A door body foaming line mold opening and closing manipulator and its use method

A foaming line, mold opening and closing technology, applied in the field of automatic door body foaming equipment assembly line mold opening and closing manipulators, can solve problems such as high cost and complicated operation, and achieve high precision, simple equipment structure, and saving working area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

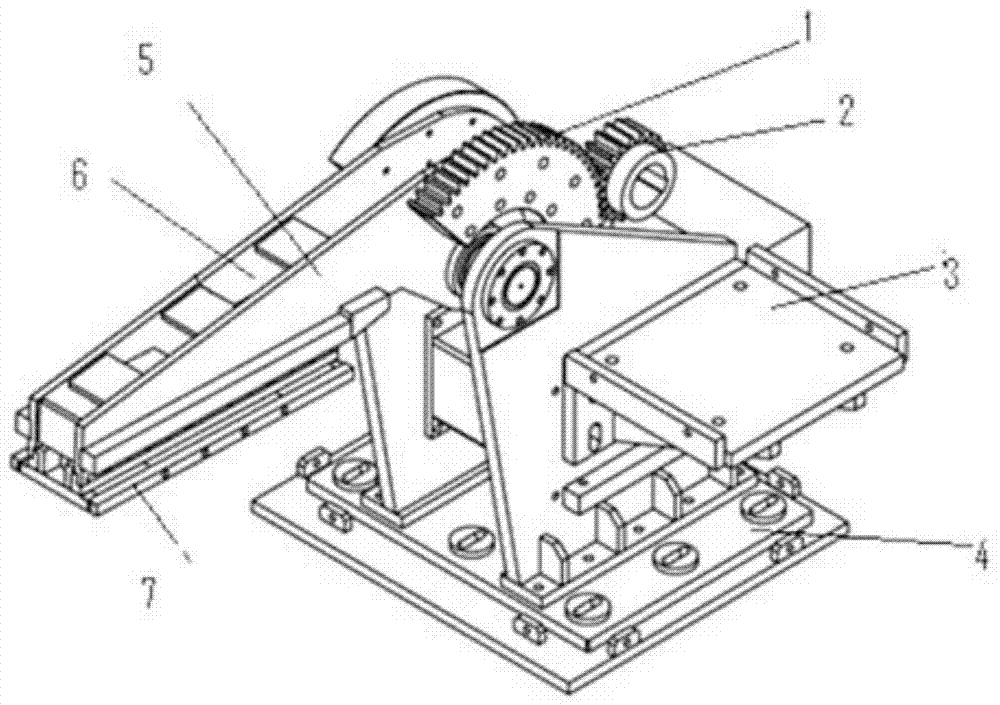

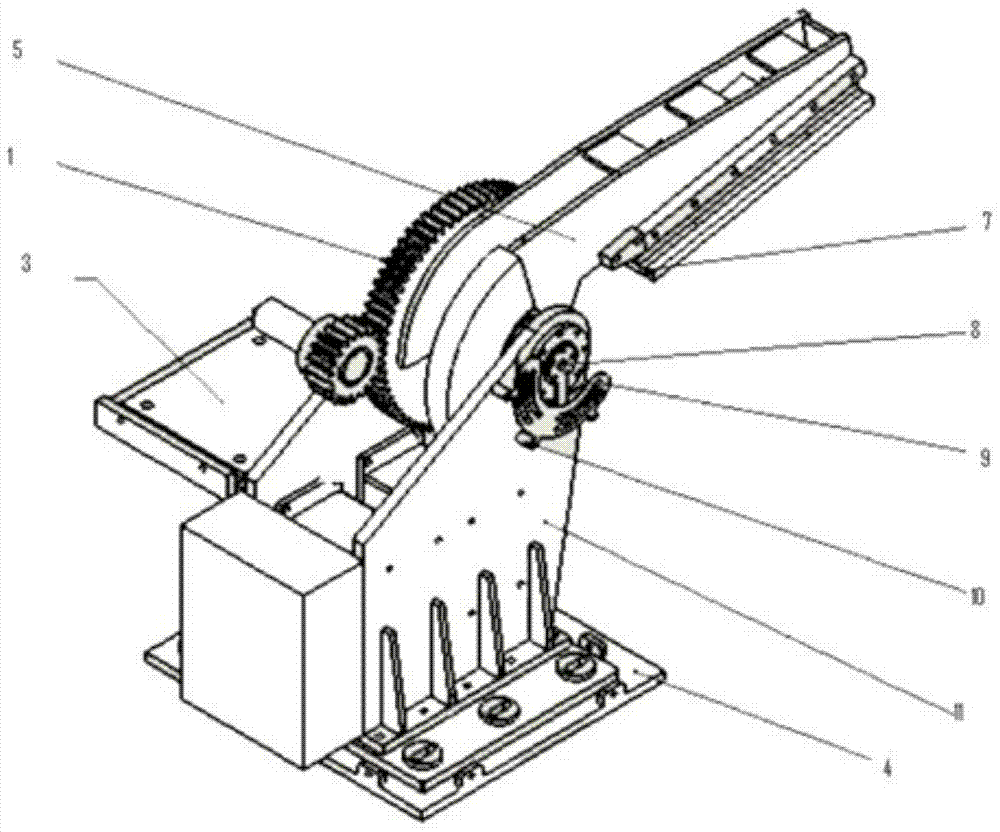

[0022] A door body foaming line mold opening and closing manipulator of the present invention comprises a rotating arm composition, a photoelectric switch composition, a support frame 11 and a telescopic tongue 7, and the telescopic tongue 7 is installed on the rotating arm 5 through matching slots and buckles. below.

[0023] The rotating arm is assembled on the support frame 11 .

[0024] Described rotating arm composition comprises intermeshed driving wheel 2 and driven wheel 1, and described driving wheel 2 and driven wheel 1 are connected with support frame 11, also comprises the rotating arm 5 that is installed on the axle of driven wheel, and rotating arm 5 follows The rotation of driven wheel 1 rotates.

[0025] An air cylinder 6 is installed on the rotating arm 5 , and the telescopic end of the air cylinder 6 is connected with the telescopic tongue 7 .

[0026] The photoelectric switch consists of a photoelectric panel 9 and a photoelectric baffle 8 .

[0027] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com