Film laminating mechanism

A packaging mechanism and coating technology, which is applied in the direction of packaging, wrapping objects, transportation packaging, etc., can solve the problems of low work efficiency, uneven coating area, and inability to automatically and continuously produce, so as to achieve high work efficiency and high coating area. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

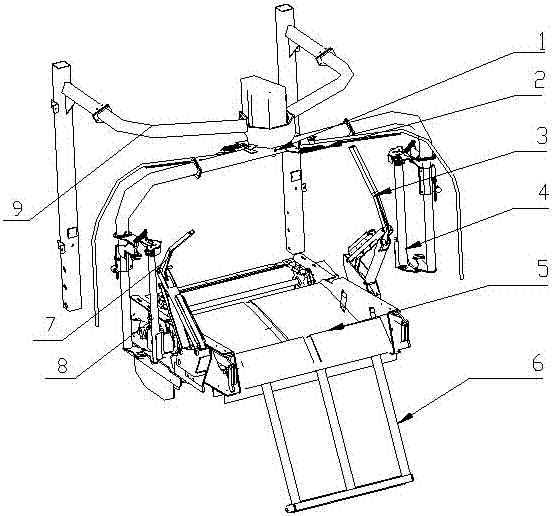

[0016] Reference figure 1 This embodiment includes a membrane platform 5 and a support 9. One side of the membrane platform 5 is provided with a first cutting mechanism 3, the other side is provided with a second cutting mechanism 7, and the upper part of the membrane platform 5 is provided with a rotating Strapping mechanism 1. One side of the rotary packaging mechanism 1 is provided with a first automatic film feeding mechanism 4, and the other side is provided with a second automatic film feeding mechanism 8. The rotary packaging mechanism 1 is fixed on a bracket 9 and the rotary packaging The mechanism 1 can rotate around a fixed point.

[0017] The coating platform 5 is provided with a transmission belt, and the surface of the transmission belt is an inwardly curved surface. The coating platform 5 is provided with an oil cylinder. Through the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com