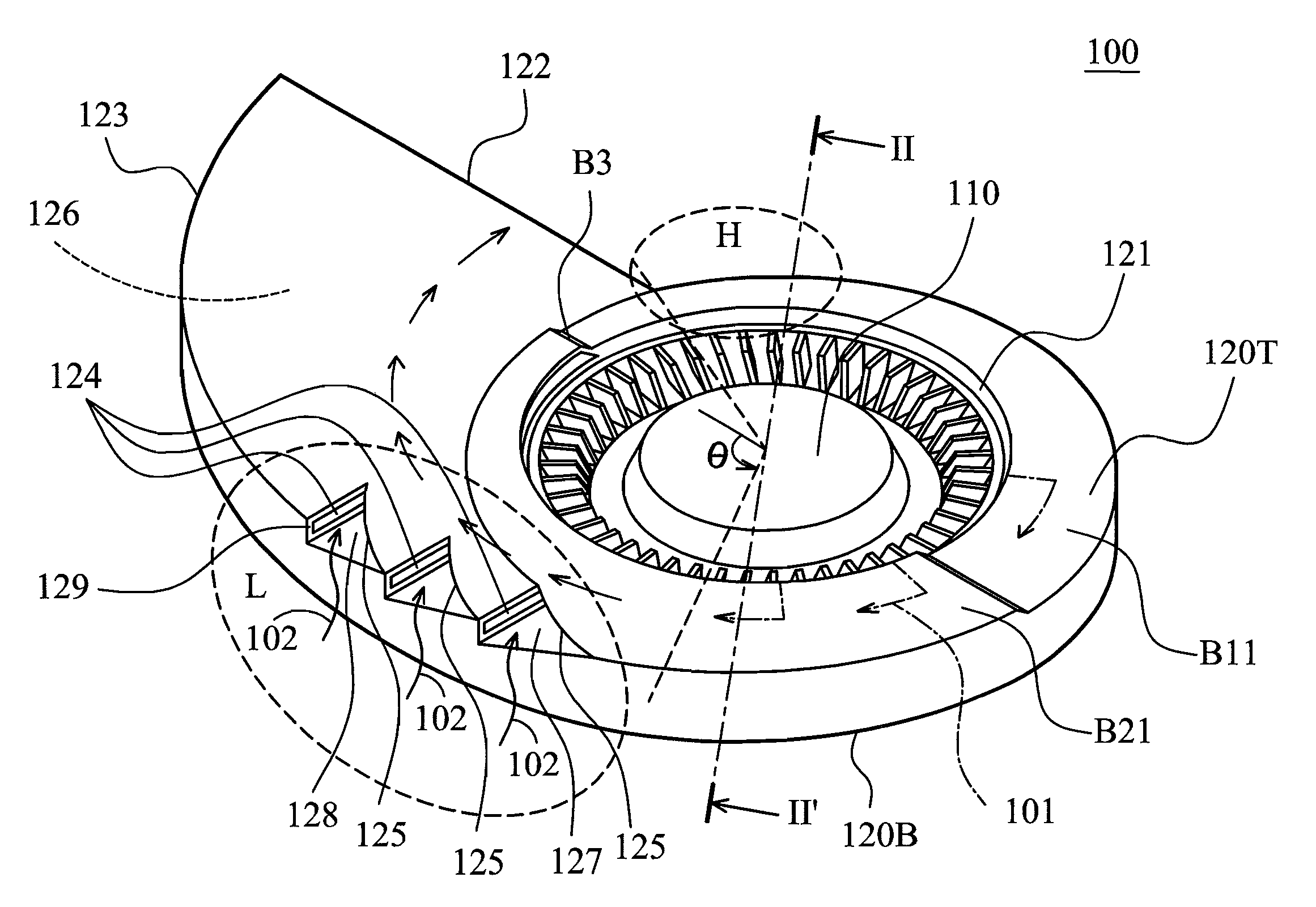

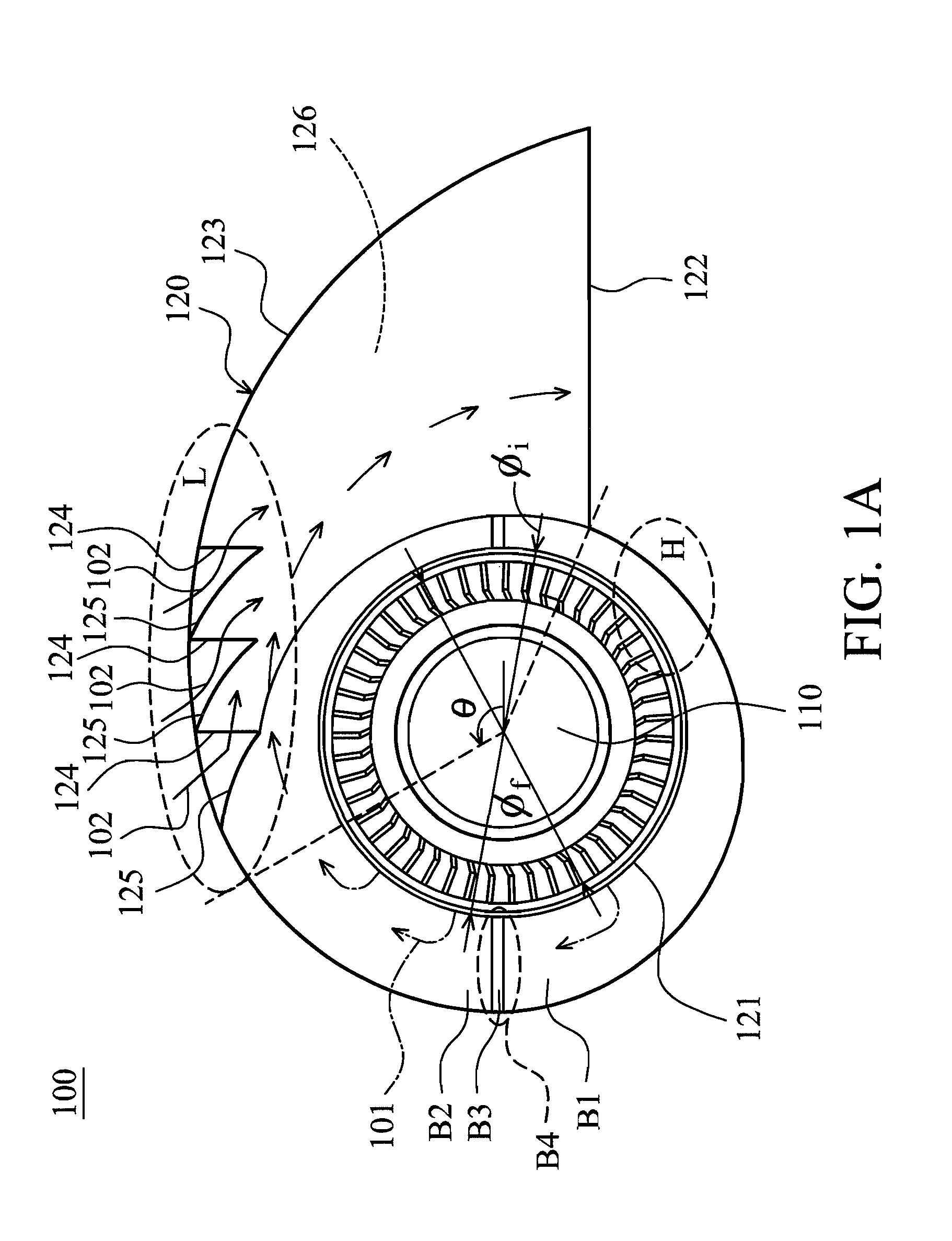

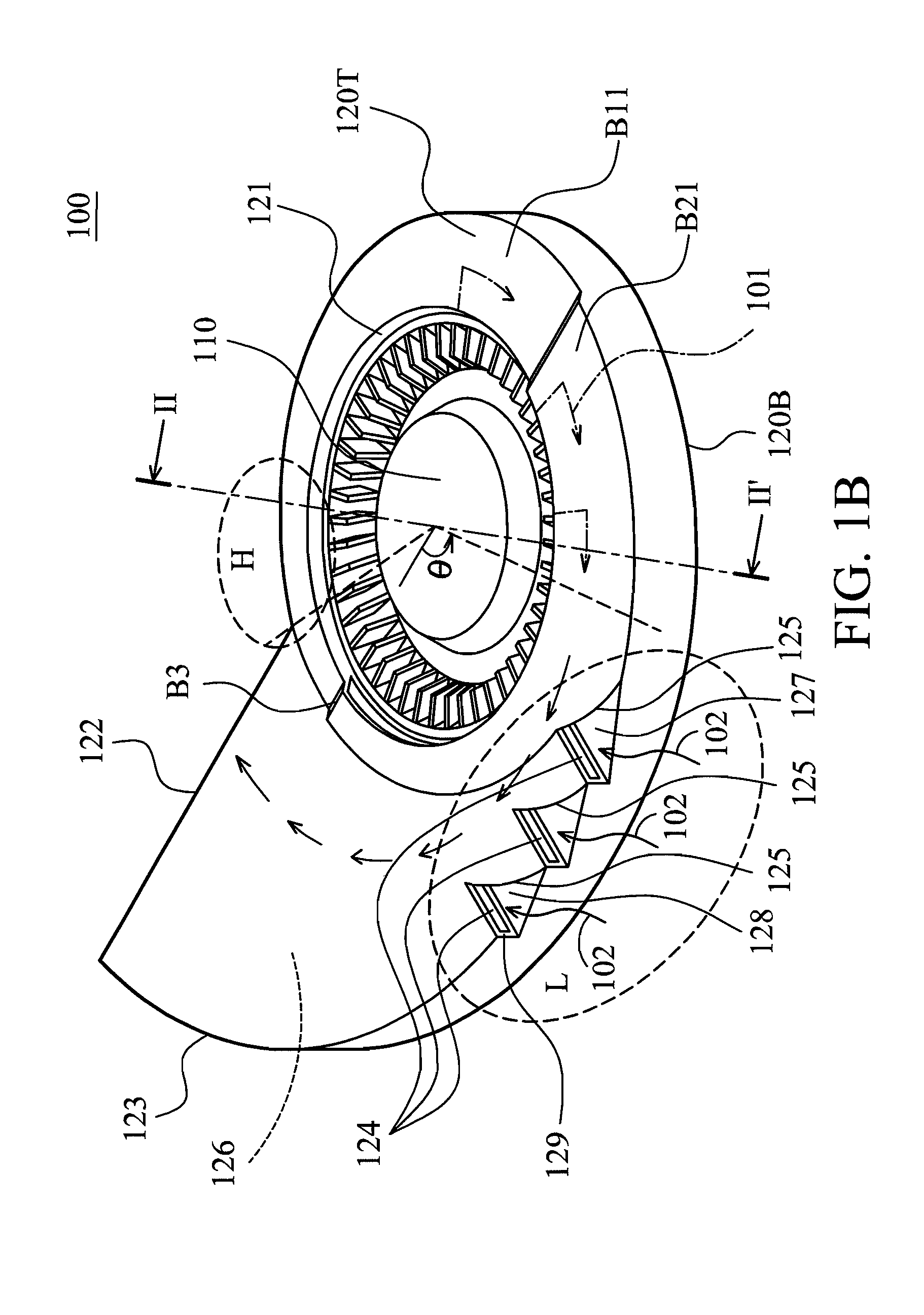

Centrifugal fan

ActiveUS20130071238A1Increase flow rateImprove cooling effectPump componentsDigital data processing detailsImpellerEngineering

A centrifugal fan is provided. The centrifugal fan includes an impeller and a housing. The impeller has an impeller diameter. The housing includes an upper plate, a lower plate and a side wall, wherein the upper plate axially corresponds to the lower plate, a side wall is formed between the upper plate and the lower plate, an axial inlet is formed on the upper plate, a lateral outlet is formed on the side wall, the impeller is disposed in the housing and corresponds to the inlet, and a flow path communicates the inlet to the outlet, wherein a greatest width of the inlet is greater than or equal to the impeller diameter.

Owner:DELTA ELECTRONICS INC

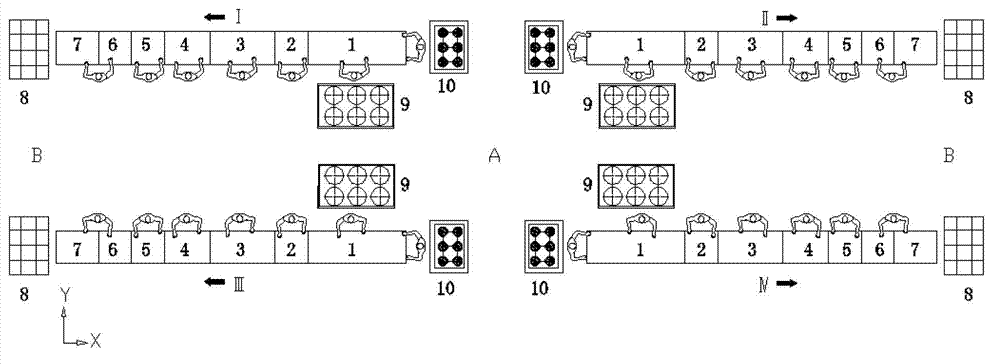

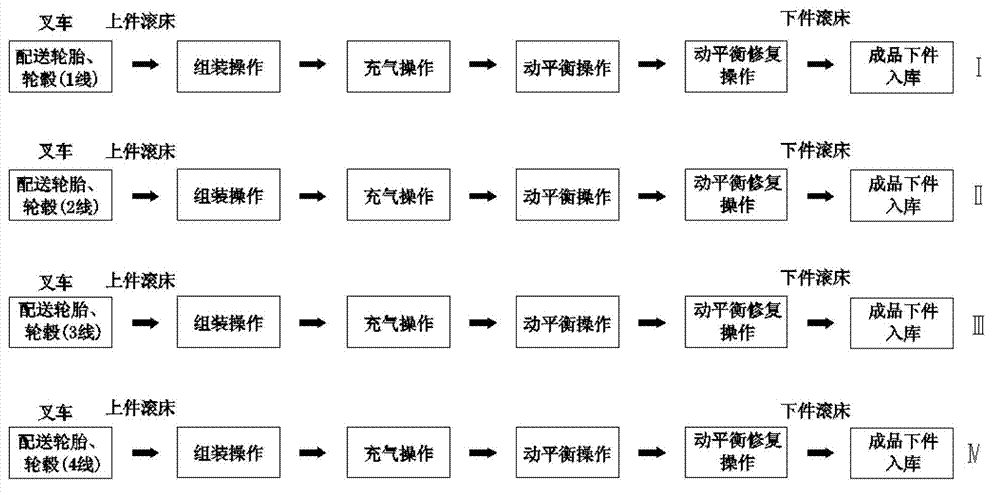

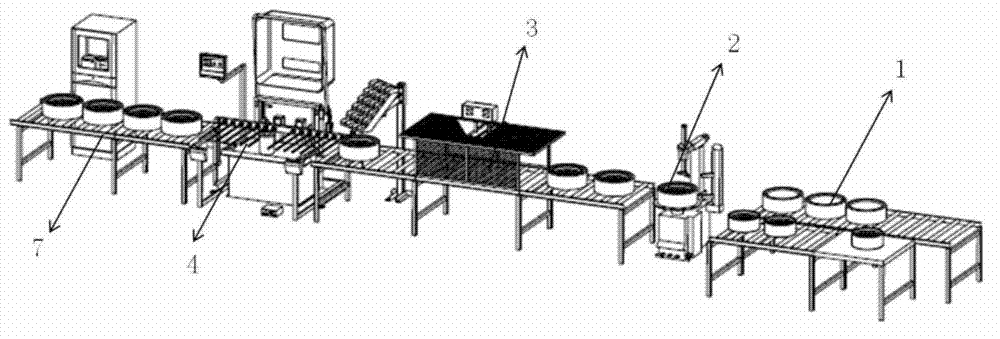

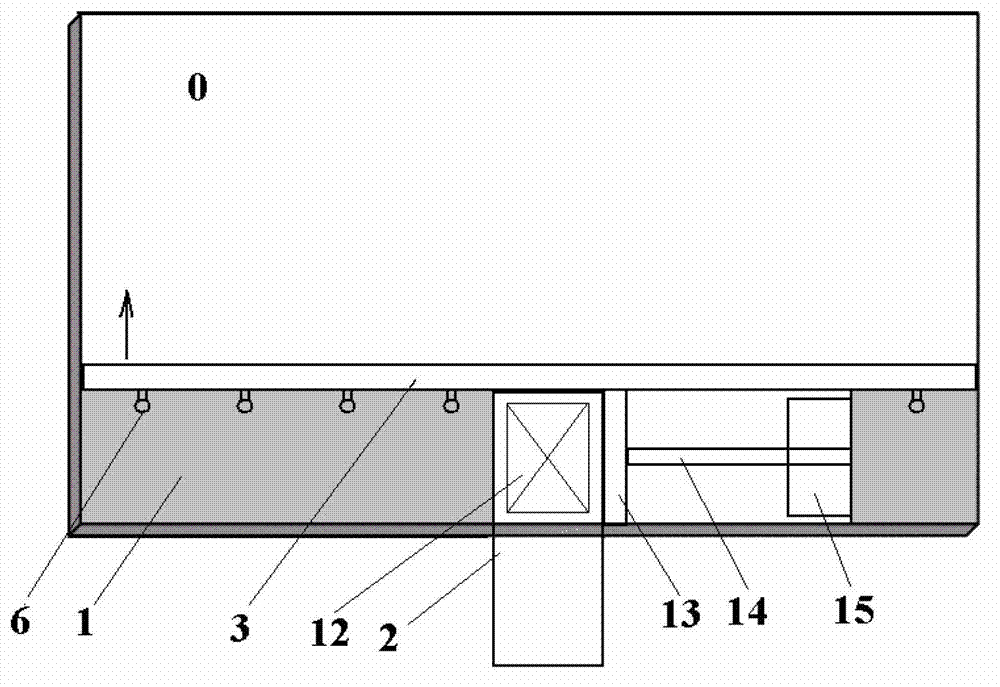

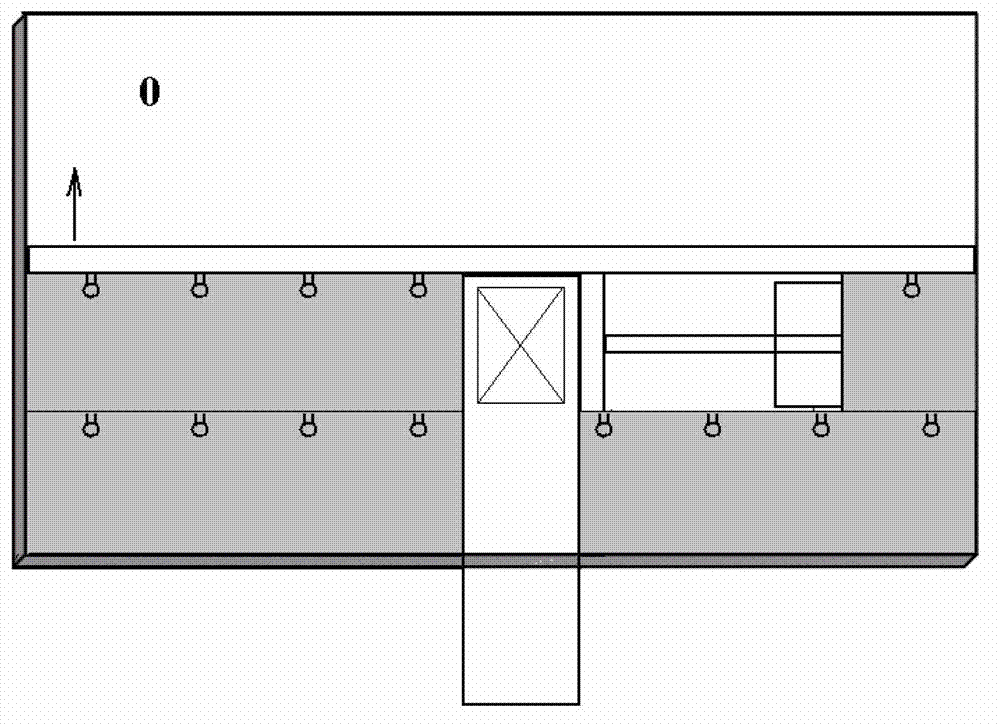

Manual assembly line layout for automobile tires

ActiveCN102756614AIncrease productivityLess investmentWheel assembling toolsBalancing machineAssembly line

The invention discloses a manual assembly line layout for automobile tires, belonging to the field of automobile tire assembly. The manual assembly line for the tires comprises more than two assembly lines, wherein each assembly line comprises a dismantling and assembling machine, an aerator, a balancing machine, a correction roller machine which are arranged in parallel along the Y-axis direction, and each assembly line is perpendicular to an assembly type part loading roller machine and an assembly type part unloading roller machine which are arranged along the X-axis direction. The manual assembly line layout has the advantages that the scattered part loading roller machines in the prior art are assembled into the part loading roller machine, the scattered part unloading roller machines in the prior art are assembled into the part unloading roller, the assembly type part loading roller machine and the assembly type part unloading roller machine are driven through a motor for transmission, the transmission spacing is carried out through an optoelectronic switch, and therefore, the convenience of manual assembly is increased, the production efficiency of the assembly line is improved, the operation region of a forklift is reduced, operating personnel are not needed in the production process, the cross operation of the forklift in the production process is eliminated, and the fluency of tire line physical distribution and the operation safety are increased. The length of equipment stations is shortened; and the effective usable areas of plants are increased.

Owner:CHERY AUTOMOBILE CO LTD

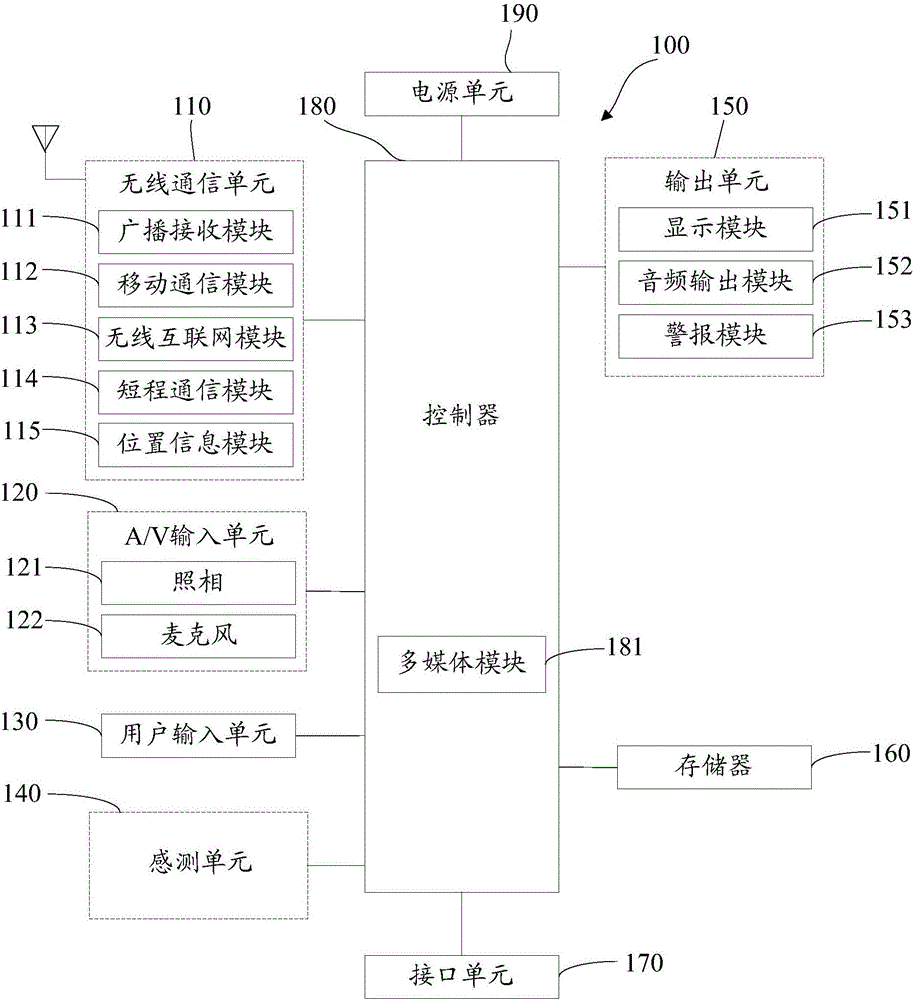

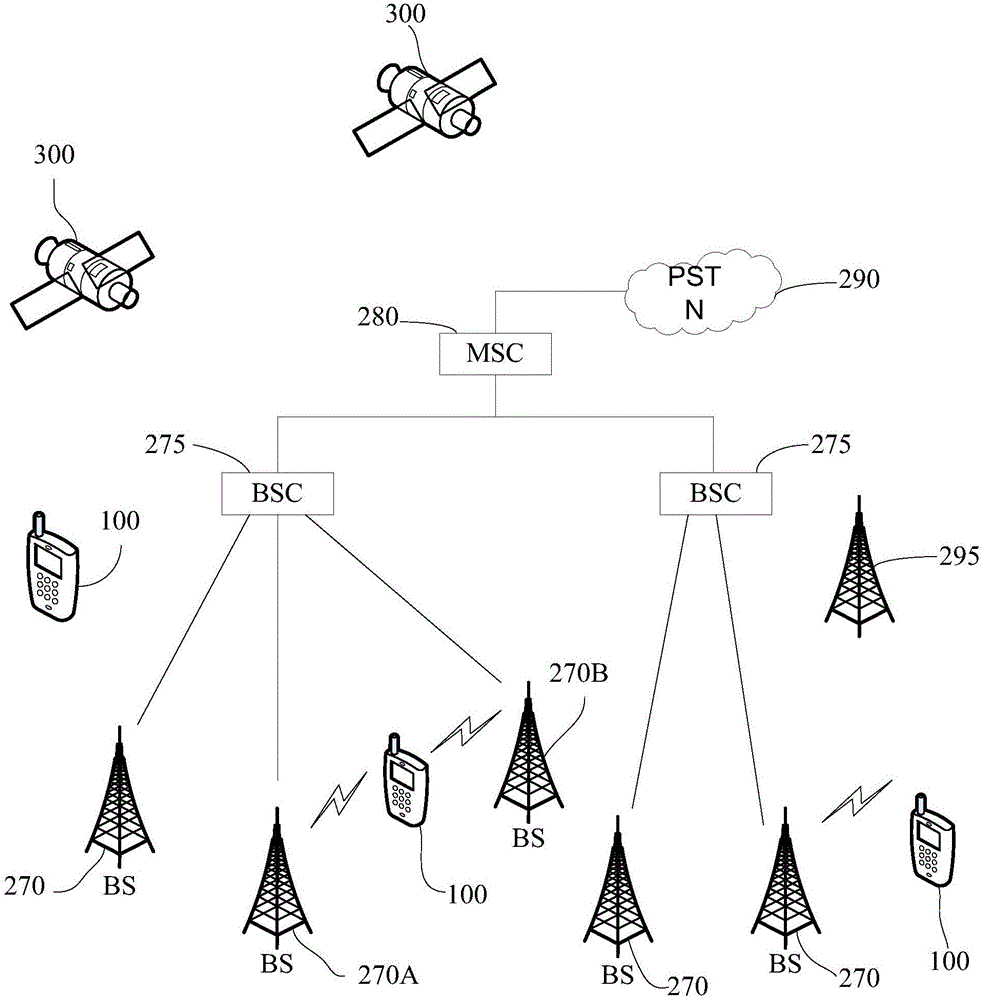

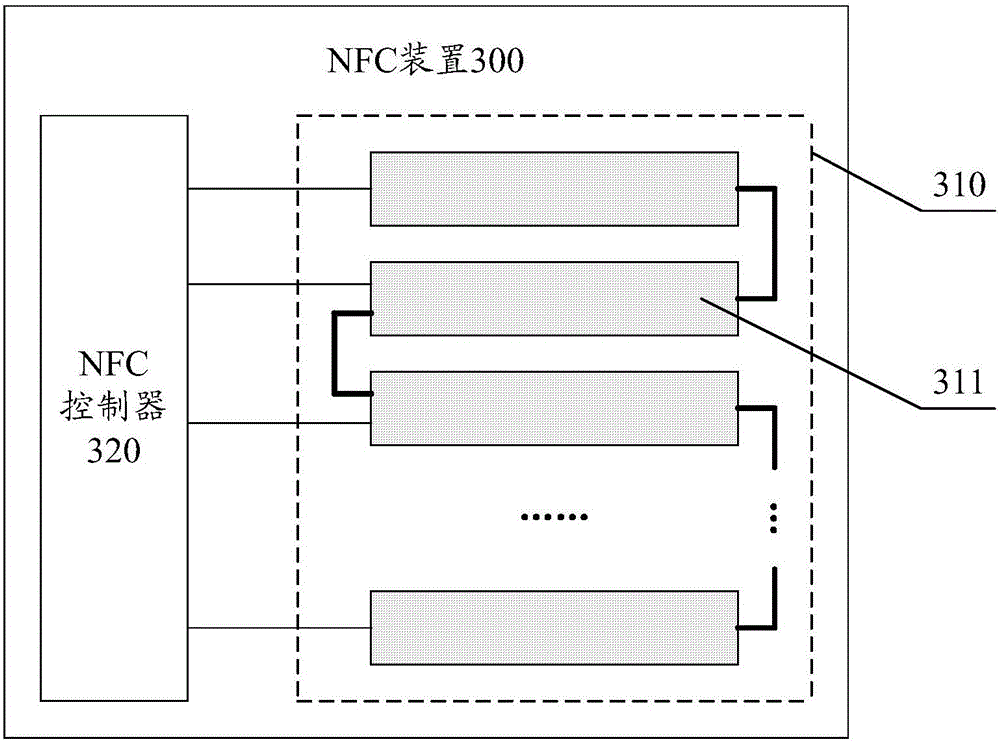

Near field communication (NFC) device and terminal equipment

ActiveCN106656278AReduce power consumptionUnable to solvePower managementNear-field systems using receiversTerminal equipmentEngineering

The embodiment of the invention discloses a near field communication (NFC) device and terminal equipment. The NFC device provided by the embodiment of the invention comprises an NFC antenna and an NFC controller, wherein the NFC antenna comprises a plurality of antenna branches; each antenna branch is connected with the NFC controller respectively; and the NFC controller is used for controlling a part of antenna branches to execute detection operations when the NFC device is in an idle state. Through adoption of the NFC device and the terminal equipment, the problem of relatively high power consumption of the NFC device since the NFC antenna is always in a working state in the prior art is solved, and the problem that the terminal equipment cannot be used normally due to interference on the terminal equipment since the NFC antenna is always in the working state when the NFC device is configured in the terminal equipment in the prior art is solved.

Owner:NUBIA TECHNOLOGY CO LTD

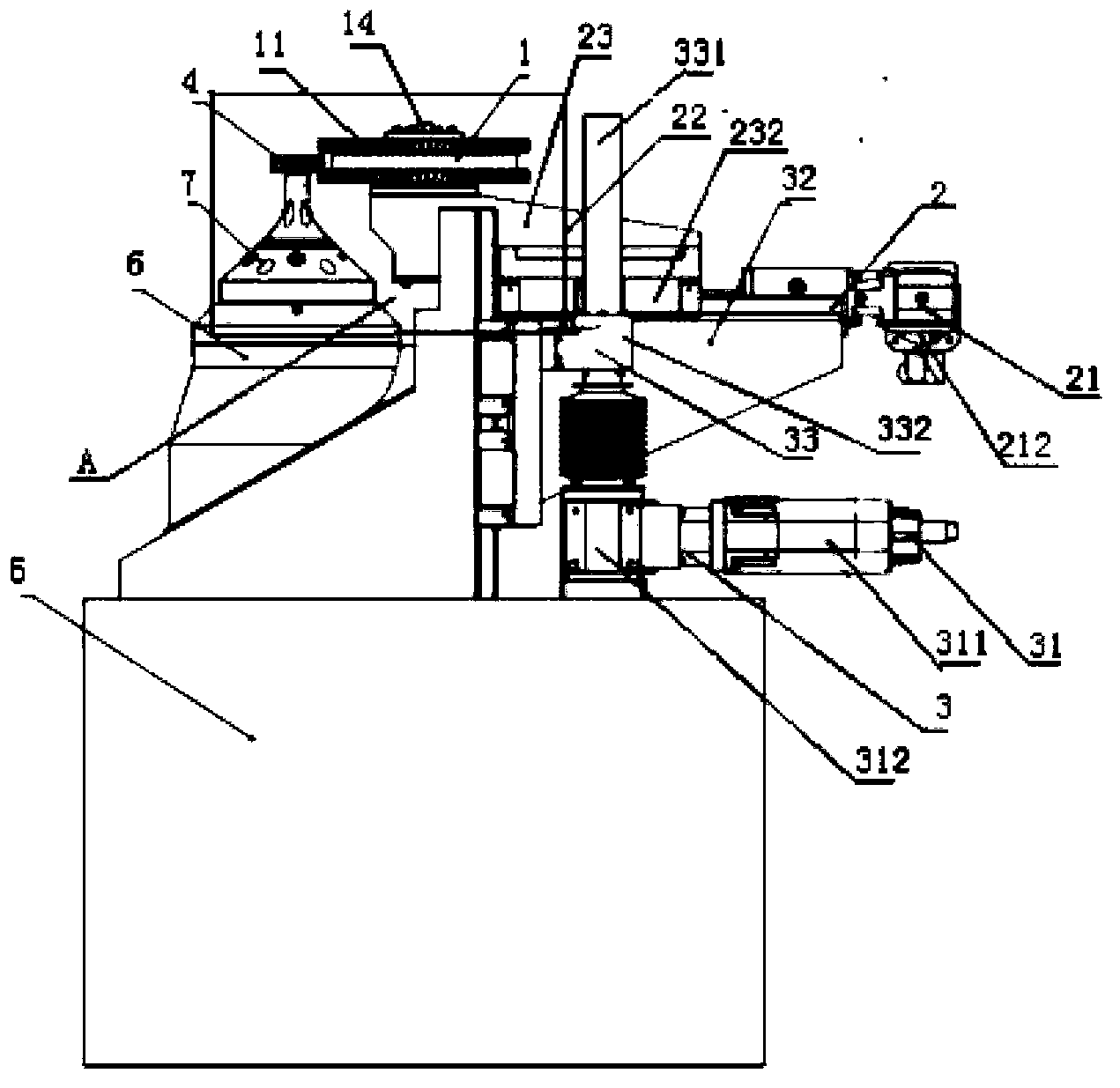

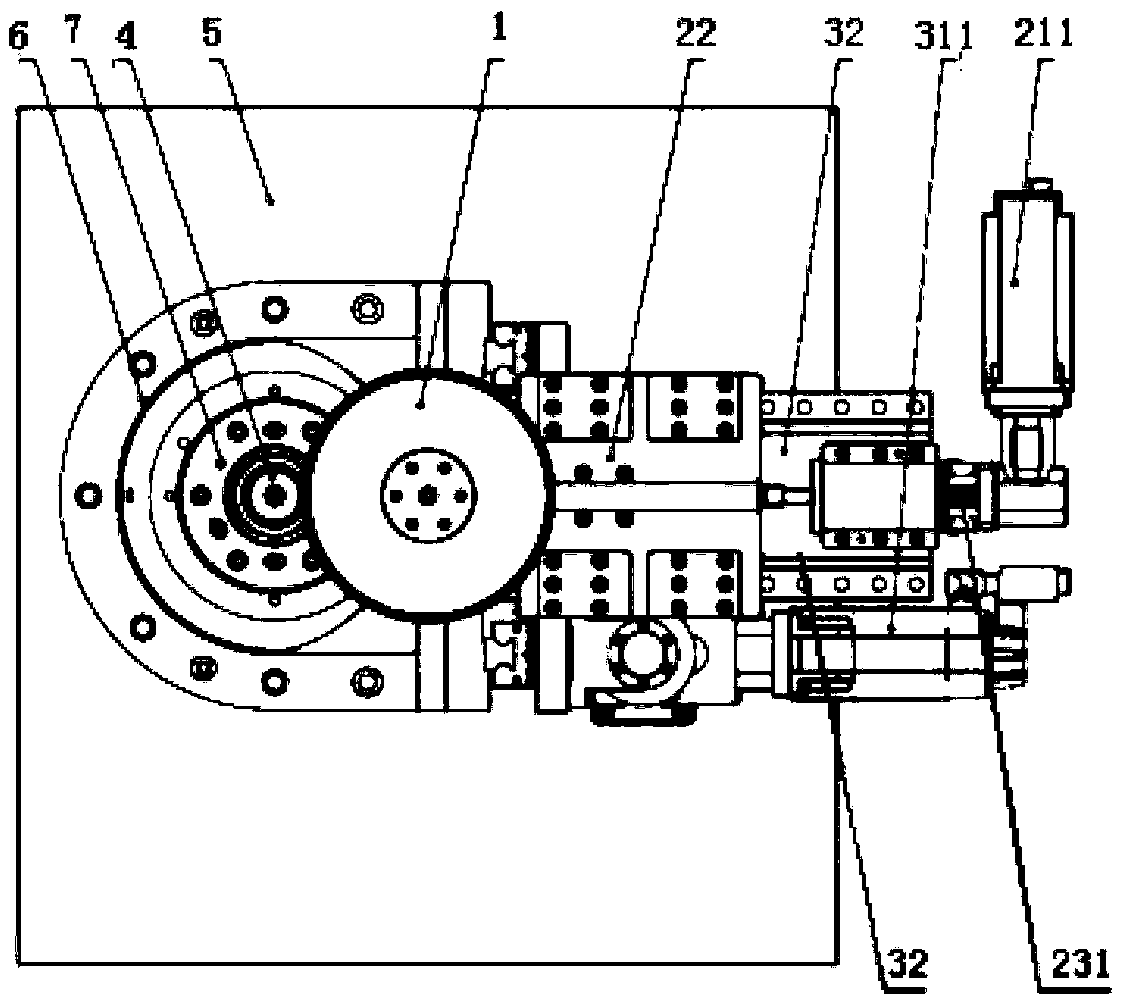

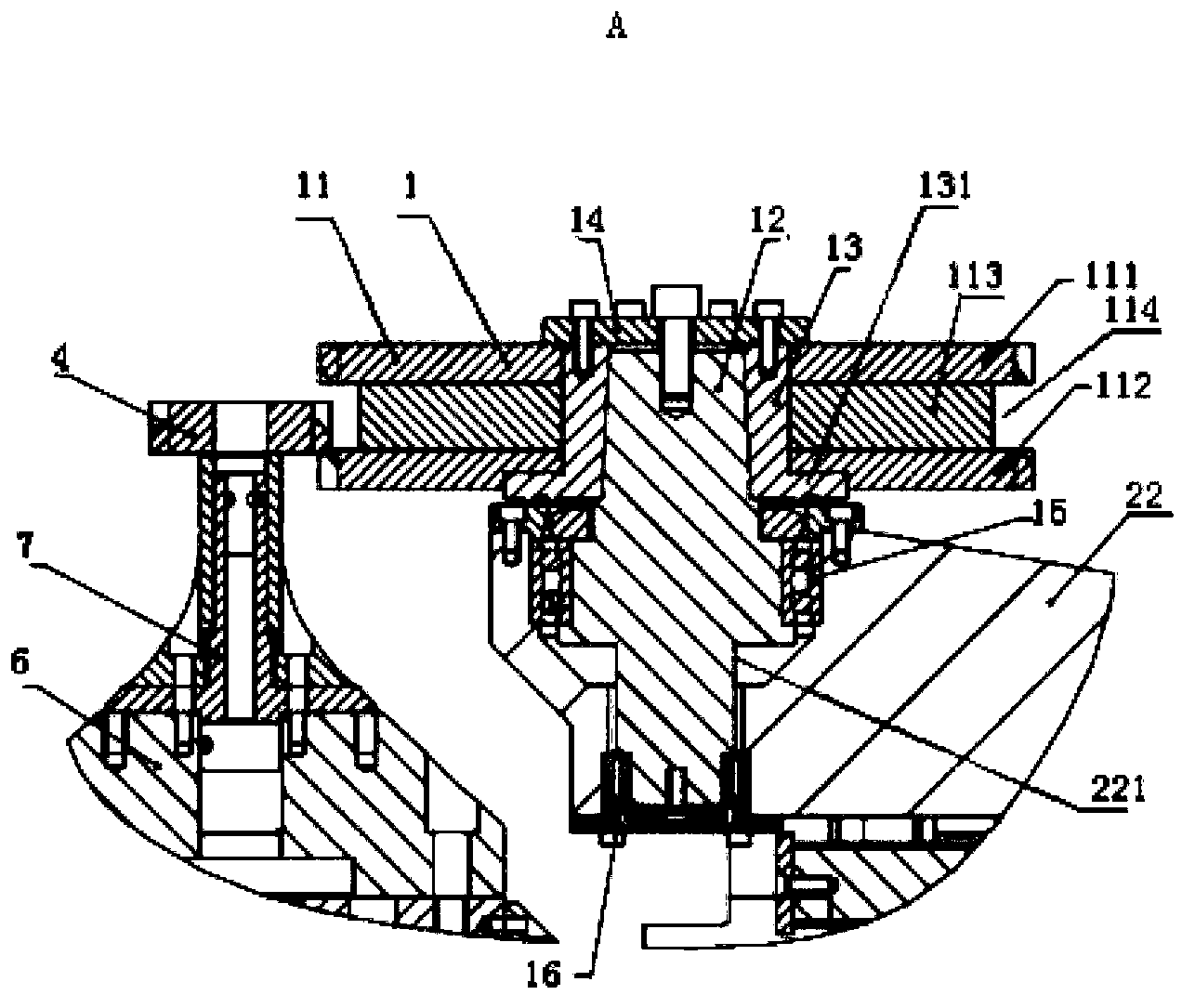

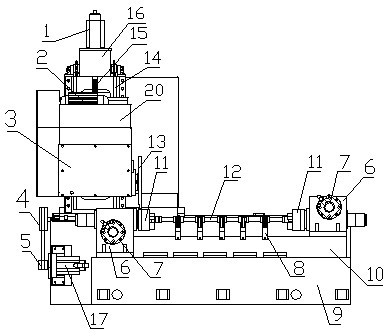

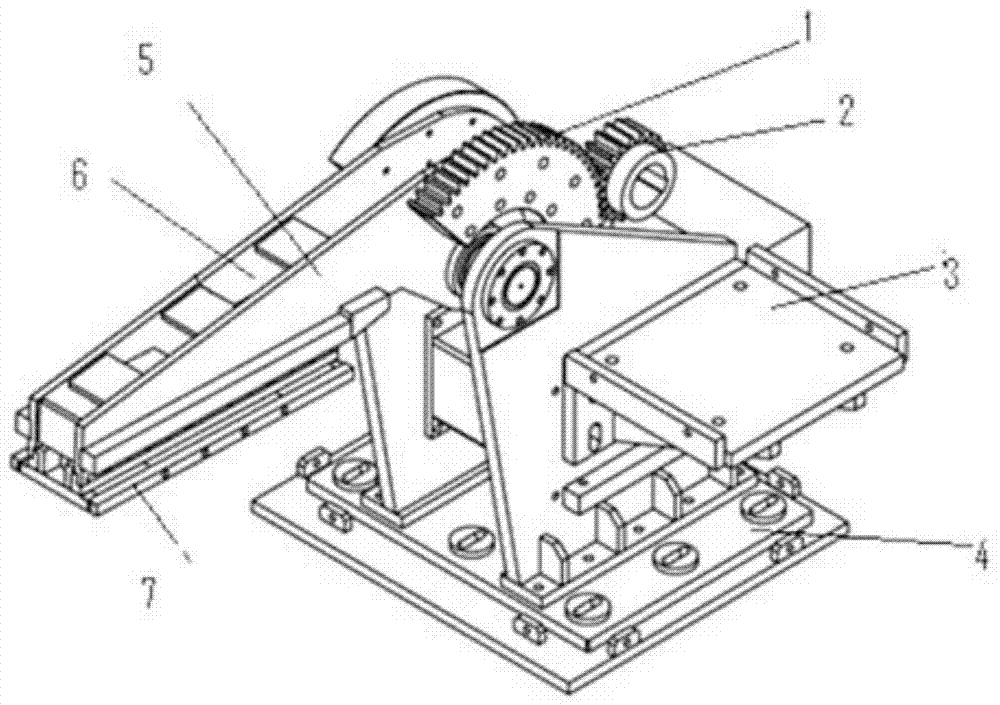

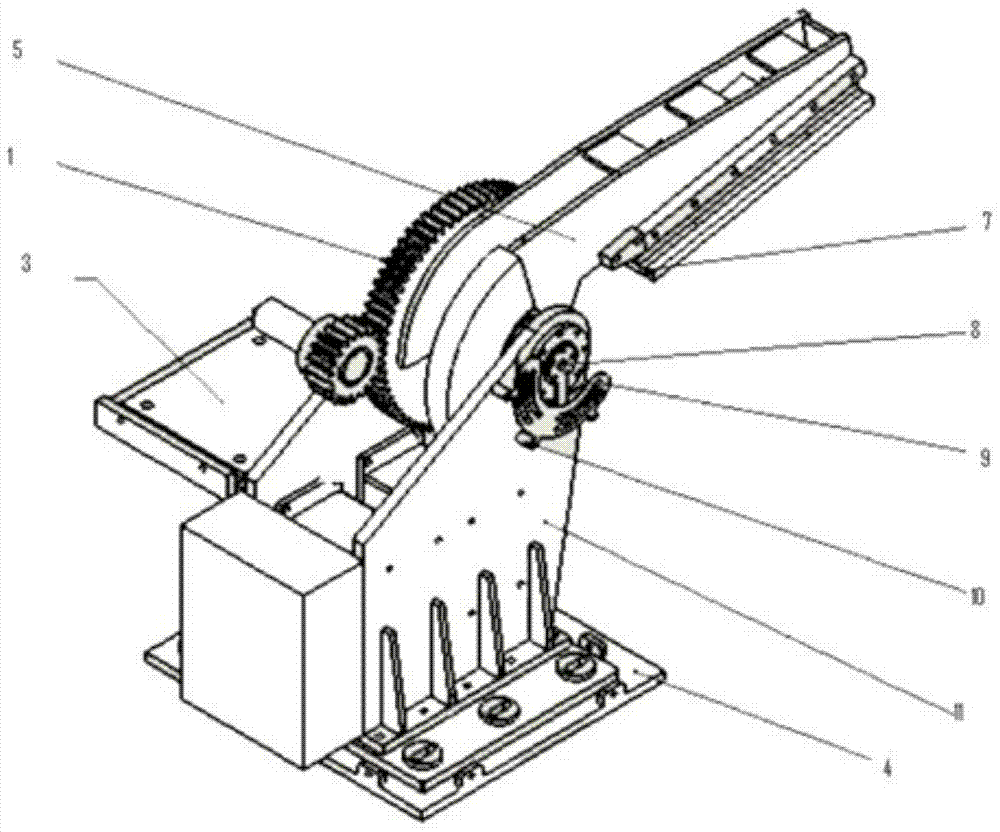

Synchronous chamfering device and gear hobbing machine

InactiveCN103406602AImprove efficiencyHigh speedFeeding apparatusGear teeth manufacturing toolsHobbingMechanical engineering

The invention discloses a synchronous chamfering device and a gear hobbing machine. A working platform is arranged on a machine body, and a workpiece is fixed on the working platform through a clamping gear of a clamp; the working platform and a cutting tool rotate and cut the workpiece to obtain the gear with burrs; the synchronous chamfering device comprises a cutter body, an X-axis moving device and a Z-axis moving device, wherein the cutter body is in contact with the burrs of the gear and used for grinding the burrs and chamfering the gear; the X-axis moving device is connected with the cutter body and used for enabling the cutter body to move in the X-axis direction; the Z-axis moving device is fixed on the machine body, is connected with the X-axis moving device and used for enabling the X-axis moving device to drive the cutter body to move in the Z-axis direction perpendicular to the X-axis direction. The synchronous chamfering device has the advantages that the efficiency and the speed that the synchronous chamfering device removes and chamfers the burrs are improved; the structure is simple, the unused space of the gear hobbing machine is fully utilized, and the working area of the synchronous chamfering device is reduced; the burrs can be removed and chamfered from gears with different number of dies and tooth widths.

Owner:SANY GRP

Vertical circulating backfilling method of household garbage

ActiveCN102861754AReduce working areaReduce operating costsLandfill technologiesSolid waste disposalTransmission beltProduct gas

The invention provides a vertical circulating backfilling method of household garbage and relates to the technical field of environmental protection. The vertical circulating backfilling method comprises the steps of: arranging a vertical backfilling region with a cuboid structure, which is close to a region to be backfilled, and arranging an unloading platform at the same side of the region to be backfilled; then, arranging a vertical backfilling bracket array at the opposite side of the unloading platform; arranging movable conveying equipment with a receiving hopper, a material distribution mechanism and a transmission belt at the middle part of the region to be backfilled and finishing the backfilling at the two sides in sequence to form a vertical backfilling region; after a backfilling operation period and regional backfilling are finished in one vertical backfilling region, carrying out gas-liquid extraction treatment; horizontally or vertically moving the vertical backfilling bracket array to the opposite side of the unloading platform and keeping a vertical guide pipe at the original position of the current vertical backfilling region; and preparing to set the operation of the next region to be backfilled until the backfilling of a whole backfilling field is finished, and carrying out soil backfilling, plant paving and field sealing treatment. According to the vertical circulating backfilling method, the energy consumption can be effectively reduced and the generation times of backfilling gas and backfilling is effectively reduced.

Owner:上海城投瀛洲生活垃圾处置有限公司 +2

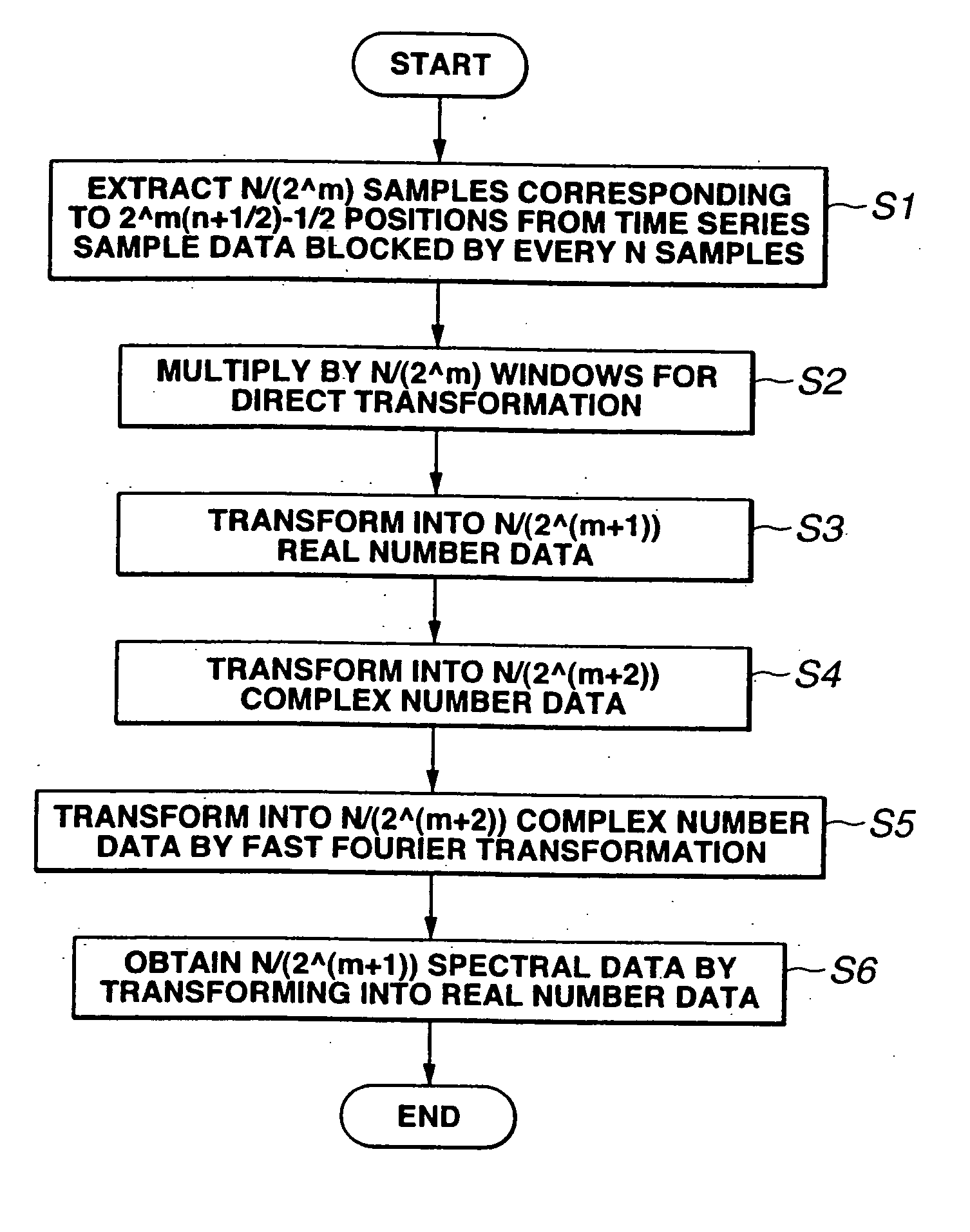

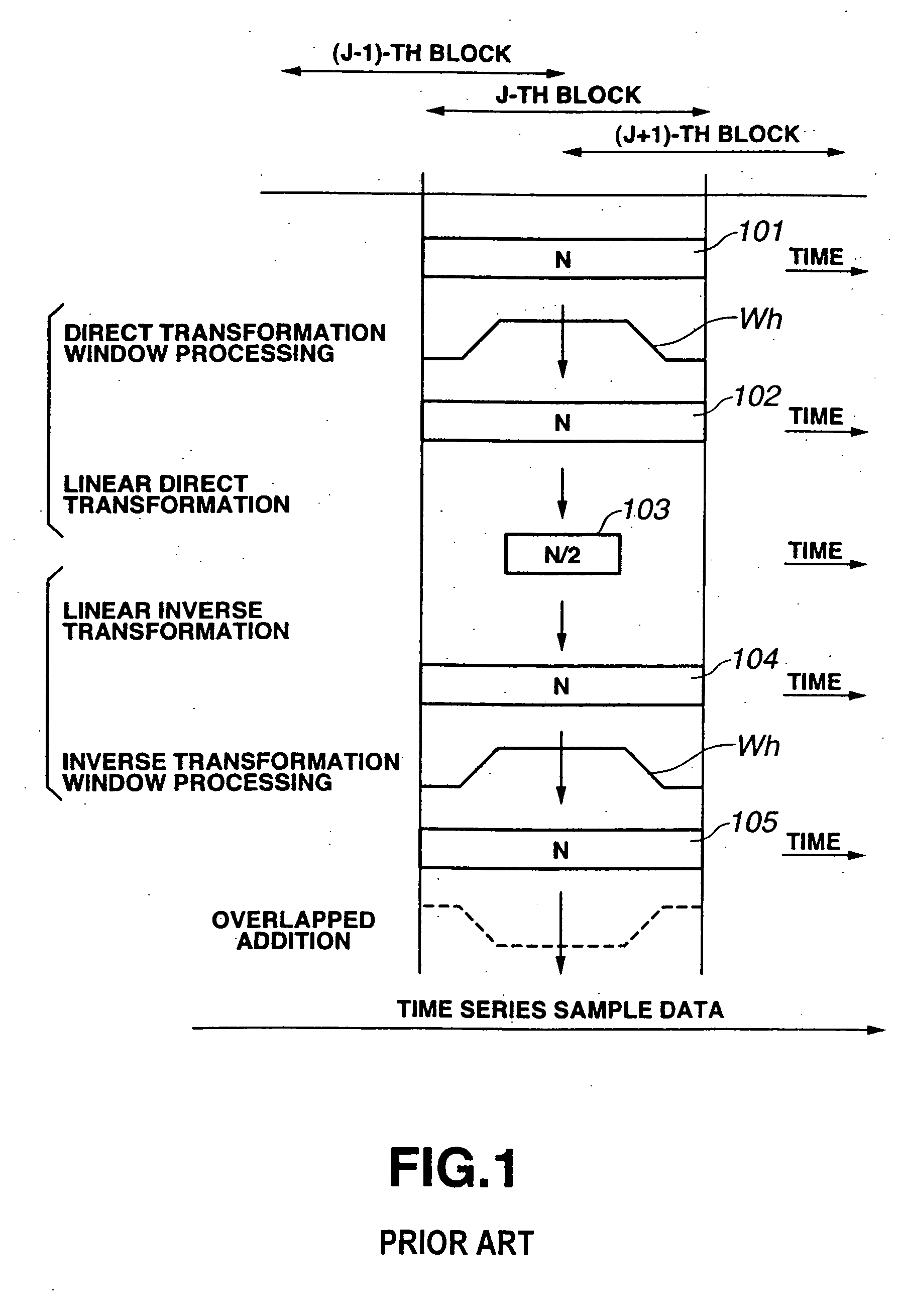

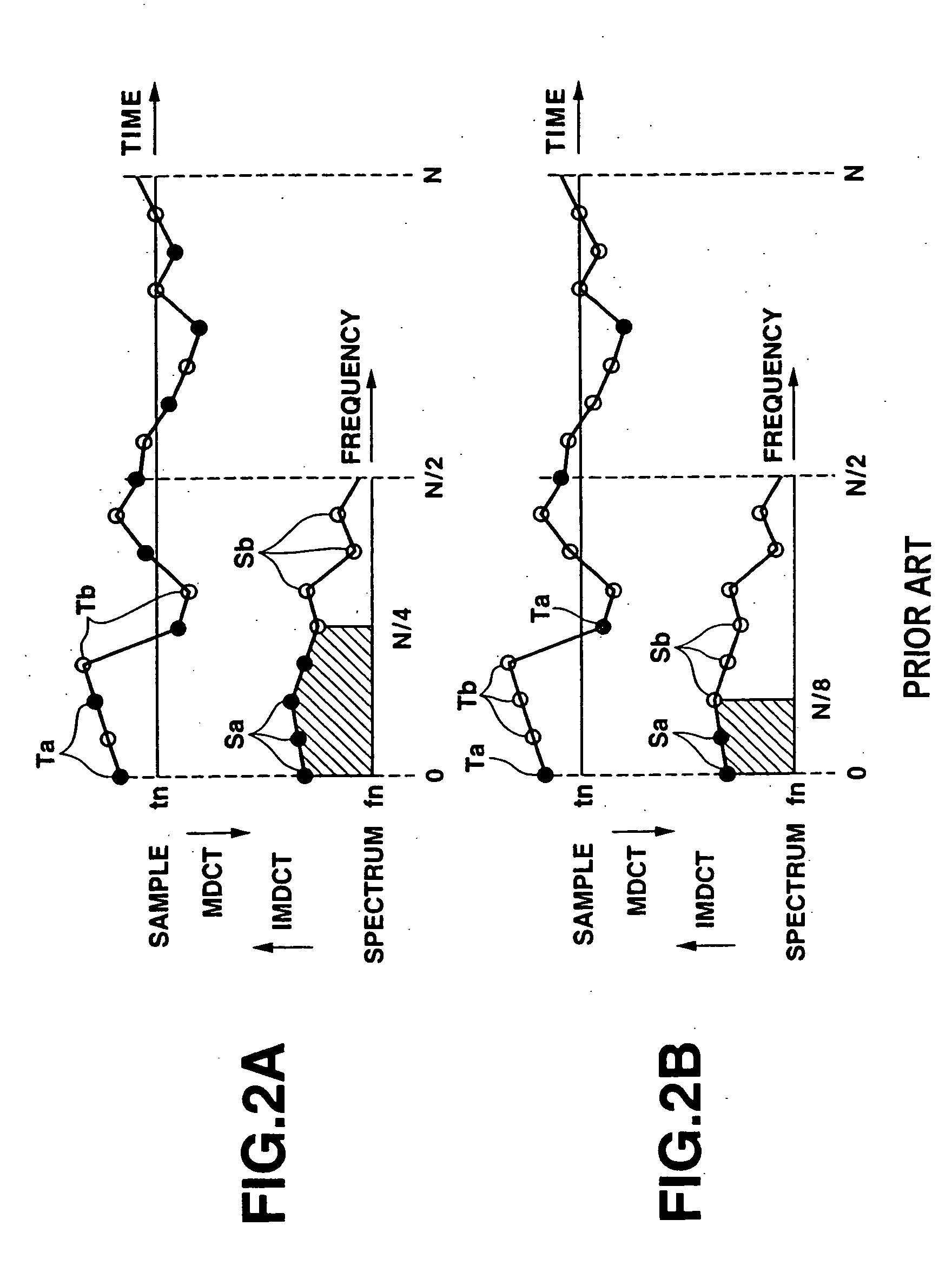

Signal processing device and signal processing method

InactiveUS20050108003A1Small working areaIncrease speedSpeech analysisCode conversionComputer scienceSignal processing

A signal processing device and method for performing a code string transform by transforming a time series signal with a frequency band from 0 to 20 kHz from a coding system into another, wherein the arithmetic operations of MDCT and IMDCT with a limited frequency band from 0 to 15 kHz are carried out at high speed by performing computations using an FFT operation with a short tap length in the IMDCT processing operation. This allows a reduced work area and a higher speed for arithmetic operations by reducing the number of multiplications and additions when performing MDCT operations, IMDCT operation and / or transforming code strings between different coding system.

Owner:SONY CORP

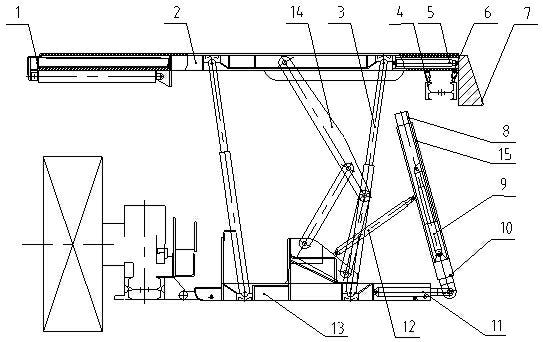

Crank type elevator with small operation area

The invention provides a crank type elevator with a small operation area. The crank type elevator with the small operation area comprises a base, a first supporting arm, a second supporting arm and aworkbench; four side brackets are symmetrically arranged on the two sides of the base; the side brackets are connected with the base by using a welding mode; the top ends of supporting legs are connected with the bottoms of the side brackets by using a hinging mode; pad feet are mounted at the bottoms of the supporting legs by using a hinging mode; one ends of first oil cylinders are connected with the side brackets by using a hinging mode; and the other ends of the first oil cylinders are connected with the supporting legs by using a hinging mode. By improving the crank type elevator, the crank type elevator with the small operation area has the advantages of reasonable structural design, convenient towing, convenient moving and transportation, smaller retracted and folded volume, smallerspace needed by unfolding, small operation area, small use limitation, good buffering and protecting effect, smaller noise, high operation stability and high practicability; and therefore, problems and shortcomings of an existign device are effectively solved.

Owner:HUIZHOU JINHENG IND MOLD DESIGN PARTNERSHIP ENTERPRISE GENERAL PARTNERSHIP

Apparatus with active material surface in contact with pheological fluid and method of enhancing performance thereof

InactiveUS20090032353A1Improve performanceReduce surface roughnessSpringsNon-rotating vibration suppressionEngineeringSurface geometry

An apparatus is provided having an active material forming a surface thereof in contact with a rheological fluid. The active material is controllable to vary a surface geometry thereof between a rough or nonsmooth surface geometry to increase drag, and achieve an increase in stress transmitted through the fluid, when a field is applied, while allowing a smooth surface geometry and an associated reduction in stress transmitted through the fluid when the field is removed. A method of enhancing performance of an apparatus that includes a rdeological fluid is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

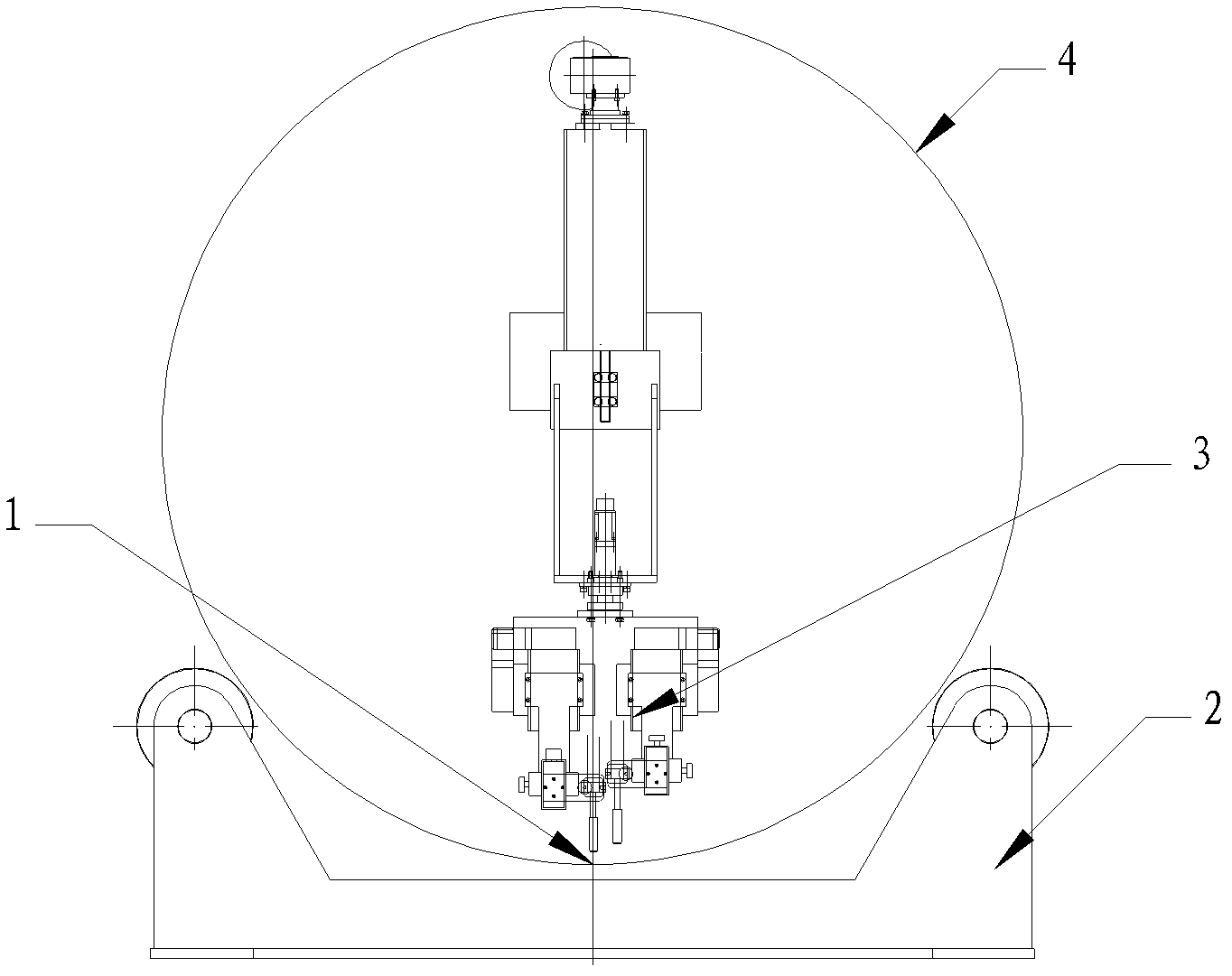

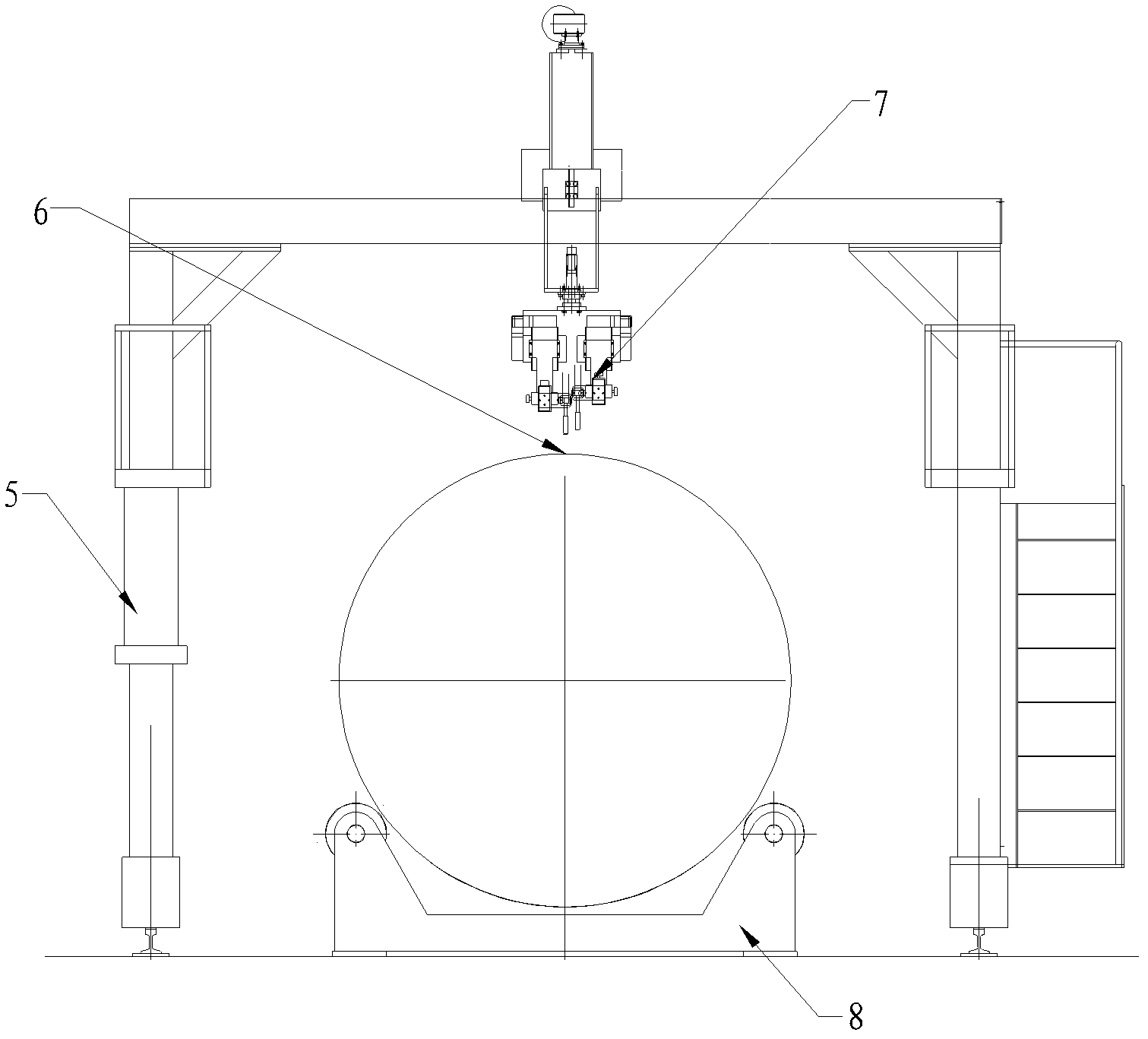

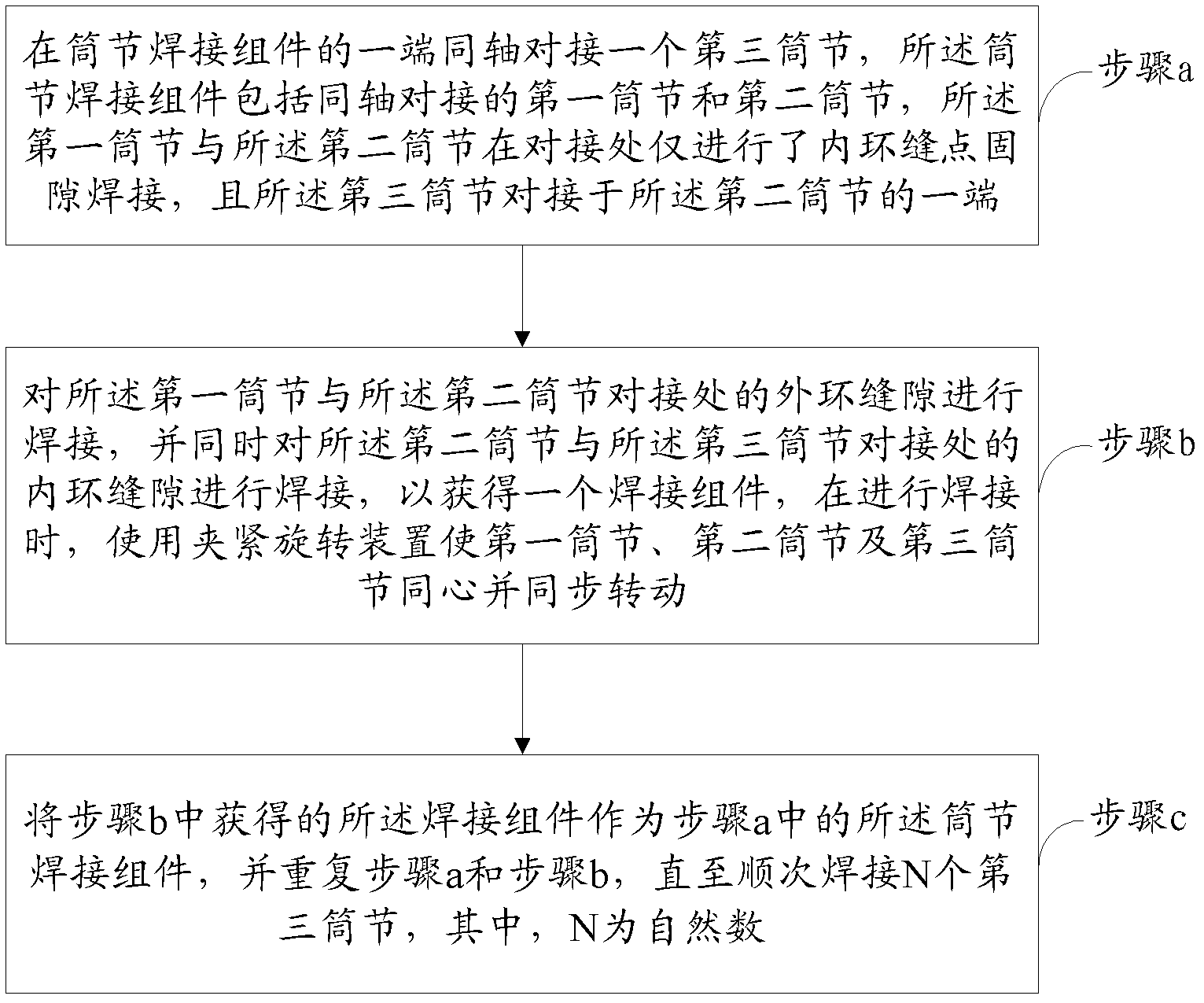

Method for welding tank shell rings

ActiveCN103071886APrevent positional movementReduce in quantityArc welding apparatusButt jointEngineering

The invention provides a method for welding tank shell rings. The method comprises that: step a, a third shell ring is in butt joint with one end of a shell ring welding assembly, wherein the shell ring welding assembly comprises a first shell ring and a second shell ring which are coaxial with each other, the butt joint parts of the first shell ring and the second shell ring are only subjected to inner ring gap tack welding, and the third shell ring is in butt joint with one end of the second shell ring; step b, an outer ring gap of the butt joint parts of the first shell ring and the second shell ring is welded, and the inner ring gap of the butt joint parts of the second shell ring and the third shell ring is welded; and step c, the welding assembly which is obtained in the step b is used as a shell ring welding assembly for the step a, and the steps a and b are repeated until N third shell rings are welded. The method is adopted to weld the inner ring gap and the outer ring gap of different positions of a same working state at the same time, so that the working efficiency is increased, and the adopted equipment number and working area are reduced; and in addition, the working station does not need to be transferred, so that processes are simplified, and the working personnel number is decreased.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

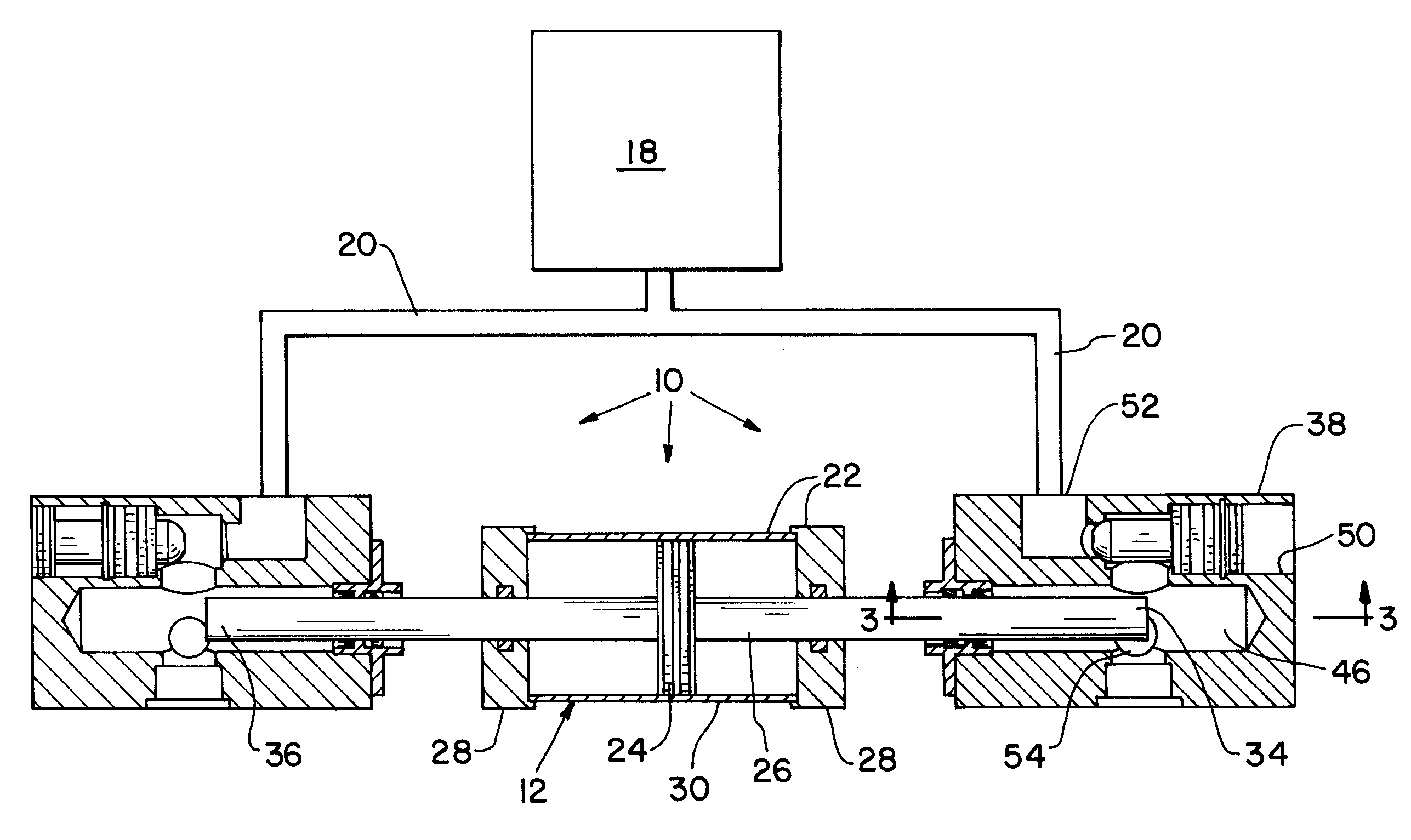

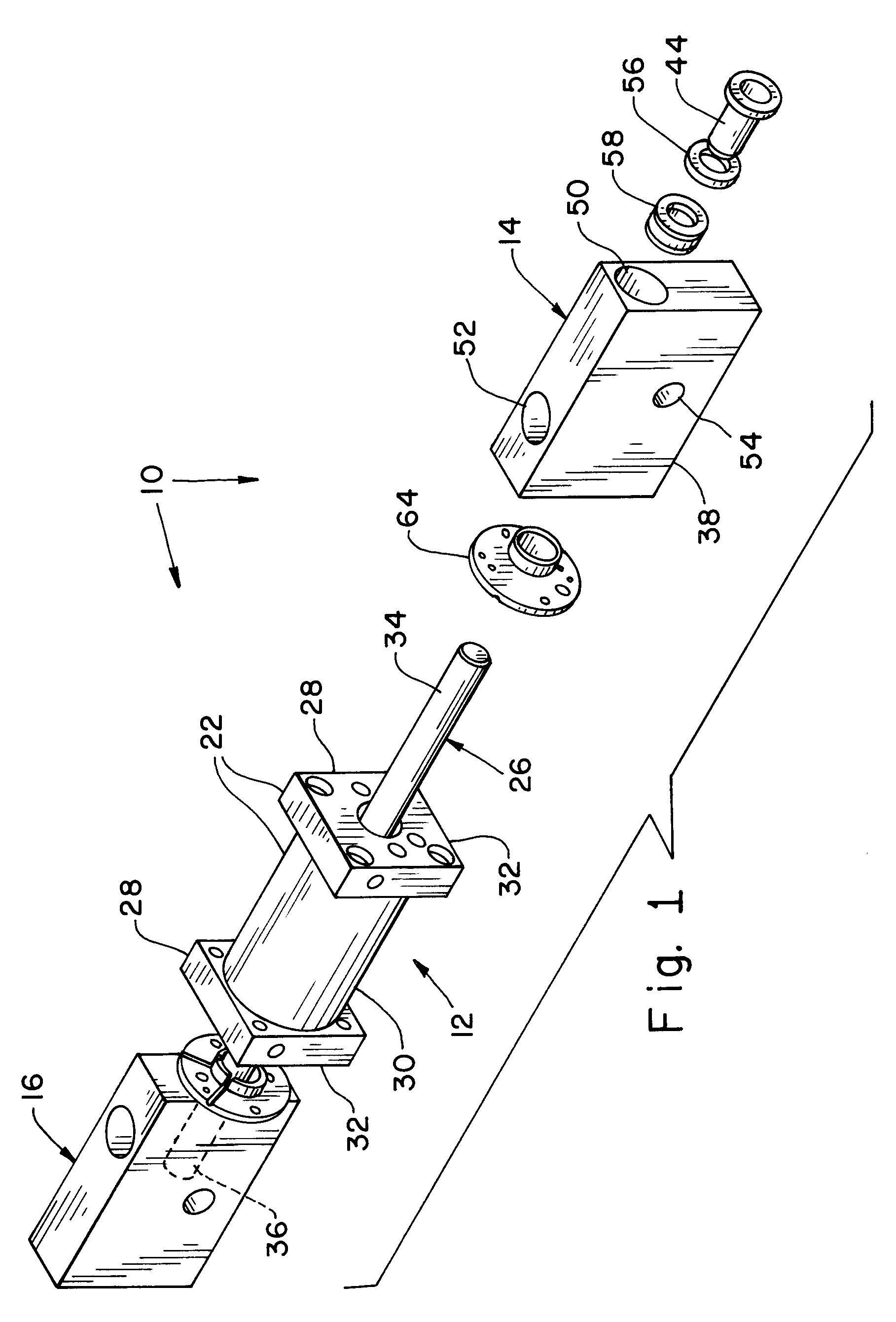

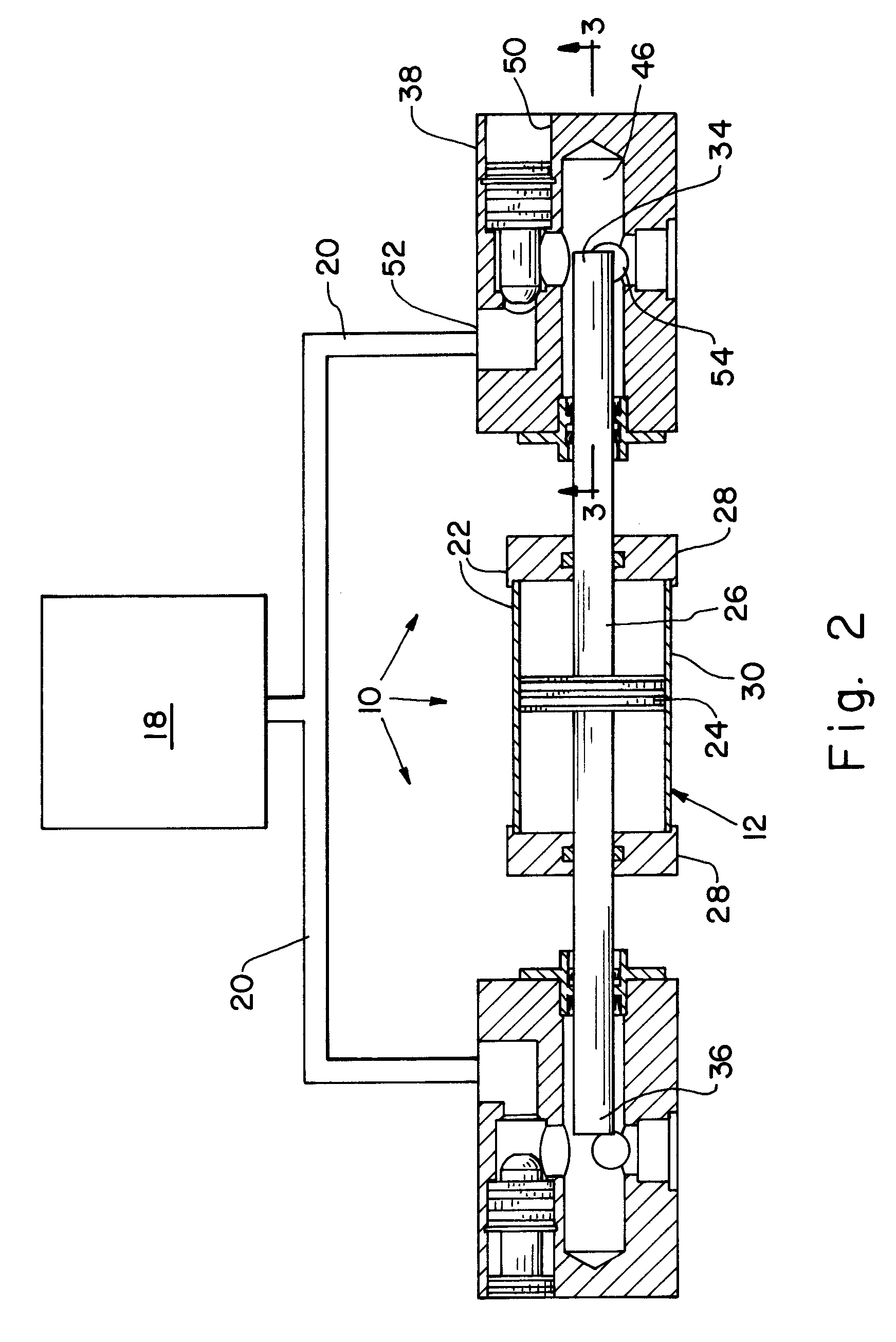

Fluid pump assembly

InactiveUS20100290937A1Cost reductionSmall working areaPiston pumpsPump installationsEngineeringPiston rod

A fluid pump assembly includes a double acting fluid cylinder with a housing, a piston reciprocally disposed within the housing, and a piston rod carrying the piston and extending from the housing. The piston rod has an end. A pump includes a pump body, a pressure loaded seal and a wiper seal. The pump body has a fluid inlet, a pump chamber and a rod port. The inlet is configured for receiving a fluid to be pumped and is in fluid communication with the pump chamber. The piston rod extends through the rod port and the end is positioned within the pump chamber. The pressure loaded seal is positioned within the rod port around the piston rod and has a pressure loaded end face toward the pump chamber. The wiper seal is positioned within the rod port around the piston rod on a side of the pressure loaded seal opposite from the pump chamber. The pump body further has a scavenging groove in an area between the pressure loaded seal and the wiper seal. The scavenging groove is in fluid communication with the inlet, whereby any fluid which leaks past the pressure loaded seal is returned to the inlet.

Owner:LILY CORP

Centrifugal fan

ActiveUS9295180B2Increase flow rateImprove cooling effectPump componentsDigital data processing detailsImpellerEngineering

A centrifugal fan is provided. The centrifugal fan includes an impeller and a housing. The impeller has an impeller diameter. The housing includes an upper plate, a lower plate and a side wall, wherein the upper plate axially corresponds to the lower plate, a side wall is formed between the upper plate and the lower plate, an axial inlet is formed on the upper plate, a lateral outlet is formed on the side wall, the impeller is disposed in the housing and corresponds to the inlet, and a flow path communicates the inlet to the outlet, wherein a greatest width of the inlet is greater than or equal to the impeller diameter.

Owner:DELTA ELECTRONICS INC

A motor reciprocating drive linear pumping machine

InactiveCN105370246AReduce starting loadShort mechanical transmission lineFluid removalElectric machineryTop dead center

The invention provides a motor reciprocating drive linear pumping machine comprising a control box and a pumping device. Control buttons are arranged on the lower side of a display screen. The pumping device comprises a drive motor, a precision reducer and a pinion. A polish rod of a sucker rod penetrates a central hole of a rack and extends out to the upper end surface of the rack. During ascend, the rack drives the sucker rod to move upward from a bottom dead center to finish a travel and reach a top dead center. At the beginning of operation start, a buffer spring at the bottom of a support cylinder releases stored energy to reduce the start current of the drive motor and increase the start torque. During descend, under the effect of the gravity of a load, the rack drives the sucker rod to move downward from the top dead center to finish a travel and reach the bottom dead center; when approaching the bottom dead center, the energy storage buffer spring begins to absorb energy and reduces the impact generated when the rack reaches the bottom dead center. The motor reciprocating drive linear pumping machine is high in efficiency, simple in structure, easy to install and transport, and small in noise, and is especially suitable for cities and regions with complex terrain and inconvenient traffic.

Owner:DINKUM TIANJIN

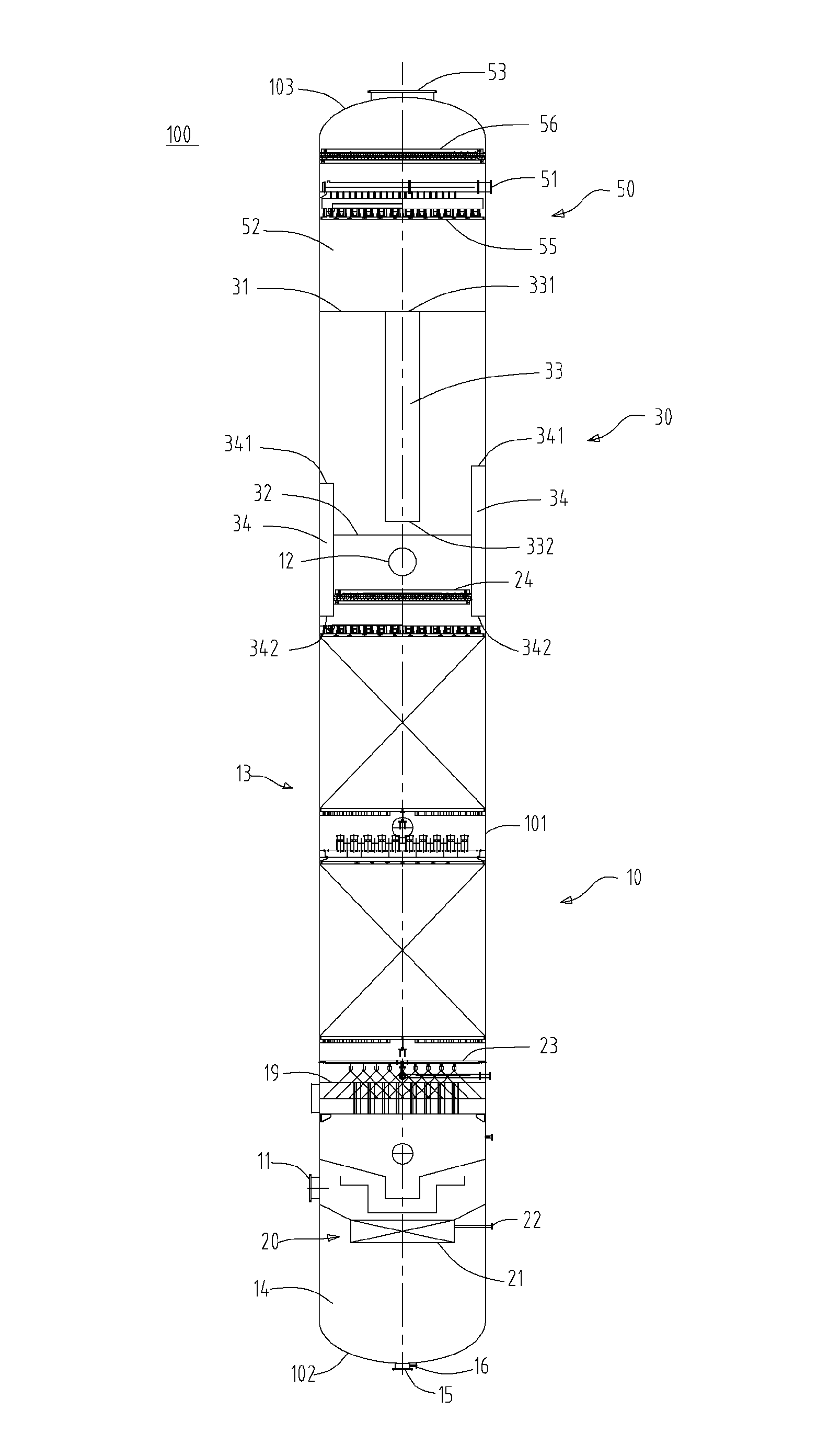

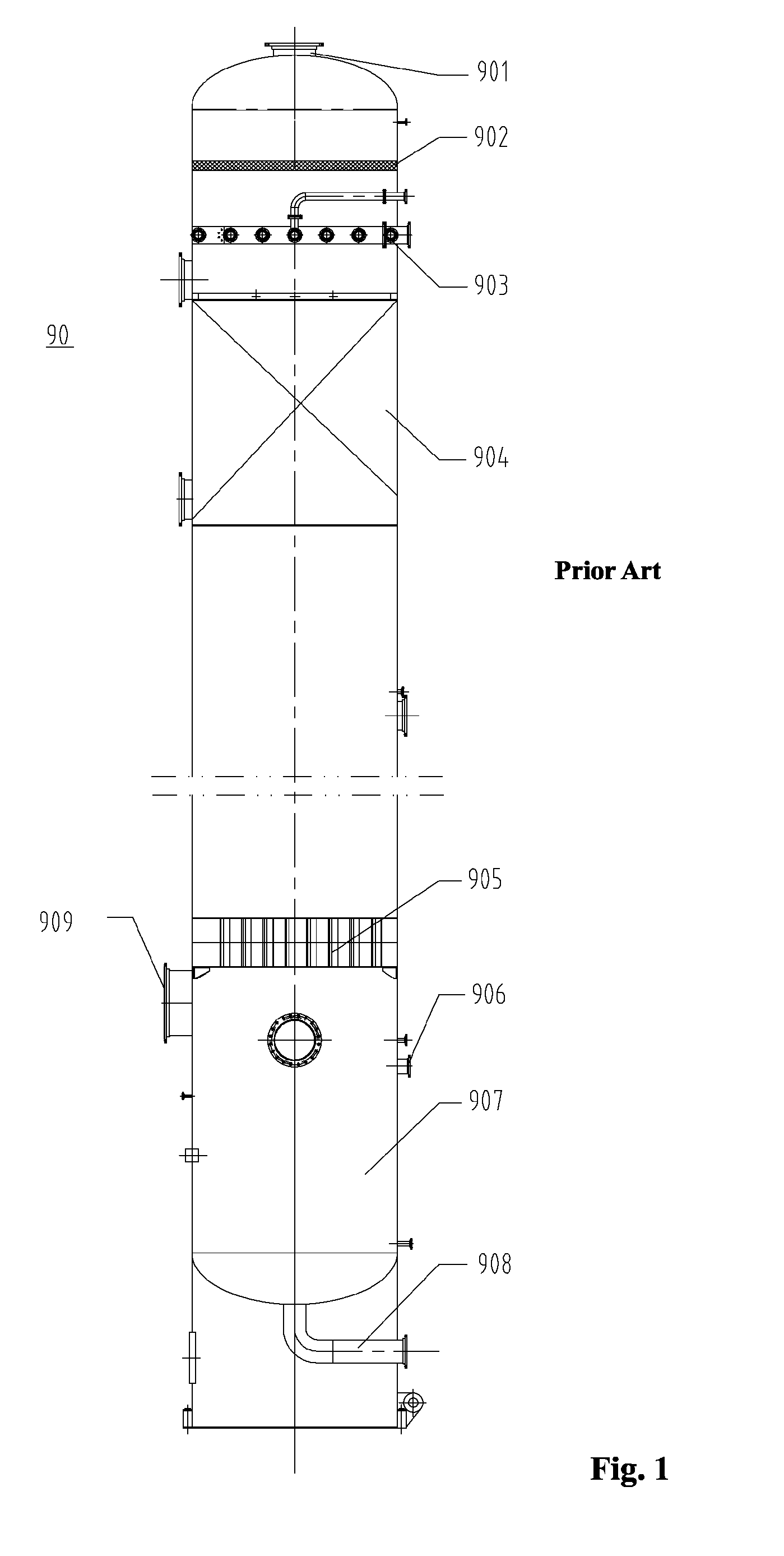

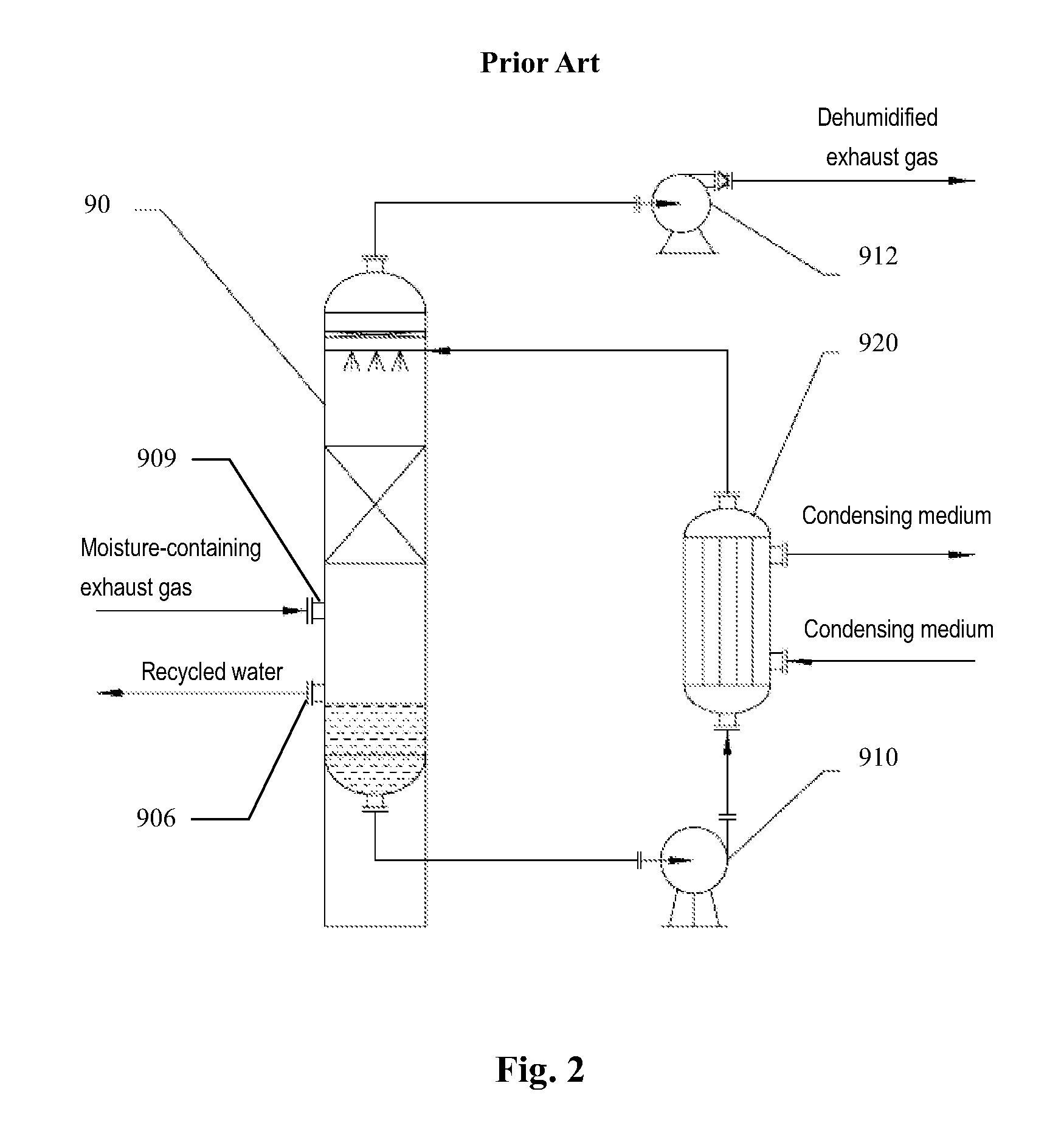

Exhaust gas separating tower and exhaust gas separating and recycling system

ActiveUS9126134B2Clean moisture vaporSmall working areaTransportation and packagingUsing liquid separation agentGas phaseDistillation

The invention relates to an exhaust gas separating tower, comprising a washing section, a flash-distilling section above the washing section, and a liquid seal means between the flash flash-distilling section and the washing section. The washing section is configured for washing exhaust gas entering the tower with a cooling liquid to at least partially remove solid dust entrained in the exhaust gas, cool the exhaust gas, and condense at least a portion of moisture in the exhaust gas into liquid. The flash-distilling section is configured for flash-distilling the cooling liquid from the washing section to produce a cooled cooling liquid and a cooling liquid vapor. The liquid seal means is configured so that the cooling liquid produced by flash-distillation can enter the washing section through the liquid seal means while the flash-distilling section is in gas-phase isolation from the washing section, wherein a pressure in the flash-distilling section is lower than that in the washing section.

Owner:NAT DRYING TECH & EQUIP ENG TECH RES CENT

Fully CNC Camshaft Milling Machine

InactiveCN102274998AExtended service lifeUniform speedFeeding apparatusMilling equipment detailsDrive wheelMilling cutter

The invention discloses a full numerical control camshaft milling machine, which comprises a bed (9), a guide rail plate (10), a guide rail (19), a rotating power head (6), a milling power head (3) and a lifting power head (16), Rotary power heads are respectively arranged at both ends of the guide rail plate, hydraulic chucks (11) are arranged on the rotating power heads, and auxiliary supports (8) are arranged between the hydraulic chucks, and the milling power heads are arranged on the lifting platform, and the lifting platform (20) can move on the column (14). The milling power head includes the milling cutter spindle (23). The column can move left and right on the guide rail (19). An inertial balance wheel (27) or a milling cutter spindle is arranged on the milling cutter spindle. The main shaft is connected with the inertia balance wheel through the driven wheel (24) on the milling cutter main shaft. The milling cutter spindle of the present invention does not generate vibration, which not only reduces the processing noise, prolongs the service life of the milling cutter, but also improves the milling quality, reduces the reserved grinding amount, reduces the grinding workload, improves the processing efficiency, and reduces the Camshaft machining cost.

Owner:胡益萍 +2

A door body foaming line mold opening and closing manipulator and its use method

The invention provides a door body foaming line mold opening and closing manipulator, which includes a rotating arm, a photoelectric switch, a support frame and a telescopic tongue, and the telescopic tongue is installed under the rotating arm through matching slots and buckles. The present invention adopts the opening and closing method to open the mold, and abandons the conventional split type, upper and lower opening and closing molds, the equipment structure is simpler and the practicability is stronger. The mold is no longer limited and needs to be set on the bracket, which is more suitable for assembly line production and further optimizes the automation of the refrigerator door foaming assembly line.

Owner:青岛合润机械工程技术有限公司 +1

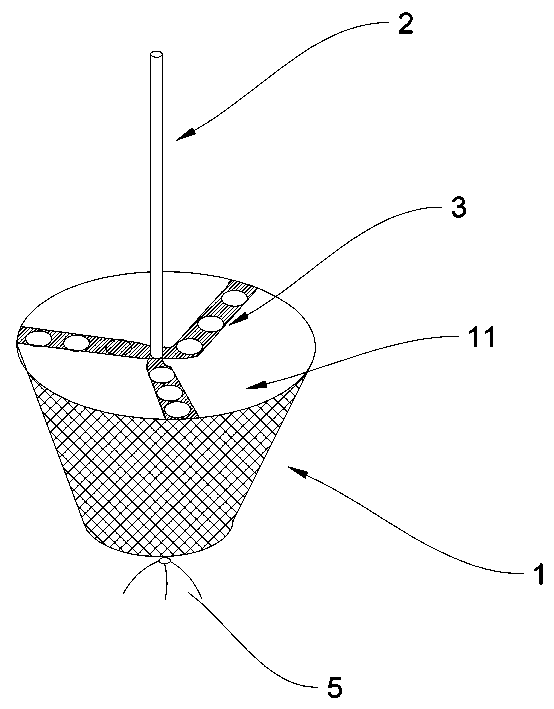

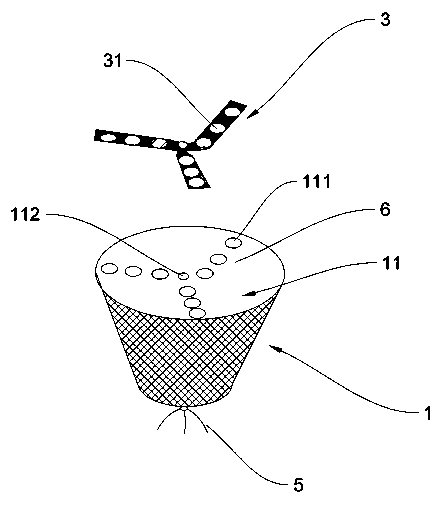

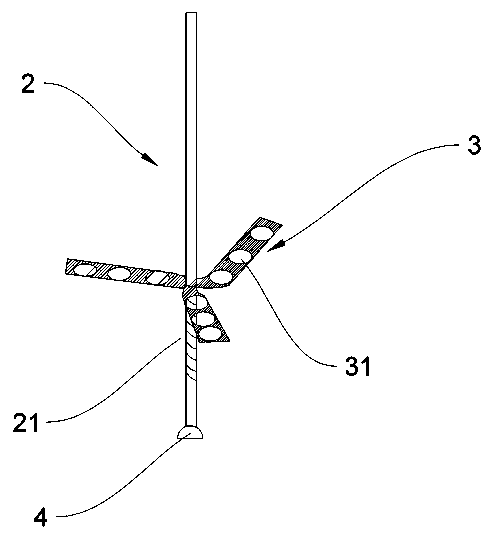

Shrimp trapping device

The invention provides a shrimp trapping device, which relates to the technical field of fishing. The shrimp trapping device comprises a collecting net cage, a central column, an elastic sealing bandand a bait box, wherein a cover body with a plurality of shrimp trapping holes is arranged on the collecting net cage, and a central hole with internal threads is formed in the central part of the cover body; the central column penetrates through the central hole, and external threads are arranged on the central column; one end of the elastic sealing band is fixedly connected to the central columnand the other end is fixedly connected to the cover body, so as to enable the elastic sealing band to cover the shrimp trapping holes, and through holes are formed in the elastic sealing band; and the bait box is fixedly connected to one end of the central column. Shrimps cannot escape from the shrimp trapping holes, the action is quick, when the shrimps are collected and taken out of the device,the shrimps in the collecting net cage can be effectively prevented from escaping quickly due to shock, so that the amount of shrimps collected is increased; and meanwhile, the device is small and convenient, easy to operate, suitable for personal use, and does not cause damage to surrounding crops.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com