Formation of large arrays of zinc oxide nanostructures using electrodeposition

a technology arrays, which is applied in the field of large arrays of zinc oxide nanostructures formed using electrodeposition, can solve the problems of unproven mass-production feds for the consumer market, and achieve the effects of enhancing the utility of nanostructures, efficient electron emitters, and uniform cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

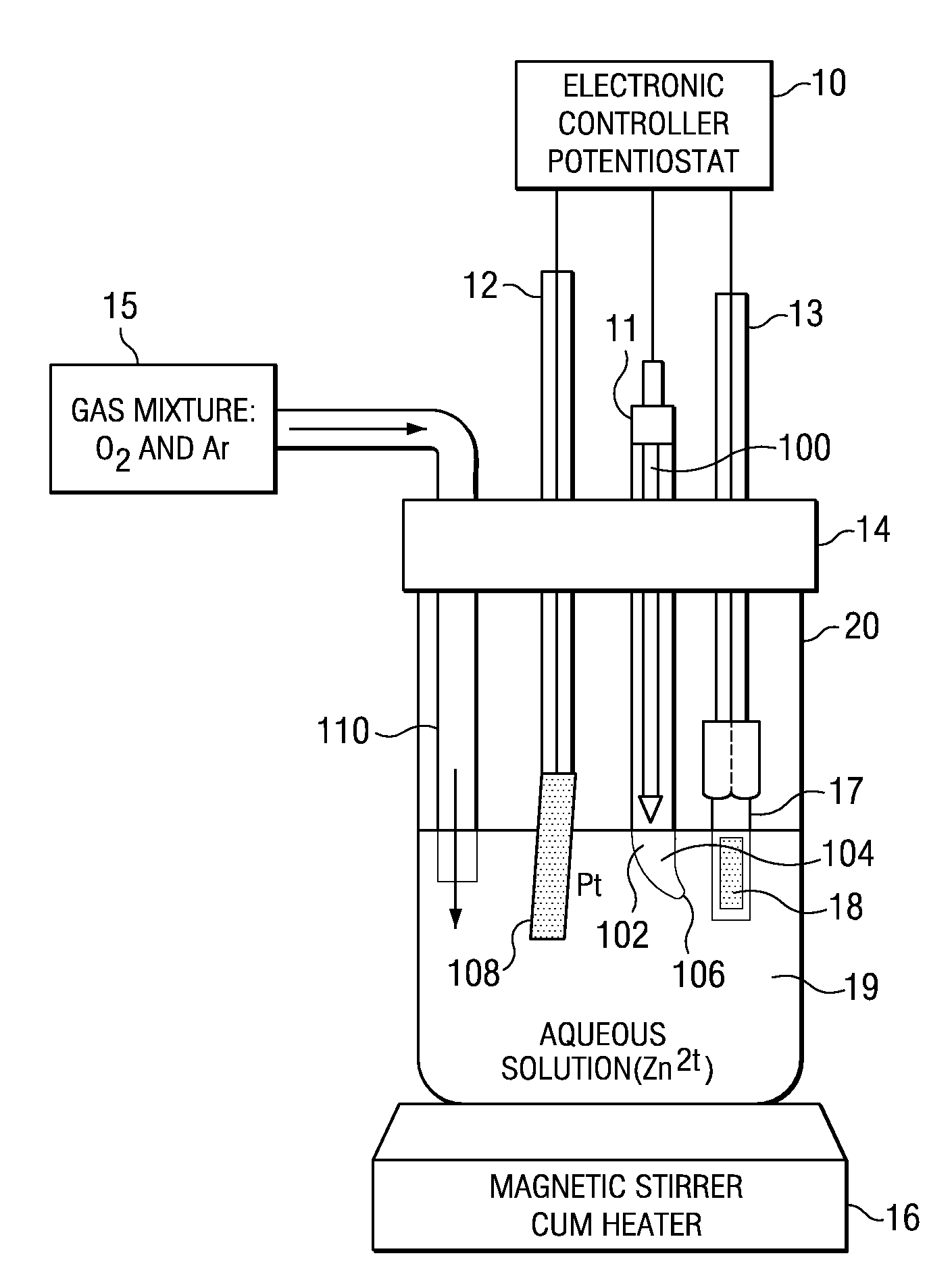

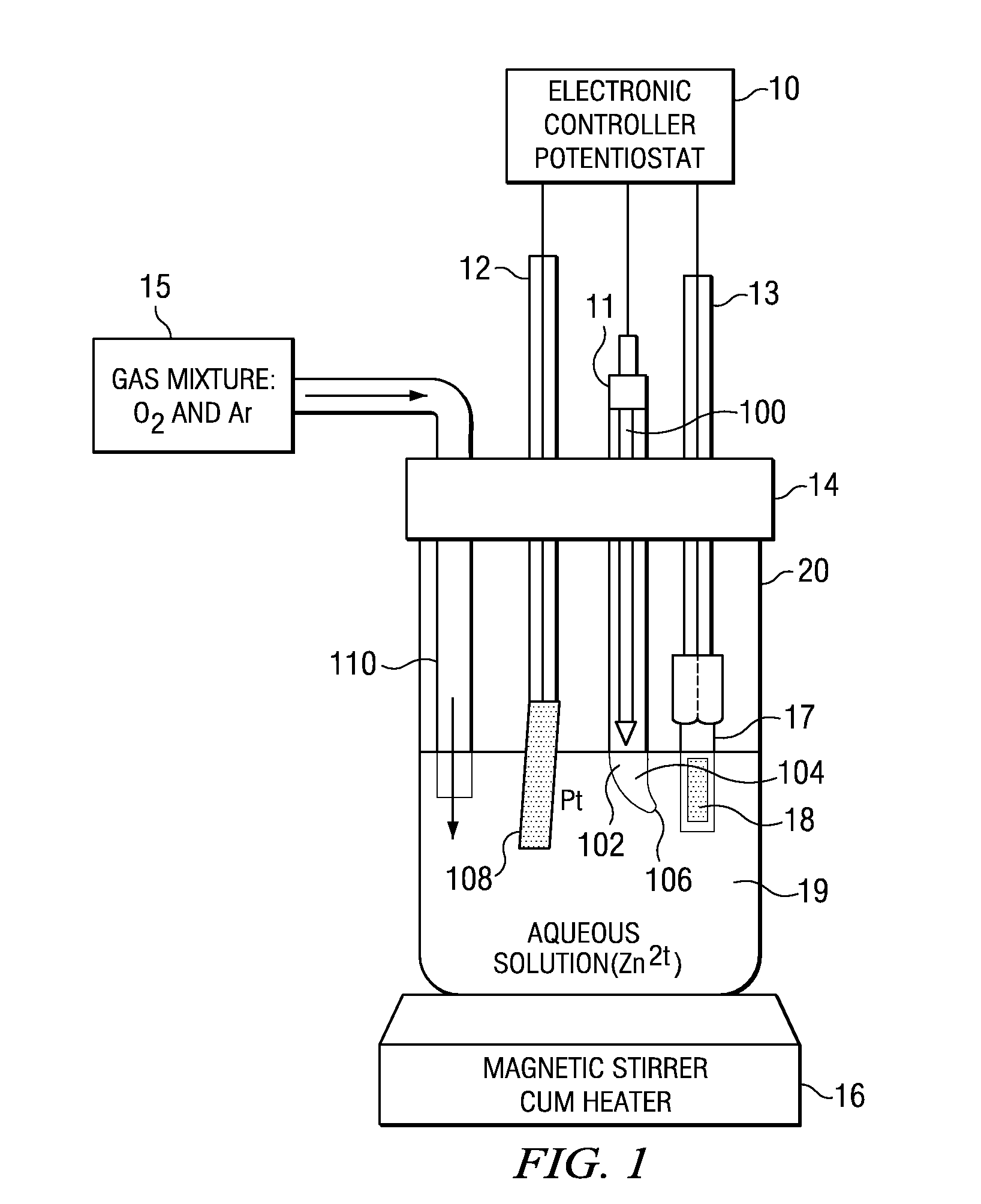

[0017]FIG. 1 depicts laboratory bench apparatus for carrying out the process of the invention. In a vessel 20 is placed an aqueous solution 19 of a water-soluble zinc salt. It is preferred that the zinc salt be selected from zinc nitrate, zinc chloride and mixtures thereof. It is particularly preferred to use ZnCl2. The zinc salt should be present in a concentration in the range of about 0.0001 M to 0.03 M. Preferably the zinc salt should be present in a concentration from 0.0007 M to 0.009 M. Most preferably the zinc salt should be present in a concentration from 0.001 M to 0.007 M.

[0018]The solvent preferably is deionized water in order to eliminate impurities in crystal formation. It is preferred that the solution also contain a supporting electrolyte such as KCl, EuCl2 or KNO3. Preferably the supporting electrolyte should be present in concentrations of 0.001 M to 0.3 M. More preferably the supporting electrolyte should be present in concentrations of 0.009 M to 0.03 M. It is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com