Patents

Literature

48results about How to "Adapt to production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

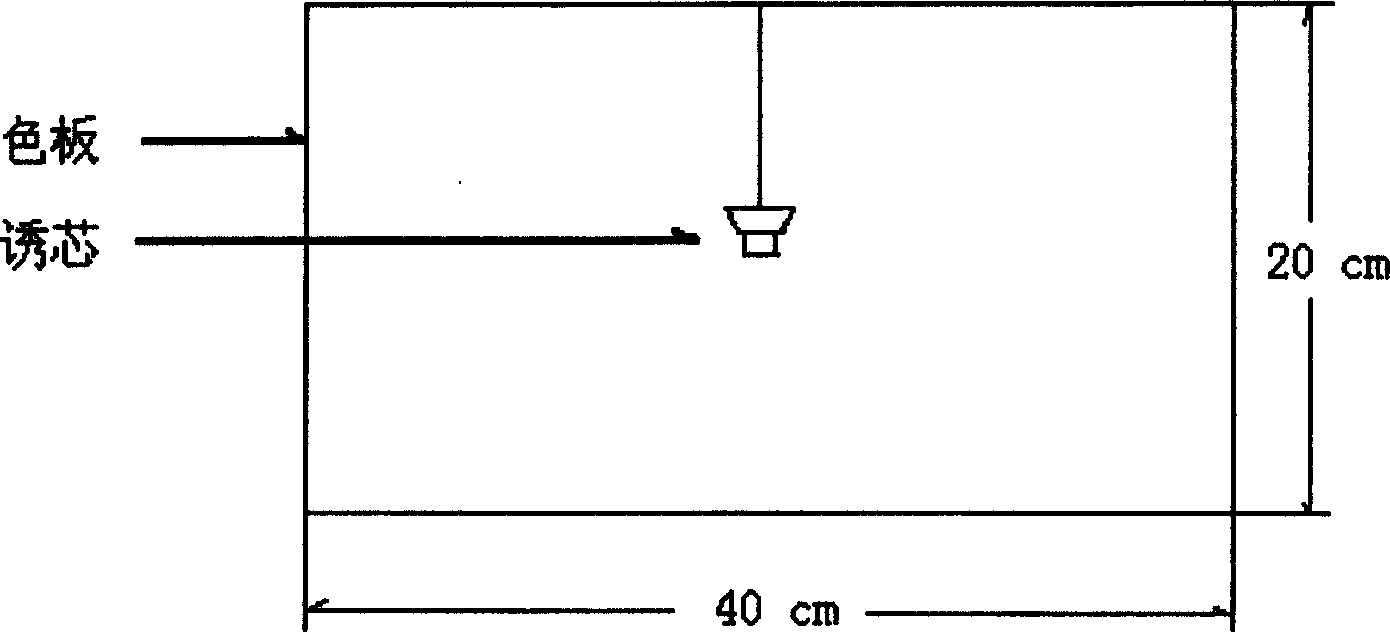

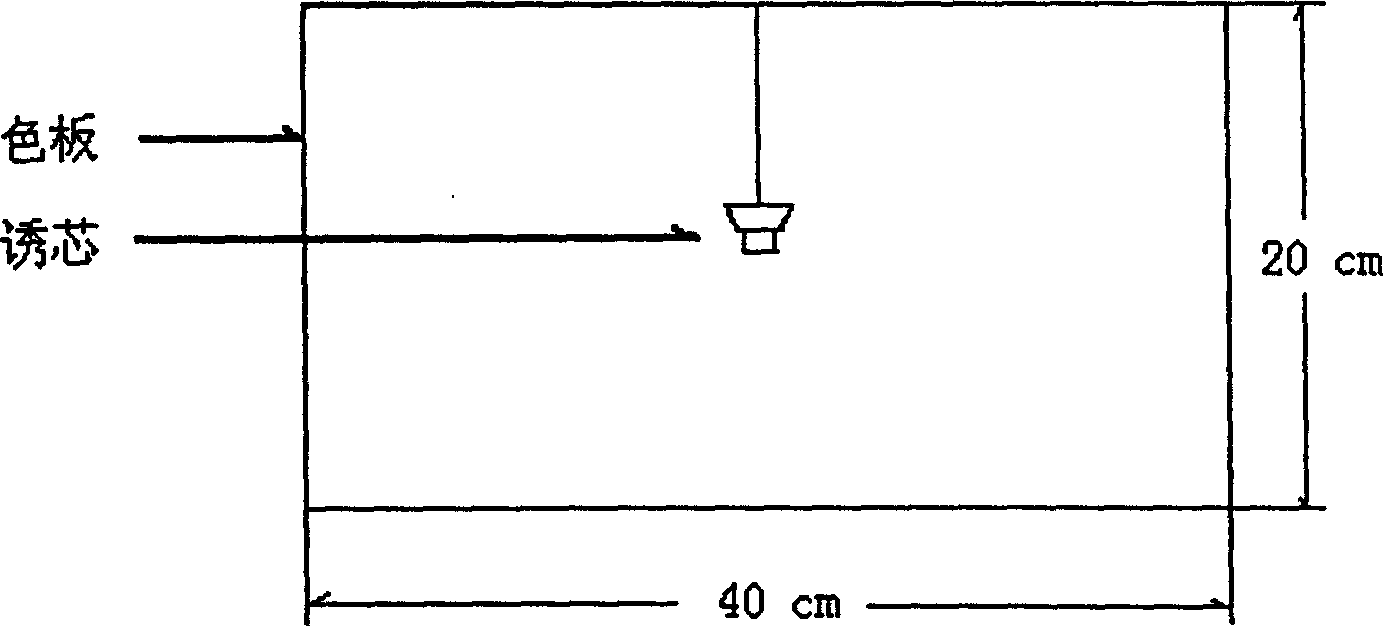

Tea garden insect trapping method

InactiveCN1593122AAdapt to productionNo pollution in the processInsect catchers and killersTrappingBud

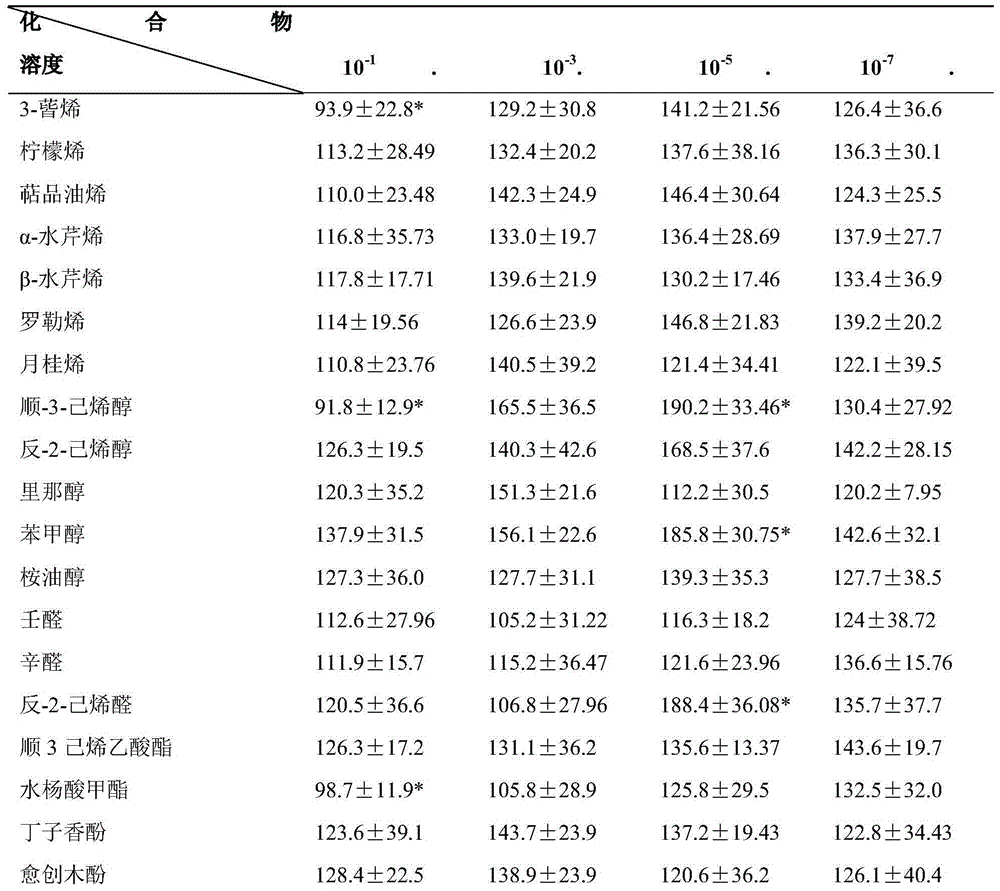

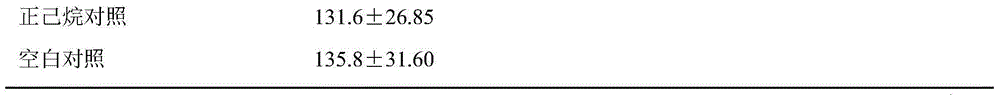

The invention discloses a method for trapping tea plantation insects comprising the steps of, (1) separating and determining 10 pest damage volatile matters by adopting adsorptive separation method, (2) determining four volatile constituents with inducement activity by biological assay method, (3) preparing four active constituents into flavor source substances, matching the four flavor source substances, so as to formulate the insect attractant, (4) determining three colors with inducement effect to insects by tea plantation small zone inducement experiments, (5) combining the bud greening color with the attractant to prepare insect trapper, and (6) placing the trapper into the field to trap the insects.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

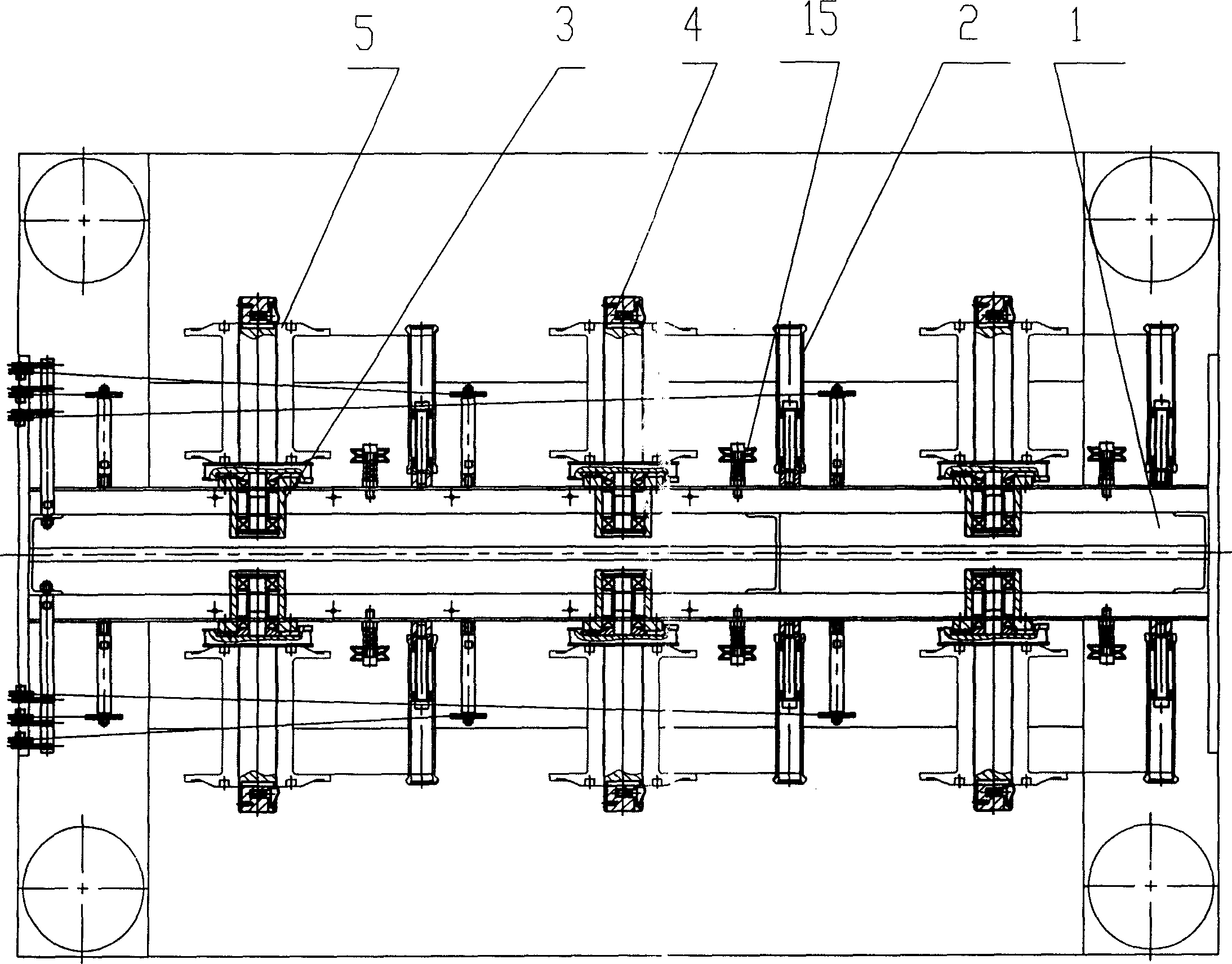

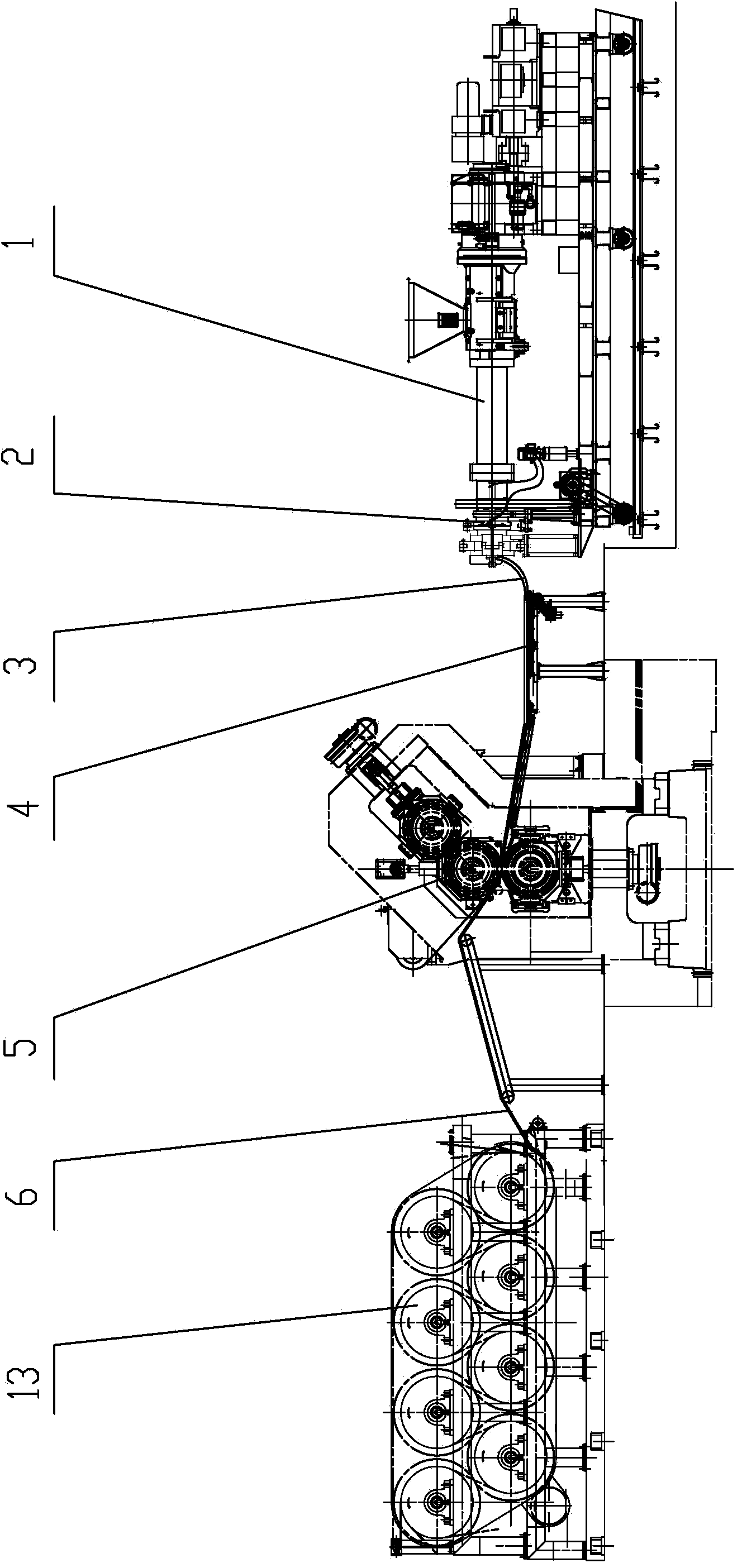

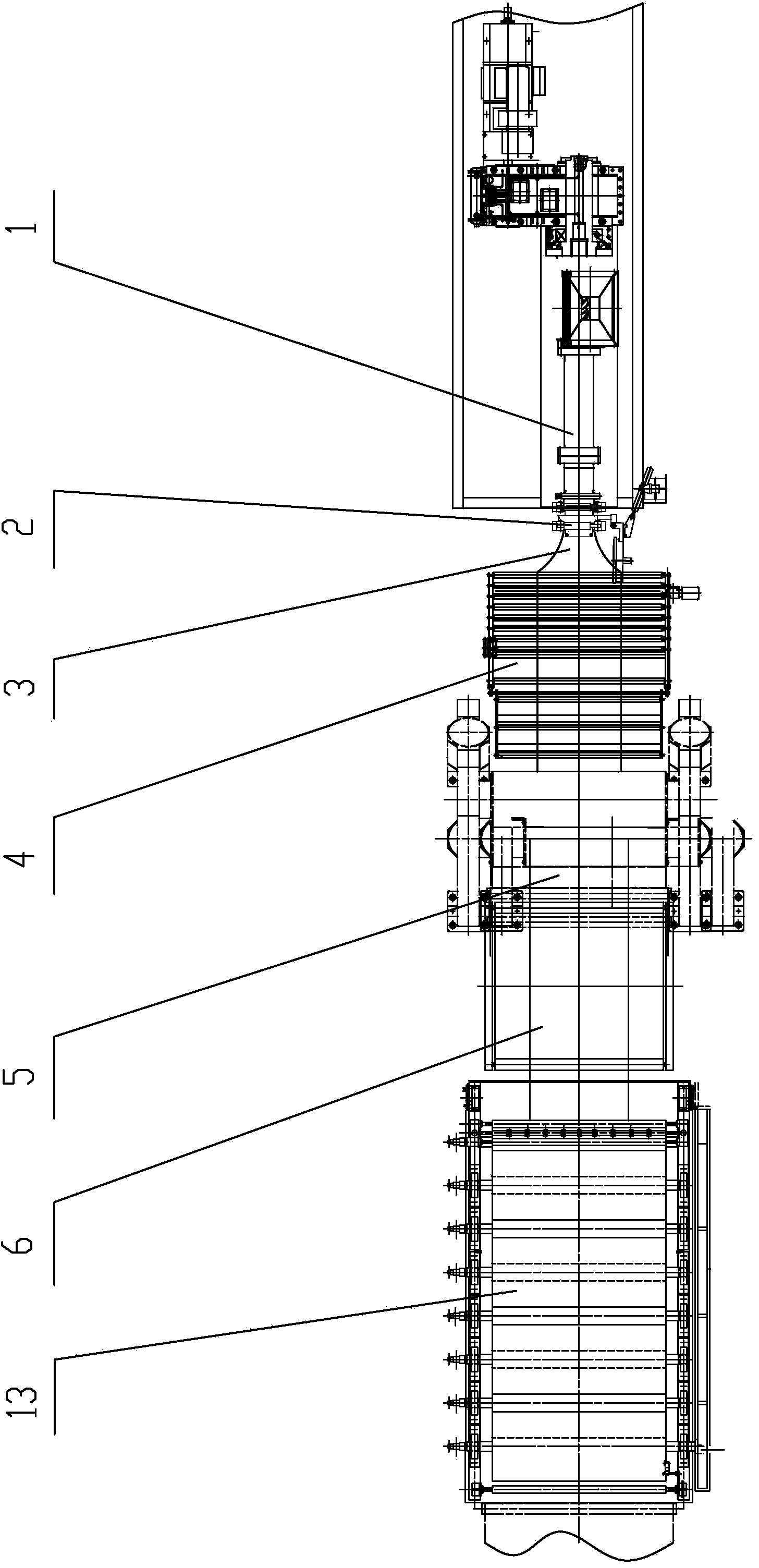

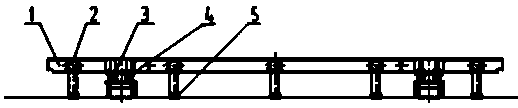

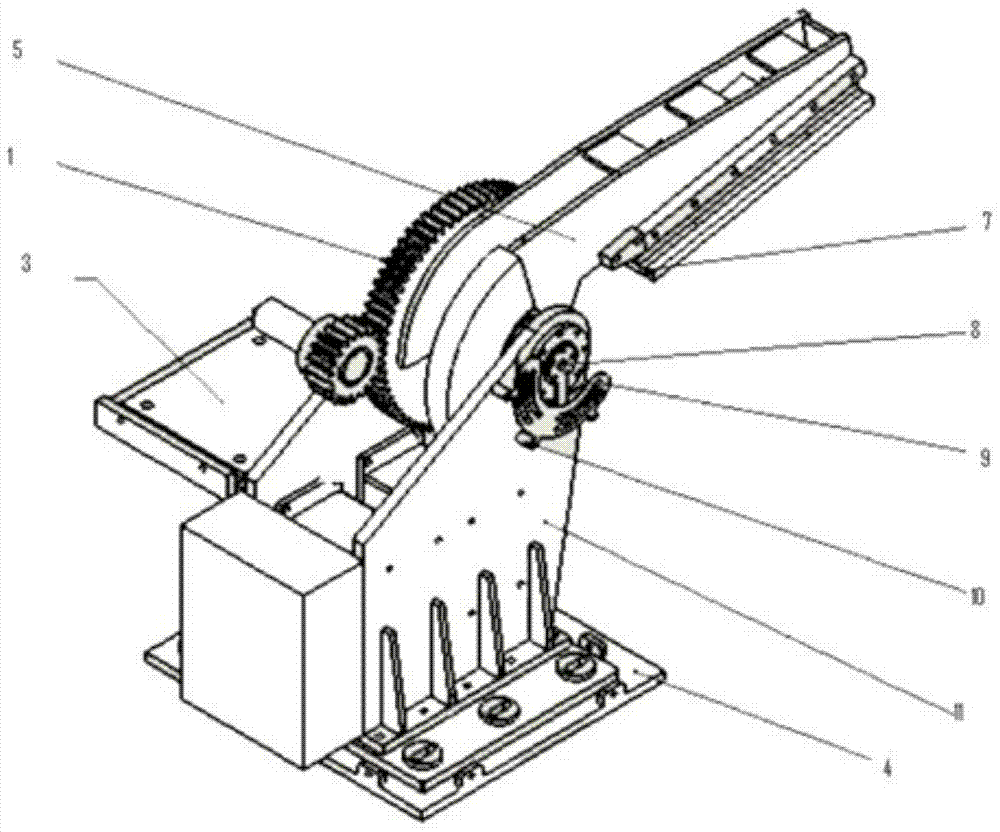

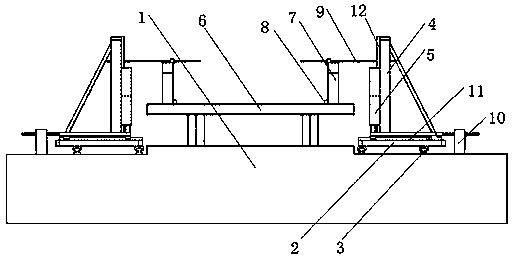

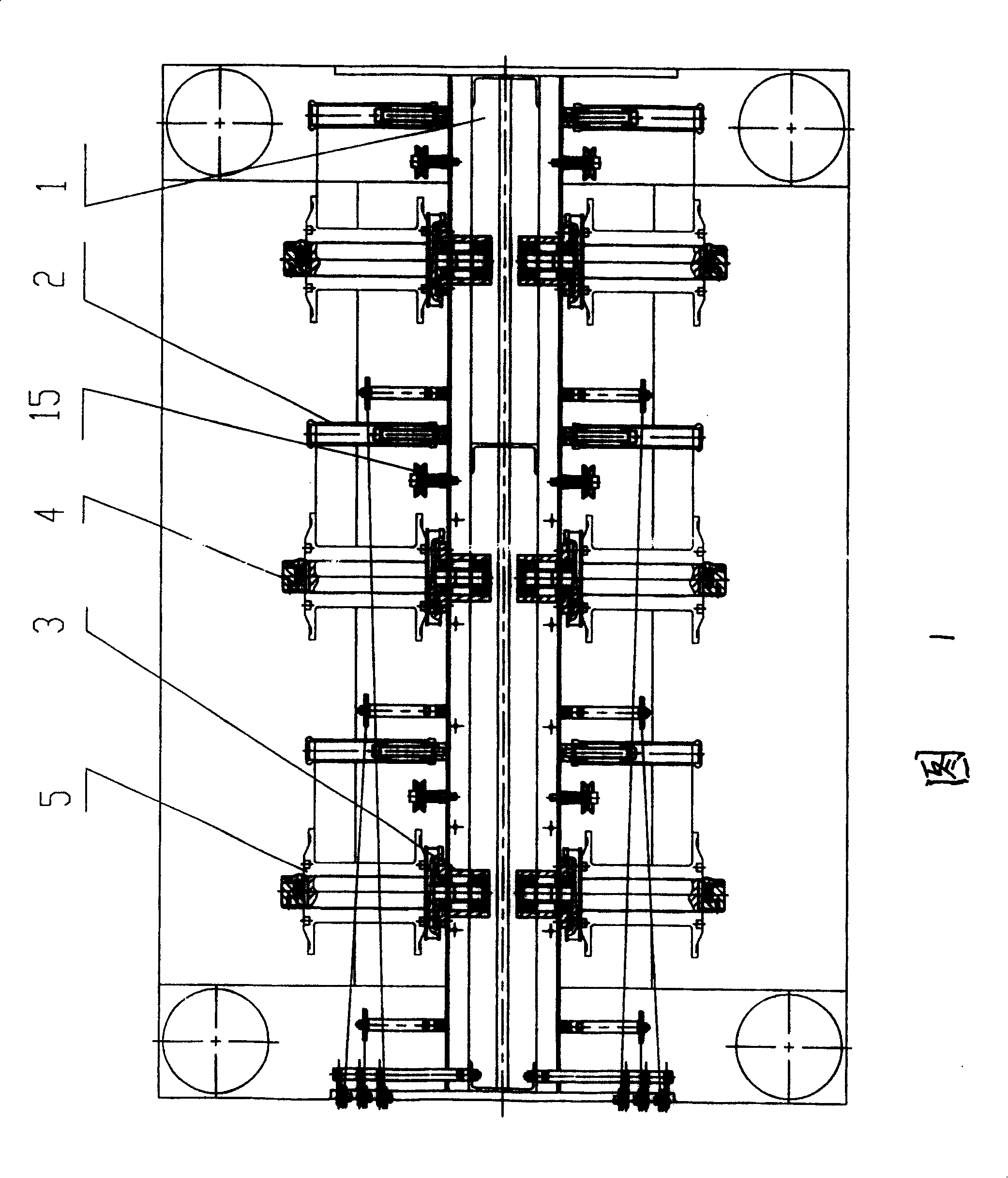

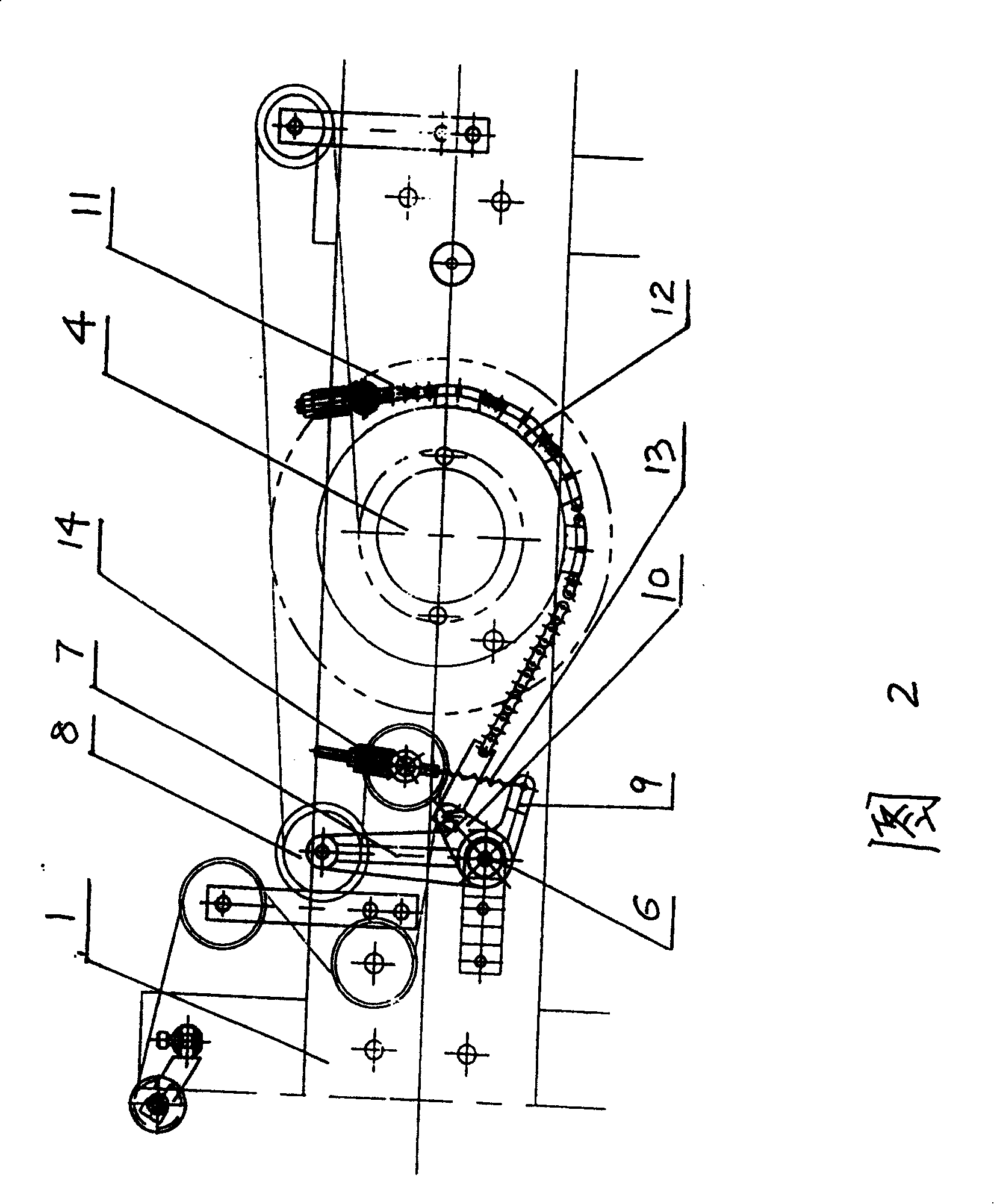

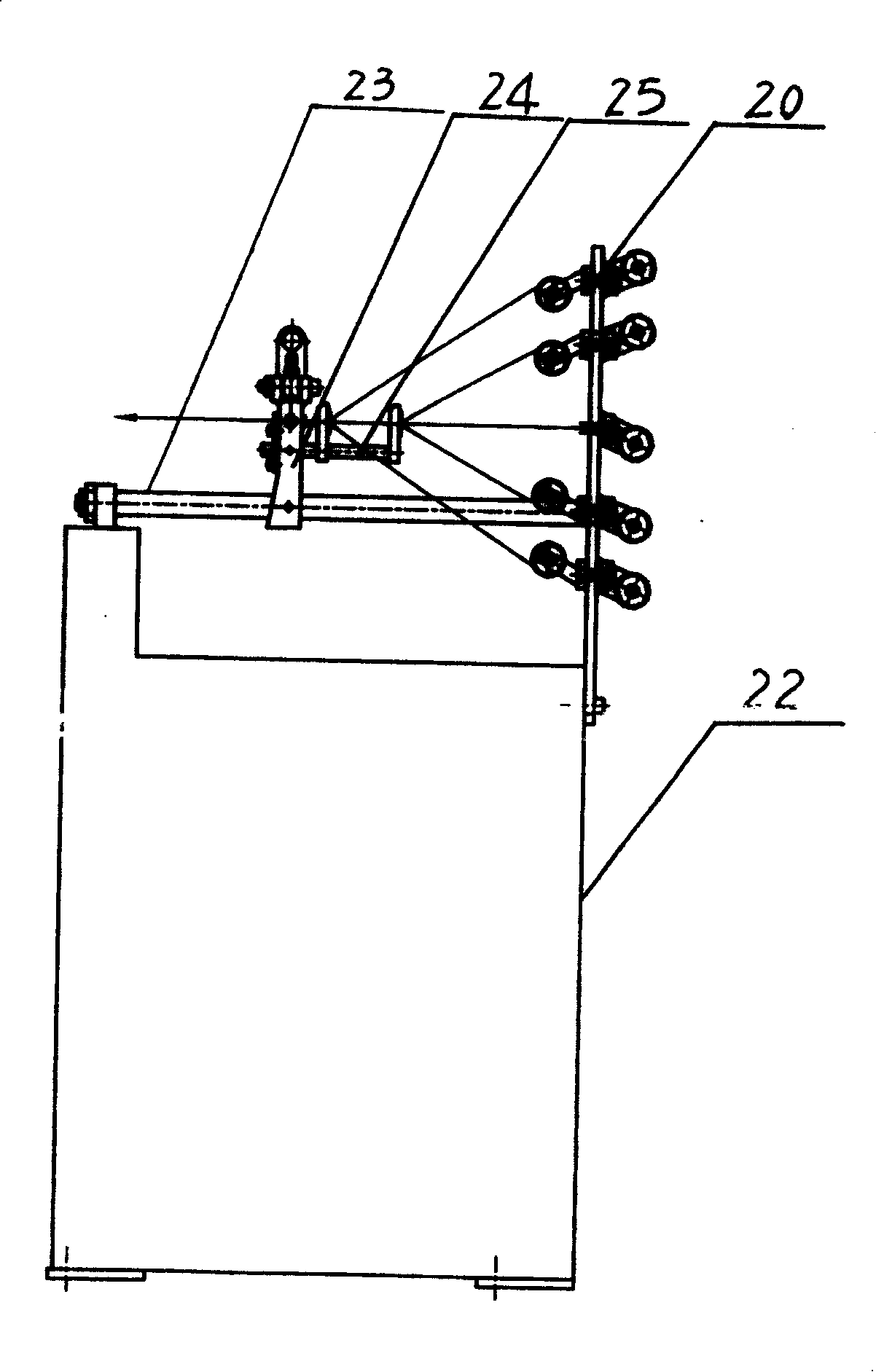

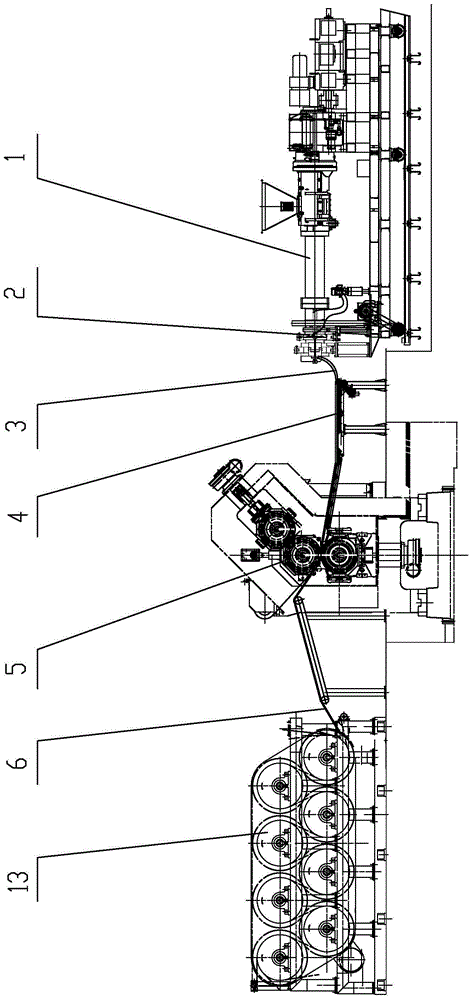

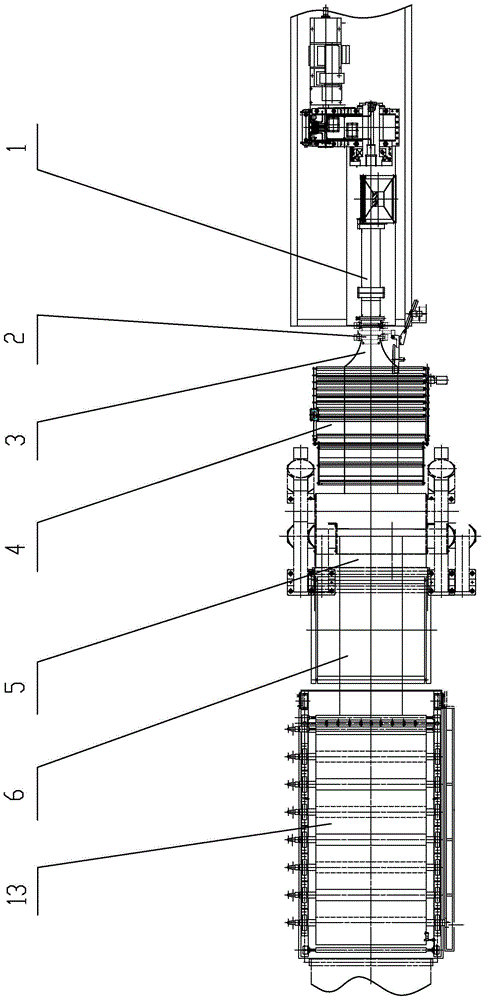

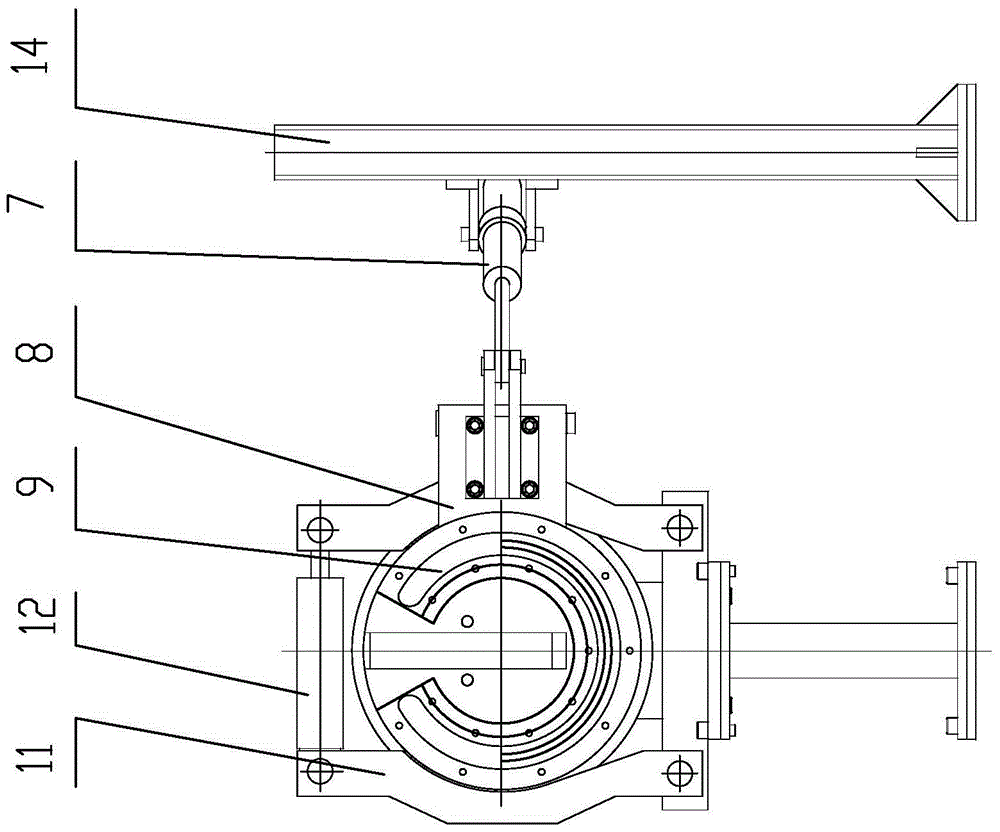

General purpose type wire stranding machine

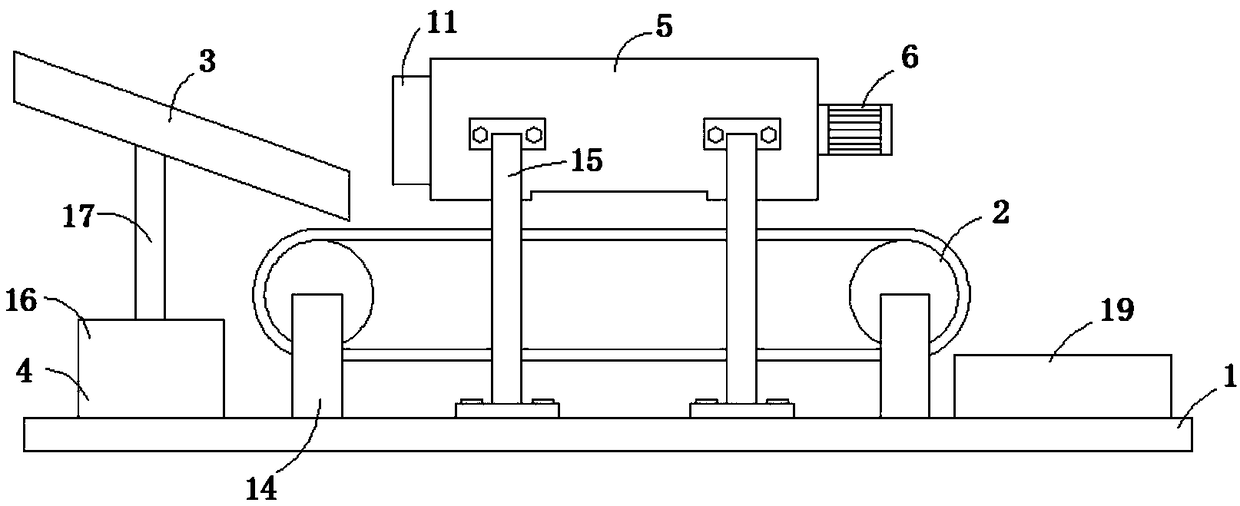

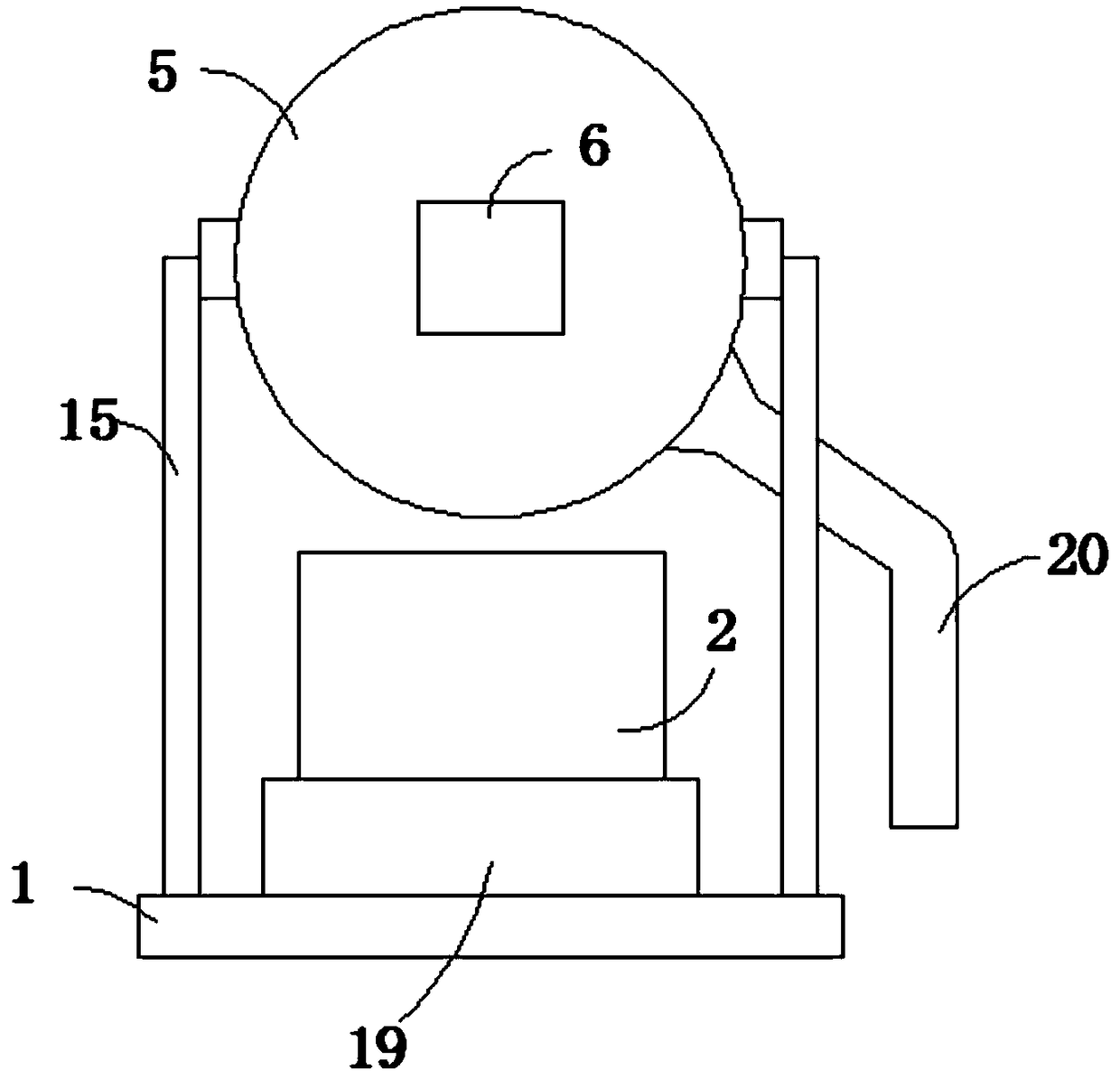

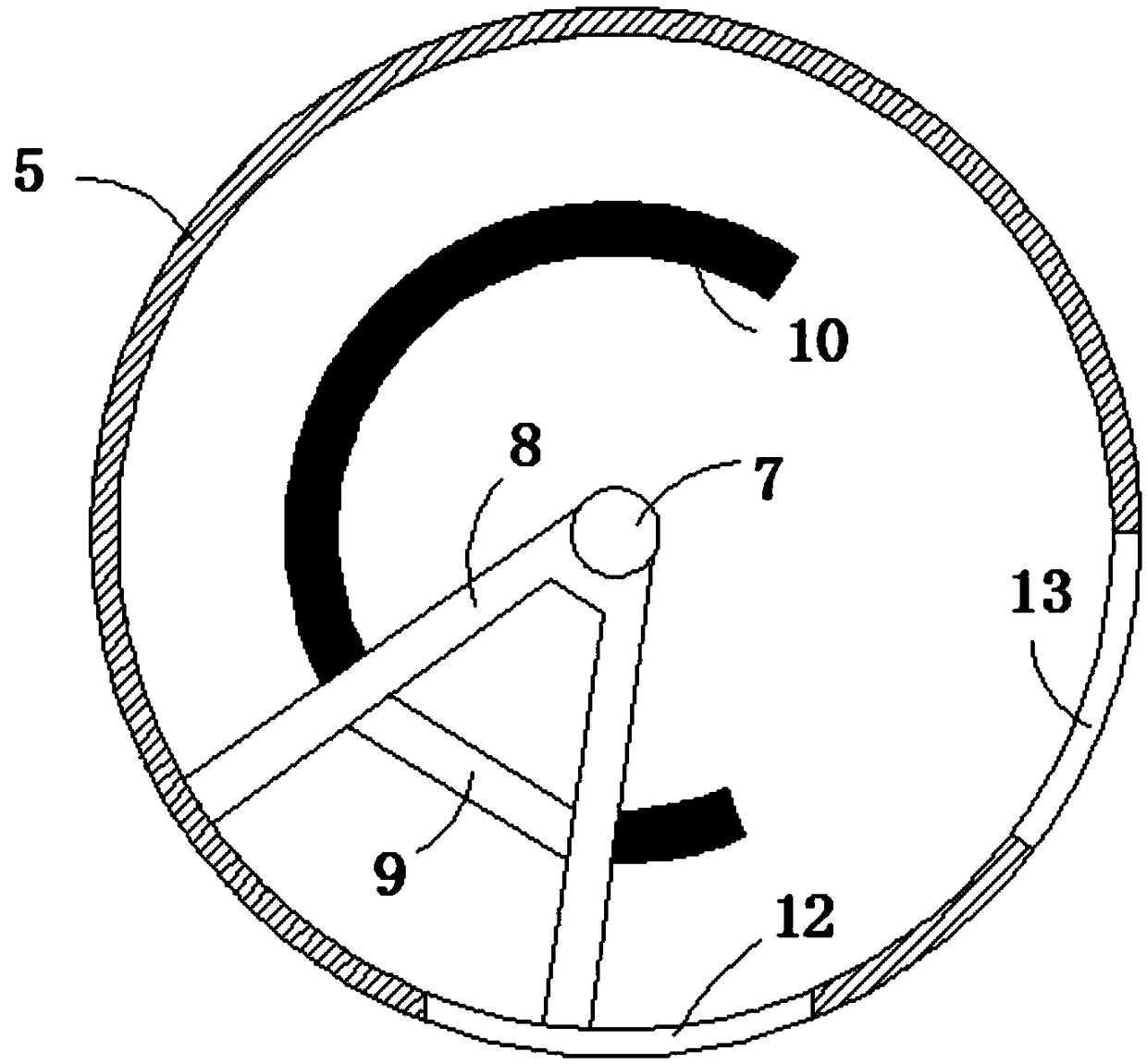

This invention discloses an all-purpose strander, which comprises a setting-out part, a branching matched part and a main frame strander contractor part, wherein the setting-out part comprises the setting-out frame (1) and setting-out seat, and the setting-out frame (1) is installed erectly with several setting-out seats in it; the main shafts of each setting-out seat are arranged horizontal in parallel, and around each setting-out seat it sets guide wheel (15) and guide pipe (2); the tension automatic adjust device are set on each setting-out seat. The strander is modularized and is fit for stranding steel cord of several formats.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Plant volatile matter imitation attractant and pesticide thereof

The invention relates to a plant volatile matter imitation attractant, a relevant pesticide, and an application of the attractant and the pesticide. The plant volatile matter imitation attractant is one or a mixture containing more of 3-carene, cis-3-hexenol, linalool, benzyl alcohol, trans-2-hexenal, methyl salicylate and eugenol. The attractant and the relevant pesticide are mainly used for controlling Bemisia tabaci and / or whitefly, and especially Bemisia tabaci and / or whitefly of tomato in greenhouse; the attractant and the relevant pesticide can be used in field to reduce or completely avoid the use of traditional chemical pesticides, and are suitable for current production of organic vegetables and nuisance-free vegetables; and the attractant and the relevant pesticide have the advantages of high efficiency, stable performances, trapping of many Bemisia tabaci and / or whitefly in an experimental area within 1-2d, convenient transportation, use convenience and low cost.

Owner:INST OF ZOOLOGY CHINESE ACAD OF SCI

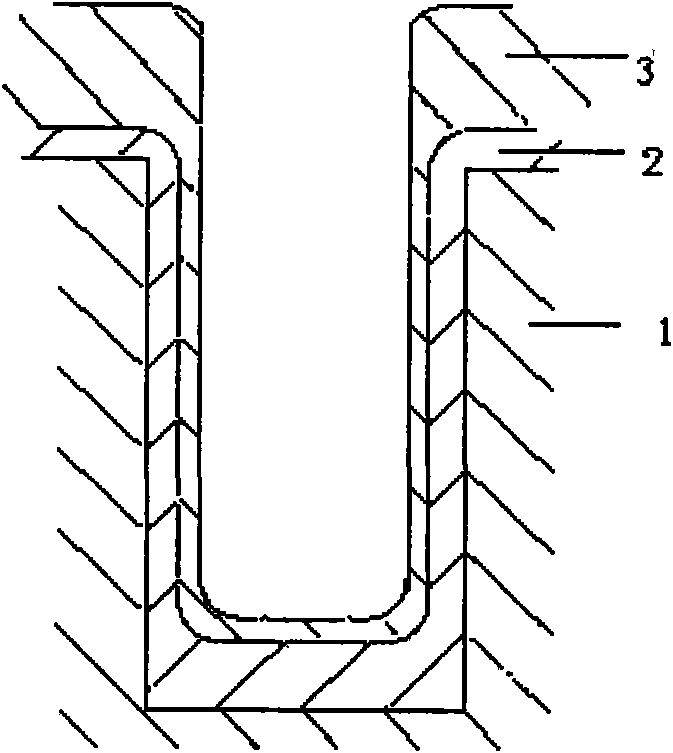

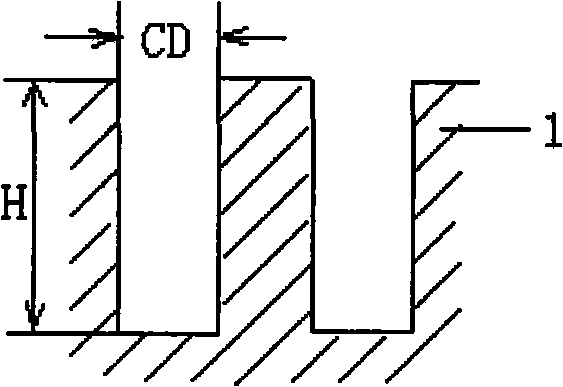

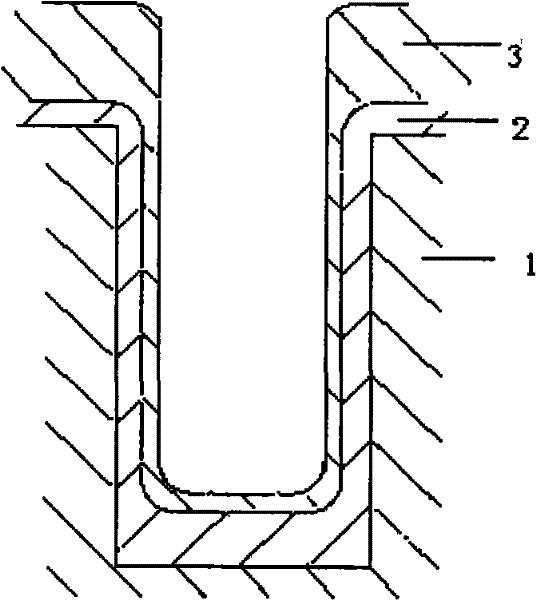

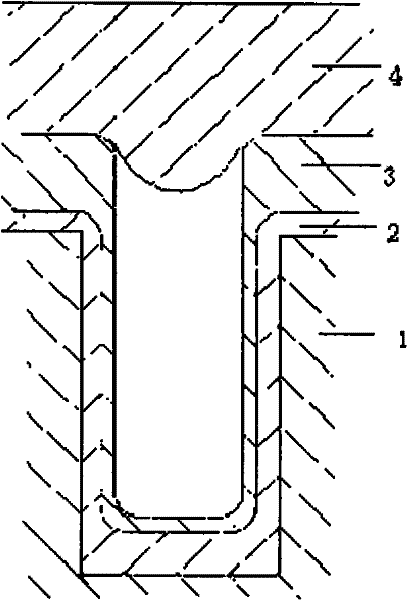

Device and process method for filling aluminum into nano through holes by using PVD method

InactiveCN101643891AExtend your lifeLower reflow temperatureVacuum evaporation coatingSputtering coatingGas phaseLine width

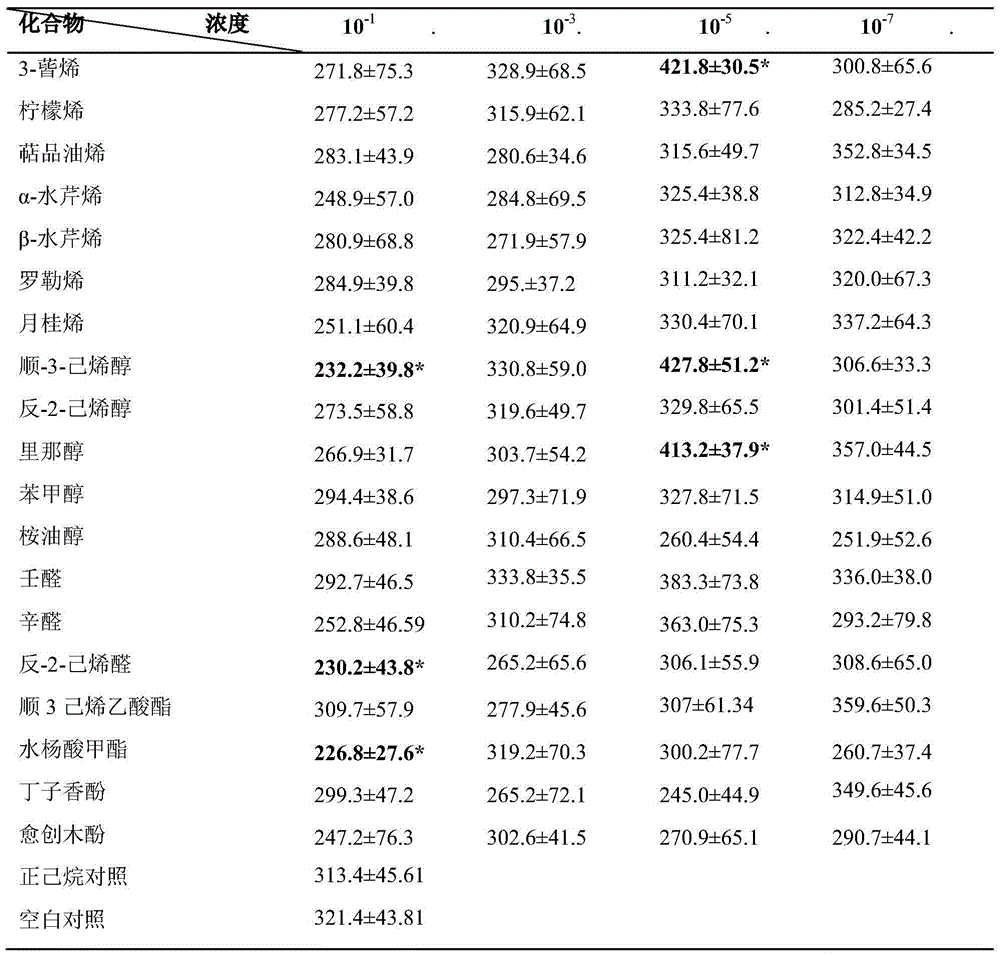

The invention relates to a device and a process method for filling aluminum into nano through holes by using a PVD method, which adopt a radio-frequency power supply and a high-frequency plasma methodof physical vapor deposition (PVD), wherein in a PVD chamber, the radio-frequency power supply is applied to a target material and a wafer respectively, and the Al is filled into the through holes ofa minisize semiconductor chip and becomes a conducting material between semiconductor layers. The device and the process method can overcome the defect that the conventional process can only reach over 0.13 micron, and extend the application of the aluminum to a degree that the characteristic line width is less than or equal to 0.1 mum and the depth-to-width ratio (h / CD) is more than or equal to6. The device and the process method reduce the device running temperature, save water, electricity and consumptive materials, greatly improve the utilization rate of production facilities and the wafer yield, can be applied to the conductive through holes between semiconductor integrated circuit chip layers, contact holes, grooves and the like for filling the conductive materials of the aluminumand the like, and also can be used for depositing the aluminum used on metal door circuits of which the line width is less than 30 nanometers. The invention particularly points out that the same method is suitable for all technical materials with low melting point.

Owner:吉和林

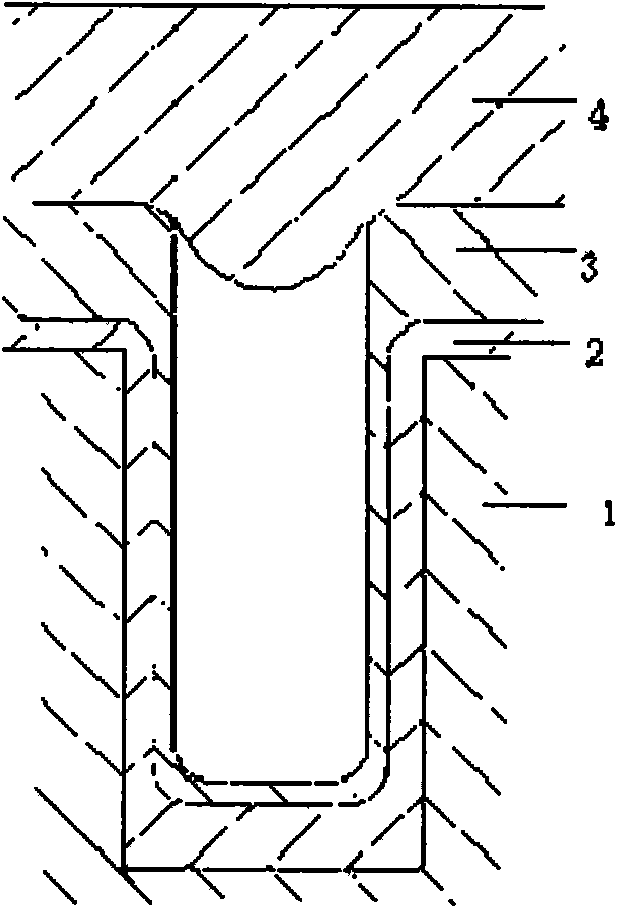

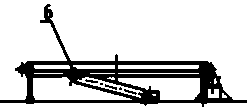

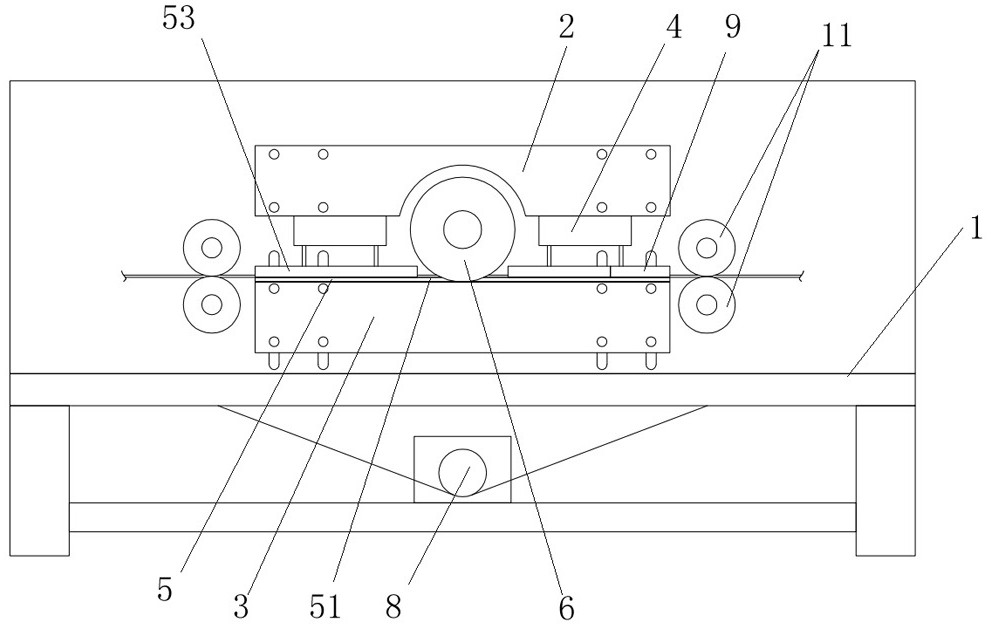

Film laminating mechanism

InactiveCN107140245AUniform areaImprove work efficiencyWrapping material feeding apparatusWeb rotation wrappingTransmission beltAssembly line

The invention discloses a film laminating mechanism which comprises a film laminating platform and a bracket, wherein a cutter mechanism is arranged on one side of the film laminating platform; a rotary baling mechanism is arranged above the film laminating platform; an automatic film supply mechanism is arranged on one side of the rotary baling mechanism; the rotary baling mechanism is fixed on the bracket; the rotary baling mechanism can rotate around a fixed point; a transmission belt is arranged on the film laminating platform; and the surface of the transmission belt is an inwards sunken arc-shaped surface. According to the film laminating mechanism, when the rotary baling mechanism rotates to laminate a material with a film, the material can also rotate in the inwards sunken arc-shaped surface of the transmission belt, so that the material can be laminated with the film in all directions; the film laminating area is uniform; and the film laminating mechanism can realize full-automatic continuous film lamination and is suitable for production of an assembly line.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

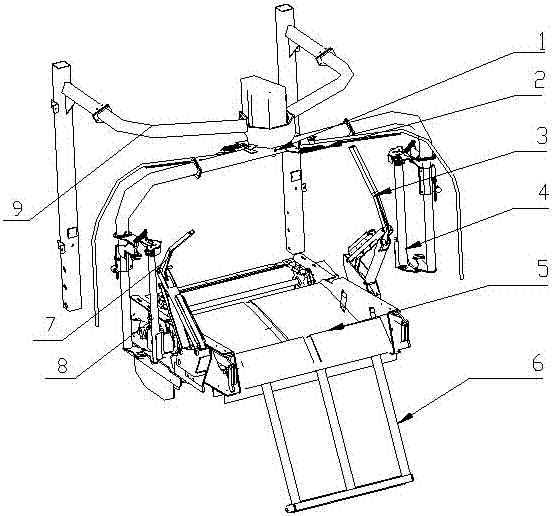

Aluminum and aluminum alloy spiral pipe forming stirring friction welding method

InactiveCN103240571ARealize digital inputRealize remote precise controlWelding/soldering/cutting articlesTubular articlesFriction weldingSeam welding

The invention discloses an aluminum and aluminum alloy spiral pipe forming stirring friction welding method which includes: coiling aluminum and aluminum alloy coiled materials into pipe billets according to preset angles; using rotation roll positioning to align pipe seams, and supporting formed pipe billets to avoid deformation; and using a stirring friction method for pipe seam welding. The method is widely applicable to welding of various grades of aluminum and aluminum alloy spiral pipes and high in efficiency.

Owner:姚雪飞

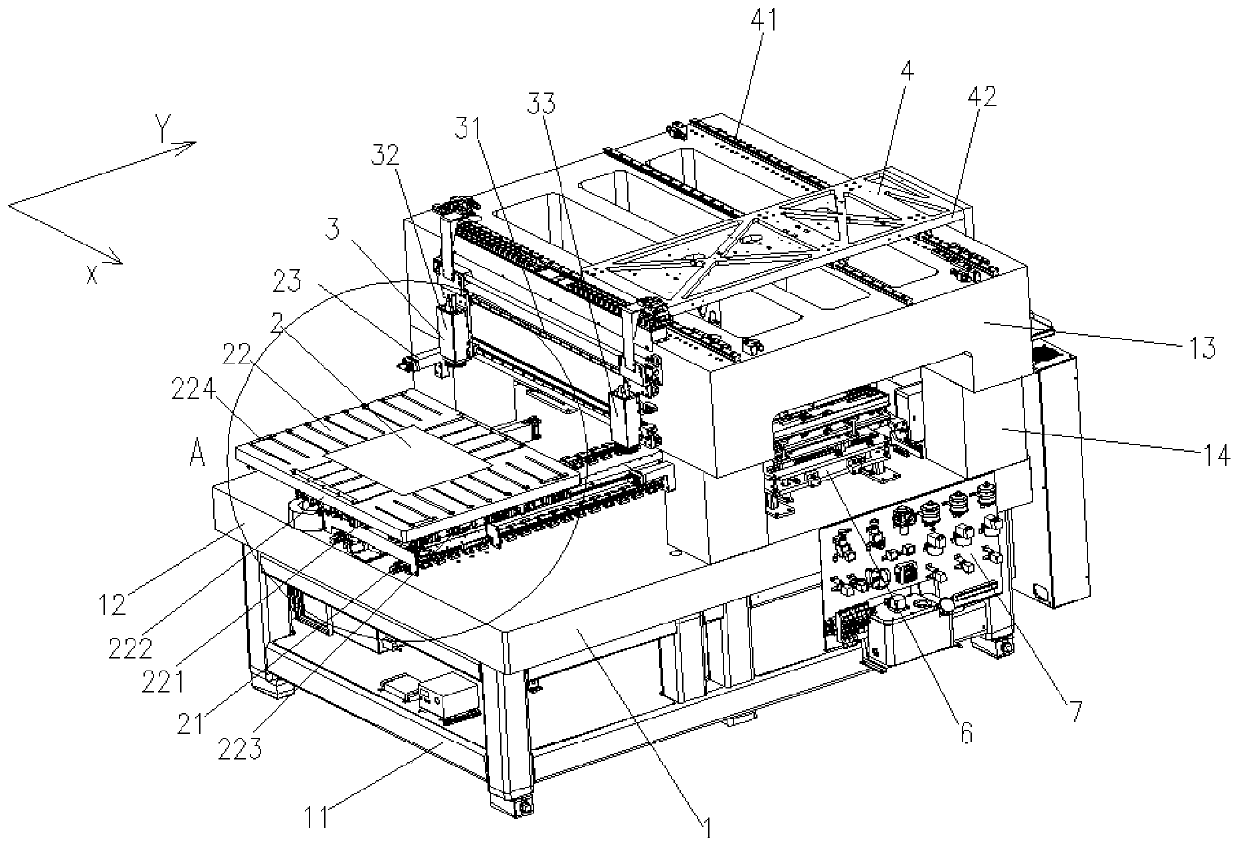

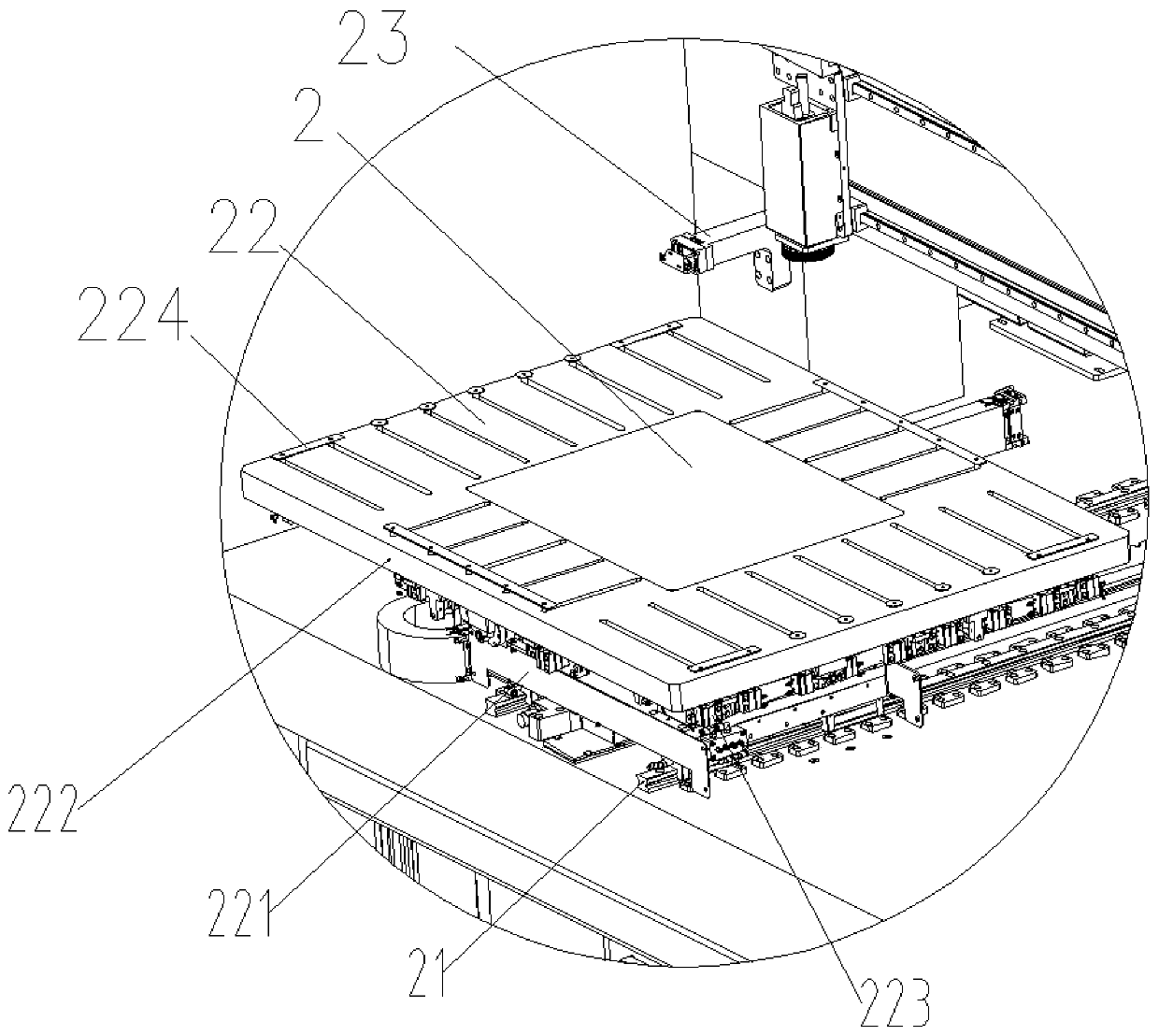

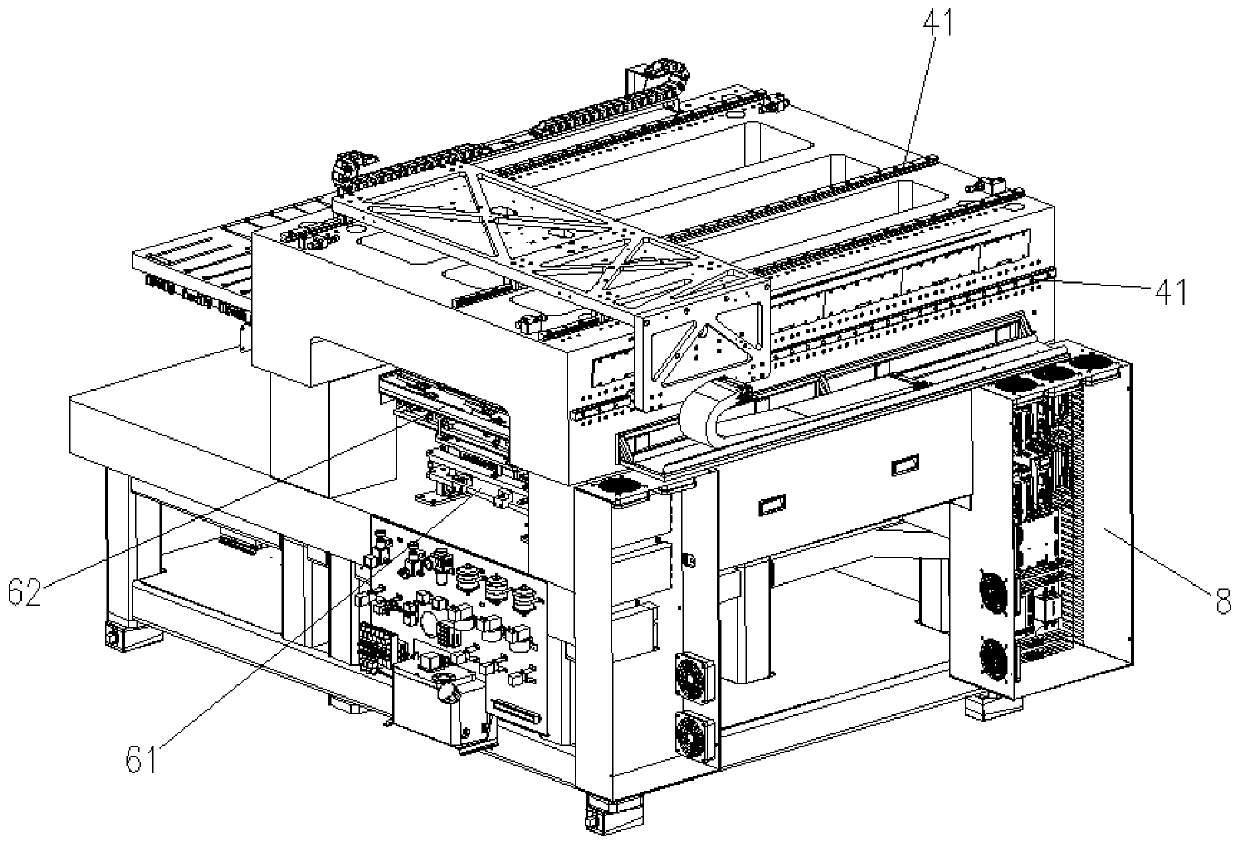

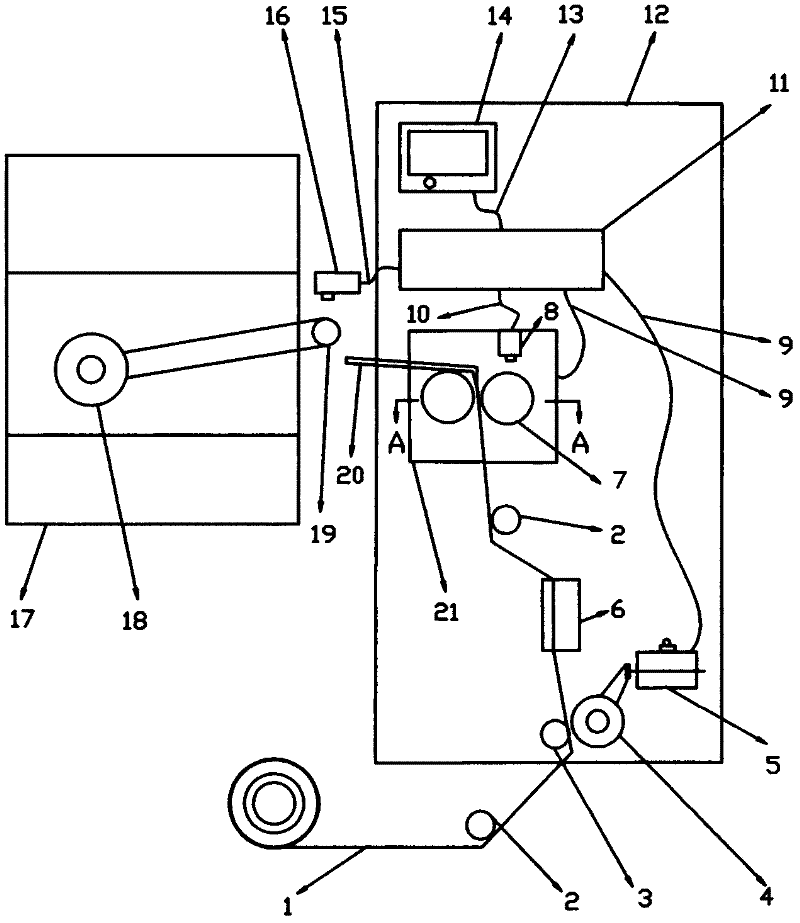

Large-sheet single-table inkjet machine

PendingCN110843349AQuick alignmentImprove efficiencyTypewritersPower drive mechanismsControl systemMechanical engineering

The invention discloses a large-sheet single-table inkjet machine which includes a machine table assembly, a printing work table assembly, a CCD alignment system, an inkjet printing trolley assembly,a pressing plate device, a nozzle cleaning device, an ink supply system and a control system. According to the large-sheet single-table inkjet machine, dual-CCD photographing is used for quickly aligning circuit boards, a bidirectional printing unit is used for performing go and return inkjet printing on the circuit boards, a printing table adopts four-sided mobile fixtures so as to meet the requirement for clamping sheets from small to large, the pressing plate device is arranged to solve the problem that sheets warps and cannot be normally produced when inkjet printing is performed on large-size sheets, and the large-sheet single-table inkjet machine can meet the requirement for production of the special large-size sheets and can flexibly adapt to production of sheets in various sizes.

Owner:선전진신테크놀로지컴퍼니리미티드

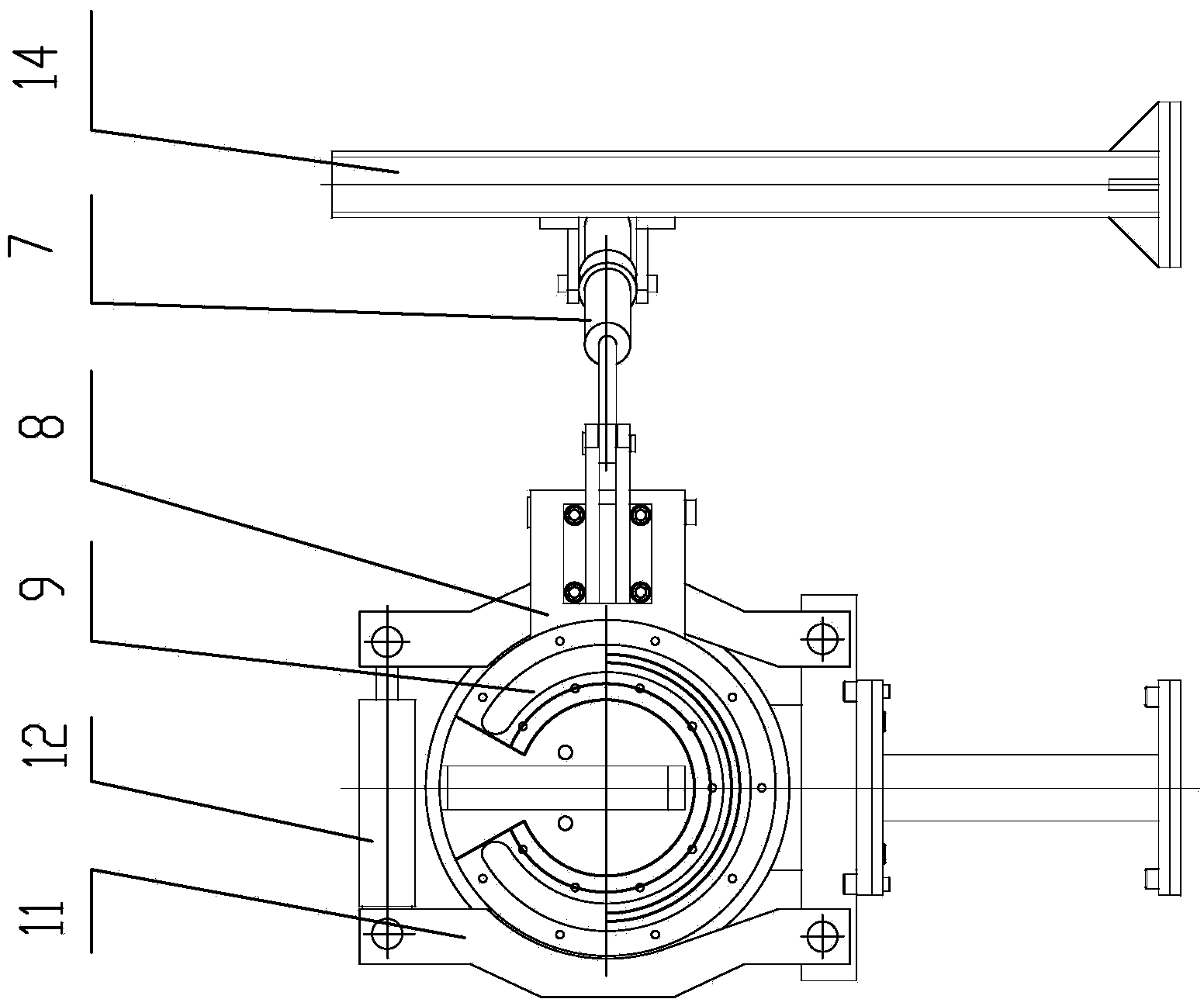

Machine head of rubber supply extruder of three-roller calender

The invention discloses a machine head of a rubber supply extruder of a three-roller calender. The machine head comprises a mold body which consists of a movable machine head mold and a fixed machine head mold, wherein the fixed machine head mold is arranged at a machine head cylinder opening of a pin cold feed extruder; the movable machine head mold is arranged on a mold opening and closing device; under a mold closing state, the mold body is locked by a mold locking device; a machine head opening is formed in the movable machine head mold and is provided with a small semicircular arc, a semicircular arc or a large semicircular arc which is downward and bilaterally-symmetric; the arc length of the machine head opening corresponds to the width of a wide-amplitude extrusion rubber tape, and the arc width of the machine head opening corresponds to the thickness of the wide-amplitude extrusion rubber tape; a material supply frame supplying rubber to the three-roller calender is arranged on an extrusion path of the wide-amplitude extrusion rubber tape, and the position of the material supply frame corresponds to the flattening spreading part of the wide-amplitude extrusion rubber tape. An extrusion calendering rubber supply path is greatly shortened, the temperature loss is small in the conveying process of rubber sheets, and the calendered rubber sheets are dense, uniform in thickness, smooth and flat in surface, bubble-free, and high in product quality.

Owner:GUILIN RUBBER MACHINERY CO LTD

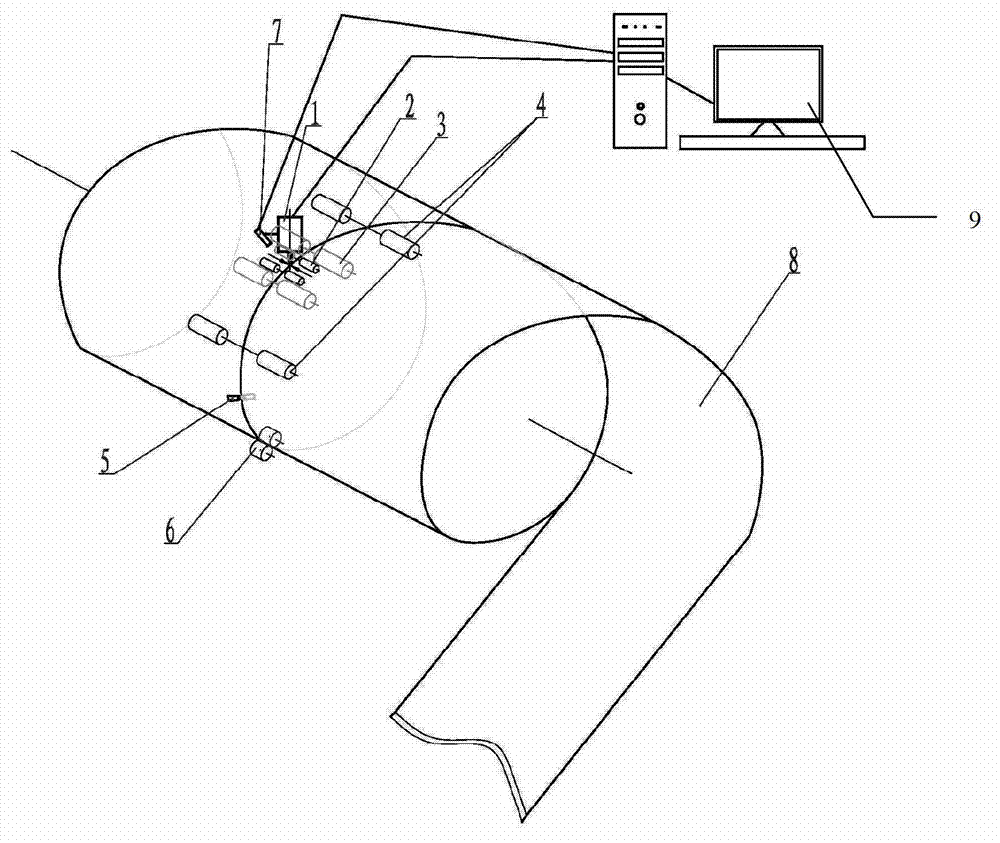

Automatic burr trimming machine for tire

The invention discloses an automatic burr trimming machine for a tire. The automatic burr trimming machine is characterized in that a rack, a conveying belt, a tire clamping mechanism and a burr trimming cutter are included; the conveying belt is arranged in the rack and used for conveying the tire to the tire clamping mechanism; the tire clamping mechanism is used for clamping the tire and driving the tire to rotate; the burr trimming cutter comprises a tire face cutter body and tire wall cutter bodies; and the tire face cutter body is arranged on the tire face of the tire, and the tire wall cutter bodies are arranged on the upper tire wall and the lower tire wall of the tire. According to the automatic burr trimming machine, the tire conveyed from the conveying belt is clamped to rotate through four kidney-shaped wheels moving from the edge to the center; through the burr trimming cutter arranged on the tire face, the upper tire wall and the lower tire wall, outer tire burrs of the tire are trimmed, and automatic trimming of multiple surfaces can be achieved at the same time; and the trimming work efficiency of the tire is greatly improved, and the automatic burr trimming machine is suitable for large-batch tire production.

Owner:无锡益联机械有限公司

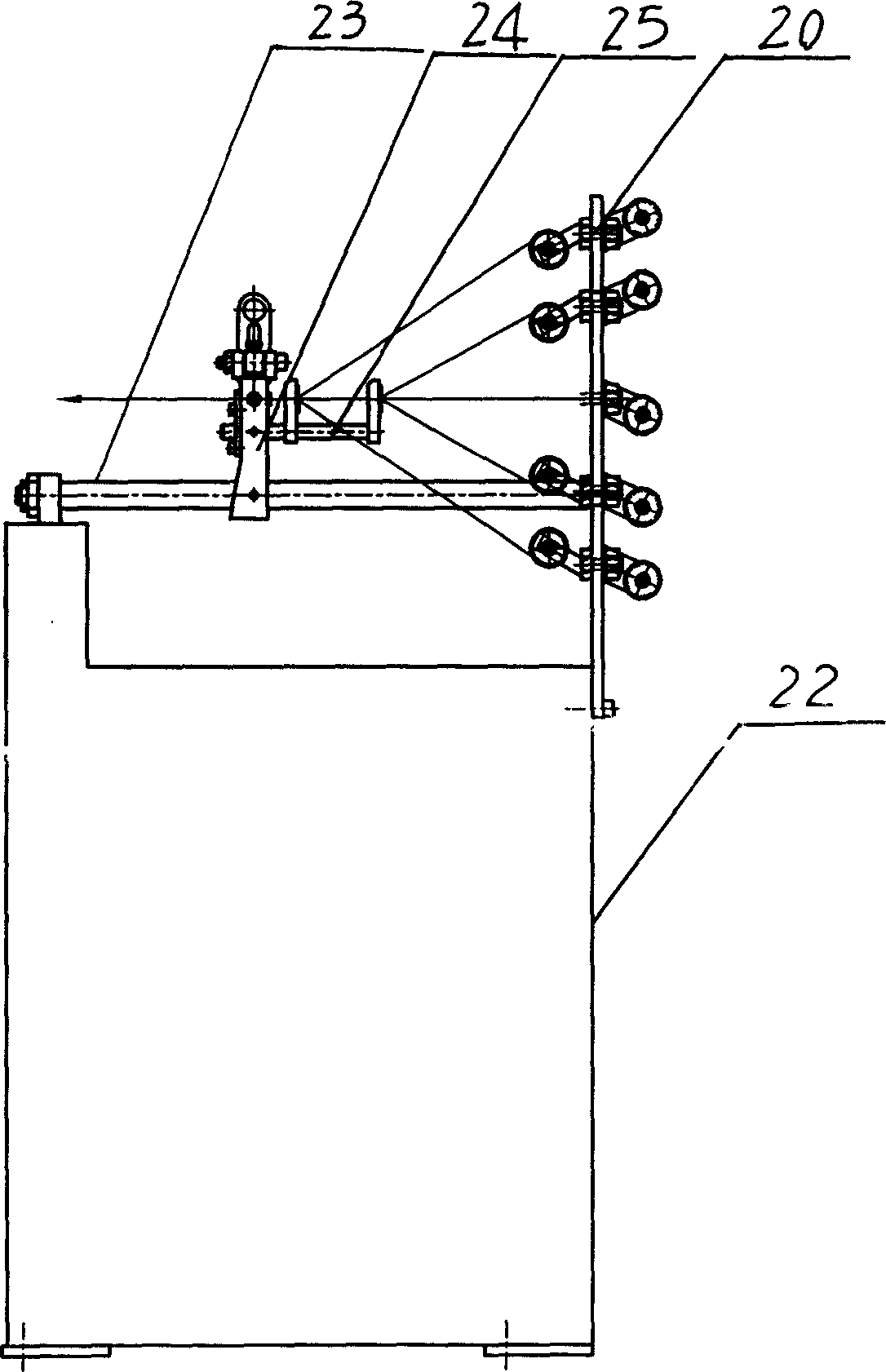

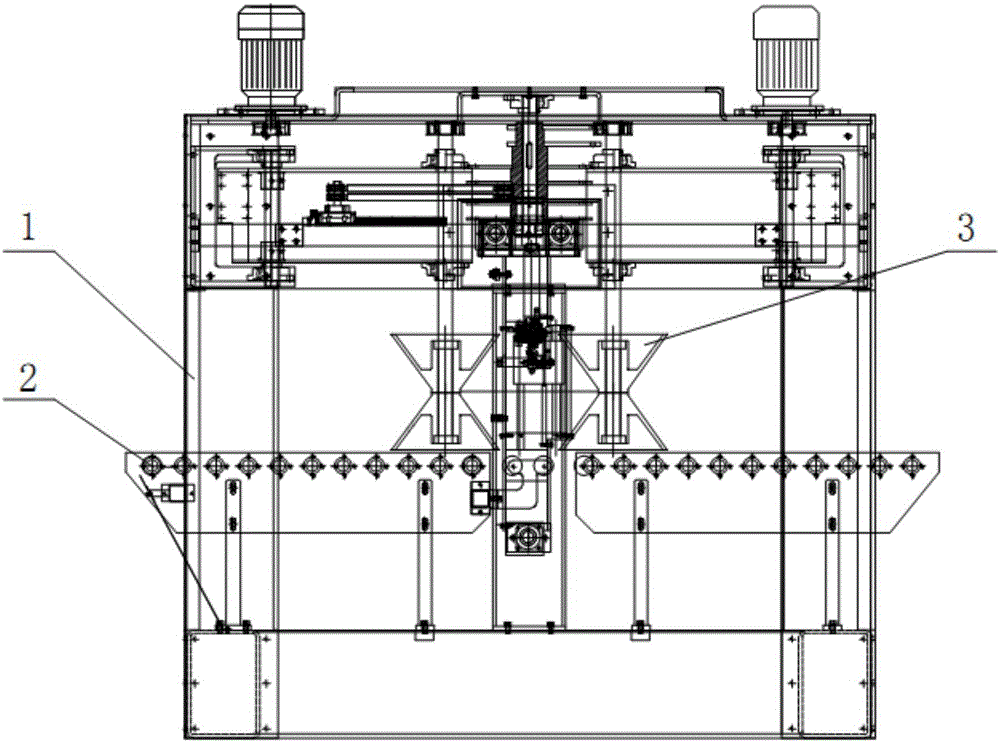

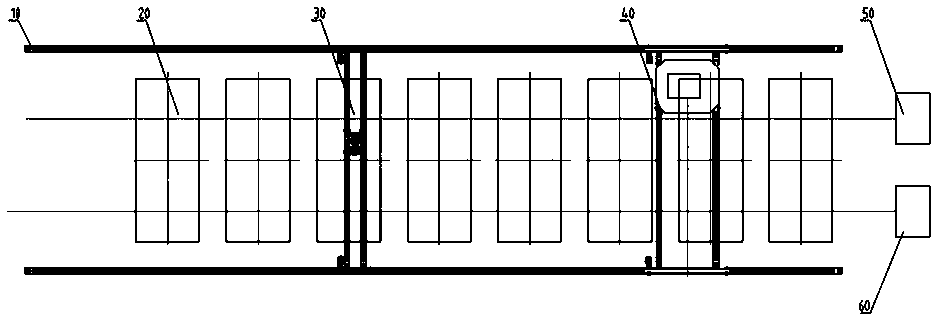

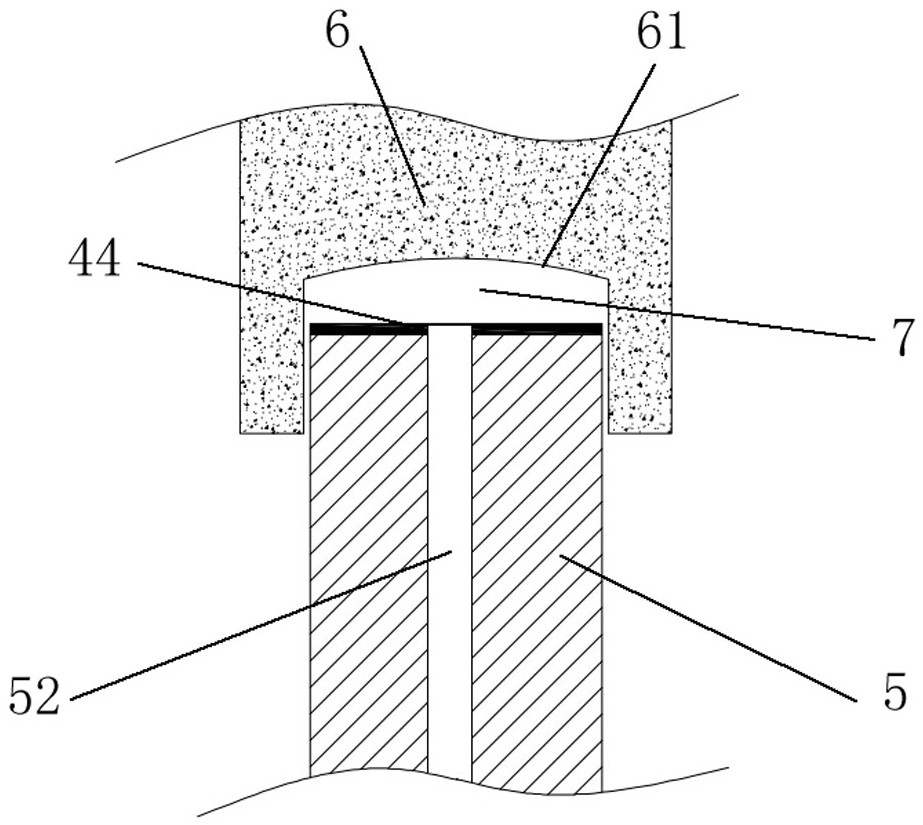

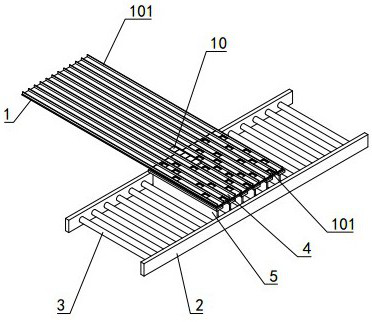

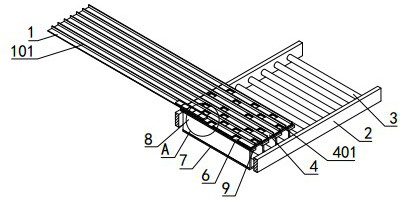

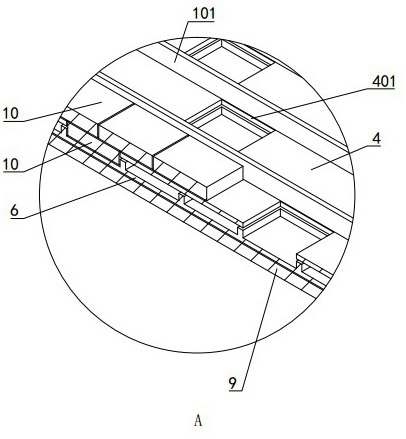

Fixed die table for PC prefabricated parts and production line of PC prefabricated parts

PendingCN109795022AEfficient use ofIncrease productivityCeramic shaping plantsFeeding arrangmentsProduction lineMaterial distribution

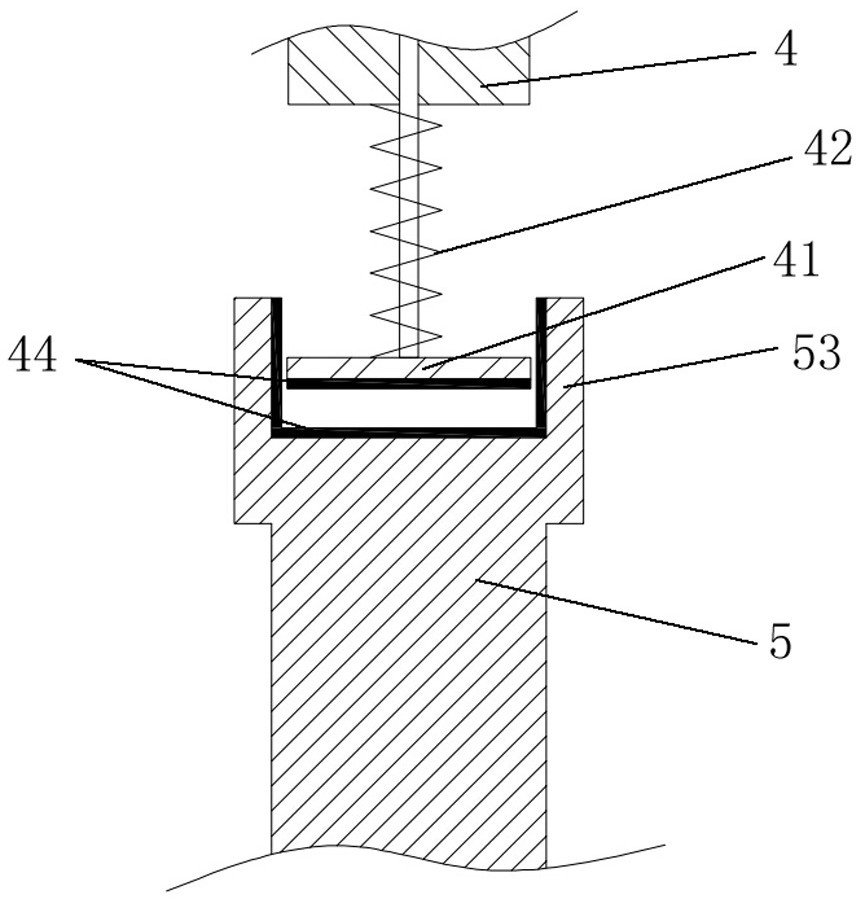

The invention discloses a fixed die table for PC prefabricated parts and a production line of the PC prefabricated parts. The fixed die table comprises a platen (1), the bottom surface of the platen (1) is connected with a shock absorption spring (5) installed on the ground through a supporting seat, a plurality of vibrators (2) are installed on the table surface of the platen (1), a hydraulic ejector pin machine (6) is installed on the ground below the platen (1), an ejector pin of the hydraulic ejector pin machine (6) is hinged to a rotary supporting seat (3) on the bottom surface of the platen (1) through a pin shaft (4), and the turnover operation of the platen (1) is realized by the hydraulic ejector pin machine (6). The fixed die table and the production line are simple and reliablein structure, space is effectively utilized, the working stability is high, automatic material distribution, automatic vibration and automatic maintenance are realized, the production efficiency of the fixed die table is improved, labor is fully reduced, and the quality stability of products is fully ensured through automatic operation.

Owner:江苏正工机械制造有限公司

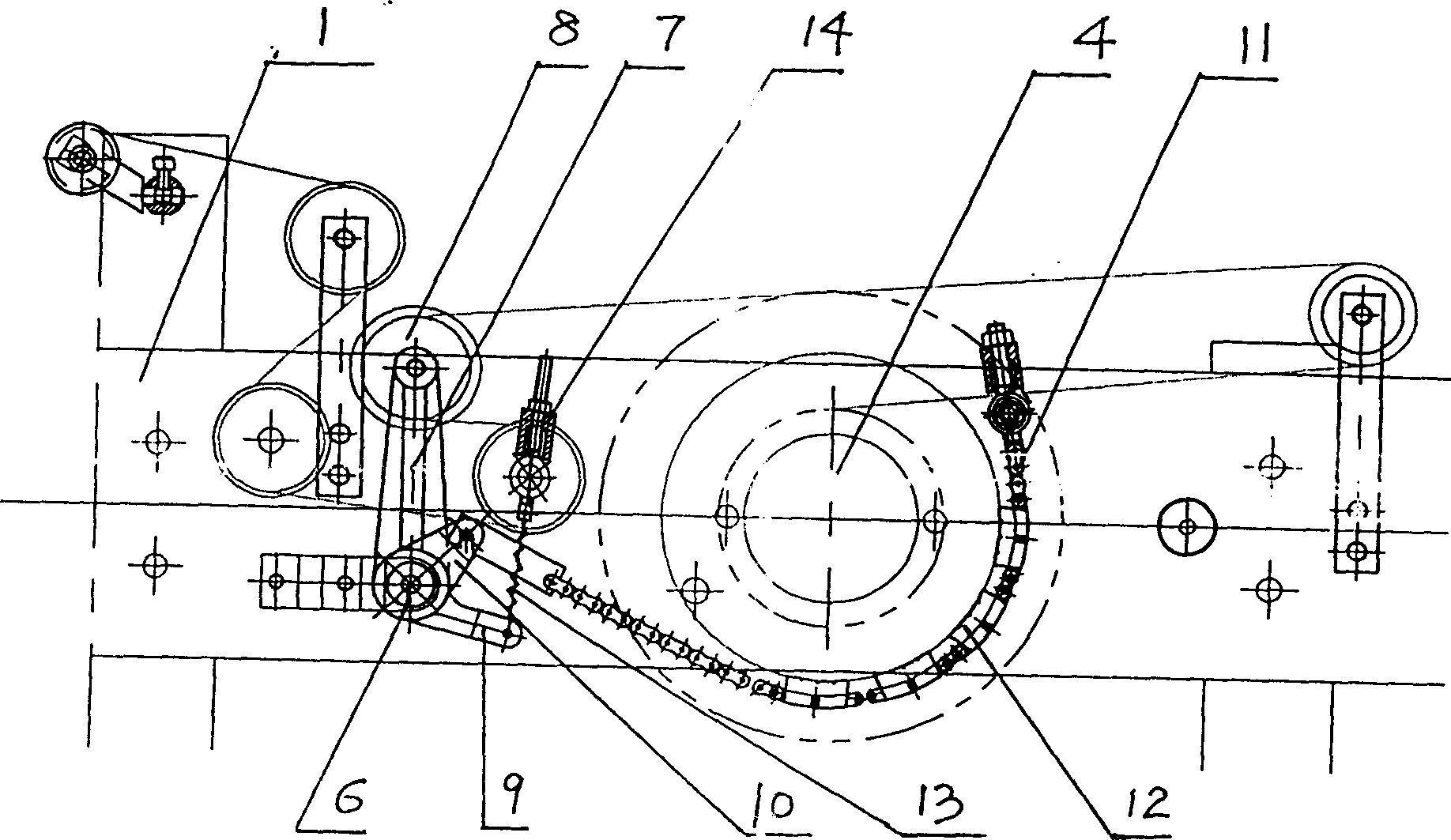

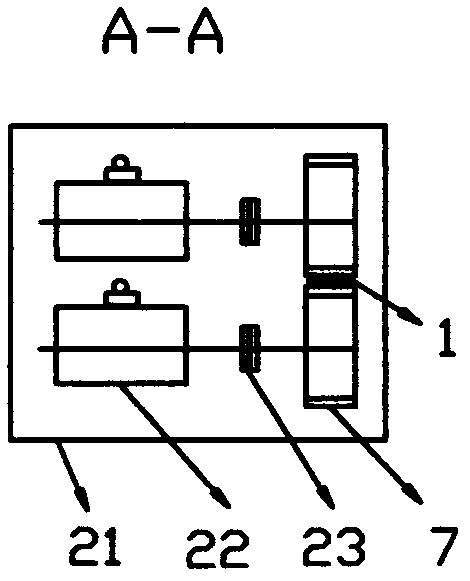

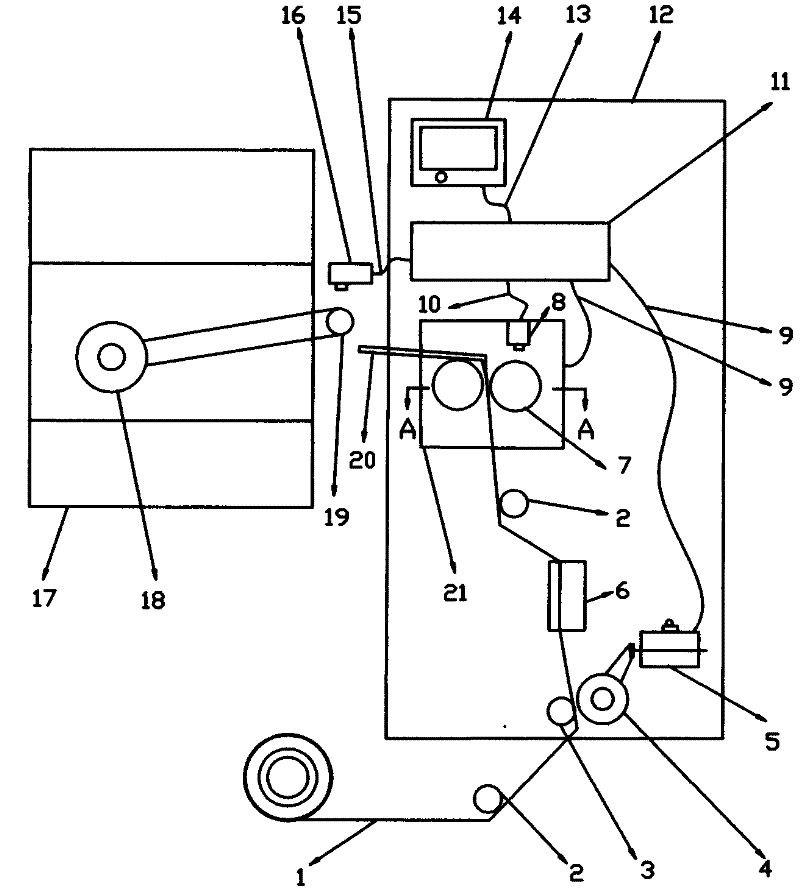

Forming machine for grooves of filter sticks

ActiveCN102511927AAdapt to productionLow degree of automationTobacco smoke filtersCardboardProgrammable logic controller

The invention provides a forming machine for the grooves of filter sticks, which comprises components, such as a paper guiding roller, a paper guiding motor, a cardboard regulator, groove rollers, servo motors of the groove rollers, a protective cover, a PLC (Programmable Logic Controller), a touch screen and the like. The touch screen is provided with a command signal line A connected with the PLC controller, and the PLC controller is provided with control lines which are respectively connected with the servo motors of the groove rollers and the paper guiding motor. When the components are matched with a forming host machine of filter sticks for cigarettes for use, the components are additionally connected with a shaft coder, the position information of a knife head shaft of the host machine of the forming machine of the filter sticks is collected by the shaft coder, the information is transmitted to the PLC controller, and then the servo motors of the two groove rollers, the paper guiding motor and the forming host machine of the filter sticks are respectively controlled to synchronously move by the PLC controller. When a system of the forming machine for the grooves of the filter sticks stops because of the occurrence of a fault, the host machine of the forming machine of the filter sticks is controlled to stop by the PLC controller. According to the forming machine for thegrooves of the filter sticks, a program control technology and a servo control technology are adopted, the automatization degree is high, the production capacity of filter sticks with grooves is enhanced, the replacement of the specifications of the products of the filter sticks is convenient, and the maintenance is convenient when a fault occurs.

Owner:NANTONG CIGARETTE FILTER

White-smoke-free promotion flux for steel fastener hot dip galvanizing and application process of white-smoke-free promotion flux

PendingCN108193154AReduce pollutionImprove working environmentHot-dipping/immersion processesHexamethylenetetramineChloride

The invention relates to the technical field of steel fastener hot dip galvanizing, in particular to white-smoke-free promotion flux for steel fastener hot dip galvanizing and an application process of the white-smoke-free promotion flux. The white-smoke-free promotion flux for steel fastener hot dip galvanizing comprises the following components: 100-200g / L of zinc chloride, 10-40g / L of magnesiumchloride, 8.0-13g / L of nickel chloride, 6.0-12g / L of hydrochloric acid, 2.0-3.5g / L of hexamethylenetetramine, 2.0-10g / L of a flux additive, and the balance of water. The application process of the white-smoke-free promotion flux comprises steps of degreasing, water cleaning, rust-removing, secondary water cleaning, promotion flux adhering, drying, galvanizing and the like. The white-smoke-free promotion flux for steel fastener hot dip galvanizing disclosed by the invention does not contain ammonium chloride which generates white smoke while encountering molten metal zinc, and can greatly reduce generation of soot during hot-dip galvanizing of the steel fastener; and a hot-dip galvanizing process which uses the promotion flux is more optimized, and has the advantages of being low in production cost, stable in plating assistance quality, capable of producing steel fasteners for hot dip galvanizing on a large scale, and the like.

Owner:WENZHOU XINDE ELECTRIC FITTINGS +2

A door body foaming line mold opening and closing manipulator and its use method

The invention provides a door body foaming line mold opening and closing manipulator, which includes a rotating arm, a photoelectric switch, a support frame and a telescopic tongue, and the telescopic tongue is installed under the rotating arm through matching slots and buckles. The present invention adopts the opening and closing method to open the mold, and abandons the conventional split type, upper and lower opening and closing molds, the equipment structure is simpler and the practicability is stronger. The mold is no longer limited and needs to be set on the bracket, which is more suitable for assembly line production and further optimizes the automation of the refrigerator door foaming assembly line.

Owner:青岛合润机械工程技术有限公司 +1

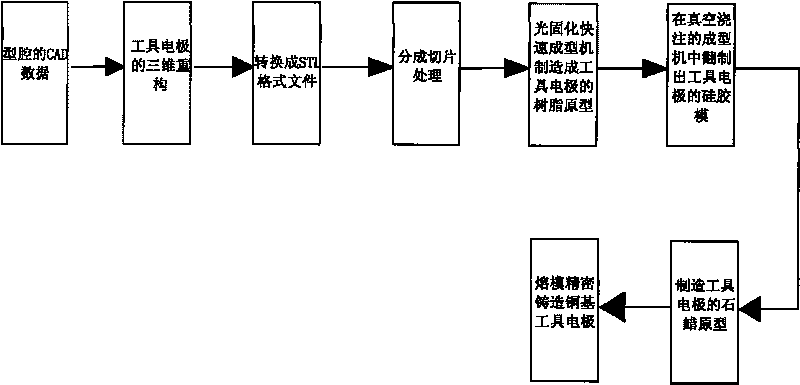

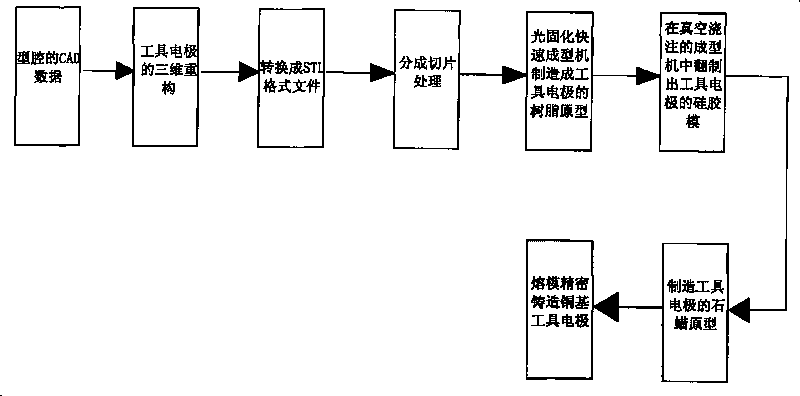

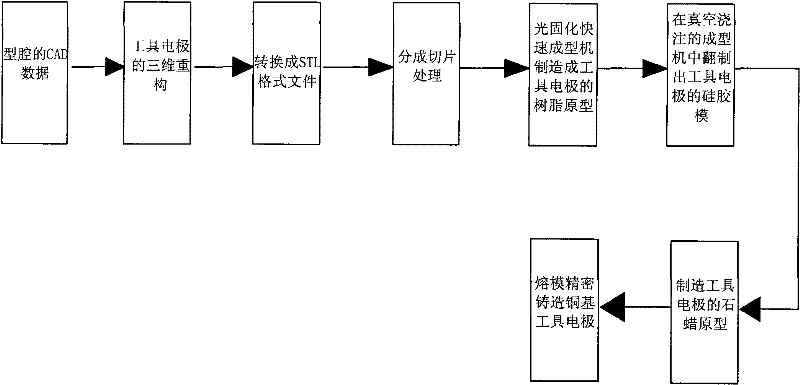

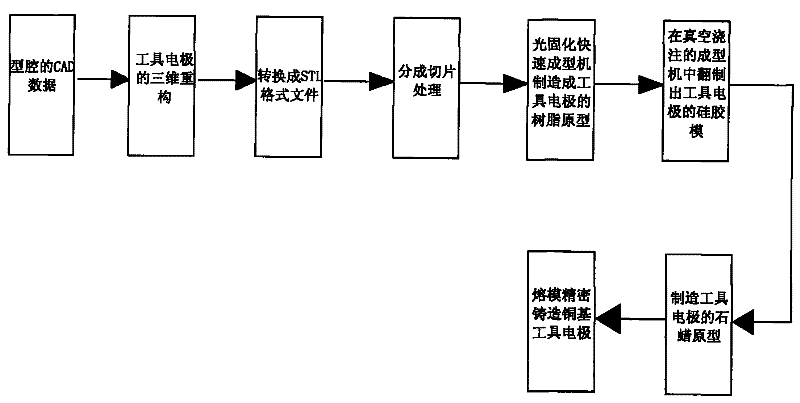

Method for producing electrical discharge copper matrix tool electrode for steel cavity mould

InactiveCN101695778ALow costImprove efficiencyElectrical-based machining electrodesInvestment castingSilica gel

The invention discloses a method for producing an electrical discharge copper matrix tool electrode for a steel cavity mould, which comprises the following steps: firstly, utilizing cartographic software to realize three-dimensional reconstruction of a tool electrode, transforming the reconstructed entity data into an STL formatted file, generating a formatted file defaulted by a photocuring rapid prototyping device after stratified slicing treatment on the STL formatted file, inputting the formatted file into the photocuring rapid prototyping device, and producing a resin prototype of the required electrical discharge copper matrix tool electrode of the steel cavity mould; arranging the produced resin prototype of the tool electrode into a vacuum casting moulding machine to duplicating a silicon mould of the tool electrode; casting a paraffin prototype of the tool electrode by using the silicon mould; and finally, producing the paraffin prototype of the tool electrode into the required copper matrix tool electrode by utilizing a investment casting method. The method for producing the electrical discharge copper matrix tool electrode for the steel cavity mould has the advantages of cost saving, high production speed and high accuracy.

Owner:BEIJING EASY CREATIVE TECH

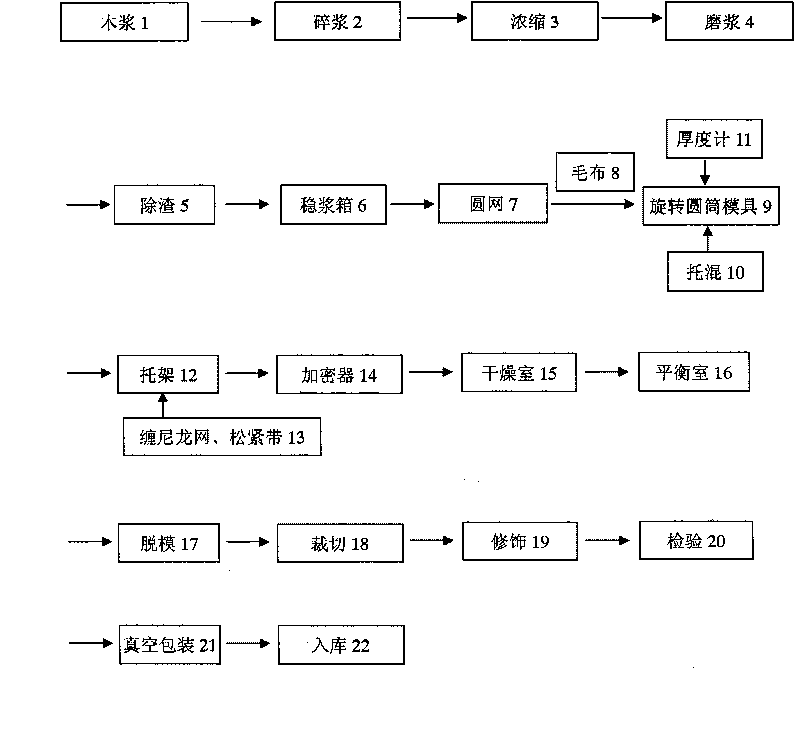

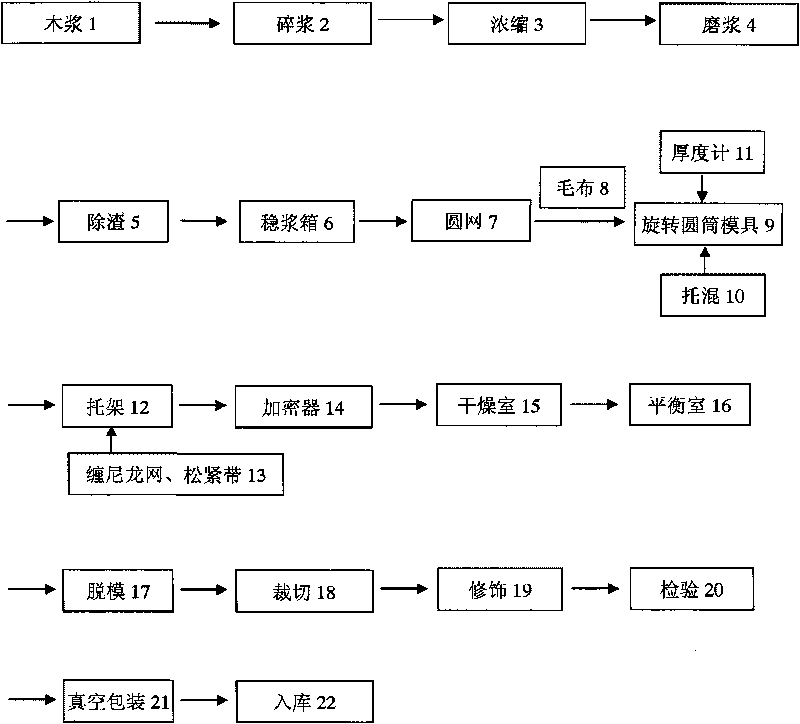

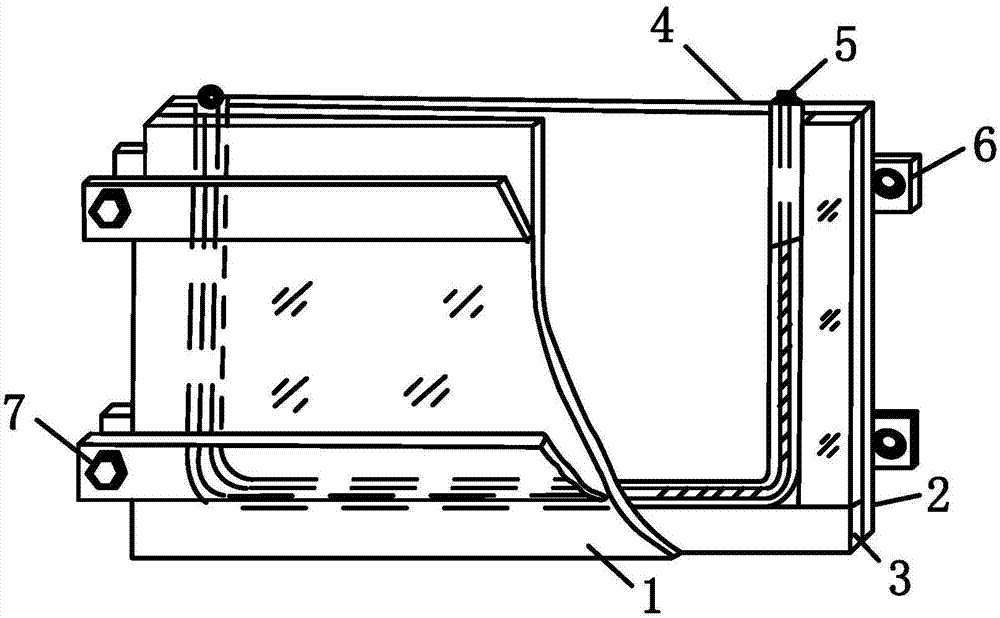

Process for producing sideless cylindrical paper boards

The invention relates to a process for producing sideless cylindrical paper boards. The process comprises the following steps: delivering paper pulp to a round net of a paper machine by a pump to form a paper blank; delivering the paper blank to a rotary cylindrical mould by coarse calico; adhering the paper blank to the mould to do circular motion so as to be thickened gradually; when the dehydrated paper blank reaches a stated thickness, stopping the pulp delivery pump, and molding the delivered pulp; hoisting the mould wound with the paper blank to a stander beside a thickener; after replacing another set of mould, repeating the production; shifting in the paper blank mould on the stander, drenching the paper blank by a nylon net to be wound tightly, and then fully winding the paper blank by an elastic band; after well winding, hoisting the paper blank mould into the thickener to perform thickening treatment and delivering the paper blank mould to a drying room for drying; and after the drying, delivering the paper blank mould to a balance chamber, slowly cooling the paper blank to room temperature and demoulding, and cutting, modifying, packaging and storing the paper blank. The process reduces the processing links, saves energy, does not lap a paper cylinder, has high precision and good performance, and is particularly suitable for ultrahigh-voltage transformers.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

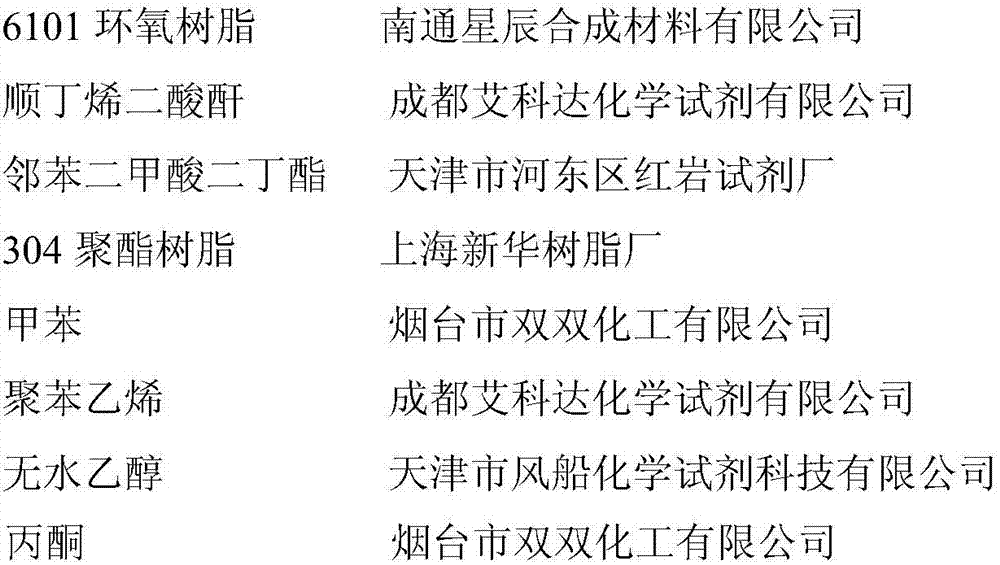

Production method of epoxy resin board for photo-elastic experimental test

InactiveCN106928657AFlexible ratioPerformance tuningForce measurement by measuring optical property variationEpoxyPolyester resin

The invention discloses a production method of an epoxy resin plate used for photoelastic experiment testing. The method uses epoxy resin, maleic anhydride, dibutyl phthalate and polyester resin as raw materials. Epoxy resin boards with different properties can be prepared by adjusting the amount of raw materials and optimizing the curing process of the mixed raw materials. The method of the invention is simple, rich in raw materials, easy to produce, high in optical sensitivity, good in transparency, small in time edge effect, and capable of producing novel photoelastic epoxy resins with elastic modulus from 1.29MPa to 57.32MPa and Poisson's ratio from 0.35 to 0.68 It can be used to make structural similar models in mechanical, water conservancy, civil engineering and other engineering, and it is an excellent material for photoelastic experiments of plane stress models.

Owner:HENAN POLYTECHNIC UNIV

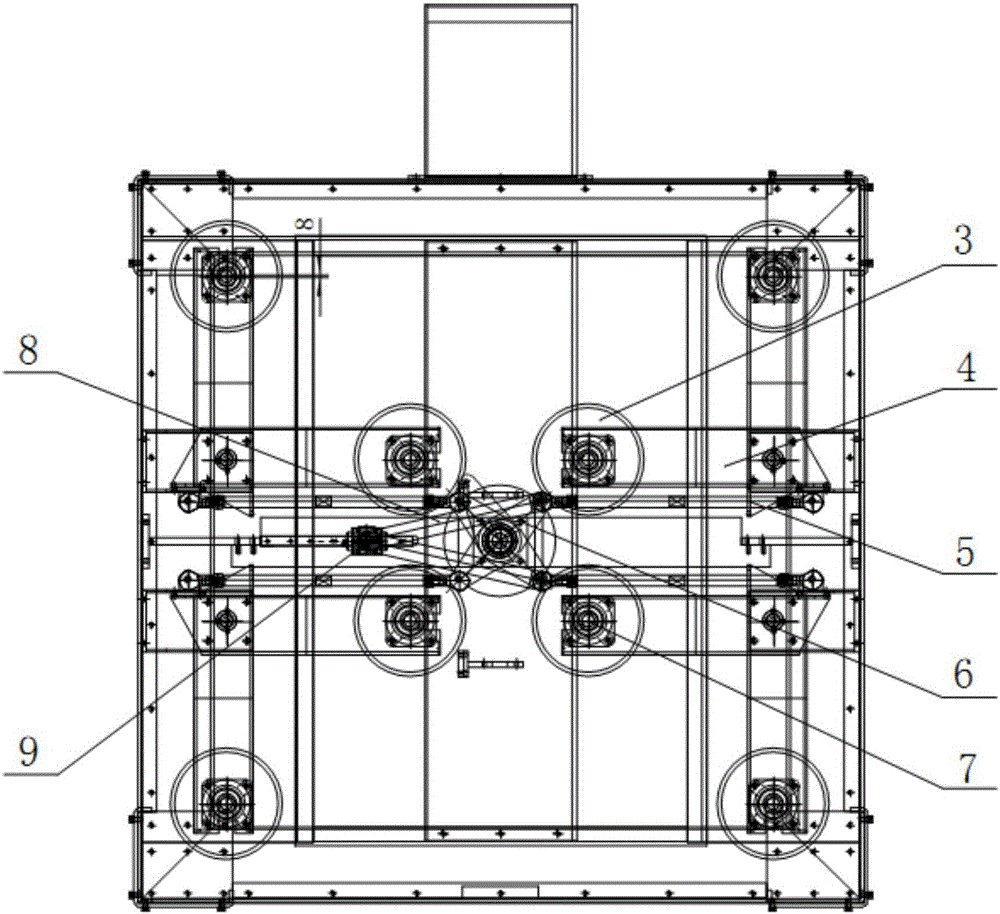

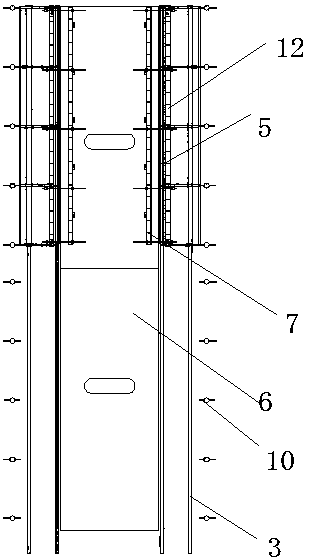

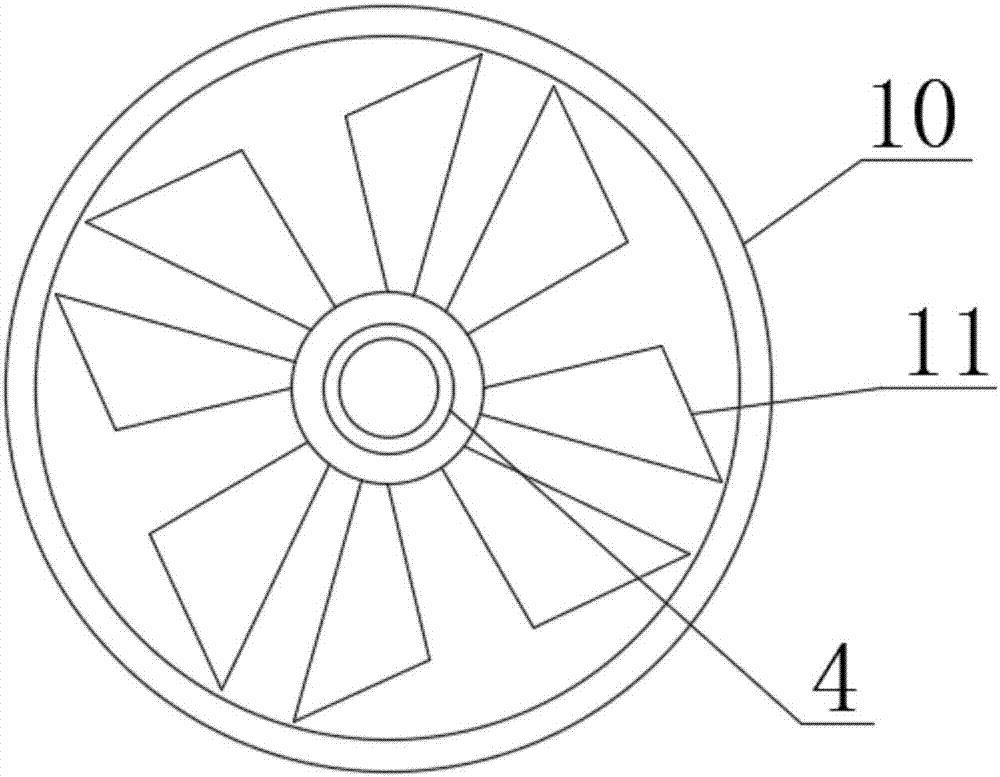

Multi-station combined-type beam column mold

PendingCN108453871AIncrease productivityAdapt to productionMouldsMould fastening meansEngineeringBeam column

The invention discloses a multi-station combined-type beam column mold. The multi-station combined-type beam column mold comprises a base, a workbench and a movable mold structure; the workbench is arranged on the base, a width adjusting module is arranged on the surface of the workbench, and the movable mold structure is arranged on the outer side of the workbench and arranged on the base; and the movable mold structure comprises height adjusting brackets, the bottoms of the height adjusting brackets are connected with a bottom plate of the movable mold structure through horizontal sliding mechanisms, a height adjusting side mold plate is arranged on the portion, close to the workbench, of the side face of each height adjusting bracket, and a longitudinal sliding mechanism is arranged between each height adjusting side mold plate and the corresponding height adjusting bracket. According to the multi-station combined-type beam column mold, the width and the height can be automaticallyadjusted as needed, therefore, the requirements of supporting molds with different specifications can be met, and mold plate installation is convenient and fast; in addition, multi-station moving of the mold can be achieved, therefore, the multi-station combined-type beam column mold can be moved to the next station for production in the beam column curing period, the cost is reduced, and the working efficiency is improved.

Owner:中建科技成都有限公司

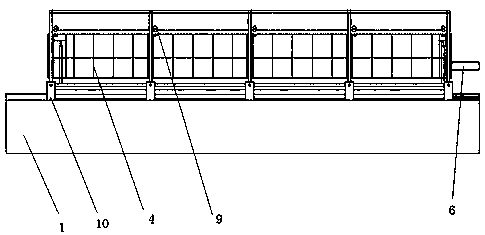

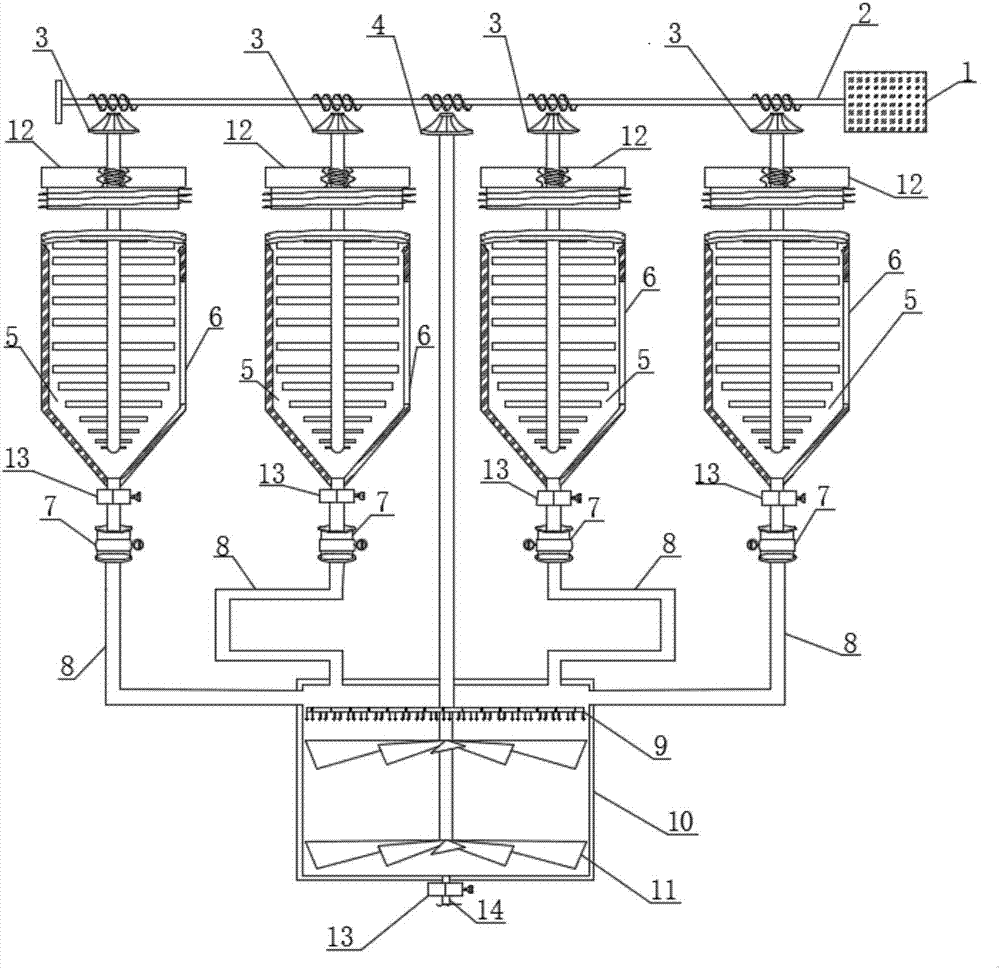

Blanket mixing, stirring and color mixing device

InactiveCN107233835ANo work stoppageReduce manufacturing costTransportation and packagingRotary stirring mixersSpiral bladeEngineering

The invention discloses a blanket mixing, stirring and color mixing device, which comprises an execution motor, output shafts, a pigment storage tank and a pigment stirring tank, wherein the output shaft is arranged on the execution motor; an output shaft gear is engaged with an input shaft I and an input shaft II. By using the structure, a mode of engaging the output shaft gear with a plurality of input shafts is used, so that the production cost is fundamentally reduced; the pigment storage tank is designed into a dismountable mode, so that the work halt cannot be caused by pigment addition in the real production process; through a lens, the pigment use condition can be observed at any time; a pulling sheet with the proper inner diameter is designed on the output shafts; a discharging pipe is designed into the same length, so that the pigment is subjected to once stirring when passing through a valve and a flow rate meter; the spiral blades are subjected to multi-angle setting, so that the pigment can be stirred for many times; a bubble brush can pierce air bubbles generated during the stirring. The novel structure has the advantages that the operation is simple; the structure is simple and easy; better adaptation to the production can be realized.

Owner:桐乡市瑞远纺织有限公司

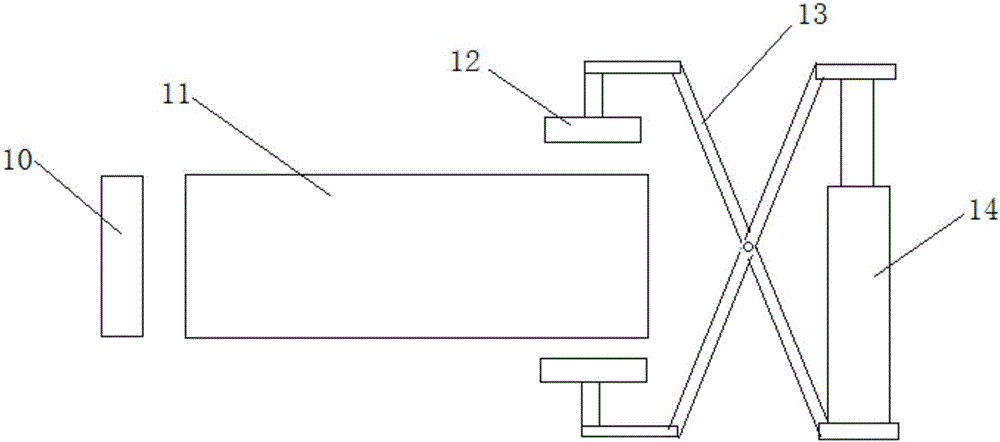

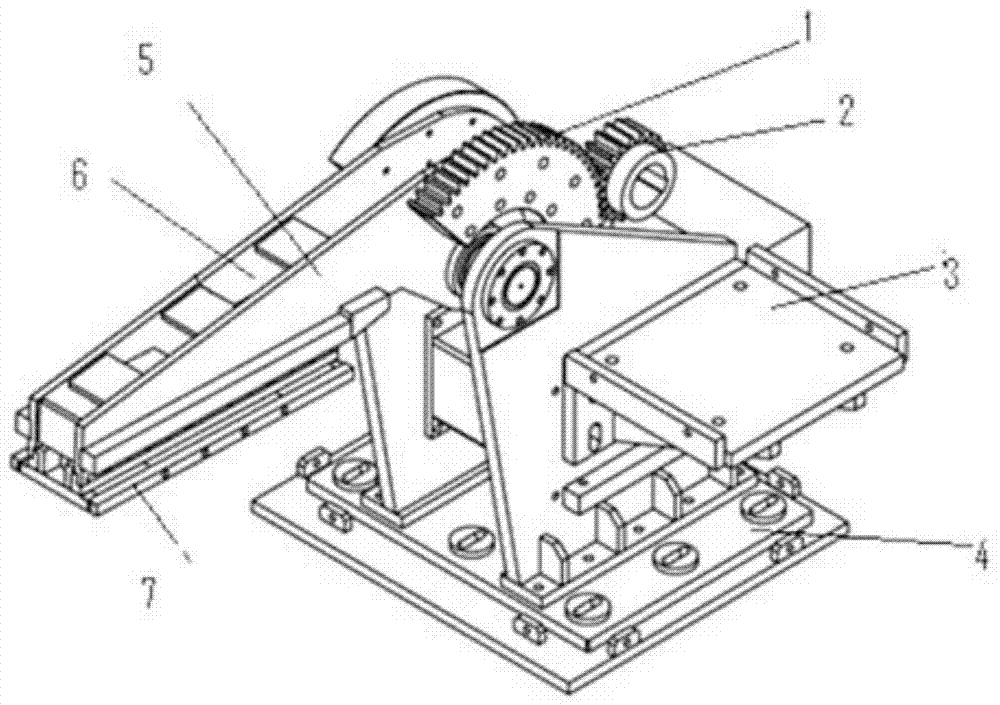

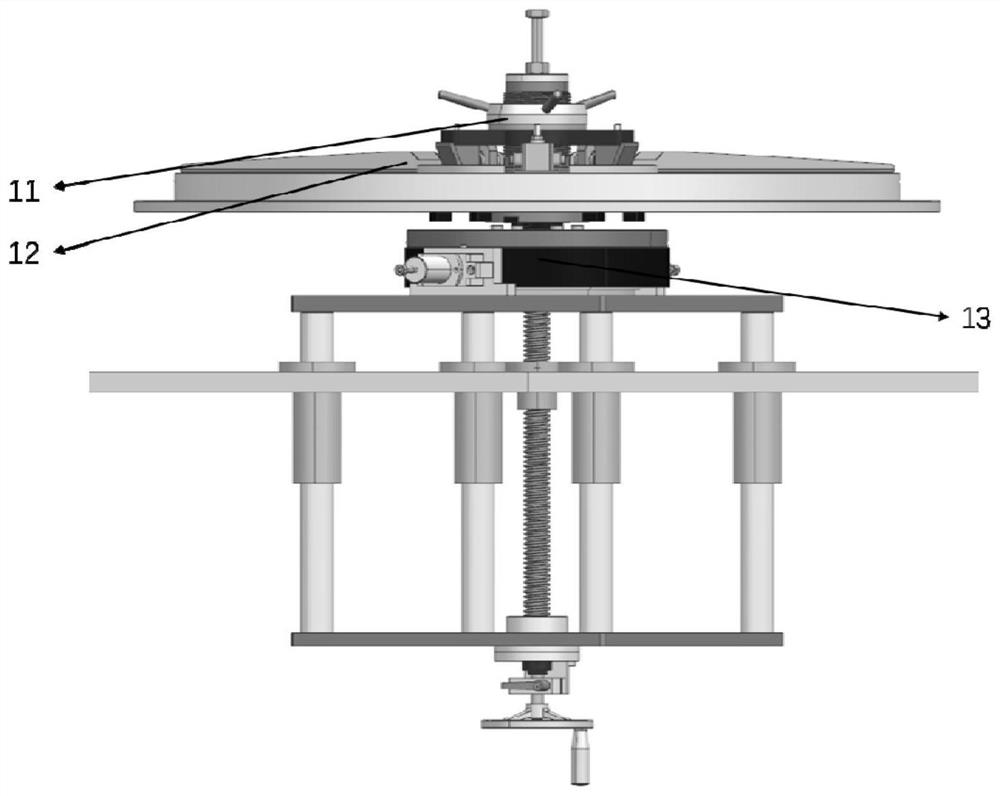

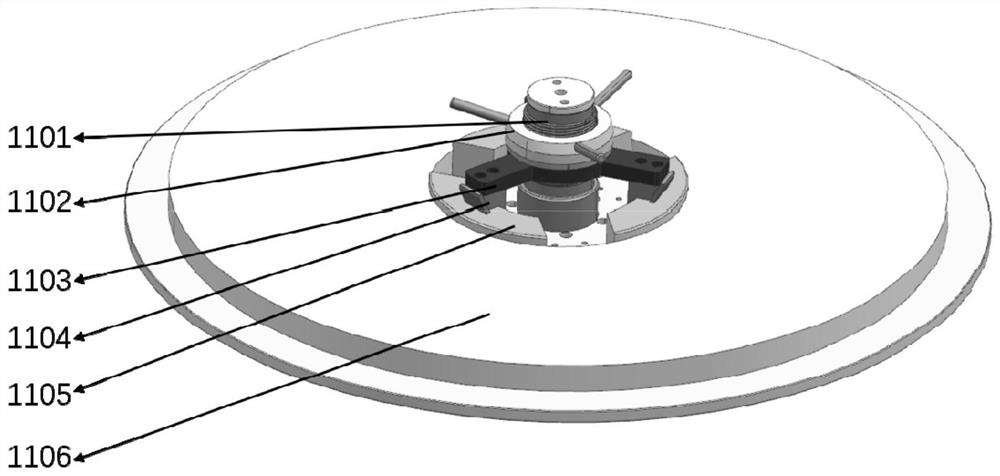

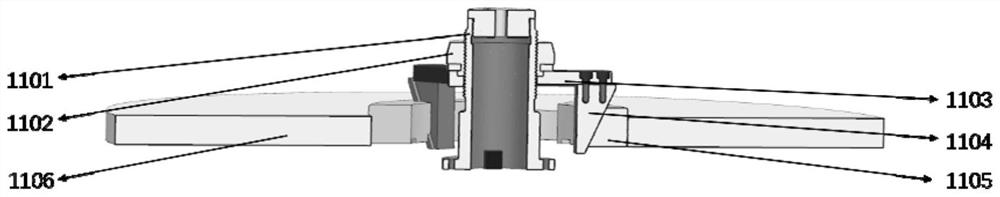

Liftable steel belt reel loading mechanism

The invention belongs to the technical field of mechanical turntable loading, and relates to a liftable steel belt reel loading mechanism. The mechanism comprises a steel belt tensioning assembly (11), a steel belt upper limiting assembly (12) and a steel belt reel lifting assembly (13), so that the functions of tensioning, limiting and winding height adjusting of a steel belt reel are achieved. While a stable bearing function is provided for winding steel strips, the distance between every two adjacent steel strips can be adjusted at the millimeter level, and stable and accurate winding is achieved. A plurality of units are used in cooperation to achieve full-size synchronous winding with a stress high-pressure die, and it is guaranteed that axial prestress of the die is uniform.

Owner:JILIN UNIV

General purpose type wire stranding machine

This invention discloses an all-purpose strander, which comprises a setting-out part, a branching matched part and a main frame strander contractor part, wherein the setting-out part comprises the setting-out frame (1) and setting-out seat, and the setting-out frame (1) is installed erectly with several setting-out seats in it; the main shafts of each setting-out seat are arranged horizontal in parallel, and around each setting-out seat it sets guide wheel (15) and guide pipe (2); the tension automatic adjust device are set on each setting-out seat. The strander is modularized and is fit for stranding steel cord of several formats.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Method for producing electrical discharge copper matrix tool electrode for steel cavity mould

InactiveCN101695778BLow costImprove efficiencyElectrical-based machining electrodesInvestment castingMetallurgy

The invention discloses a method for producing an electrical discharge copper matrix tool electrode for a steel cavity mould, which comprises the following steps: firstly, utilizing cartographic software to realize three-dimensional reconstruction of a tool electrode, transforming the reconstructed entity data into an STL formatted file, generating a formatted file defaulted by a photocuring rapid prototyping device after stratified slicing treatment on the STL formatted file, inputting the formatted file into the photocuring rapid prototyping device, and producing a resin prototype of the required electrical discharge copper matrix tool electrode of the steel cavity mould; arranging the produced resin prototype of the tool electrode into a vacuum casting moulding machine to duplicating asilicon mould of the tool electrode; casting a paraffin prototype of the tool electrode by using the silicon mould; and finally, producing the paraffin prototype of the tool electrode into the required copper matrix tool electrode by utilizing a investment casting method. The method for producing the electrical discharge copper matrix tool electrode for the steel cavity mould has the advantages of cost saving, high production speed and high accuracy.

Owner:BEIJING EASY CREATIVE TECH

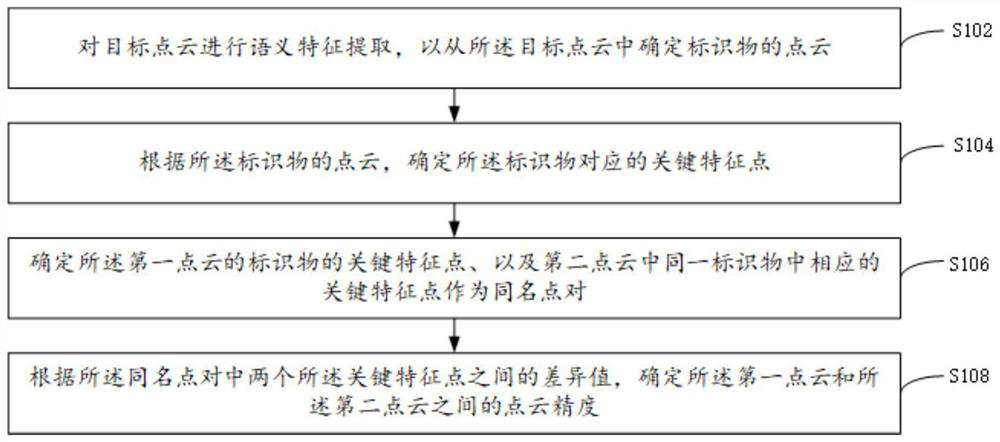

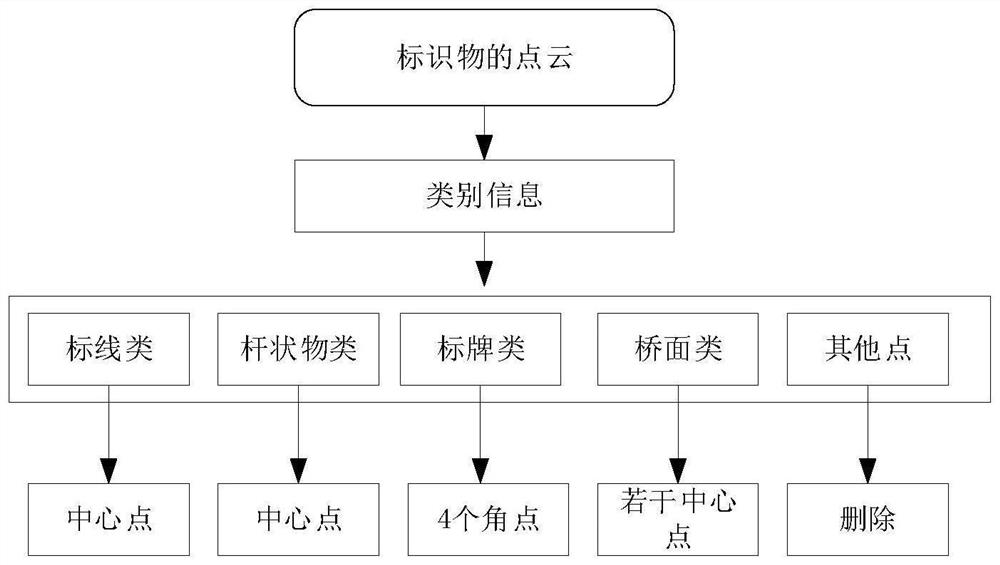

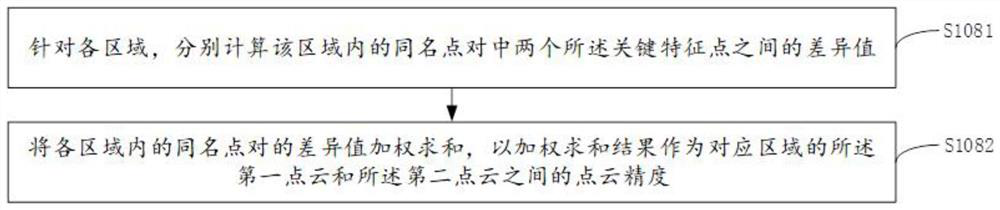

Point cloud precision determination method, electronic equipment and computer storage medium

PendingCN114722944AImprove determination efficiencyAdapt to productionCharacter and pattern recognitionElectromagnetic wave reradiationComputational scienceFeature extraction

The embodiment of the invention provides a point cloud precision determination method, electronic equipment and a computer storage medium. The method comprises the steps that semantic feature extraction is carried out on target point clouds to determine point clouds of markers from the target point clouds, the target point clouds comprise a first point cloud and a second point cloud, and the first point cloud and the second point cloud are any two point clouds in multiple point clouds; determining key feature points corresponding to the marker according to the point cloud of the marker; determining key feature points of the marker of the first point cloud and corresponding key feature points in the same marker in the second point cloud as homonymy point pairs; and determining the point cloud precision between the first point cloud and the second point cloud according to a difference value between the two key feature points in the homonymy point pair. According to the method, the point cloud precision of the point clouds collected at different times can be quickly and accurately obtained.

Owner:AUTONAVI

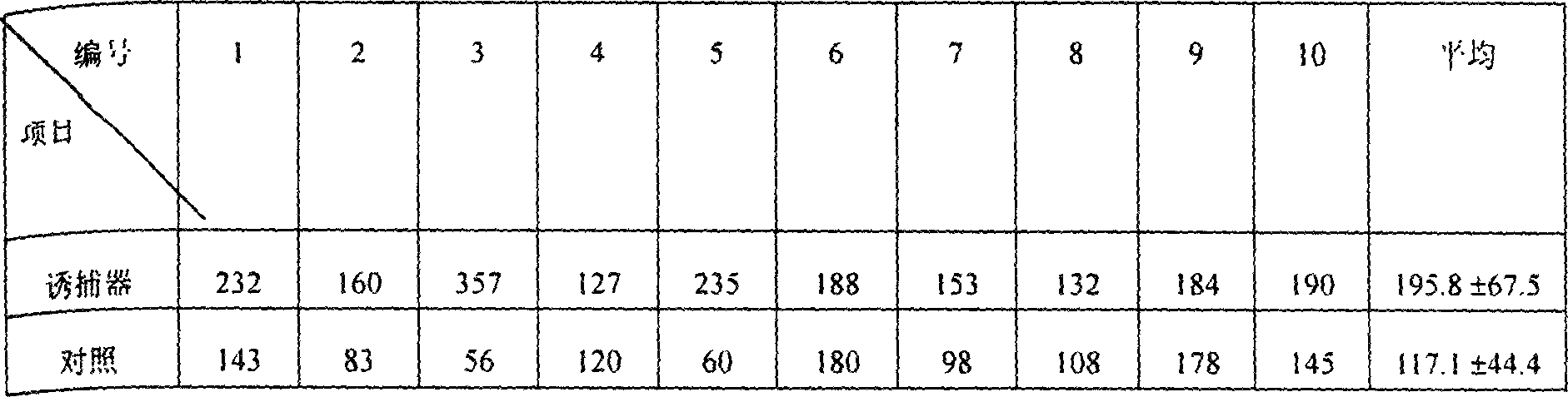

Method for trapping Empoasca vitis Gothe imago/nymph and Aleurocanthus spiniferus imago

The invention discloses a trap method for Empoasca vitis Gothe imago,nympha and spiny white fly imago, comprising the steps: 1)separating and authenticating 9 volatile matter from sturdy tea twig using adsorption method 2) determining three volatile ingredient with allure activity using biological determination method 3)respectively preparing three active ingredient, concentration 0.01-20mu g / ml, mixing according to 1:0.2-1.5:0.1-1, preparing attractant, 4)determining three colors with alluring effect to Empoasca vitis Gothe and spiny white fly from ten colors in the tea garden allure experiment, three colors being parrot green, bud green and jasmine yellow 5) combining attractant with bud green and jasmine yellow, making trapper for Empoasca vitis Gothe and spiny white fly The advantage of the invention : 1)no pollution, adapting to organic tea and nuisance free tea production, 2) low cost.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

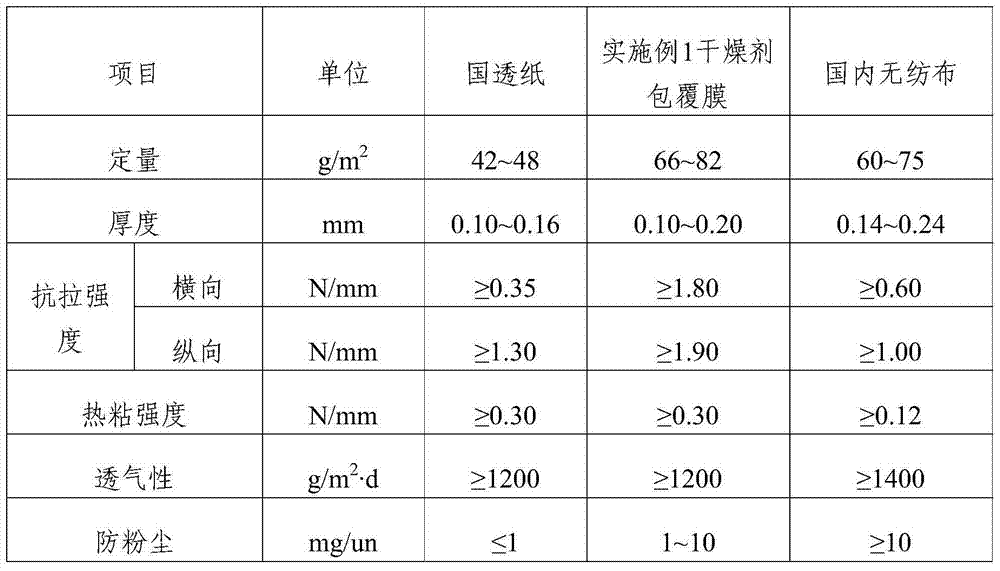

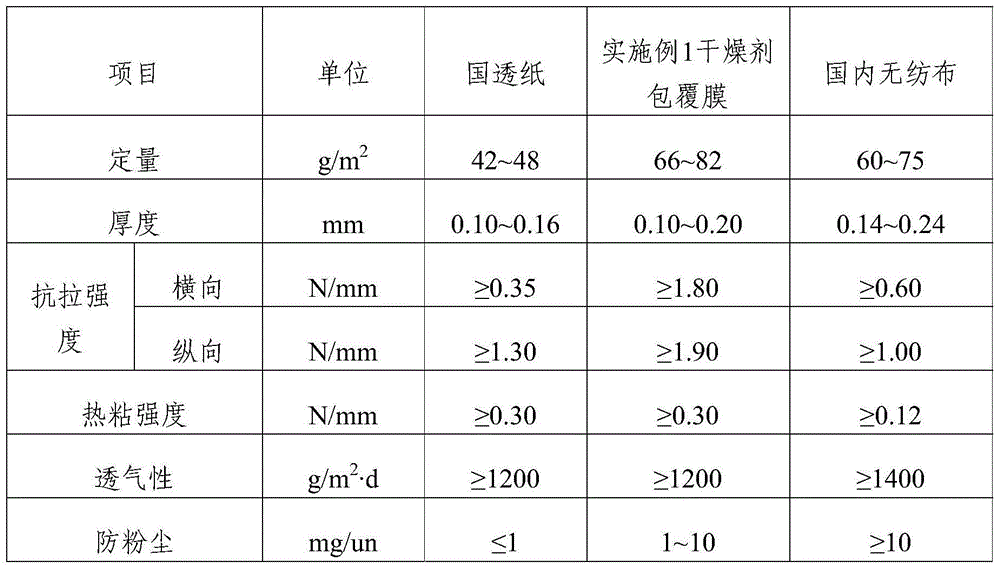

Drying agent coating film

ActiveCN103569503ABoth featuresCombines the performance of spunbond nonwovensFlexible coversWrappersDesiccantEngineering

The invention provides a drying agent coating film, i.e. Wiener non-woven cloth. The drying agent coating film is characterized by being formed by coating and then carrying out hot-pressing composition waterborne polyurethane resin on macromolecule plastic non-woven cloth and macromolecule plastic spunbond non-woven cloth. The drying agent coating film is high in strength and relatively high in dust prevention property, and can be adapted to production of automatic multi-column and high-speed production equipment.

Owner:昆山建全防水透气材料有限公司

Bamboo chip polishing equipment for bamboo summer sleeping mat

InactiveCN111618701ANormalize the direction of movementGuaranteed uniformityEdge grinding machinesGrinding carriagesAgricultural engineeringStructural engineering

The invention aims to provide bamboo chip polishing equipment for a bamboo summer sleeping mat so as to solve problems in the prior art. The equipment comprises a bracket, and an upper base and a lower base arranged on the bracket and arranged up and down. Upper modules and a lower module extending from upstream to downstream are detachably arranged on opposite surfaces of the upper base and the lower base, separately. The upper modules are arranged in a spaced manner and a grinding wheel is arranged between two adjacent upper modules. Grinding grooves are formed in the peripheral surfaces ofthe grinding wheels. The grinding grooves and the top of the lower module are combined to form a polishing space where bamboo chips pass. The bamboo chip polishing equipment for the bamboo summer sleeping mat has good supporting and guiding limiting effects to ground bamboo chips, so that the ground parts of the bamboo chips are high in horizontal capacity and the moving paths relative to the grinding wheels are stable, and therefore, the polished bamboo chips are good in thickness uniformity in the length direction, stability of surface quality and stability of section shapes.

Owner:浙江茂林竹木工艺有限公司

Magnetic separation device with uniform diluting feeding function

The invention discloses a magnetic separation device with a uniform diluting feeding function. The magnetic separation device comprises a bottom plate. A belt conveyor is arranged on the upper side ofthe bottom plate; the belt conveyor is fixedly connected to the bottom plate through a plurality of first fixed bars; a feeding rail is fixedly connected to the upper end surface of the bottom platethrough a vibrating mechanism; a rotary drum is fixedly connected to the upper end surface of base through a plurality of second fixed bars; one end of the rotary drum is fixedly connected to a motor;a rotary shaft is horizontally arranged in the rotary drum; a groove is formed in the end, far away from the rotary shaft, of a rotating block; an electromagnet is fixedly connected in the groove; apower supply is electrically connected to an arc-shaped conductive block; one end of the electromagnet is in contact with the arc-shaped conductive block; a magnetic separation port is formed in the lower end wall of the rotary drum; a discharge port is formed in the side wall of the rotary drum; and the discharge port corresponds to the arc-shaped conductive block in position.

Owner:FOSHAN CHENG XIAN TECH CO LTD +1

Mosaic placing method

InactiveCN112848774AAdapt to productionSimple structureOrnamental structuresStructural engineeringMechanical engineering

Owner:李斌

Three-roll calender for rubber extruder head

Owner:GUILIN RUBBER MACHINERY CO LTD

A desiccant coating film

ActiveCN103569503BAdapt to use requirementsHigh strengthSynthetic resin layered productsNon-woven fabricsDesiccantHigh intensity

The invention provides a drying agent coating film, i.e. Wiener non-woven cloth. The drying agent coating film is characterized by being formed by coating and then carrying out hot-pressing composition waterborne polyurethane resin on macromolecule plastic non-woven cloth and macromolecule plastic spunbond non-woven cloth. The drying agent coating film is high in strength and relatively high in dust prevention property, and can be adapted to production of automatic multi-column and high-speed production equipment.

Owner:昆山建全防水透气材料有限公司

Device and process method for filling aluminum into nano through holes by using PVD method

InactiveCN101643891BAdapt to productionLower temperature limitVacuum evaporation coatingSputtering coatingGas phaseLine width

The invention relates to a device and a process method for filling aluminum into nano through holes by using a PVD method, which adopt a radio-frequency power supply and a high-frequency plasma method of physical vapor deposition (PVD), wherein in a PVD chamber, the radio-frequency power supply is applied to a target material and a wafer respectively, and the Al is filled into the through holes of a minisize semiconductor chip and becomes a conducting material between semiconductor layers. The device and the process method can overcome the defect that the conventional process can only reach over 0.13 micron, and extend the application of the aluminum to a degree that the characteristic line width is less than or equal to 0.1 mum and the depth-to-width ratio (h / CD) is more than or equal to6. The device and the process method reduce the device running temperature, save water, electricity and consumptive materials, greatly improve the utilization rate of production facilities and the wafer yield, can be applied to the conductive through holes between semiconductor integrated circuit chip layers, contact holes, grooves and the like for filling the conductive materials of the aluminumand the like, and also can be used for depositing the aluminum used on metal door circuits of which the line width is less than 30 nanometers. The invention particularly points out that the same method is suitable for all technical materials with low melting point.

Owner:吉和林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com