Forming machine for grooves of filter sticks

A forming machine and groove technology, applied in the fields of smoke oil filter element, application, tobacco, etc., can solve the problem that the automatic assembly line production operation of the finished groove filter rod cannot be fully realized, and the filter rod forming machine is not mentioned, not mentioned Cardboard position adjustment, accident disposal and other issues, to achieve the effect of reducing the rate of defective products, convenient maintenance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

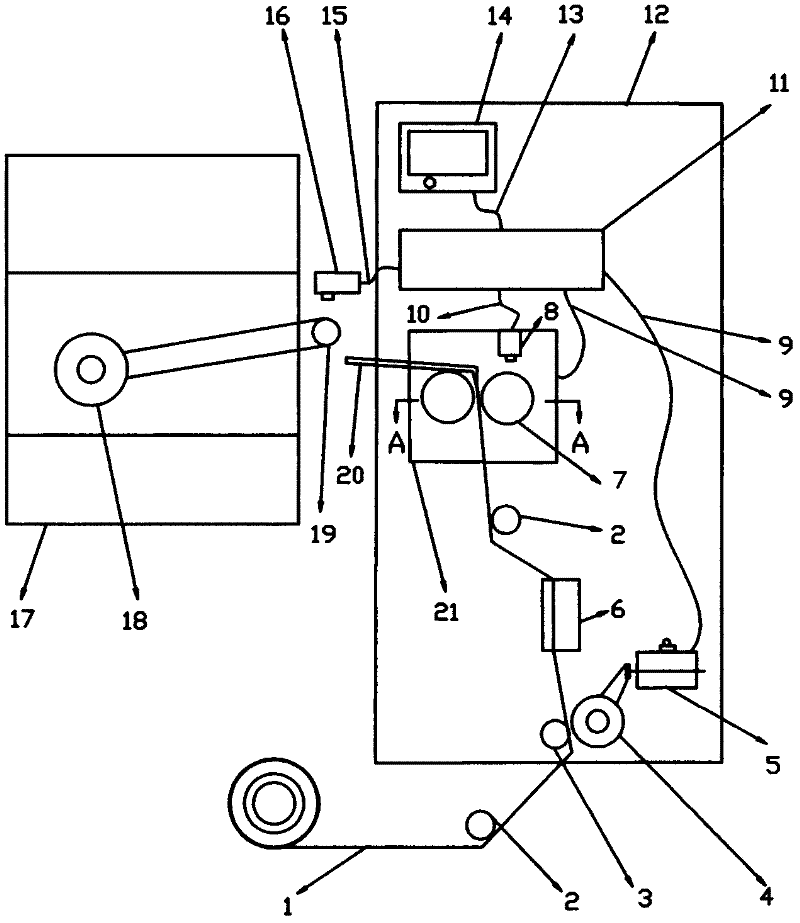

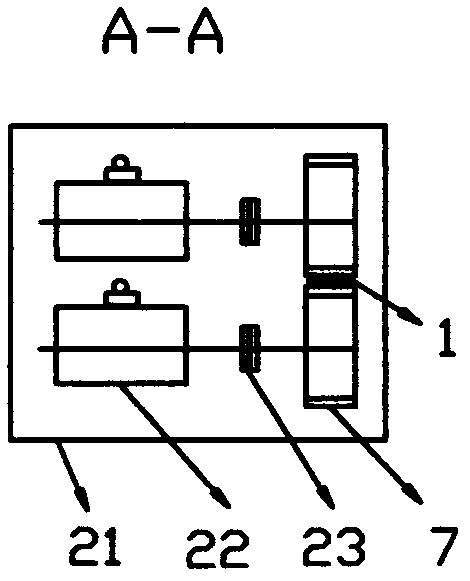

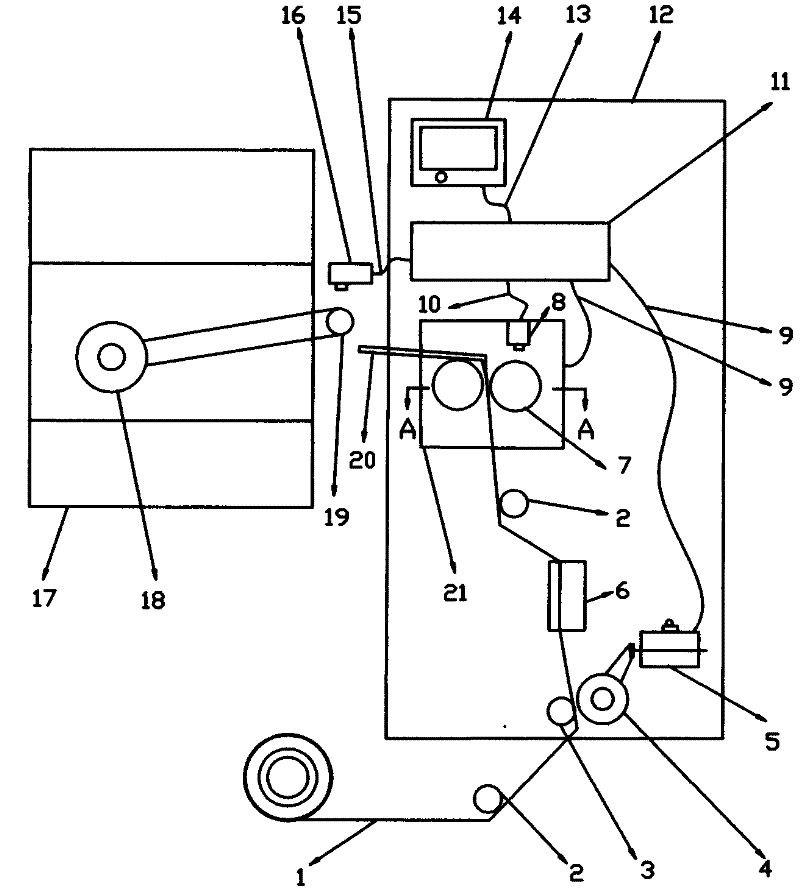

[0024] as attached figure 1 part of figure 2 The shown filter rod groove forming machine 12 has a paper guide roller 2, a paper guide motor 5, a paper pressure roller 3, two groove rollers 7 and corresponding two groove roller servo motors 22, a coupling 23, Parts such as protective cover 21, PLC controller 11, touch screen 14.

[0025] The touch screen 14 has a signal line A13 connected to the PLC controller 11, and the PLC controller 11 has control lines respectively connected to the two grooved roller servo motors 22 and the paper guide motor 5, and the protective cover 21 is on the periphery of the two grooved rollers 7.

[0026] There are grooved teeth meshing with each other on the two grooved rollers 7, the paper guide roller 2, the paper guide motor 5, and the paper pressure roller 3 are used to transport the cellulose paper 1 to between the two grooved rollers 7, and the two grooves The grooved roller servo motor 22 drives two grooved rollers 7 to rotate, and after...

Embodiment 2

[0030] as attached figure 1 , attached figure 2 As shown, when the various components of the filter rod groove forming machine 12 in Embodiment 1 are used in conjunction with the cigarette filter rod forming host 17, the body of the filter rod groove forming machine 12 is additionally connected with a shaft encoder 16, through The shaft encoder 16 collects the position information of the cutter head shaft 18 of the main frame 17 of the filter rod forming machine, and the signal line C15 connected with the shaft encoder 16 sends the information to the PLC controller 11, and the PLC controller 11 controls the two parts respectively through the control lines. Only the groove roller servo motor 22 and the paper guide motor 5 make them move synchronously with the filter rod forming main frame 17.

[0031] Enter a password through the touch screen 14 to enter the specification replacement interface, so that the system can be adapted to the production of filter rods of different sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com