Patents

Literature

45results about How to "Constant area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

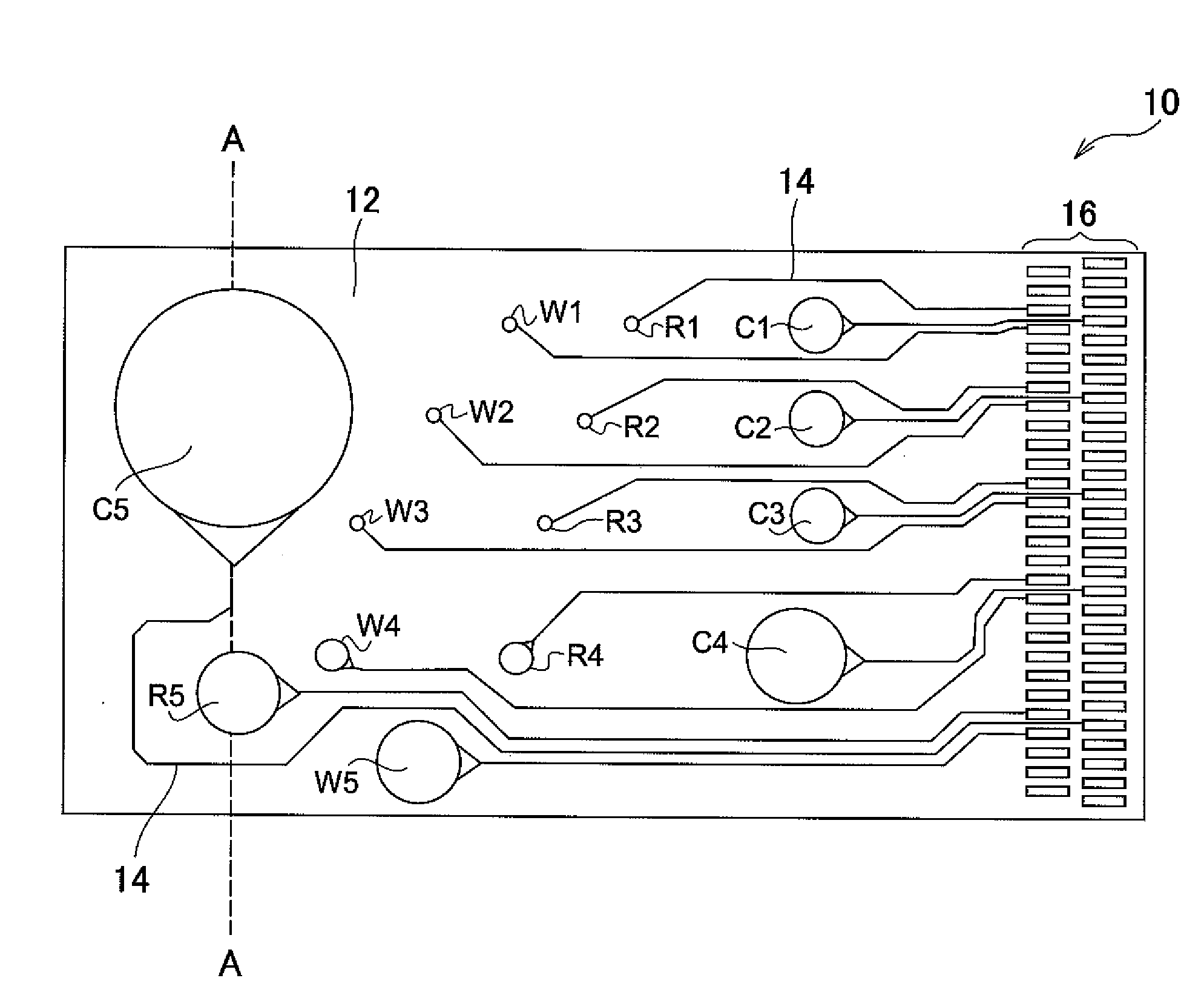

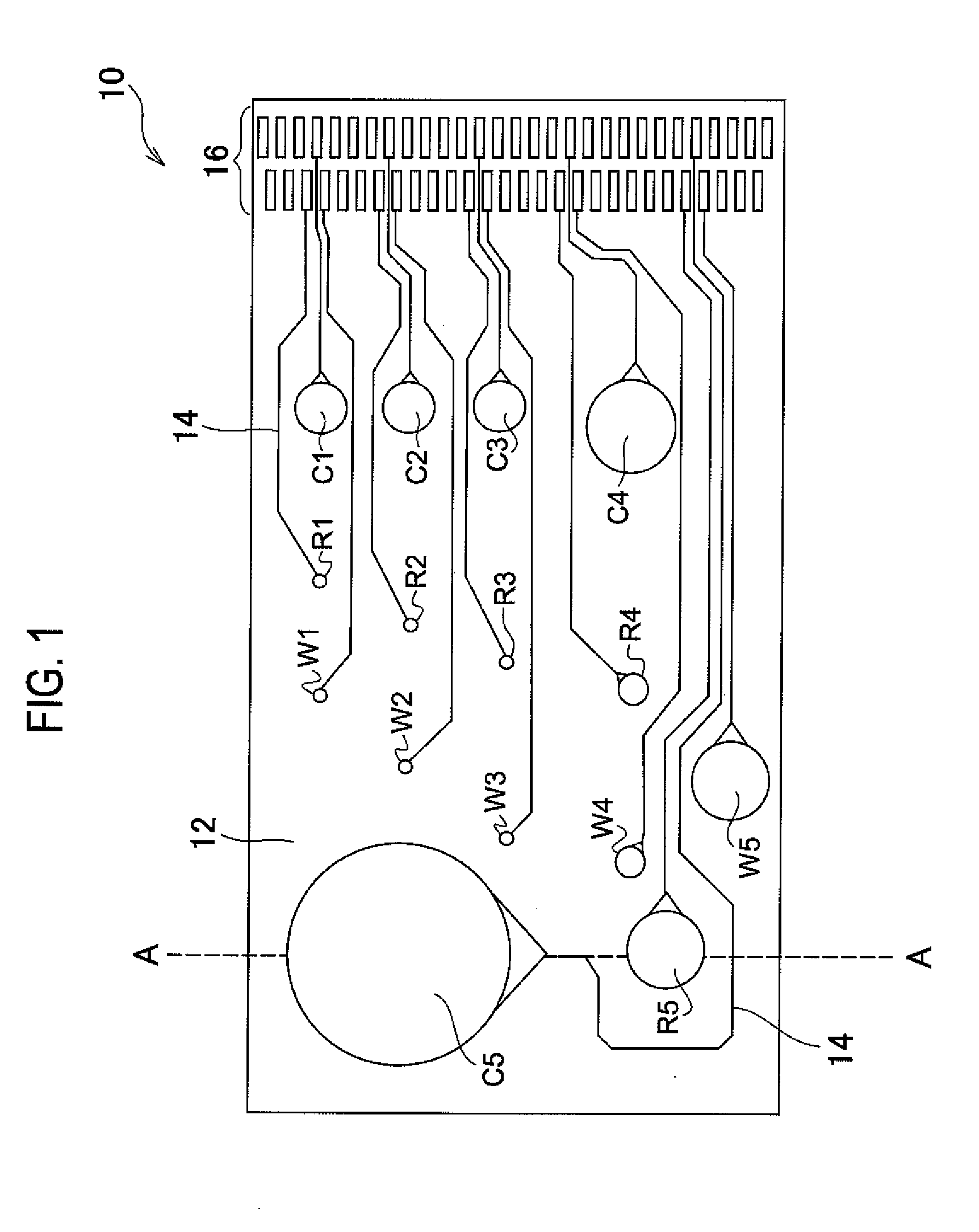

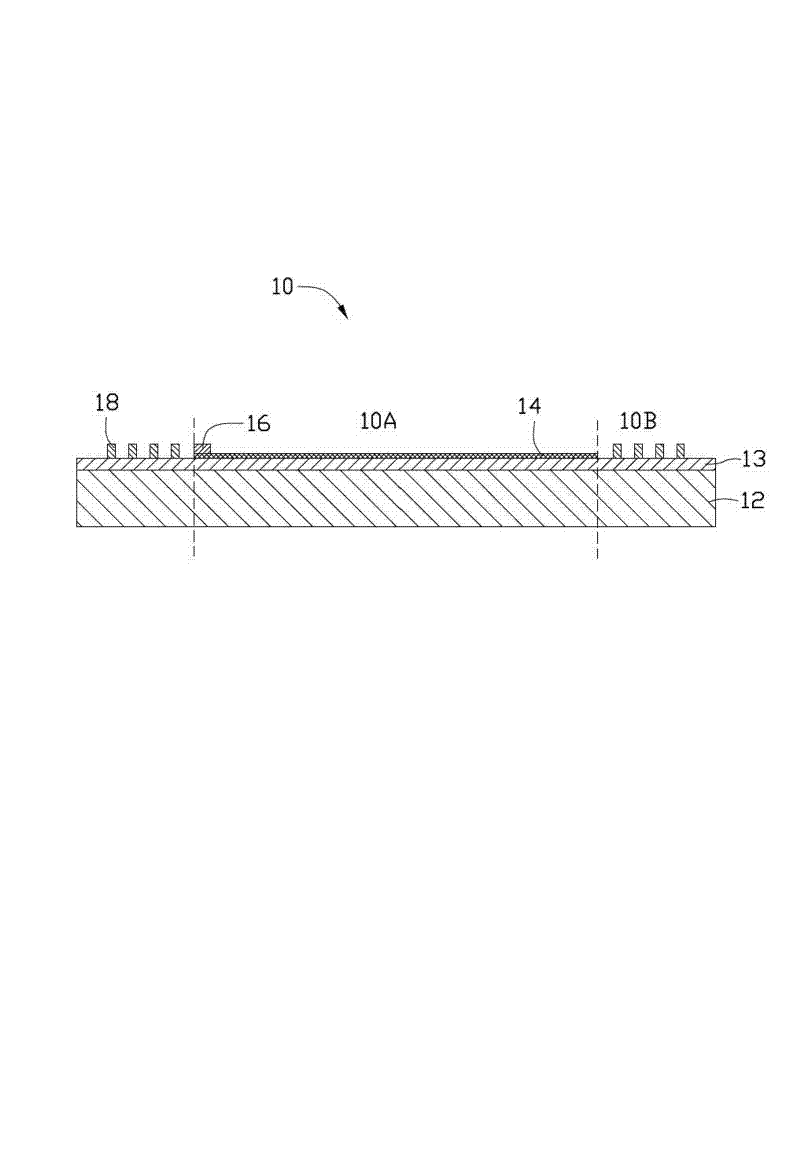

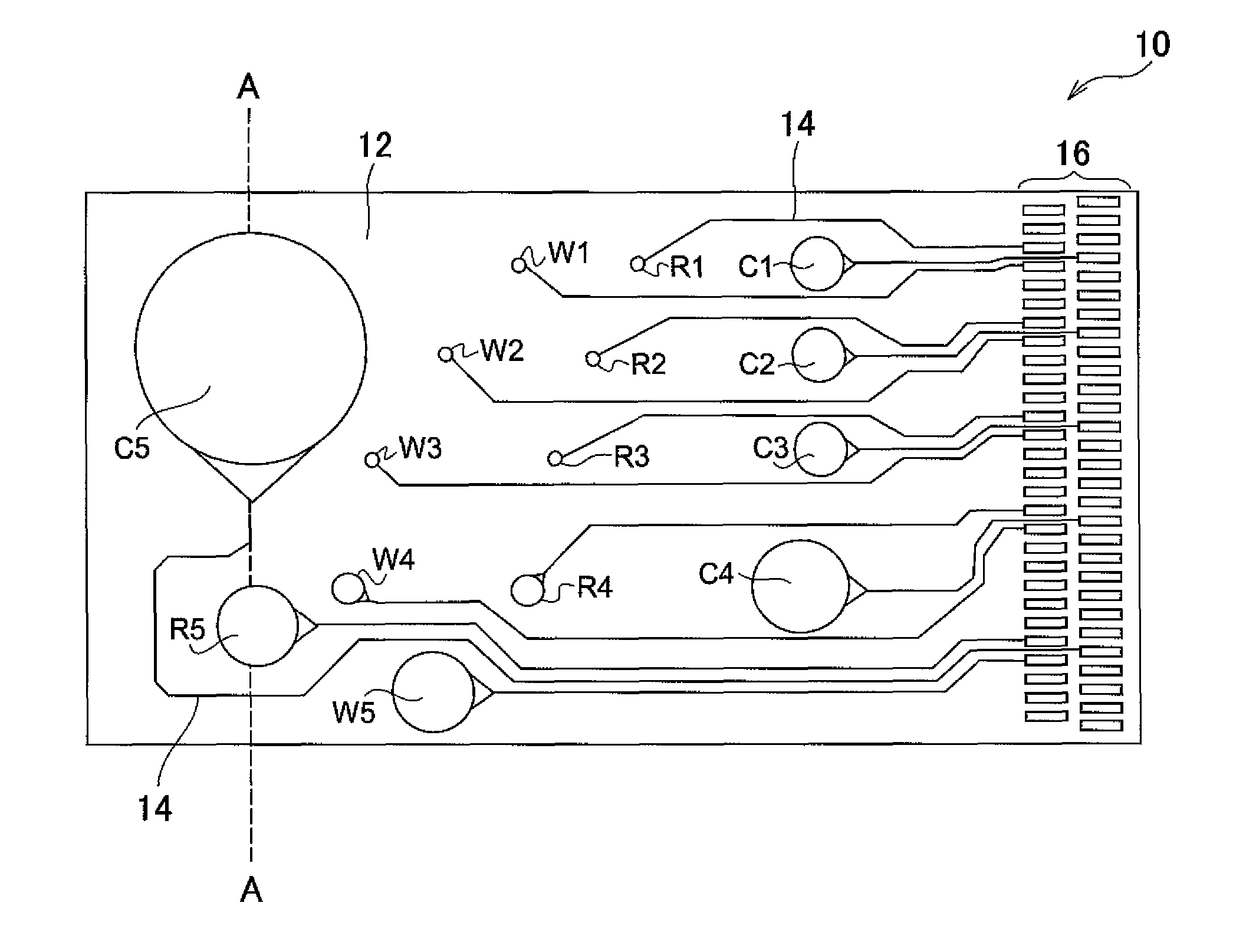

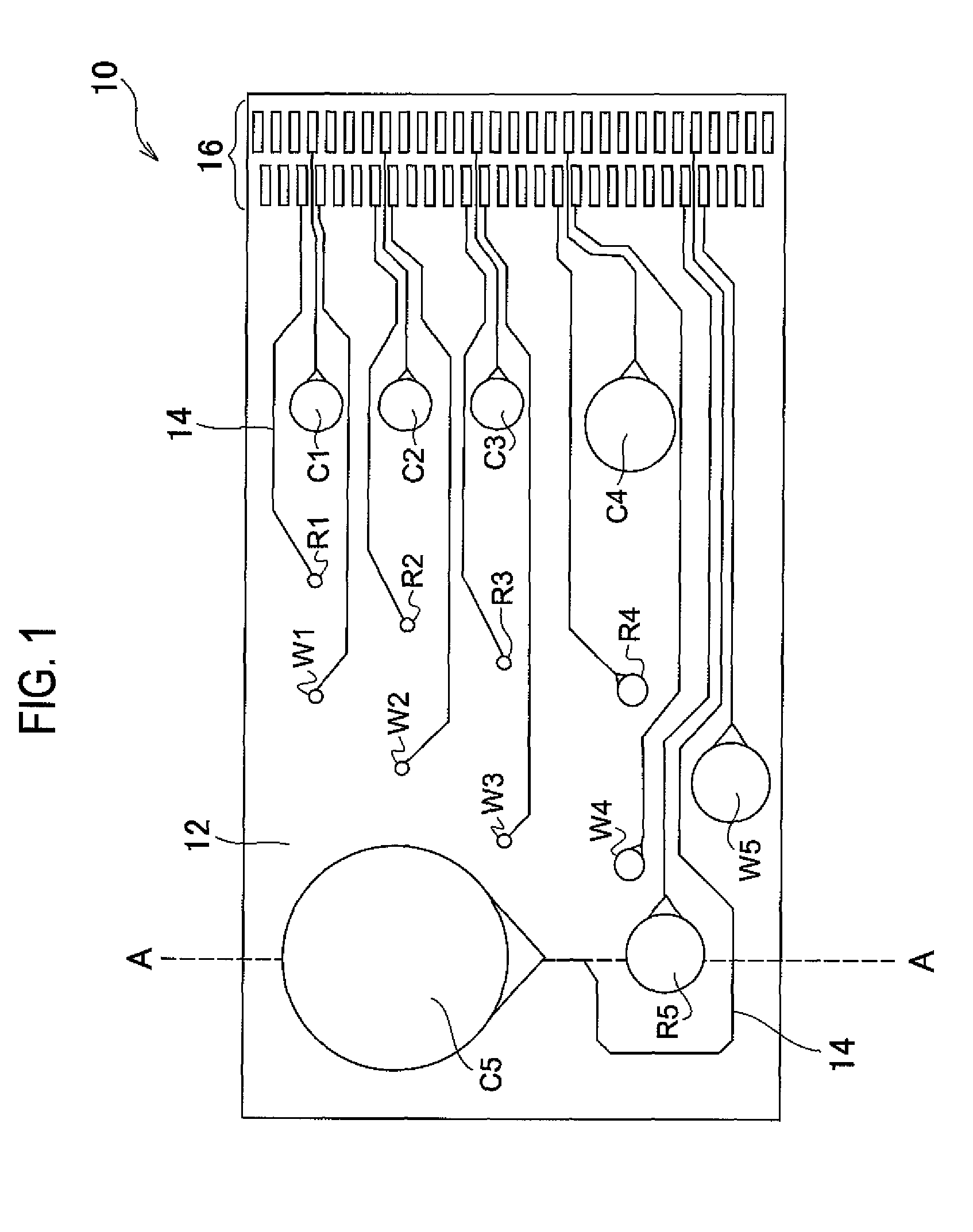

Sensor, sensor system, portable sensor system, method of analyzing metal ions, mounting substrate, method of analyzing plating preventing chemical species, method of analyzing produced compound, and method of analyzing monovalent copper chemical species

InactiveUS20100253361A1Good reproducibilityConstant areaMaterial electrochemical variablesAnalyteChemical species

This invention provides a sensor having such a structure that the area in which a sensor electrode comes into contact with a liquid, a mist or a gas containing an analyte has been previously specified. The sensor comprises at least an electroconductive first electrode, an electroconductive second electrode, electroconductive first and second wirings connected to the first and second electrodes, and an insulating part for insulating the first and second wirings from each other and from a liquid, a mist or a gas containing the analyte. The insulating part is formed of an organic material. In the first and second electrodes, at least the surface, which comes into contact with a liquid, a mist or a gas containing the analyte, is formed of a material which is insoluble in a liquid or a mist containing the analyte, or is not attacked by a gas containing the analyte.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

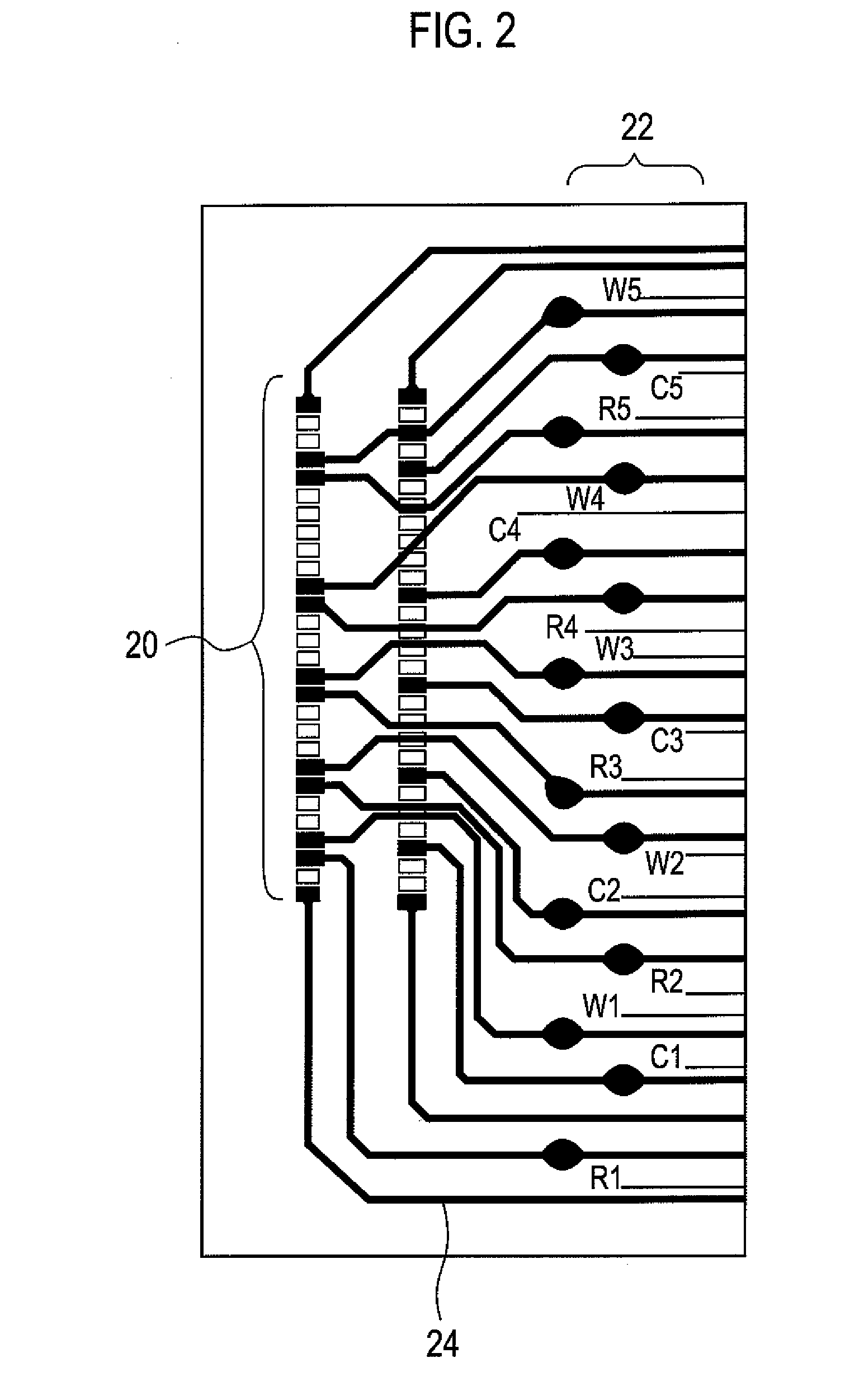

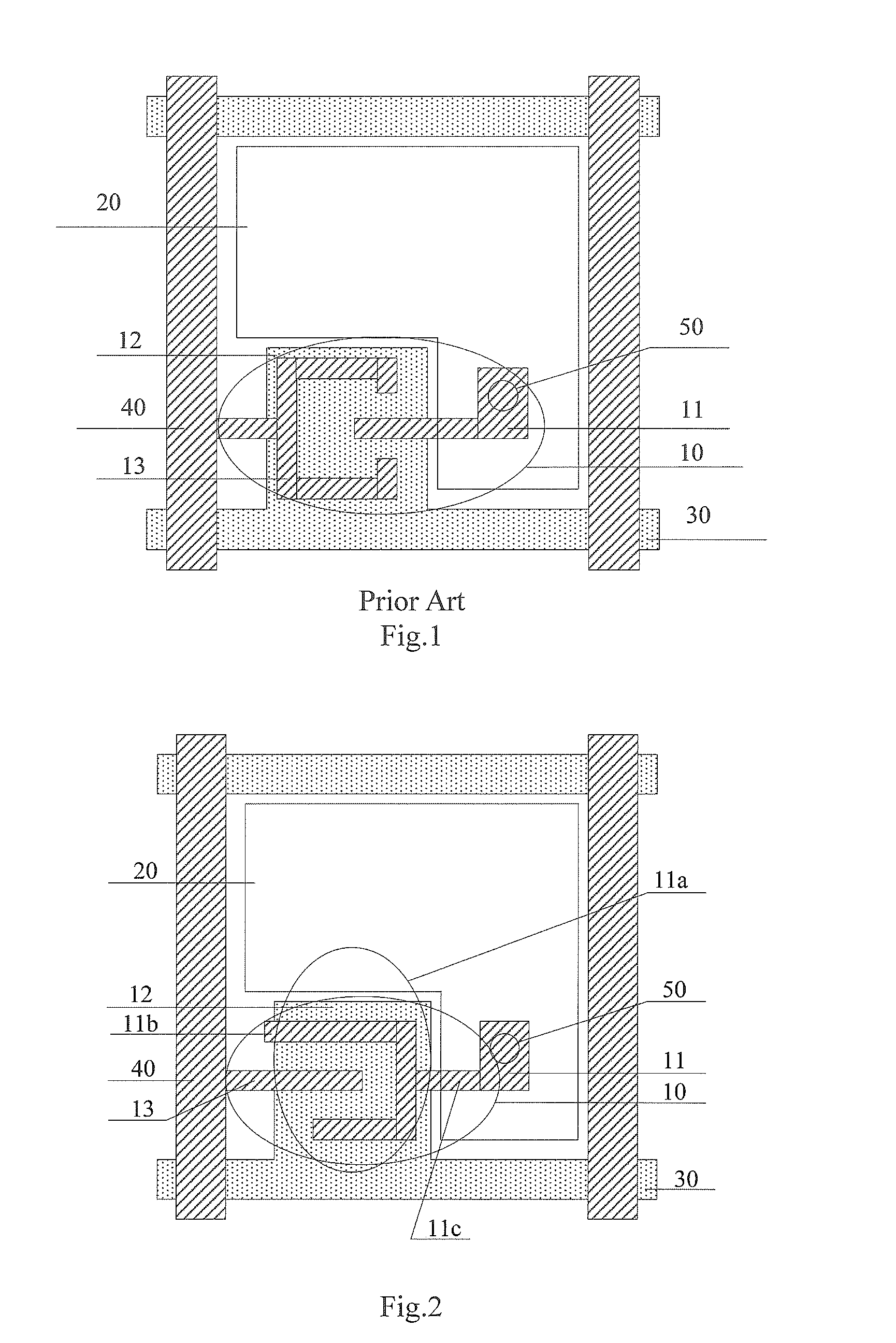

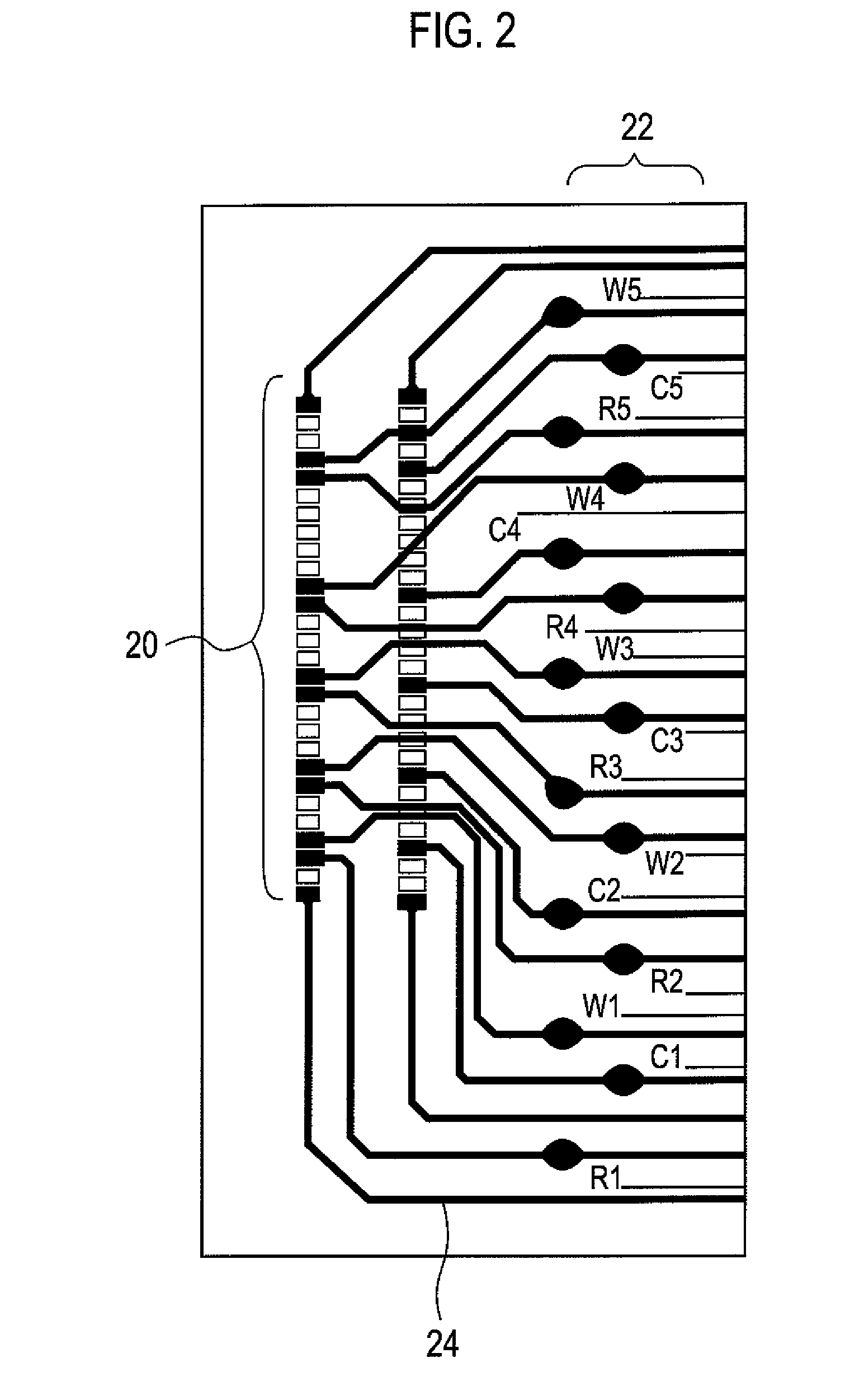

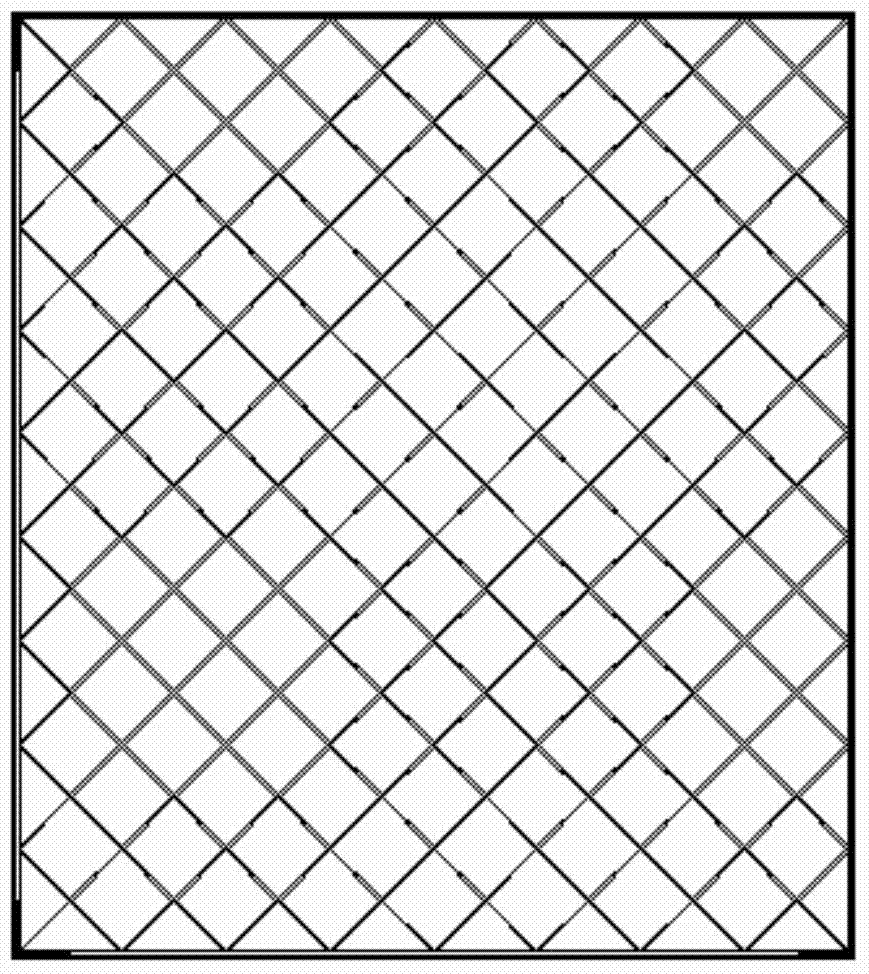

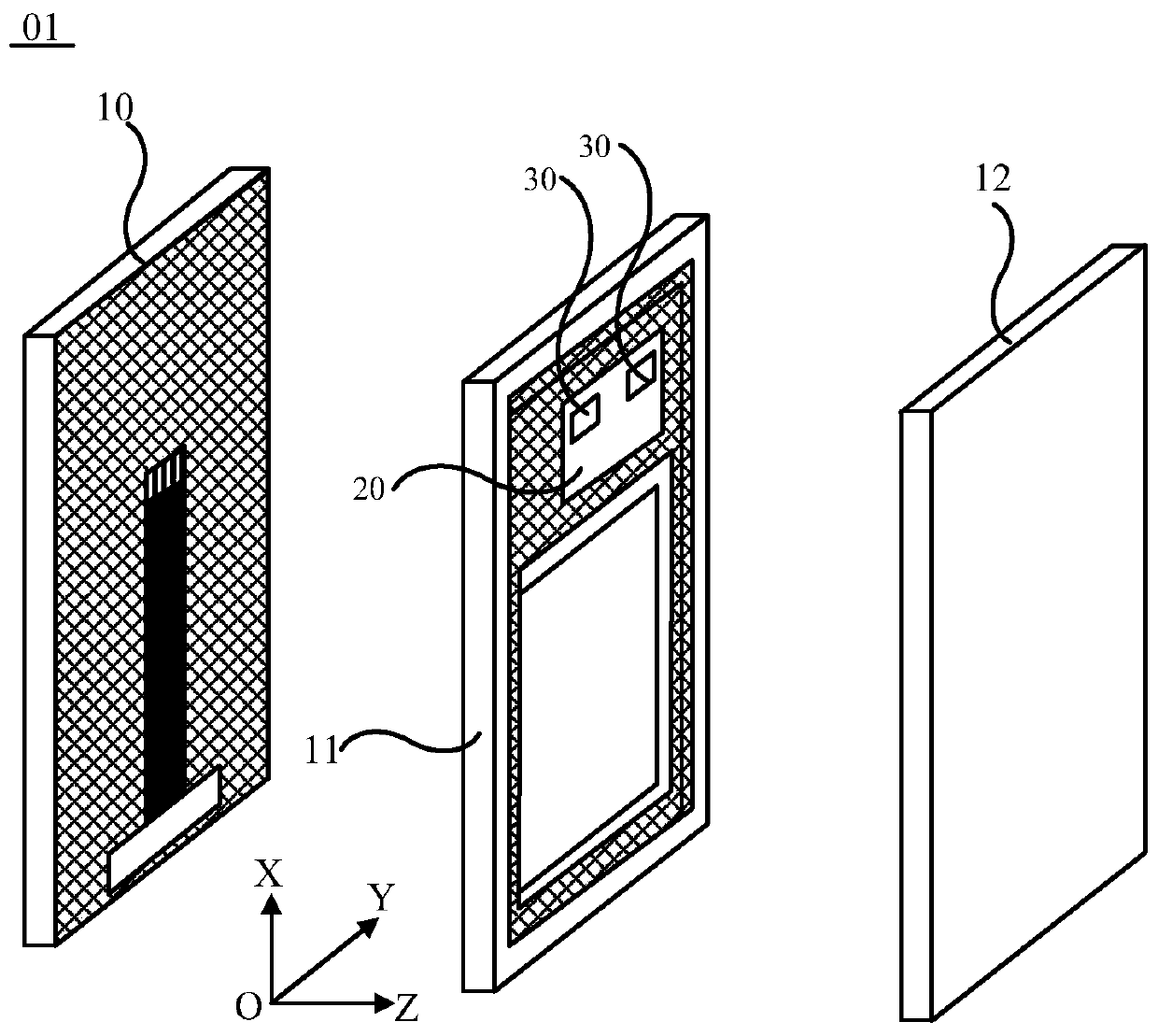

Touch screen panel

ActiveCN102419655AHigh resolutionReduced trace area areaInput/output processes for data processingElectricityEngineering

The invention discloses a touch screen panel which comprises an insulation substrate, a transparent conducting layer, a plurality of sensor electrodes and a plurality of lead wires. The touch screen panel comprises a touch area and a route area. The transparent conducting layer is fixed on one surface of the touch area corresponding to the insulation substrate, the plurality of sensor electrodes are mutually arranged at intervals and are electrically connected with the transparent conducting layer, the plurality of lead wires are laid in the route area and are used for the electrical signal transmission between the sensor electrodes and an external controller, wherein the touch area comprises at least a first touch area, and the quantity distribution density per unit area corresponding to the sensor electrodes of the first touch area is greater than the quantity distribution density per unit area corresponding to the sensor electrodes of other touch areas.

Owner:贵州富纳源创科技有限公司 +1

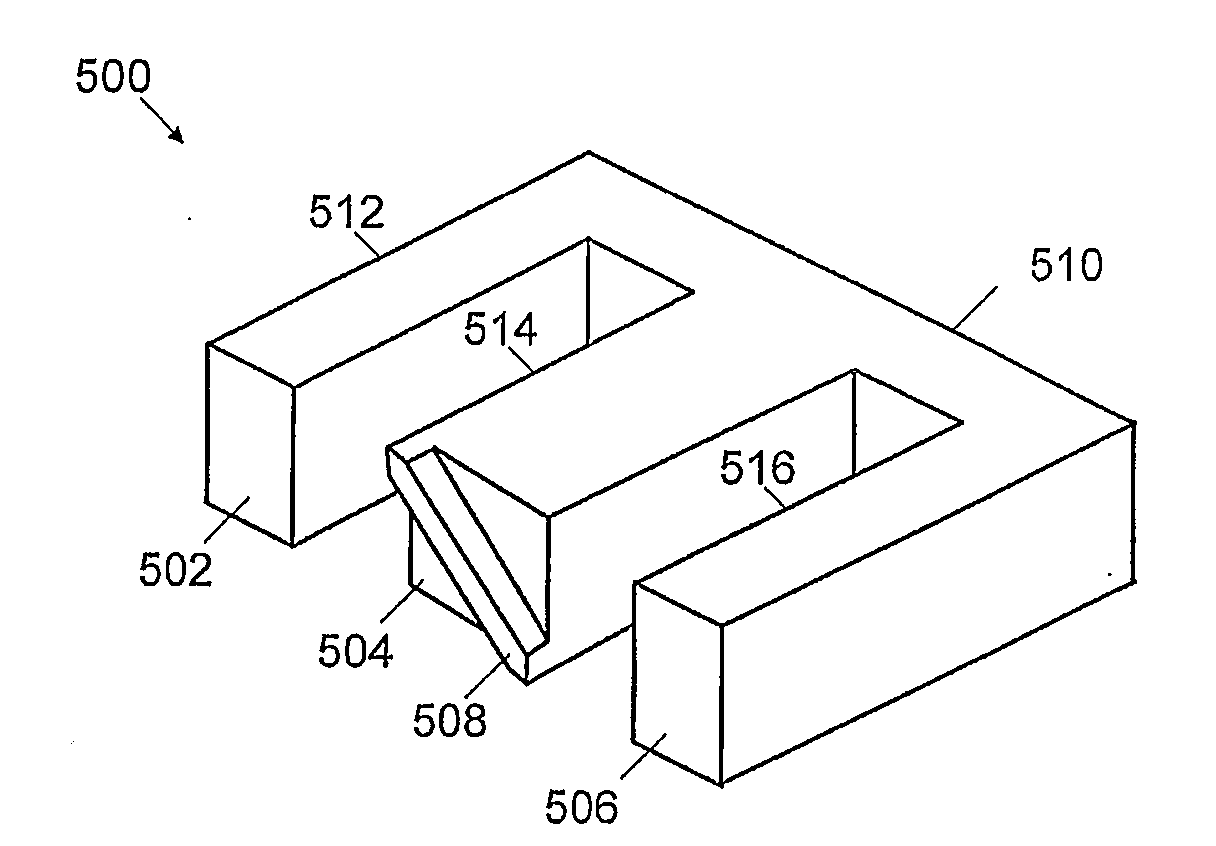

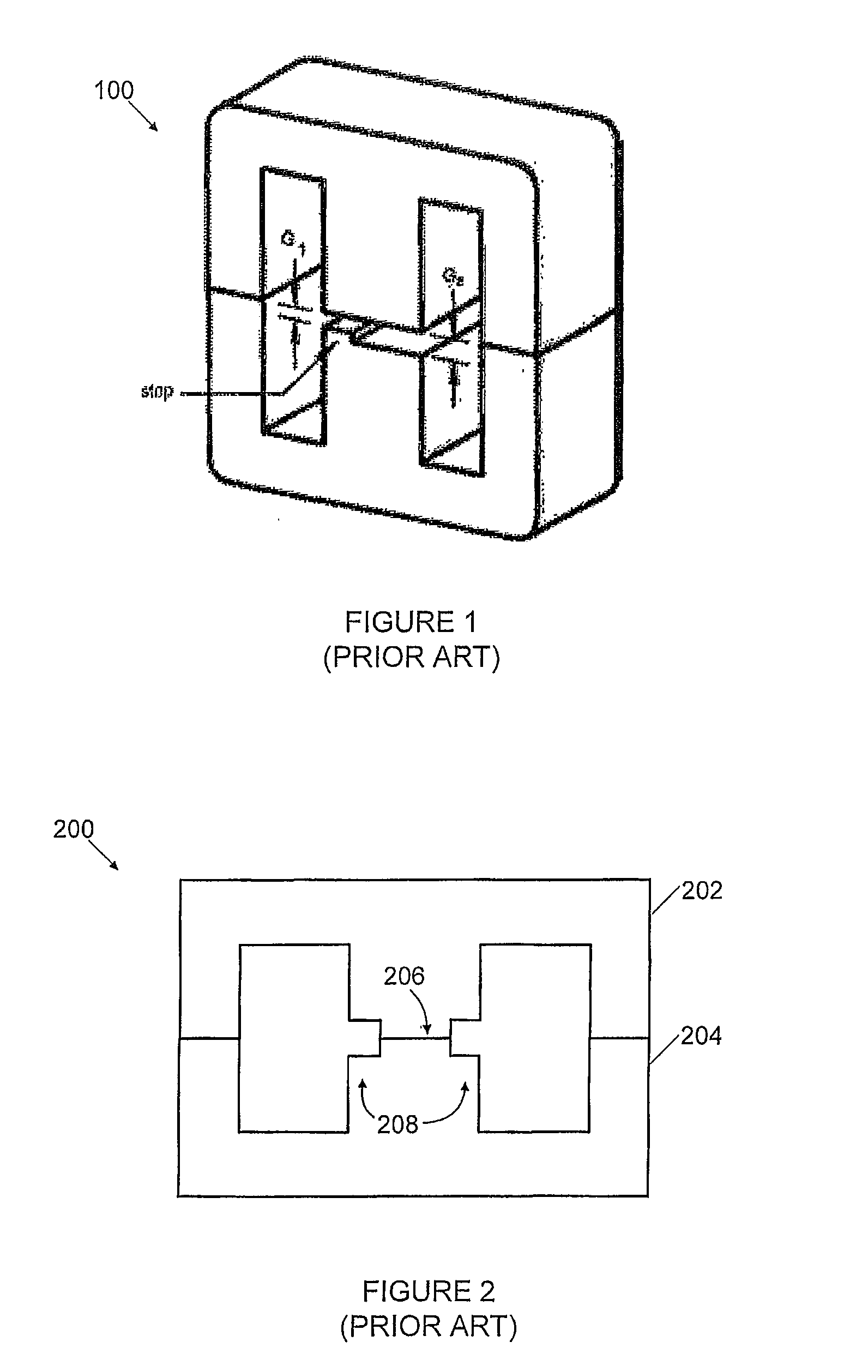

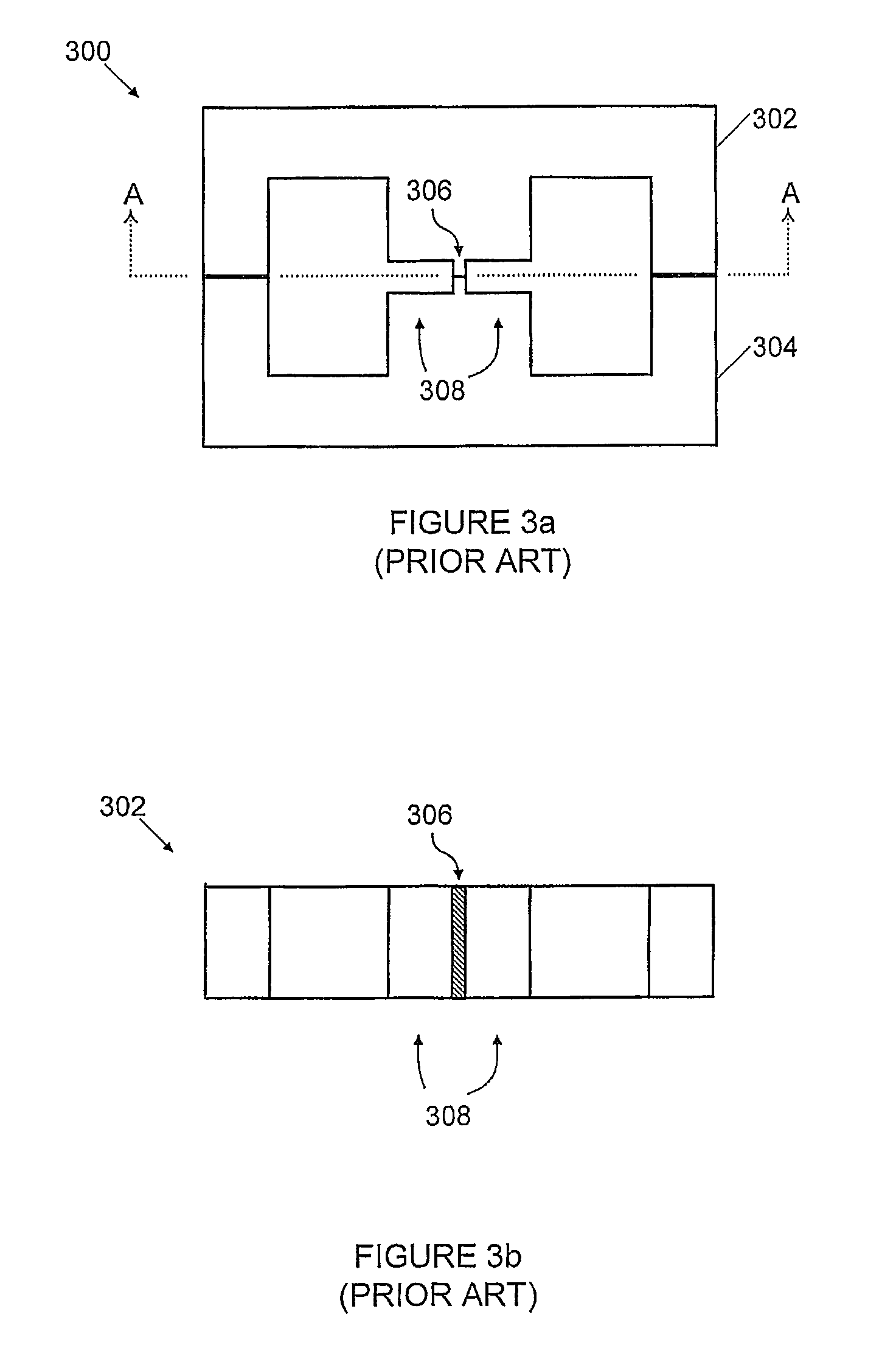

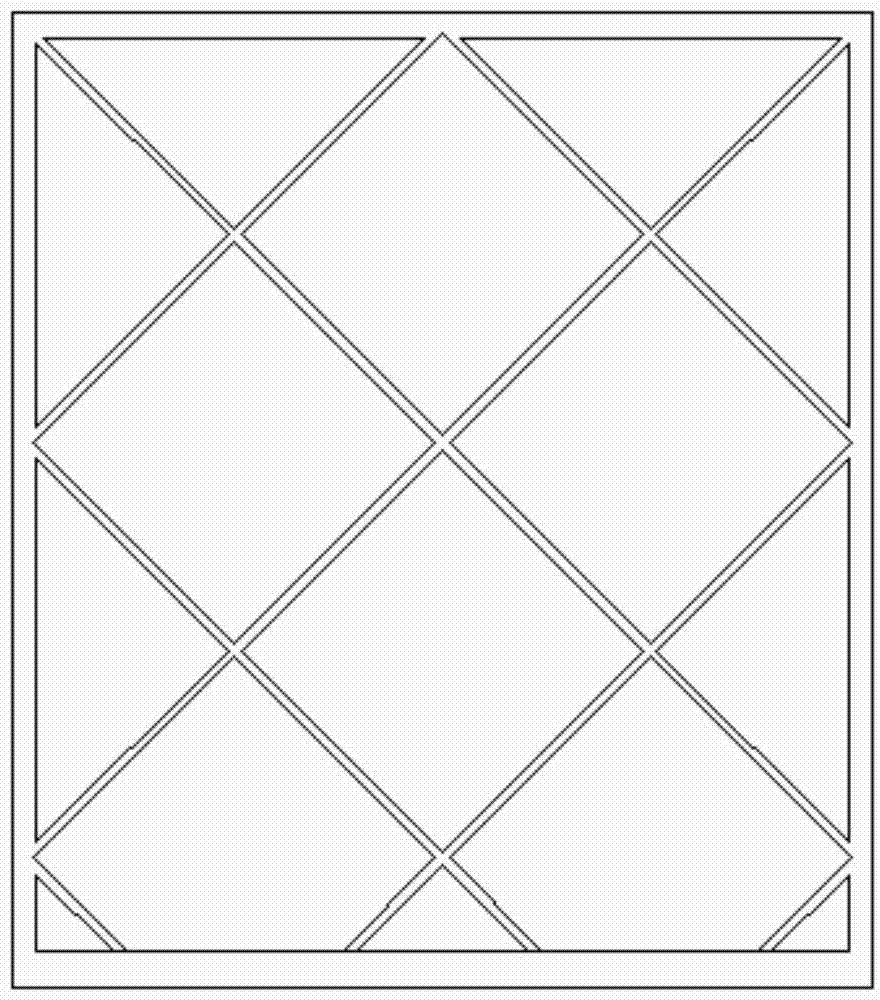

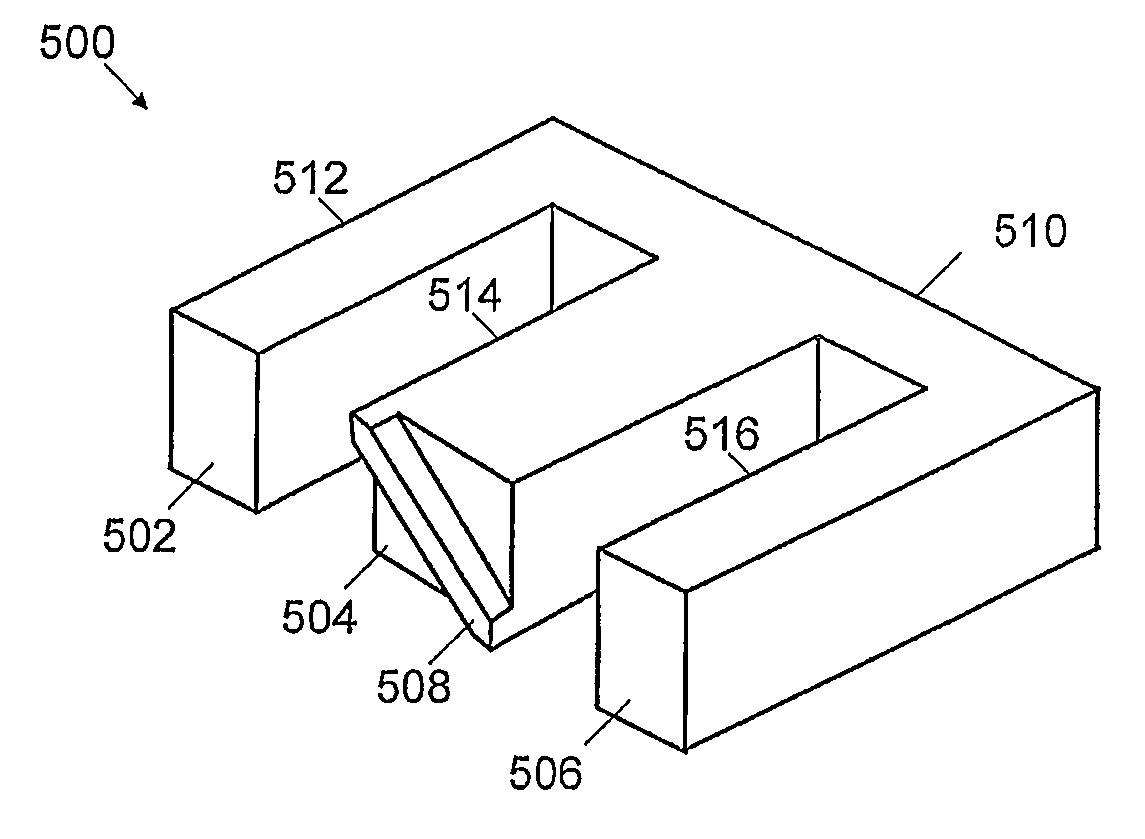

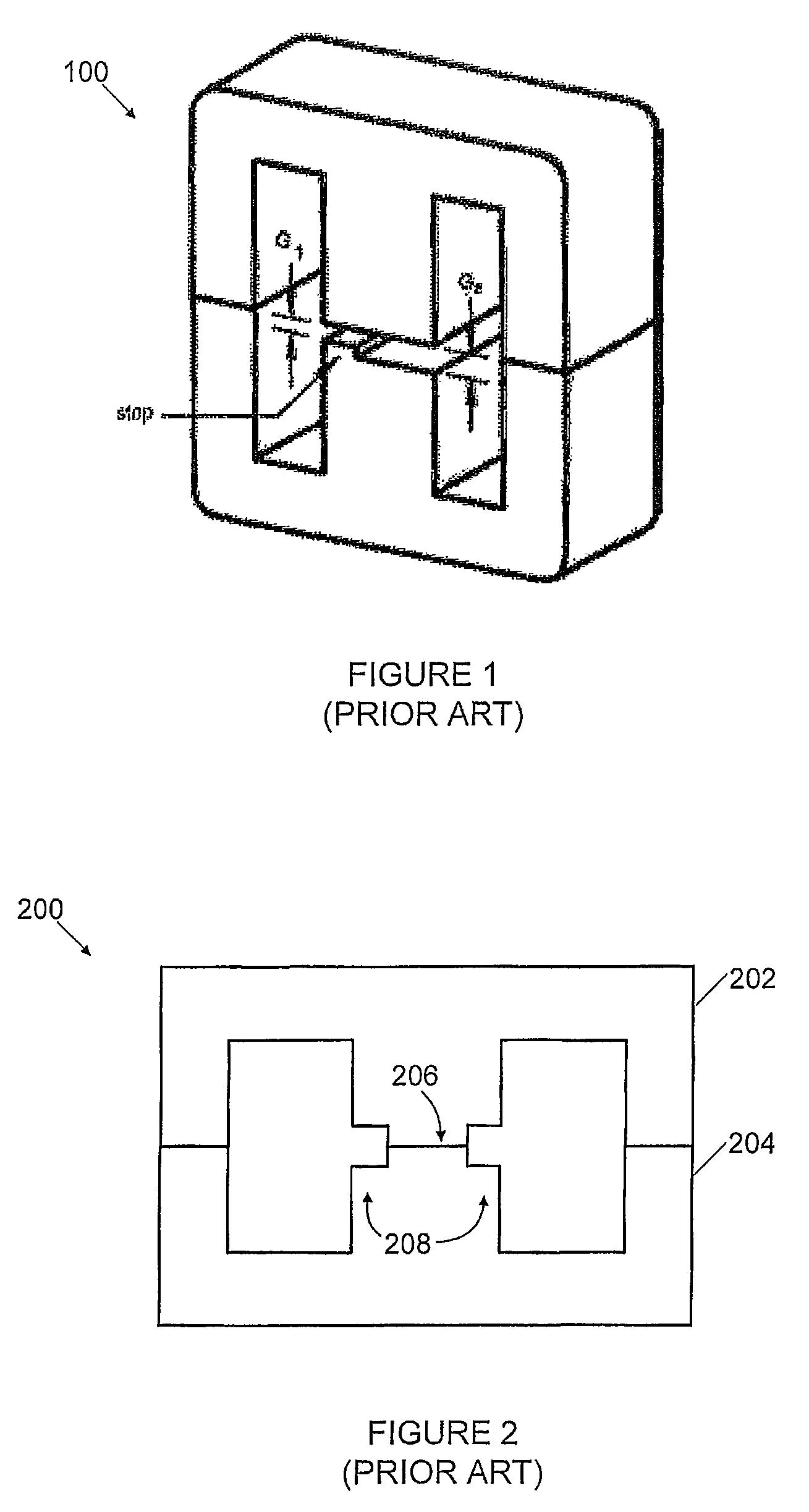

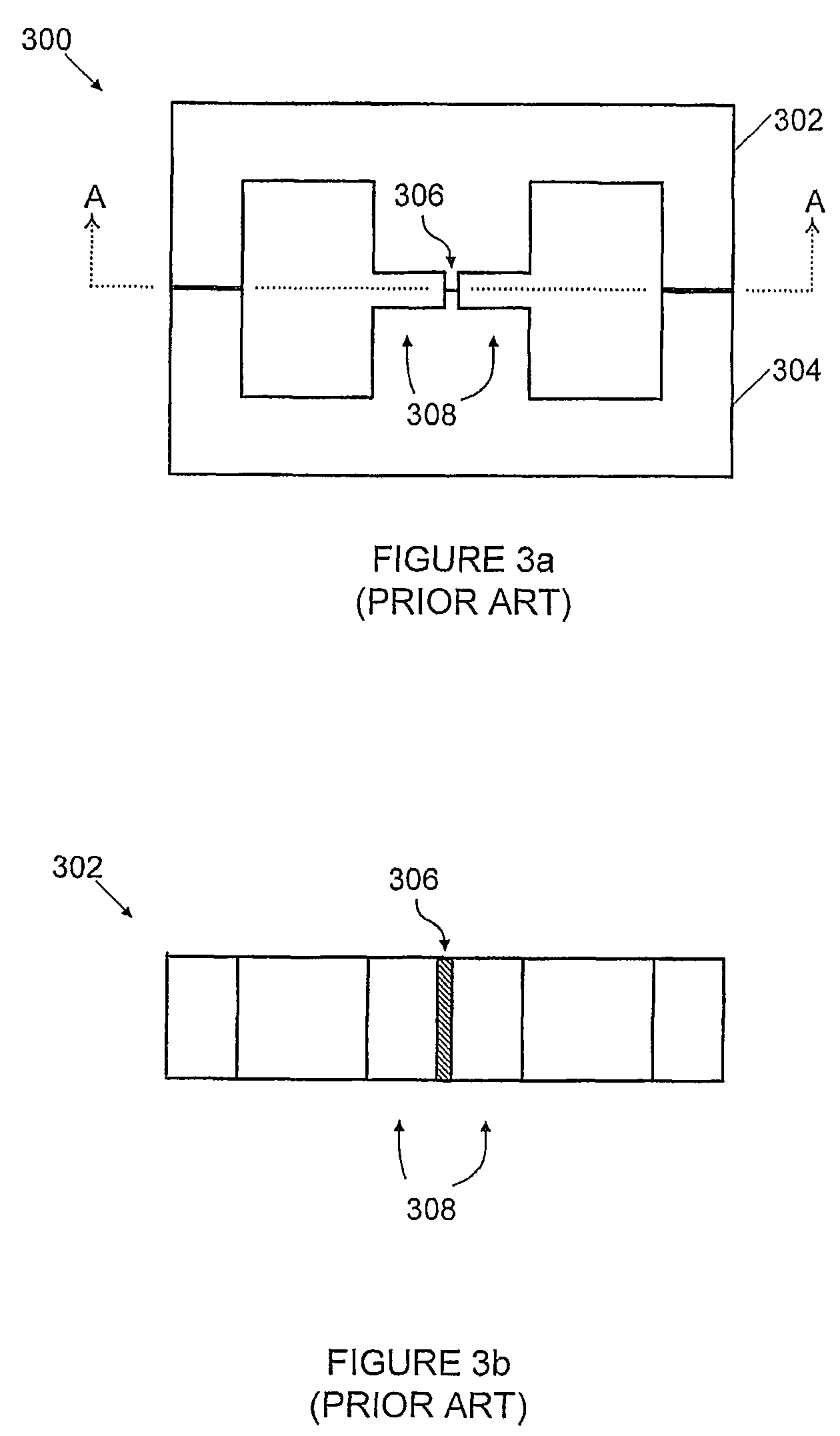

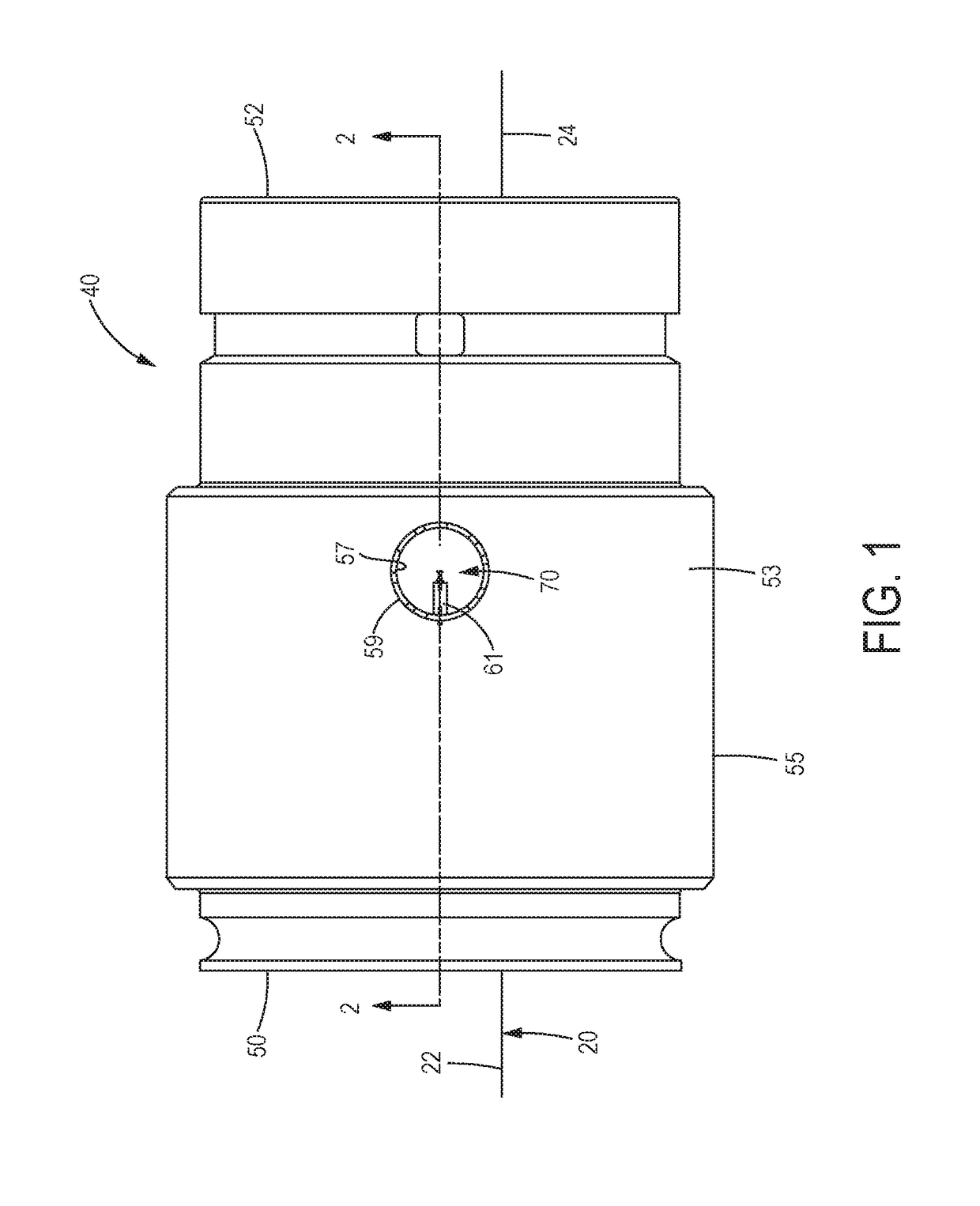

Crossed gap ferrite cores

InactiveUS20100085138A1Variable sizeLess susceptibleFixed inductancesTransformers/inductances magnetic coresInductorMagnetic core

The invention relates to swinging inductors of a stepped-gap construction. We describe an inductor core structure having first and second core segments, constructed and arranged such that distal ends of legs of the first core segment are paired with distal ends of legs of the second core segment in an opposing relation. The at least one distal ends of the first core segment has a ridge projecting therefrom and is paired with the at least one distal ends of the second core segment which has a ridge projecting therefrom in an opposing relation, such that opposingly paired projecting ridges form a cross arrangement.

Owner:POWER INTEGRATIONS INC

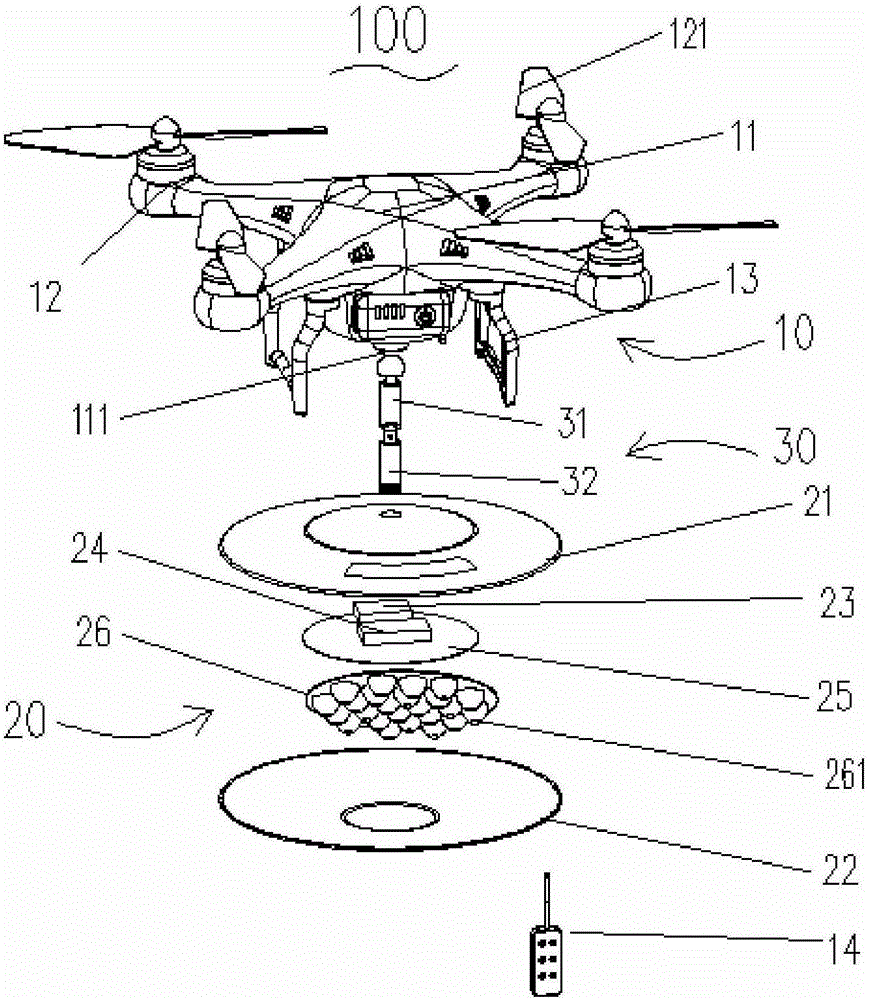

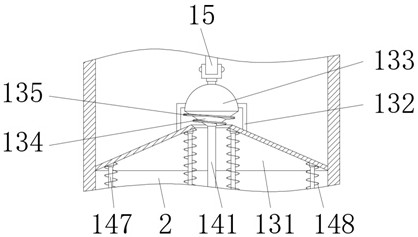

Unmanned aerial vehicle carrying lighting lamp

Owner:JIAXING YAOU PHOTOELECTRIC TECH CO LTD

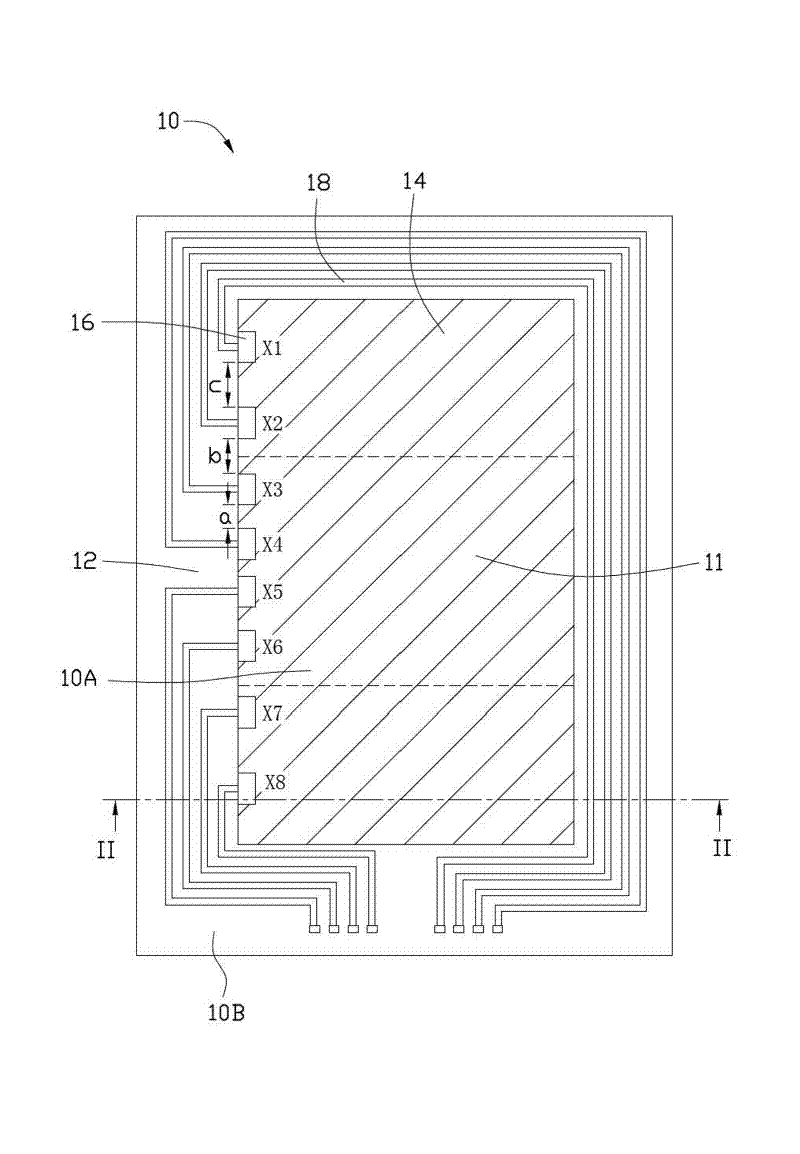

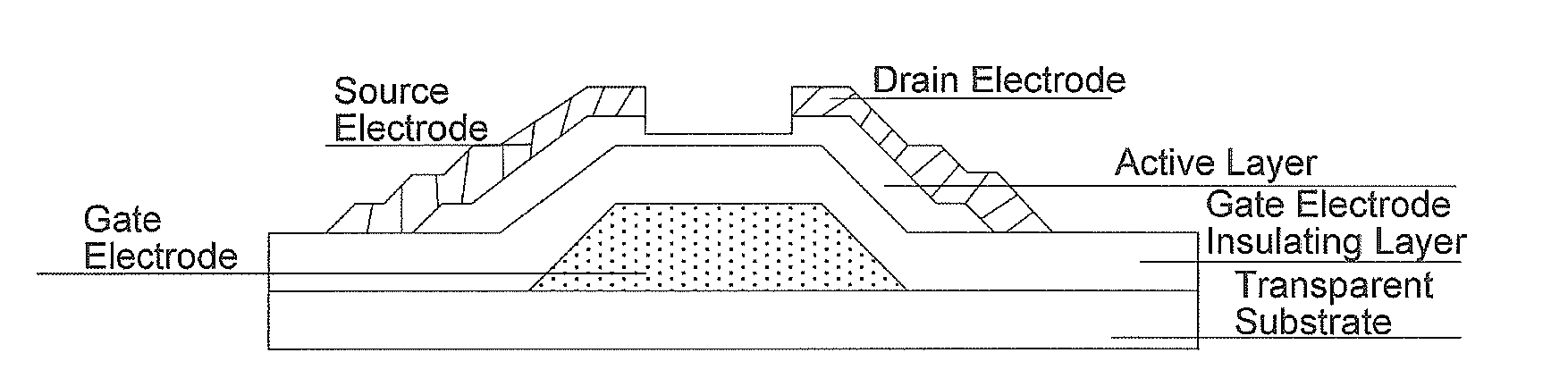

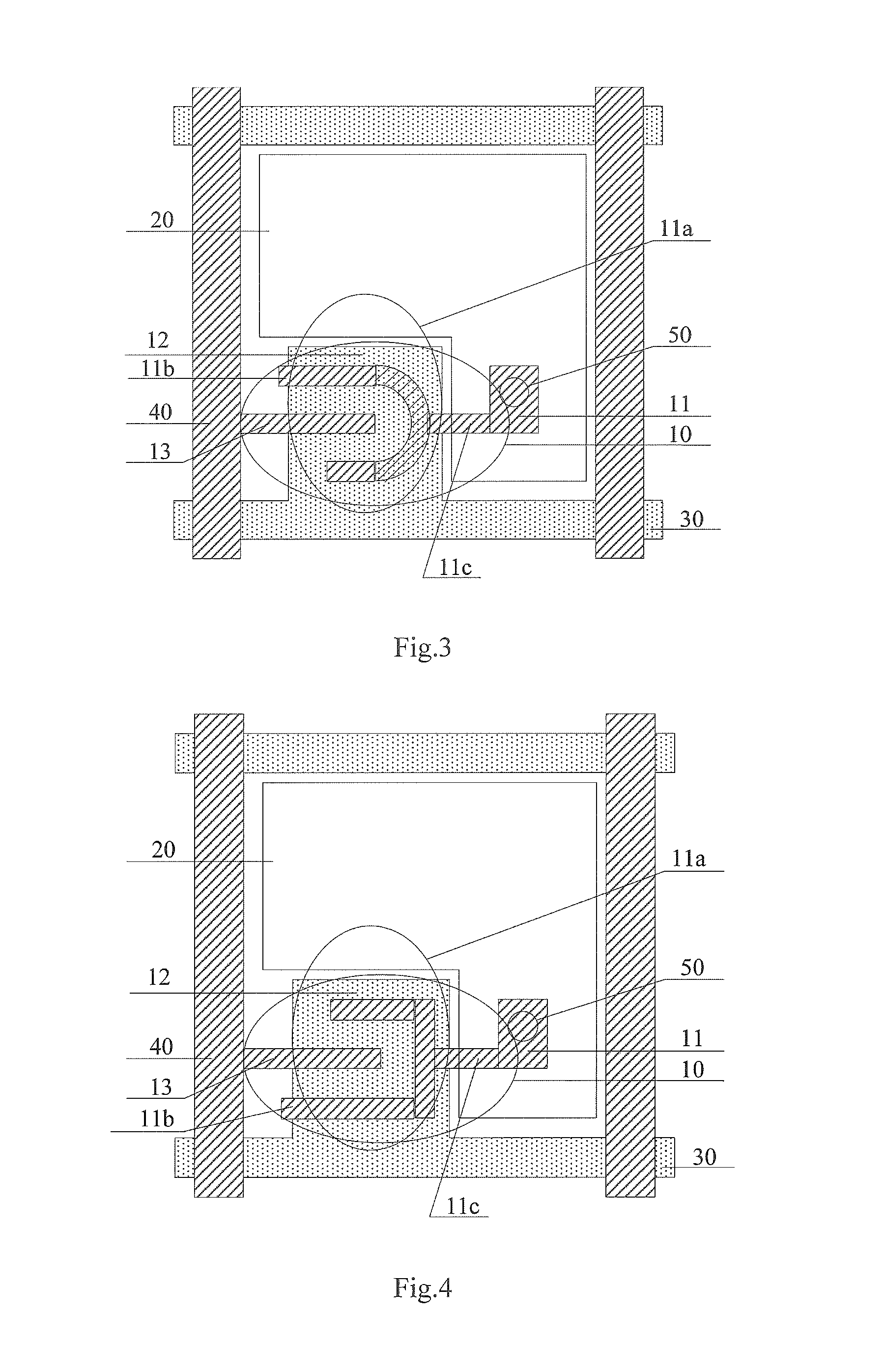

Array substrate and method for manufacturing the same, and display device

ActiveUS20150129882A1Eliminate the problemUniform gray scaleTransistorSolid-state devicesDisplay deviceOptoelectronics

The invention relates to an array substrate for a display device and to a method for manufacturing an array substrate comprising a thin-film transistor (“TFT”). An array substrate according to an embodiment of the invention comprises a source electrode, a gate electrode and a drain electrode, wherein the gate electrode is located on a first metal layer, the source electrode and the drain electrode are located on a second metal layer, and in the case that dislocation occurs between the first metal layer and the second metal layer, the area of the overlapping region between the source electrode and the gate electrode keeps constant.

Owner:BOE TECH GRP CO LTD +1

Sensor, sensor system, portable sensor system, method of analyzing metal ions, mounting substrate, method of analyzing plating preventing chemical species, method of analyzing produced compound, and method of analyzing monovalent copper chemical species

InactiveUS8648605B2Good reproducibilityConstant areaImmobilised enzymesBioreactor/fermenter combinationsAnalyteChemical species

This invention provides a sensor having such a structure that the area in which a sensor electrode comes into contact with a liquid, a mist or a gas containing an analyte has been previously specified. The sensor comprises at least an electroconductive first electrode, an electroconductive second electrode, electroconductive first and second wirings connected to the first and second electrodes, and an insulating part for insulating the first and second wirings from each other and from a liquid, a mist or a gas containing the analyte. The insulating part is formed of an organic material. In the first and second electrodes, at least the surface, which comes into contact with a liquid, a mist or a gas containing the analyte, is formed of a material which is insoluble in a liquid or a mist containing the analyte, or is not attacked by a gas containing the analyte.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

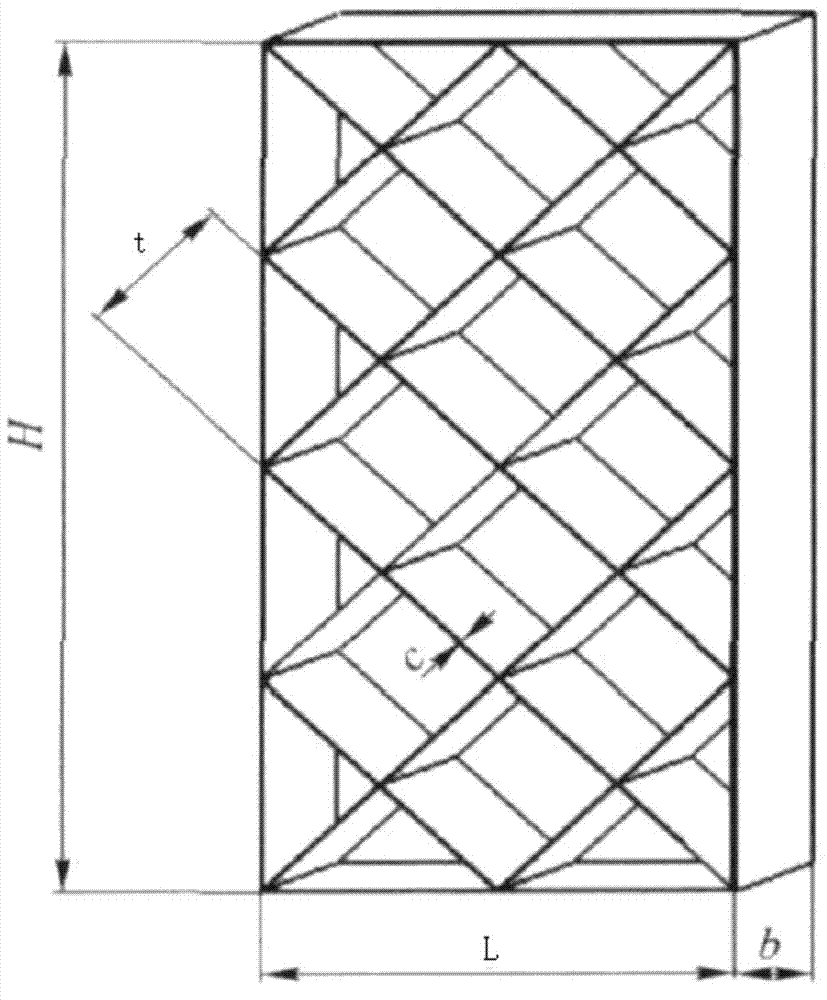

Grid wing wind tunnel test model scaling method

The invention discloses a grid wing wind tunnel test model scaling method. According to the method, every two adjacent unit grids are combined, the grid wing chord length is increased, the wall thickness of each grid and the thickness of a frame are increased, and therefore it is guaranteed that the attach angle lift force area is zero and the windward resistance area is kept unchanged after a model is scaled, and the increase multiples of the chord length and the increase multiples of the wall thickness of each grid are proportional to the combination number of the unit grids. By means of the grid wing wind tunnel test model scaling method, processing difficulty is greatly lowered, a processing period is shortened, and in a wind tunnel test process, under the action of supersonic velocity air flow, the grid wing model is not broken off or damaged. Through verification of a wind tunnel test, pneumatic characteristics of an original design scheme is restored really, and the grid wing wind tunnel test model scaling method is suitable for wind tunnel test model design that the size is too small after grid wings are scaled.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

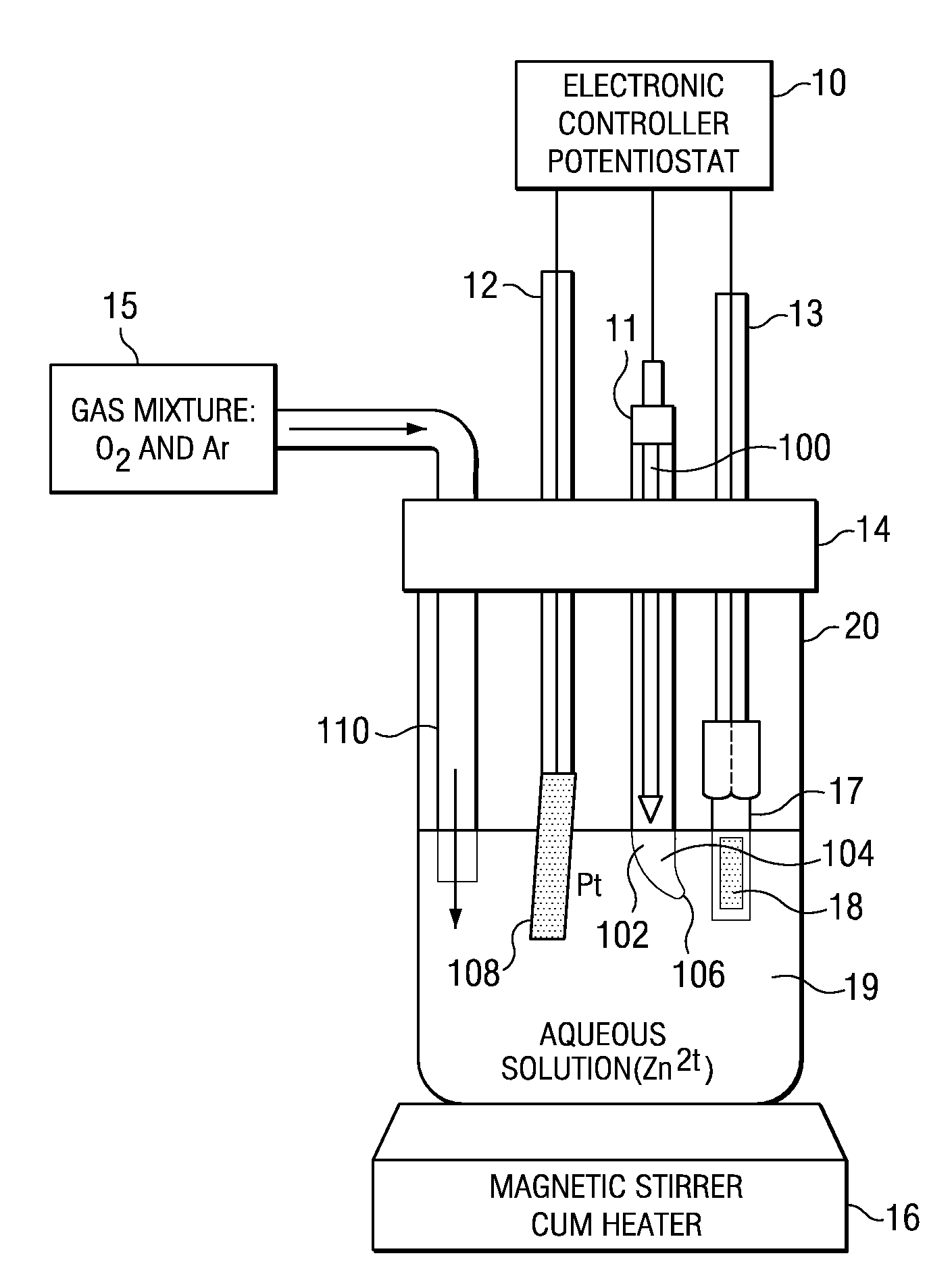

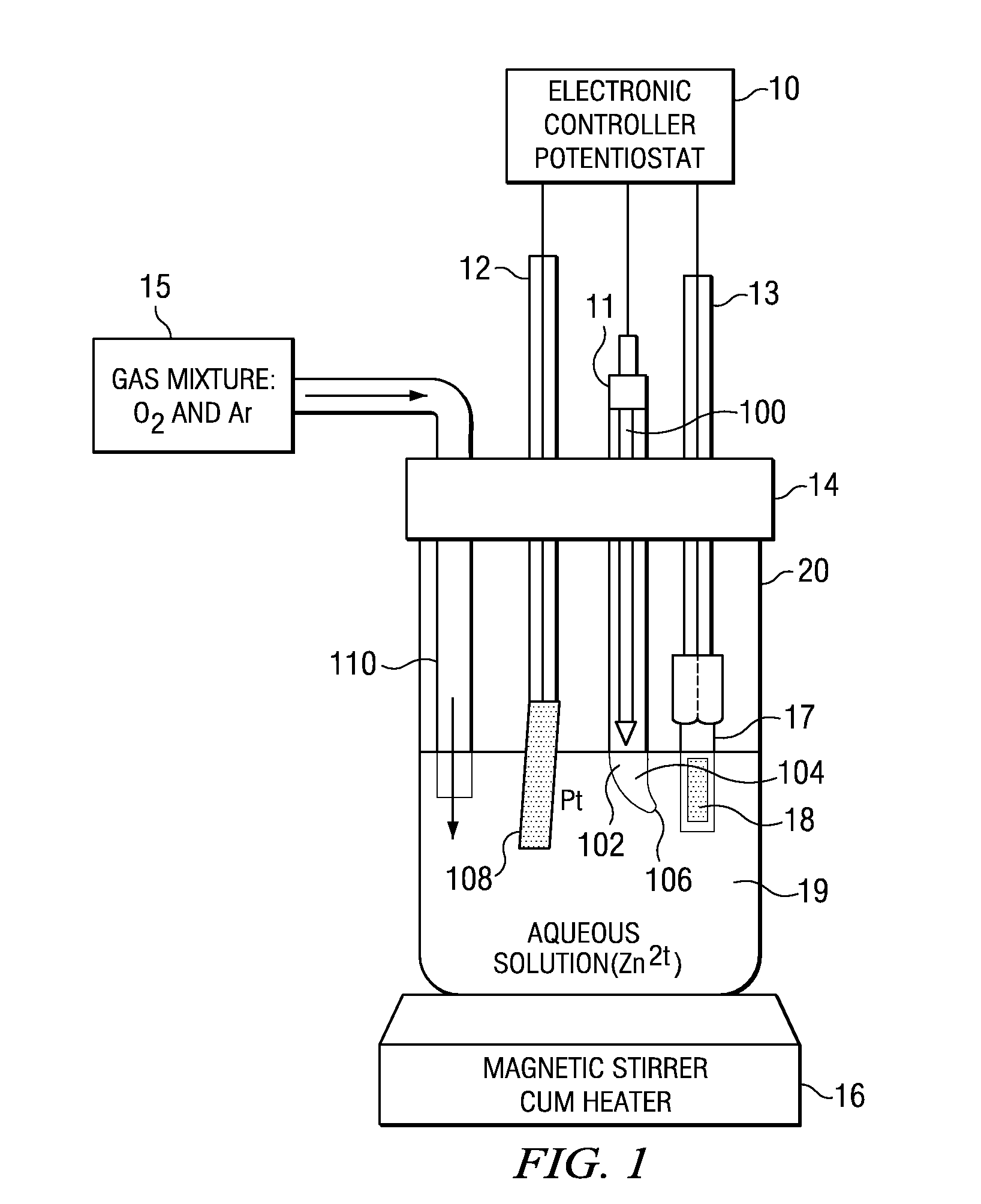

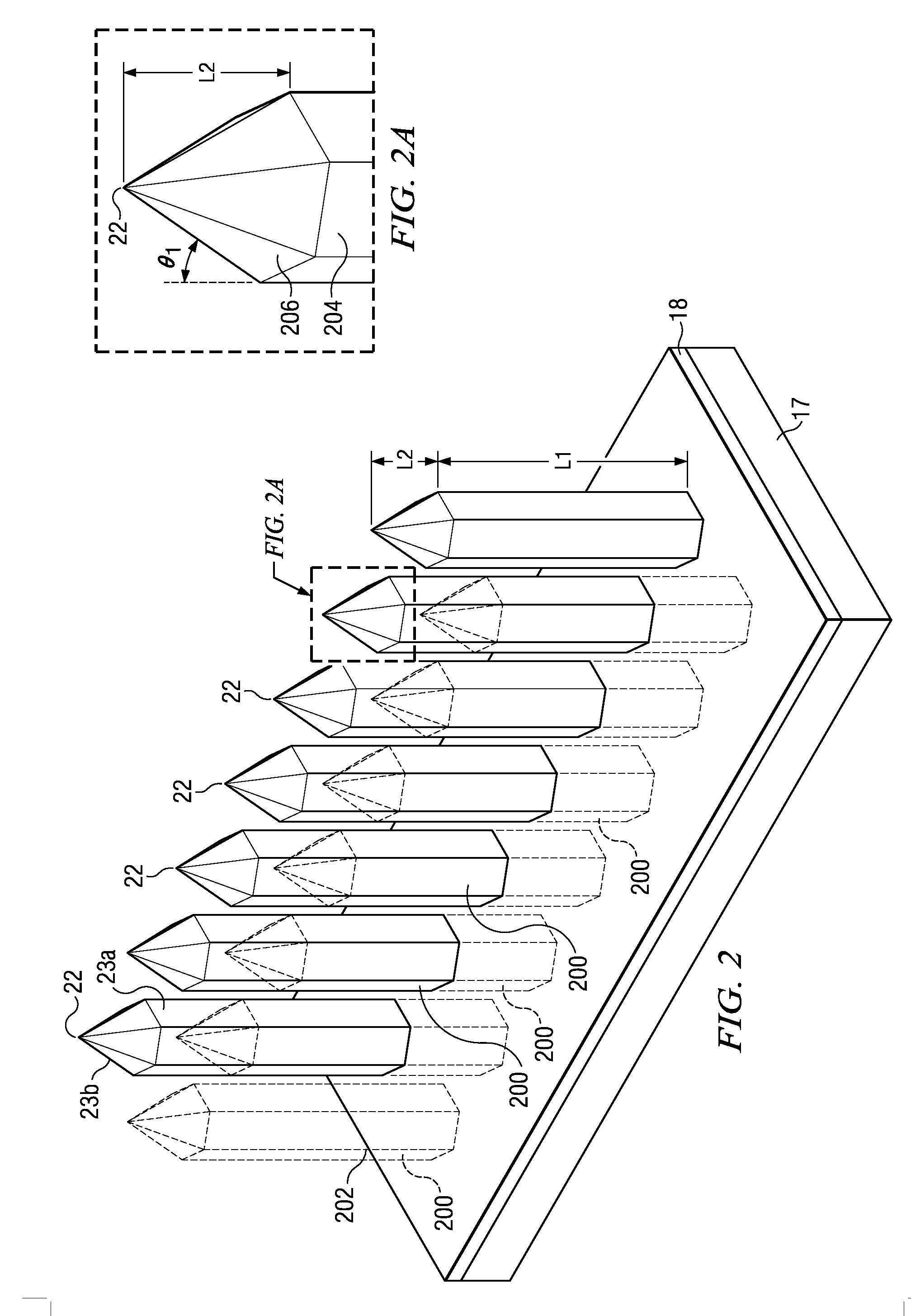

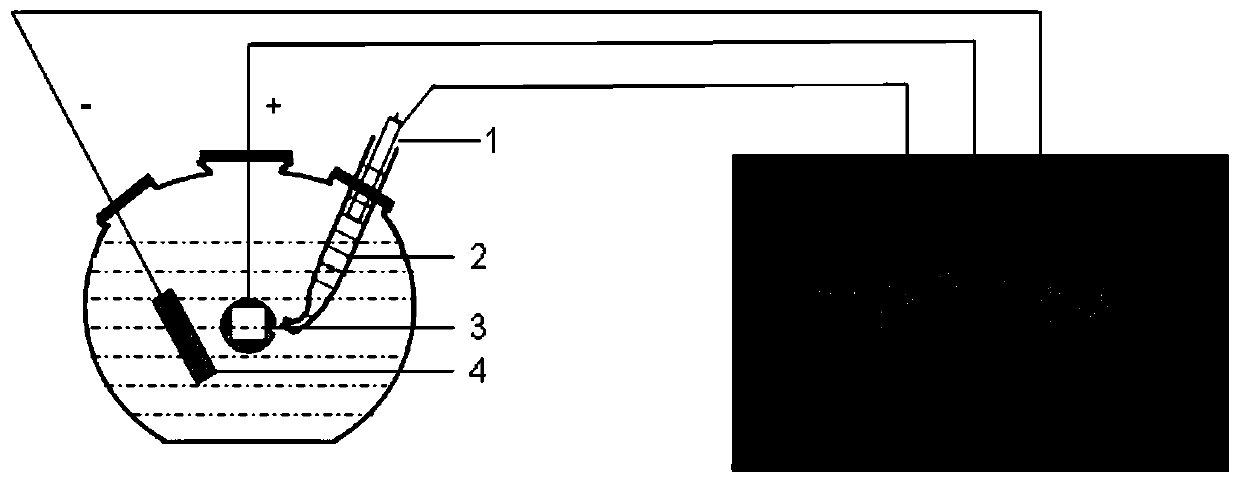

Formation of large arrays of zinc oxide nanostructures using electrodeposition

InactiveUS20090011224A1Increase profitUniform cross-sectional areaElectrolytic inorganic material coatingLayered productsDisplay deviceOxygen

In an aqueous solution of a zinc salt, counter, reference and working electrodes are placed, and an electric potential is applied across the working and reference electrodes. A gas including oxygen and an inert gas is introduced into the aqueous solution. Responsive to these conditions an array of zinc oxide nanostructures grows on a conductive nucleation plate that is a part of the working electrode. The nanostructures have sharp tips, have a more efficient electron emissivity than nanorods made from other materials, and can be used in fabricating field emission lamps and displays.

Owner:NOVAKOR

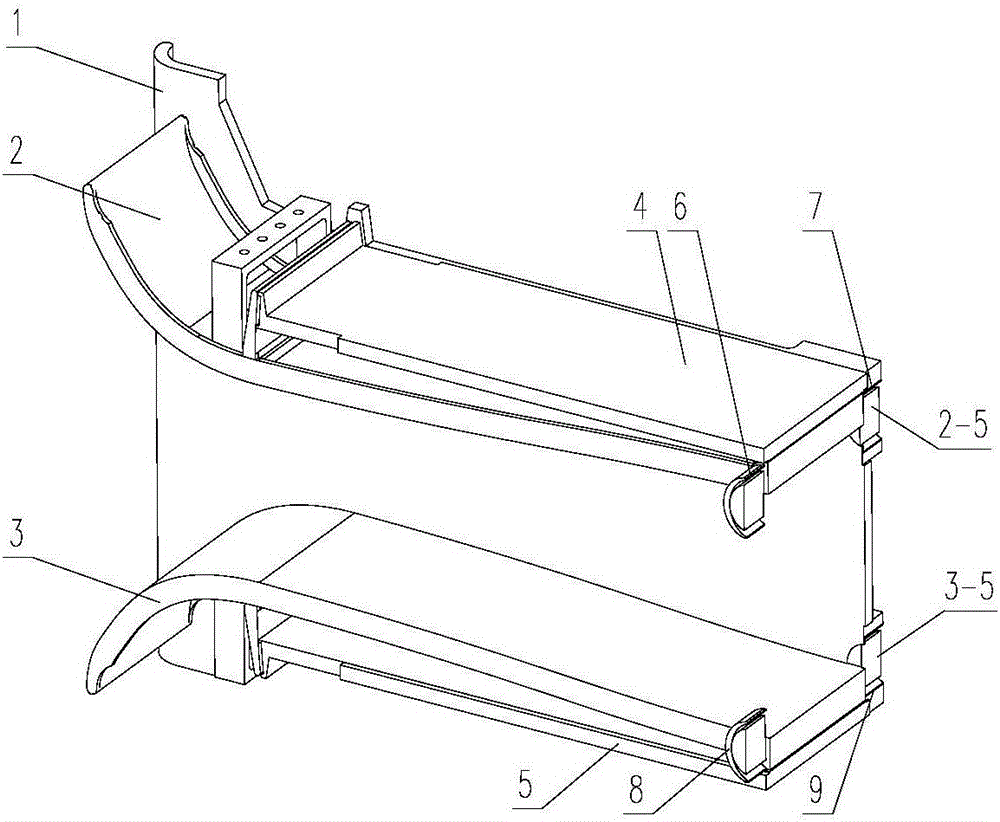

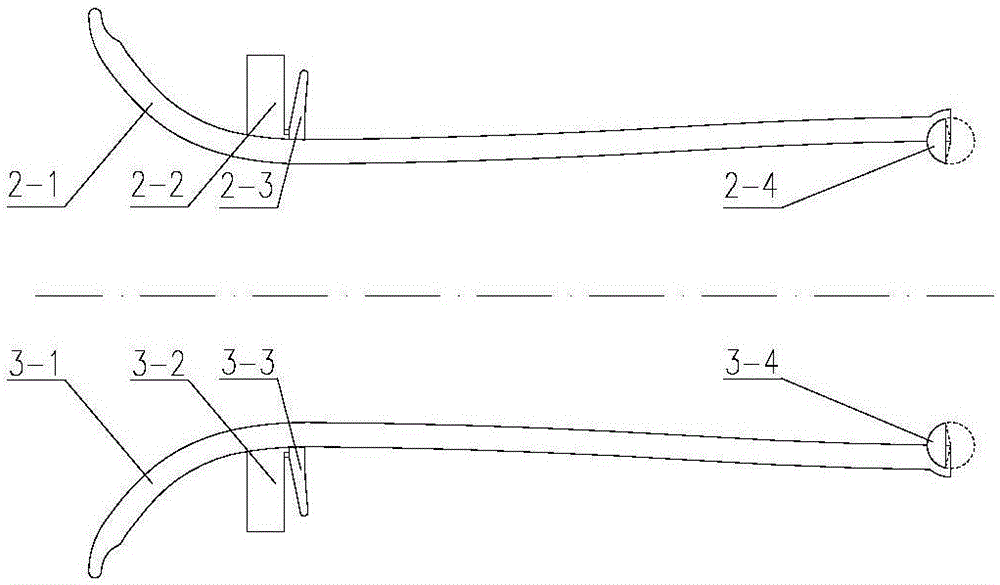

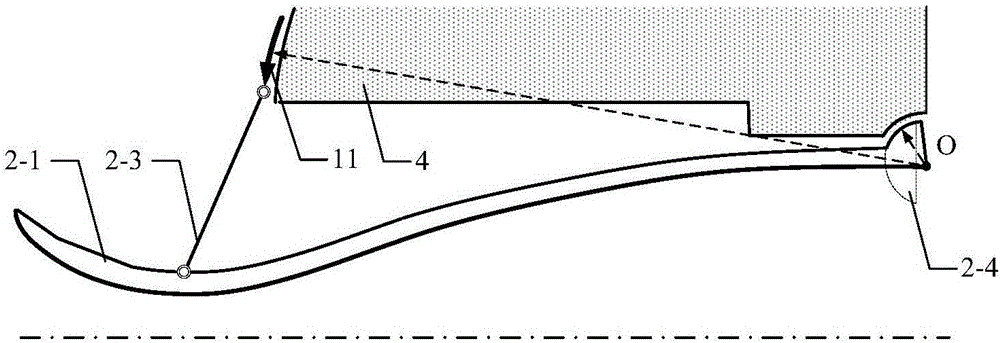

Variable Mach number rotating mechanism based on semicircular bearings

ActiveCN106640418ASimple designReliable designAerodynamic testingJet propulsion plantsEngineeringMechanical engineering

The invention relates to a variable Mach number rotating mechanism based on semicircular bearings. The mechanism comprises a left side wall 1, an upper molding surface mechanism 2, a lower molding surface mechanism 3, an upper support plate 4, a lower support plate 5, an upper right semicircular bearing 6, an upper left semicircular bearing 7, a lower right semicircular bearing 8, a lower left semicircular bearing 9 and a right side wall 10. For a free jet spraying pipe with an open type outlet, the semicircular shaft lug design of the rotating mechanism effectively guarantees a rigid molding surface rotating center shaft as a spraying pipe molding surface outlet edge line so as to effectively guarantee the reference uniformity of the sectional area of the outlet of the spraying pipe and the throat way control height in the Mach number adjusting process; and a fixed molding surface driving end adopts an arc guide rail mode to effectively compensate the defect of incapability of locking the semicircular bearings, so that the adjustment of a driving mechanism is effective and fast.

Owner:AECC SICHUAN GAS TURBINE RES INST

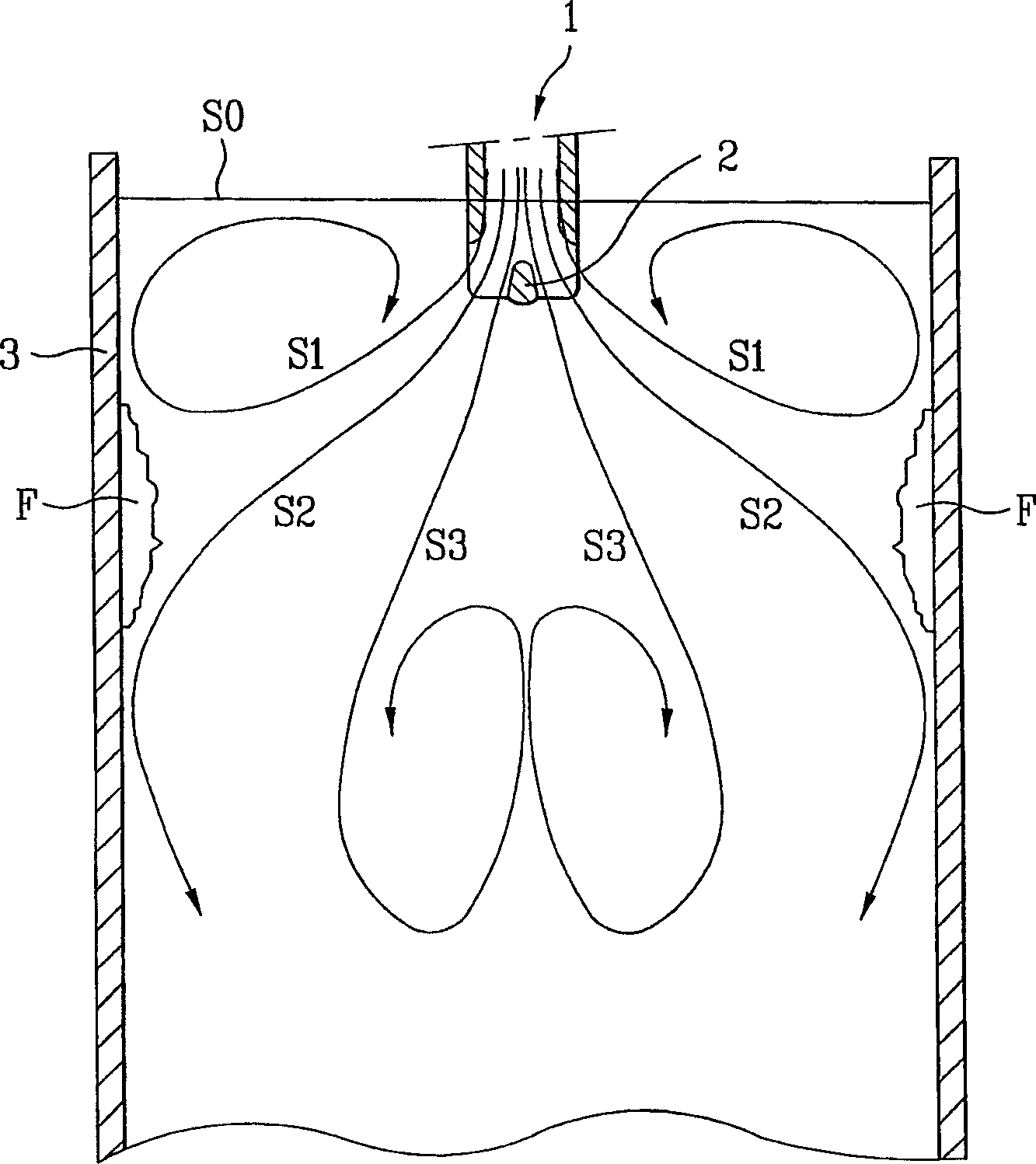

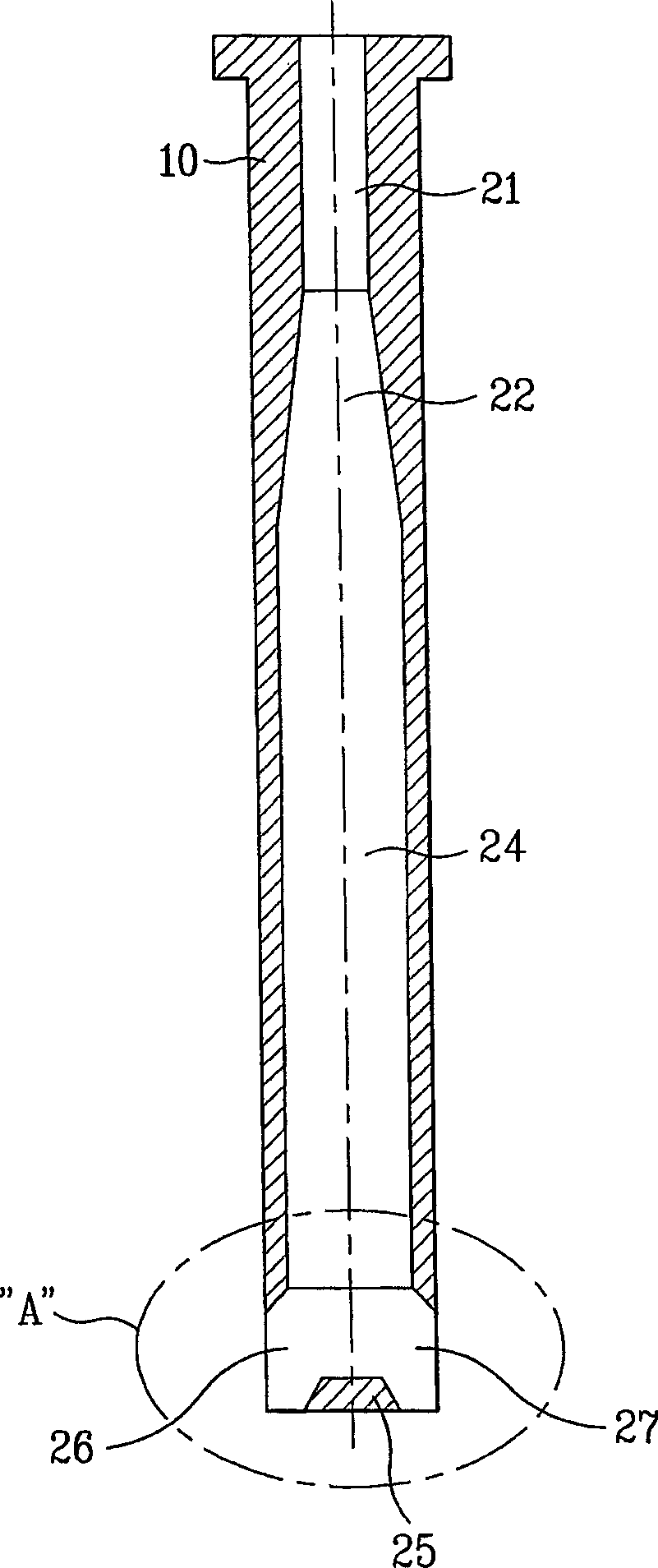

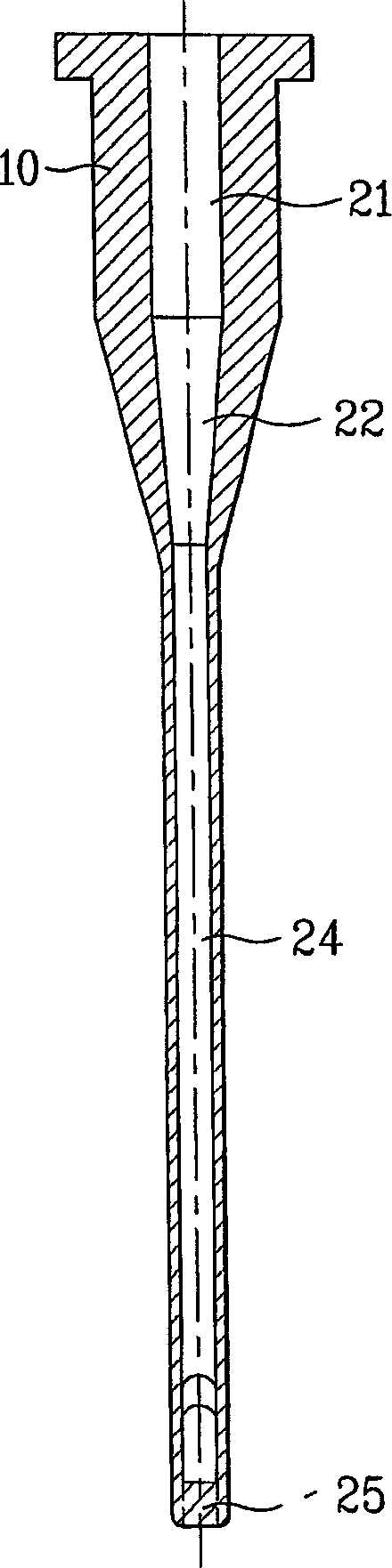

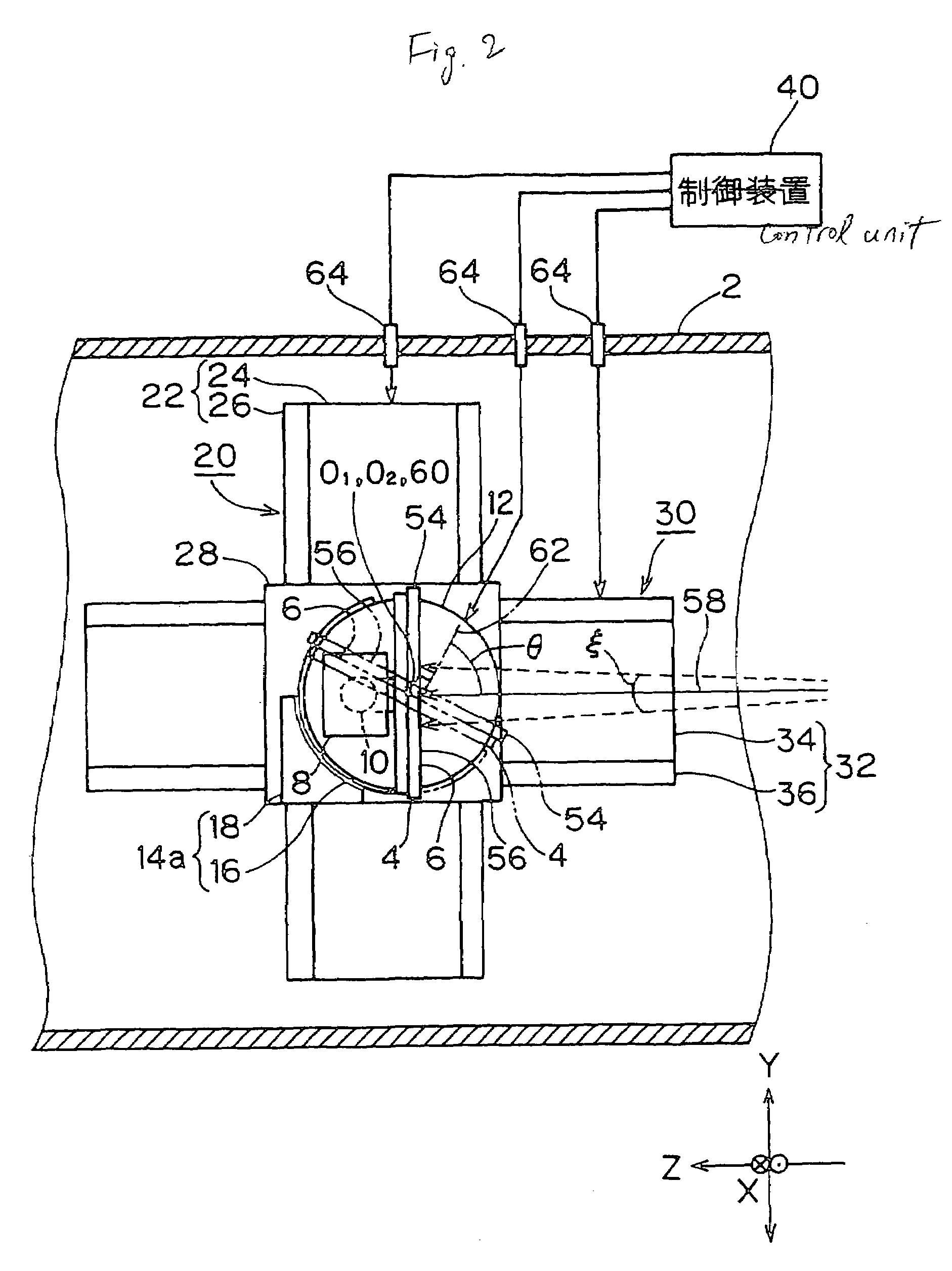

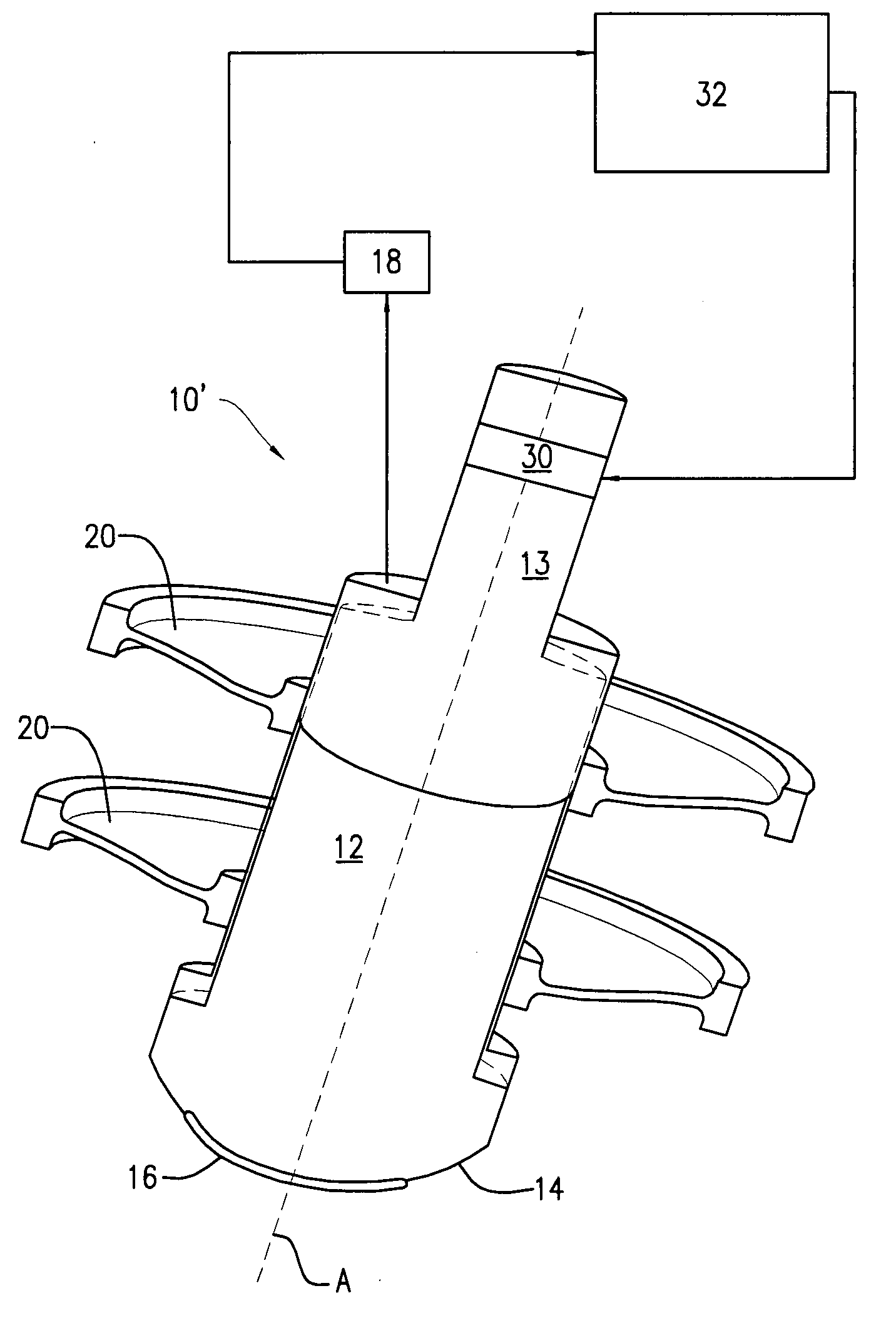

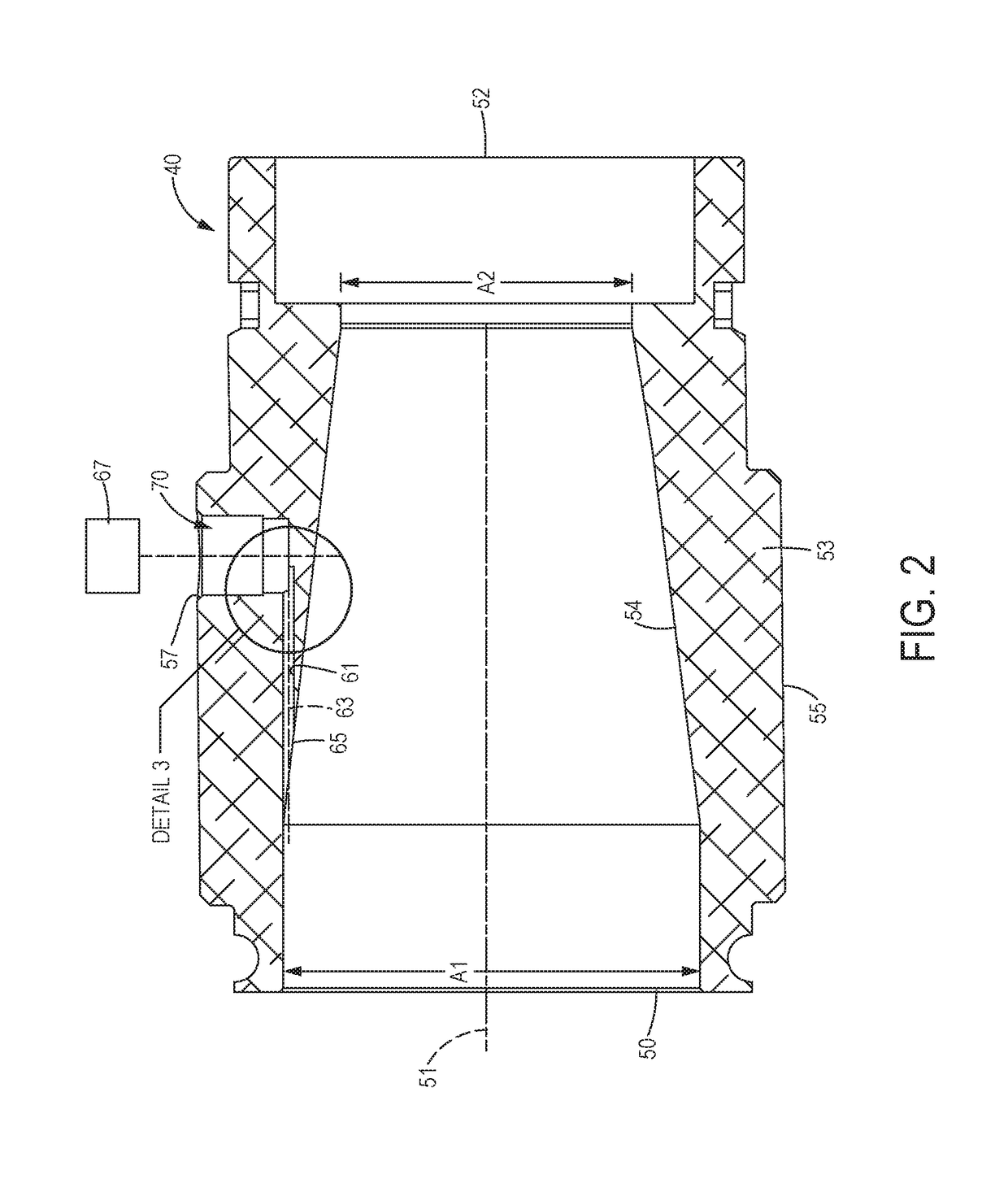

Submerged entry nozzle for continuous casting

ActiveCN1842386AEasy to shapeInhibition stagnation zoneMelt-holding vesselsCasting cleaning apparatusNarrow faceSurface level

This invention provides a submerged entry nozzle for continuous casting which has the optimized nozzle inner shape and is formed in a median strip shape to prevent stagnation region of molten steel from being produced in the nozzle, reduce height difference according to fluctuation of the surface level of molten steel and produce a good quality casting slab having uniform thickness of solidified shell. The submerged entry nozzle for continuous casting comprises: an upper part(31) which is equipped with a refractory material(30) having a convergent inlet(30a), a rest part of which is connected to the inlet to form a slot shaped cross-sectional flow path such that distance(e) between narrow faces of the flow path is long as a whole, distance between wide faces of the flow path is short, and cross sectional area of the flow path is not changed; a conversion part(32) which is connected to the upper part such that thickness of the wall surface of the nozzle is gradually thinned as it goes from the upper part side to the exit side and comprises a slot shaped cross-sectional flow path such that distance between narrow faces of the flow path is gradually increased, distance between wide faces of the flow path is reduced, and cross sectional area of the flow path is not changed; and a lower part(33) which is connected to the conversion part such that thickness of the wall surface of the nozzle is hardly changed as it goes from the conversion part side to the exit side, and in which distance between narrow faces of the flow path is slowly increased, wherein discharge ports(35,36) for guiding flow of molten steel into a mold are installed at an end part of the lower part such that the discharge ports are in the symmetrical state by a separation member(34).

Owner:CHOSUN REFRACTORIES CO LTD

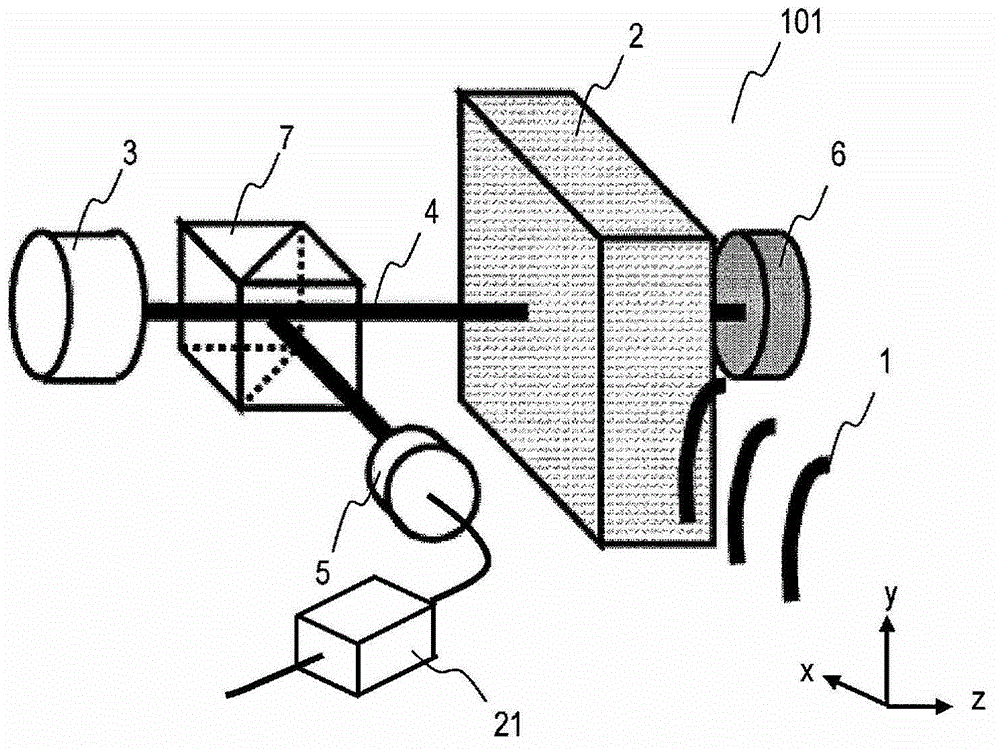

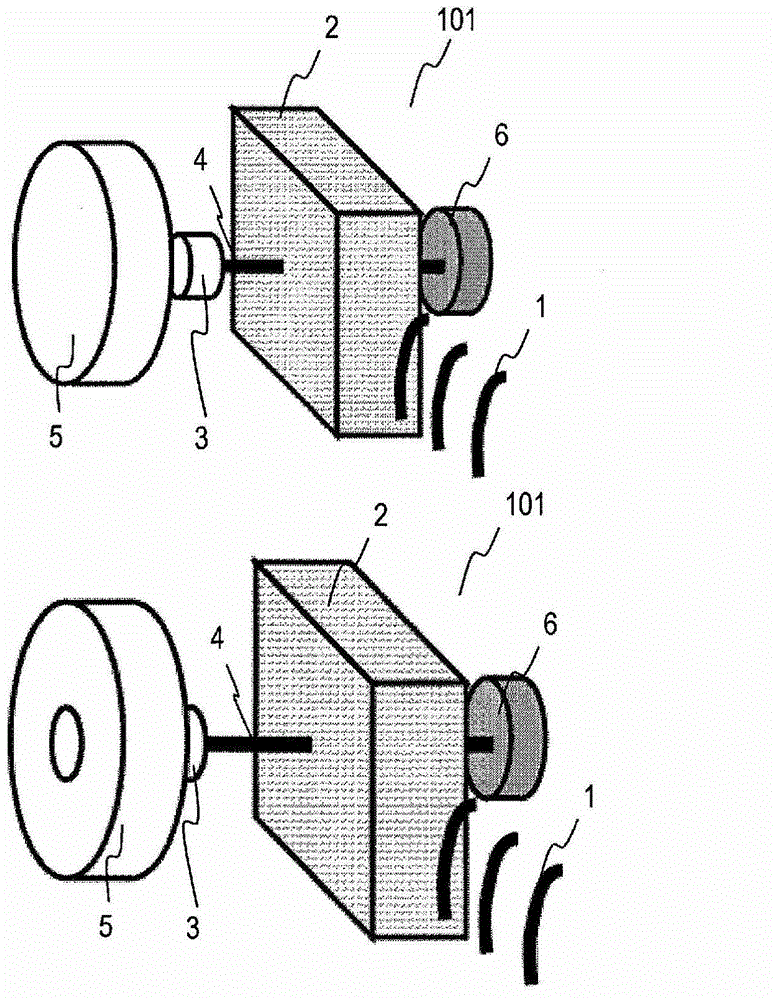

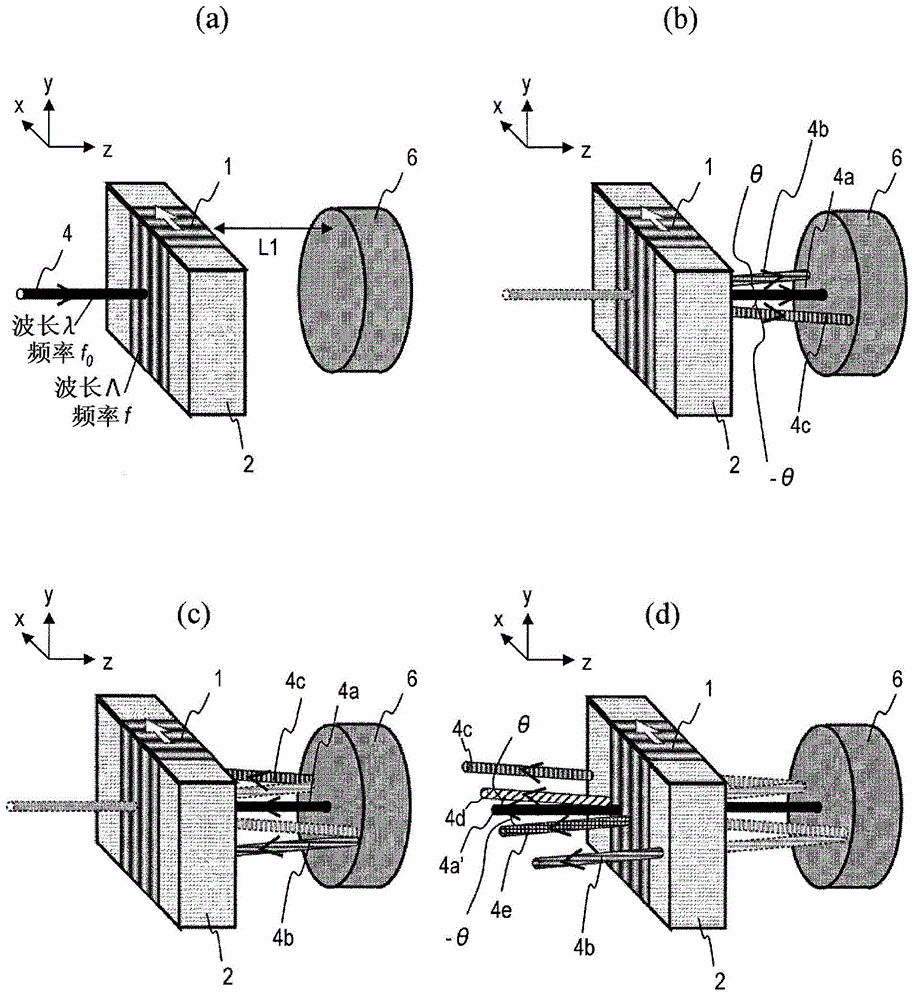

Optical microphone

InactiveCN103154683AConstant areaOptical signal transducersSubsonic/sonic/ultrasonic wave measurementAcoustic waveElectric signal

An optical microphone is provided with a propagation medium unit through which an acoustic wave propagates, a light source which emits a light wave that crosses the acoustic wave propagating through the propagation medium unit and is transmitted through the propagation medium unit, a reflection unit which retroreflects the light wave transmitted through the propagation medium unit, and a photoelectric conversion unit which receives the light wave reflected by the reflection unit and transmitted through the propagation medium unit and outputs an electric signal. In an outward route in which the light wave emitted from the light source is transmitted through the propagation medium unit, a zero-order diffracted light wave, a positive first-order diffracted light wave, and a negative first-order diffracted light wave are each generated according to the refractive-index distribution of the propagation medium unit caused by the propagation of the acoustic wave, and in a return route in which the zero-order diffracted light wave generated in the outward route is transmitted through the propagation medium unit by being reflected by the reflection unit, a zero-order diffracted light wave, a positive first-order diffracted light wave, and a negative first-order diffracted light wave are generated according to the refractive-index distribution of the propagation medium unit caused by the propagation of the acoustic wave. The photoelectric conversion unit detects interference light between the positive first-order diffracted light wave generated in the outward route and the negative first-order diffracted light wave generated in the return route and / or interference light between the negative first-order diffracted light wave generated in the outward route and the positive first-order diffracted light wave generated in the return route.

Owner:PANASONIC CORP

Crossed gap ferrite cores

InactiveUS8035472B2Variable sizeLess susceptibleFixed inductancesTransformers/inductances magnetic coresEngineeringInductor

Owner:POWER INTEGRATIONS INC

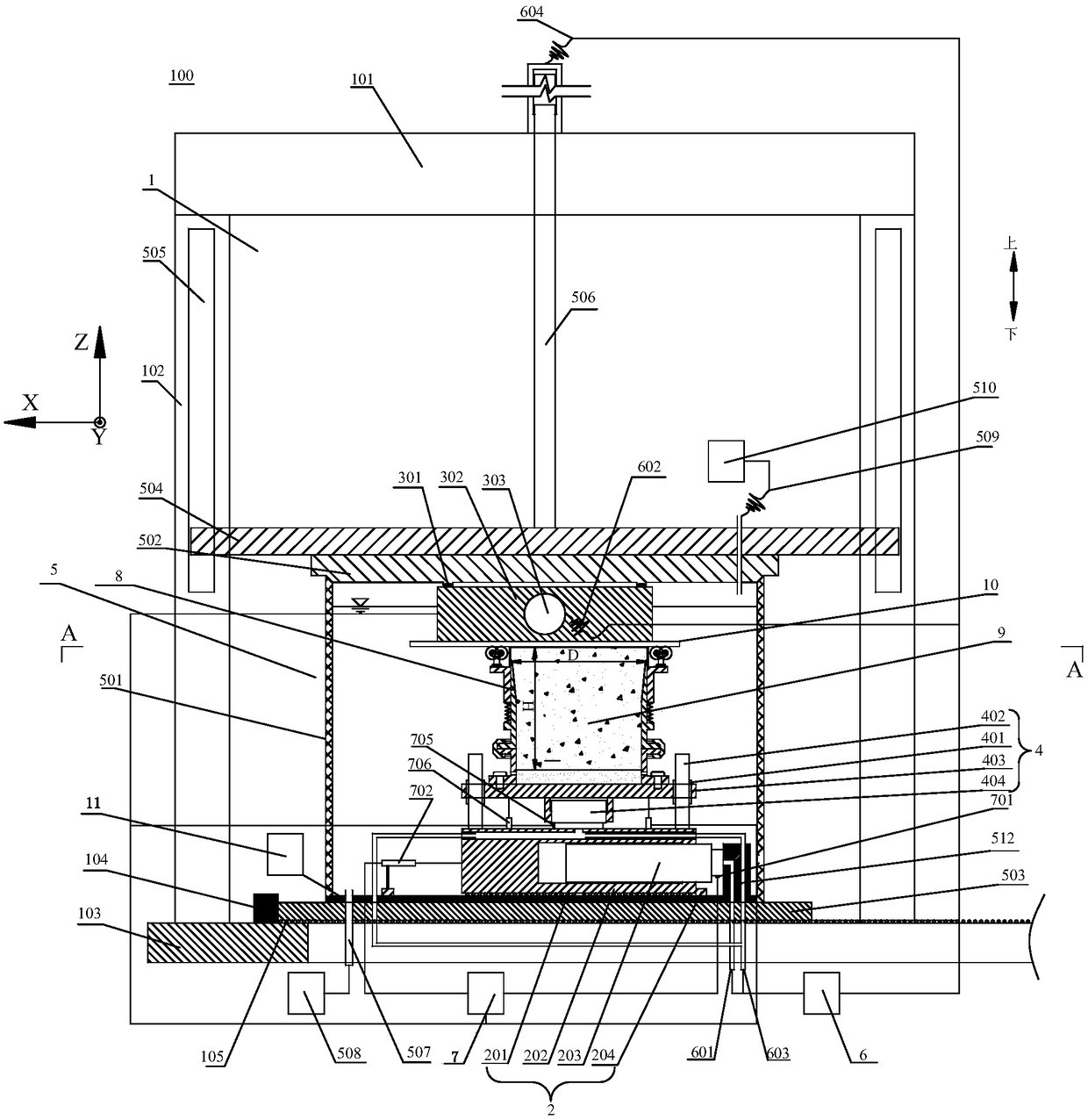

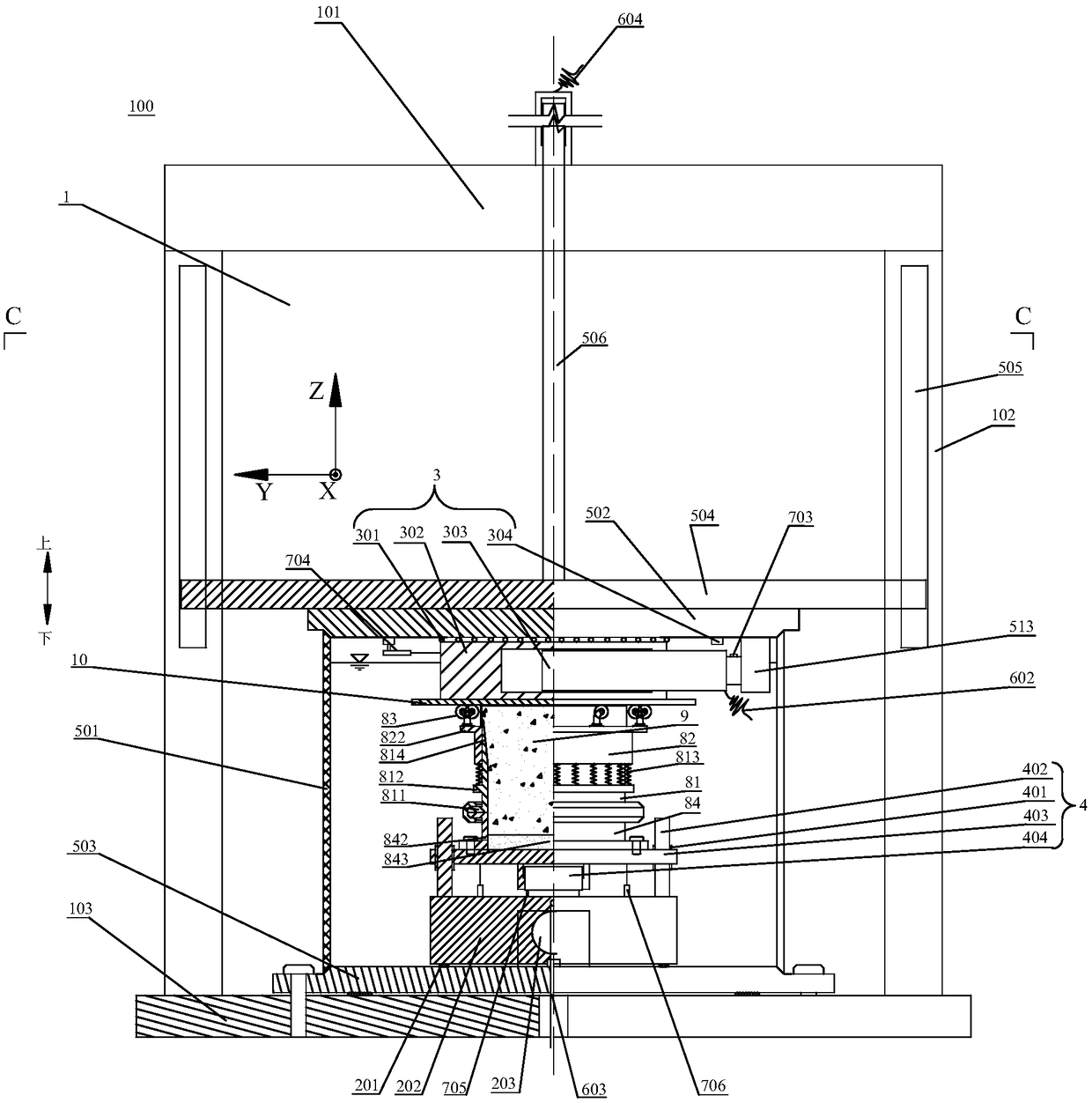

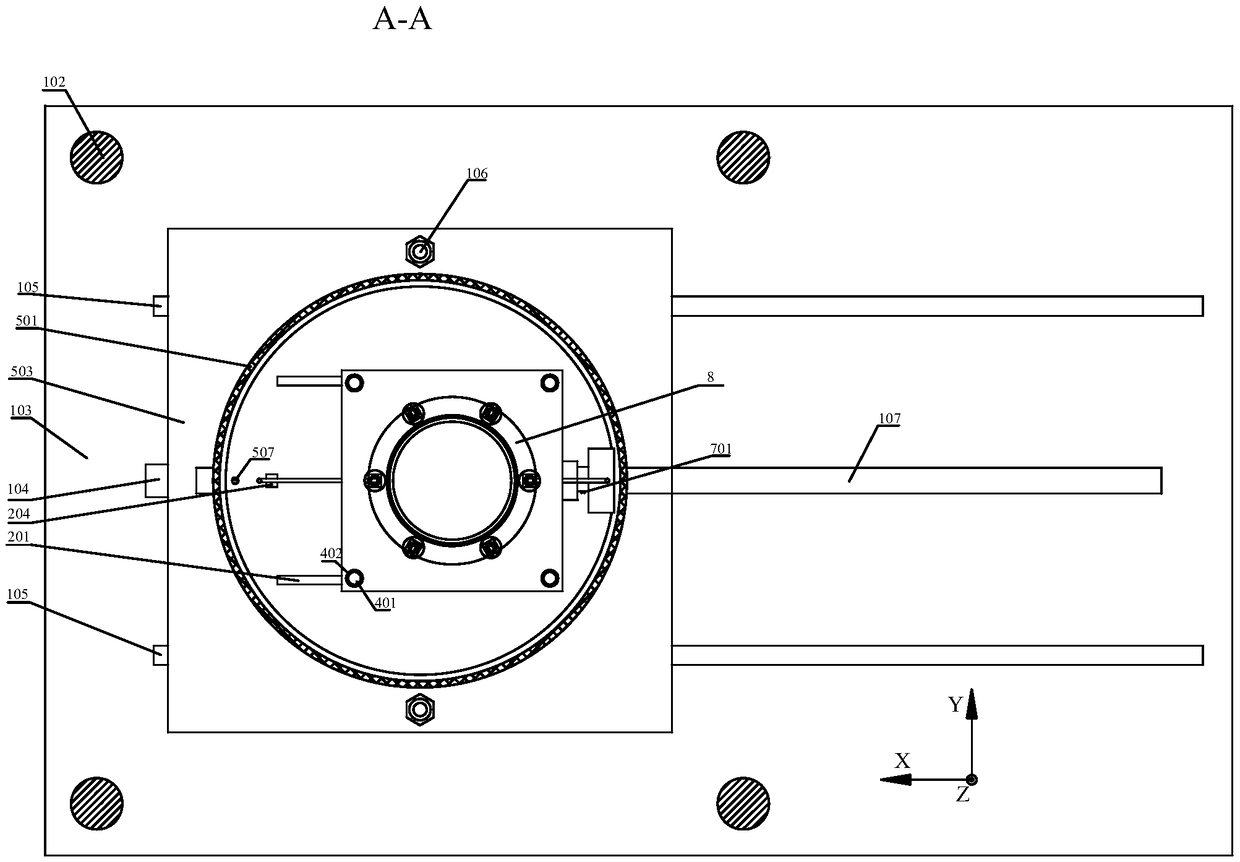

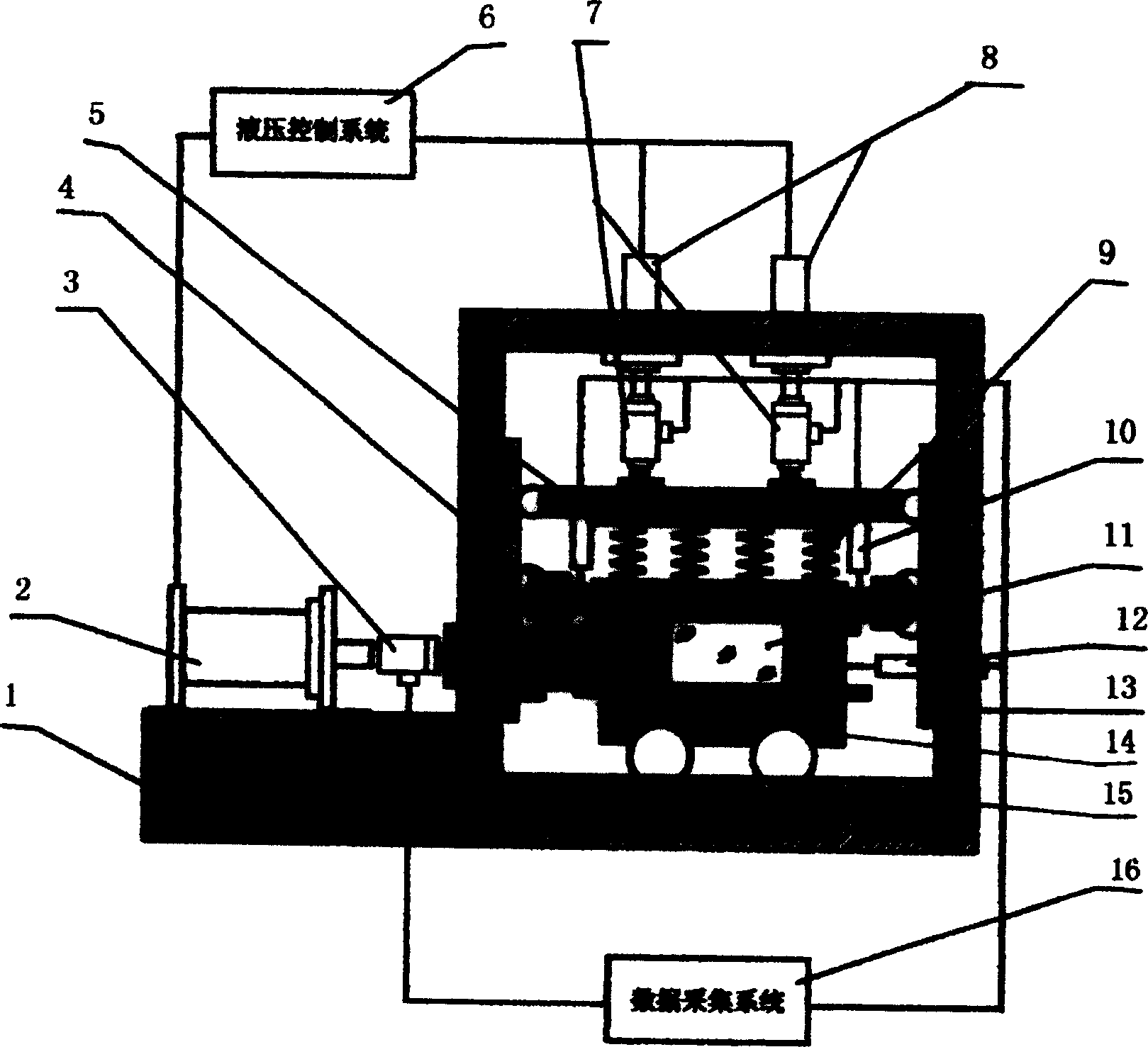

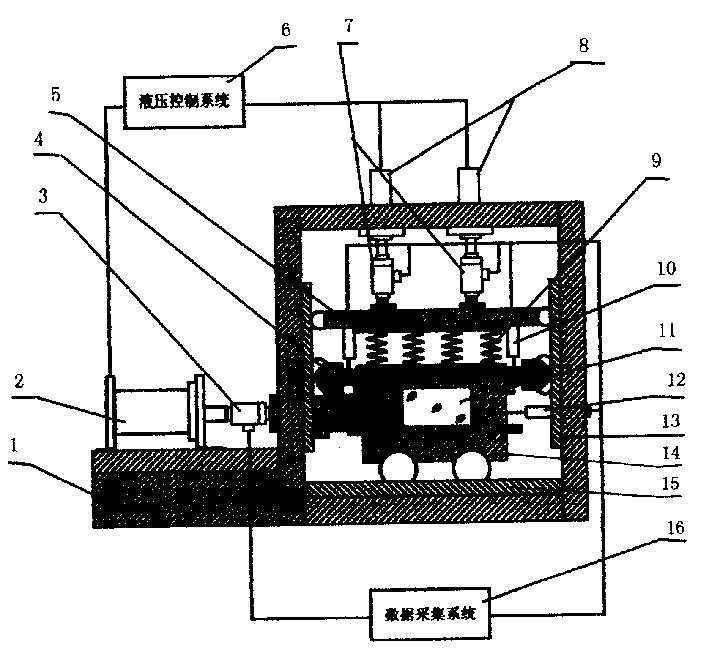

Soil and structure contact surface testing machine

PendingCN109060504AConstant areaUniform strainMaterial strength using steady shearing forcesSoil typeTemperature control

The invention discloses a soil and structure contact surface testing machine. The soil and structure contact surface testing machine comprises a body frame, a structure panel, an X-direction motion system, a Y-direction motion system, a Z-direction motion system, a hydraulic loading and control system, a data acquisition system, a confining pressure chamber system, a temperature control system andthe like. The soil and structure contact surface testing machine is specially designed for researching the problem of the soil and structure contact surfaces, and can complete the research on the problem of the contact surfaces between various soil types, such as clay, fine-grained soil and coarse-grained soil and all kinds of structural panels under various saturation or non-saturation temperature field conditions. The normal stress is directly applied to the contact surfaces during the test. The concept is clear and the stress state is clear, the uniform strain of the soil can be ensured, the strain localization phenomenon is eliminated, the constant areas of the contact surfaces are ensured, and it is ensured that the results are true and reliable.

Owner:TSINGHUA UNIV

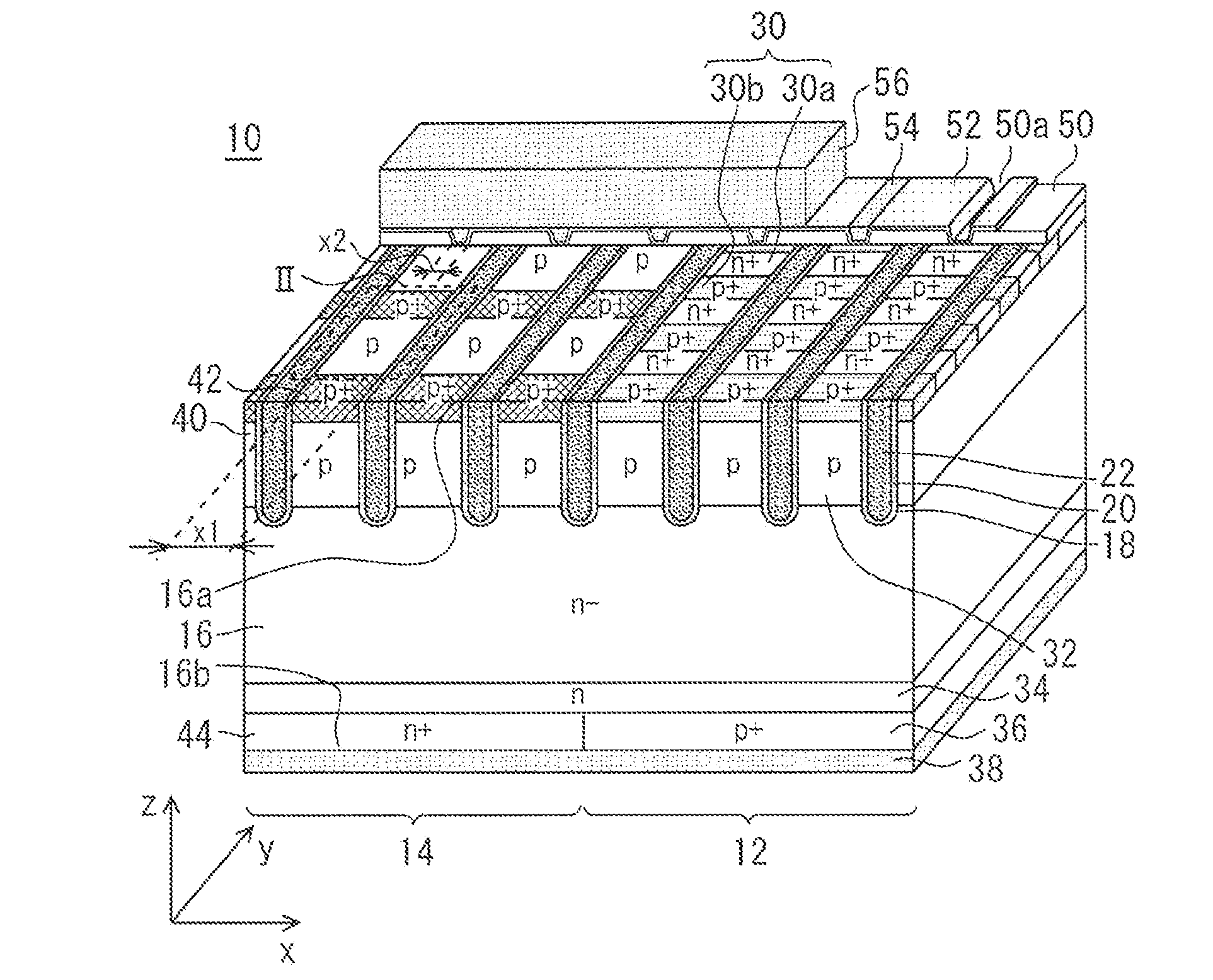

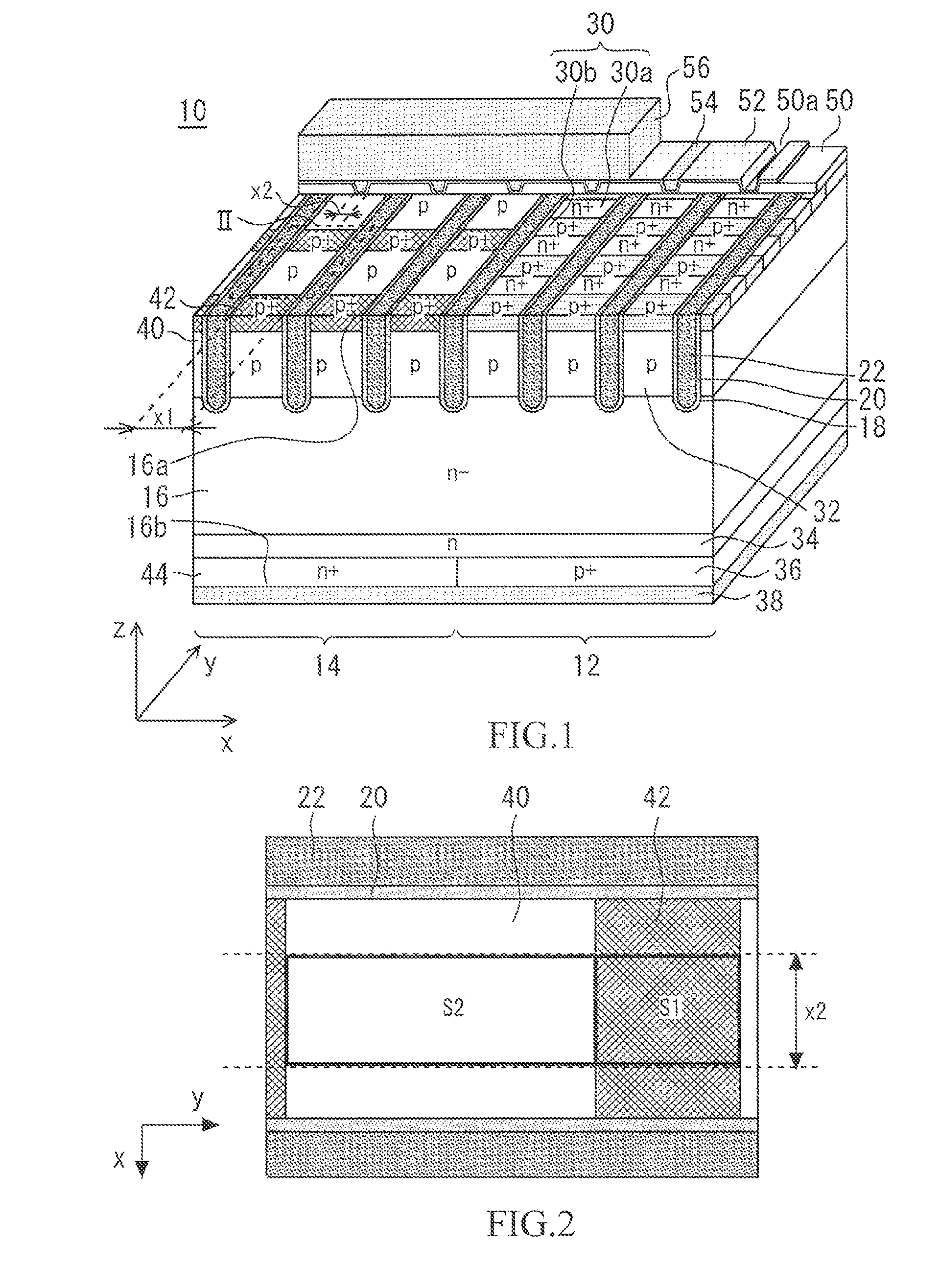

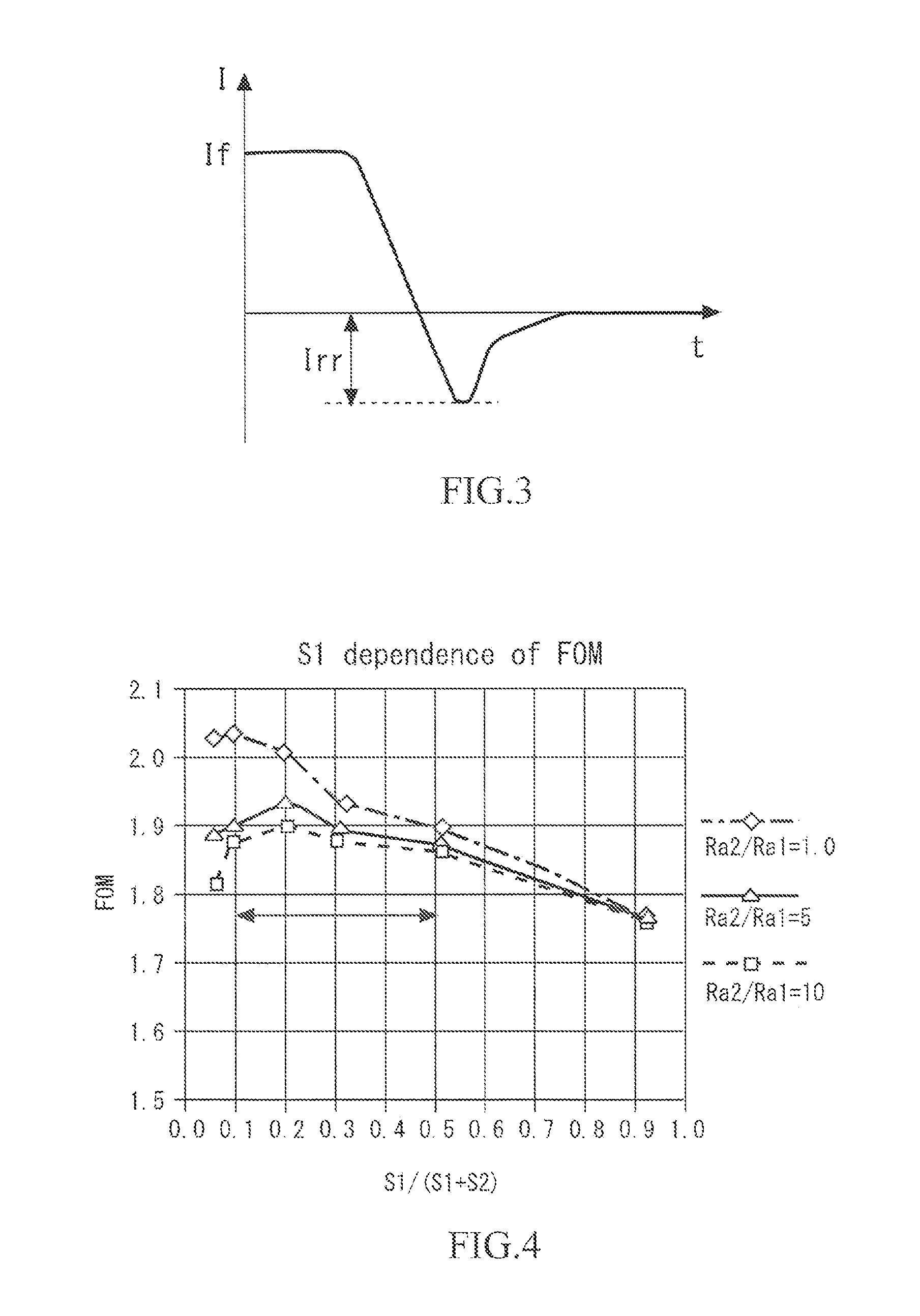

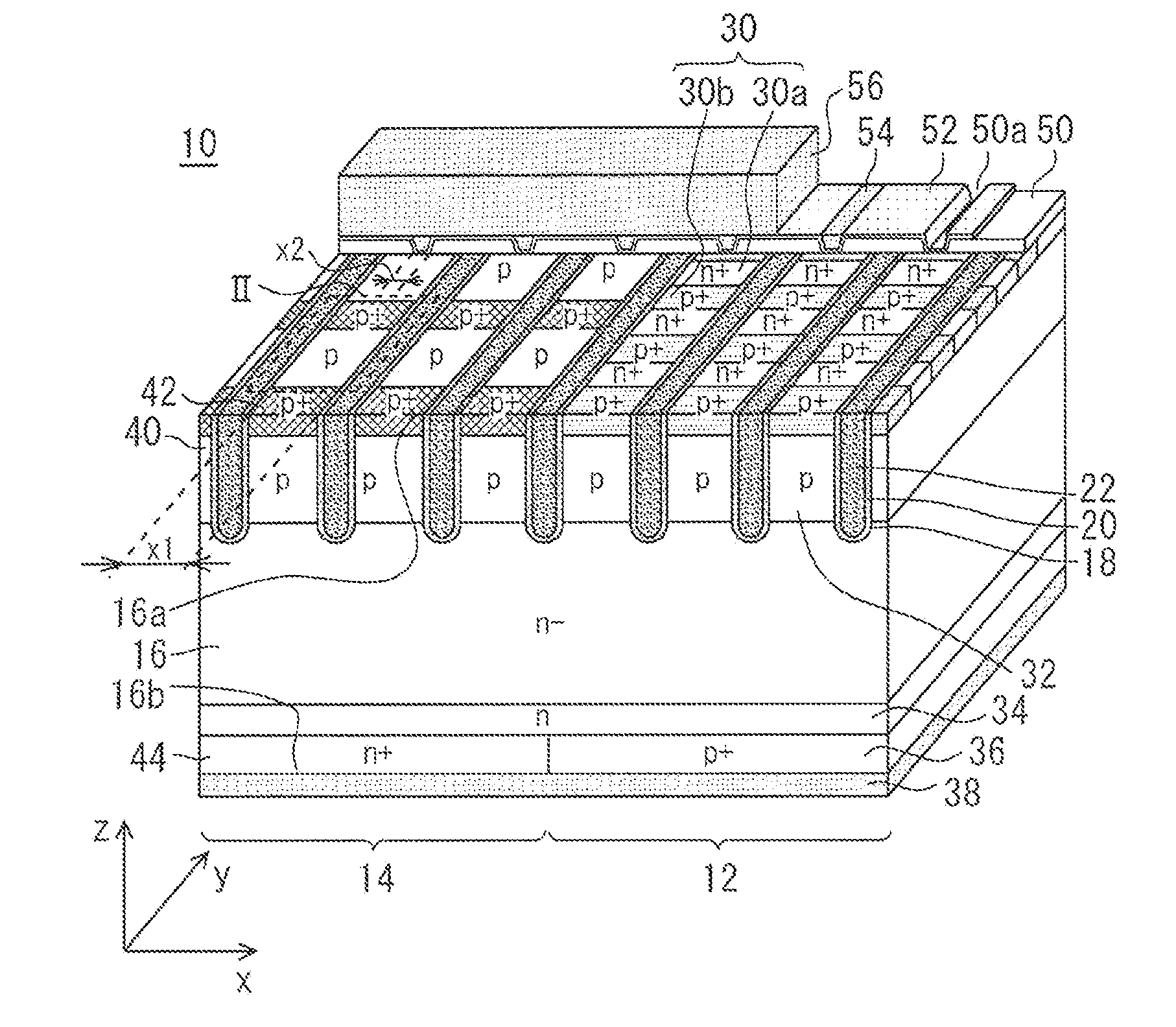

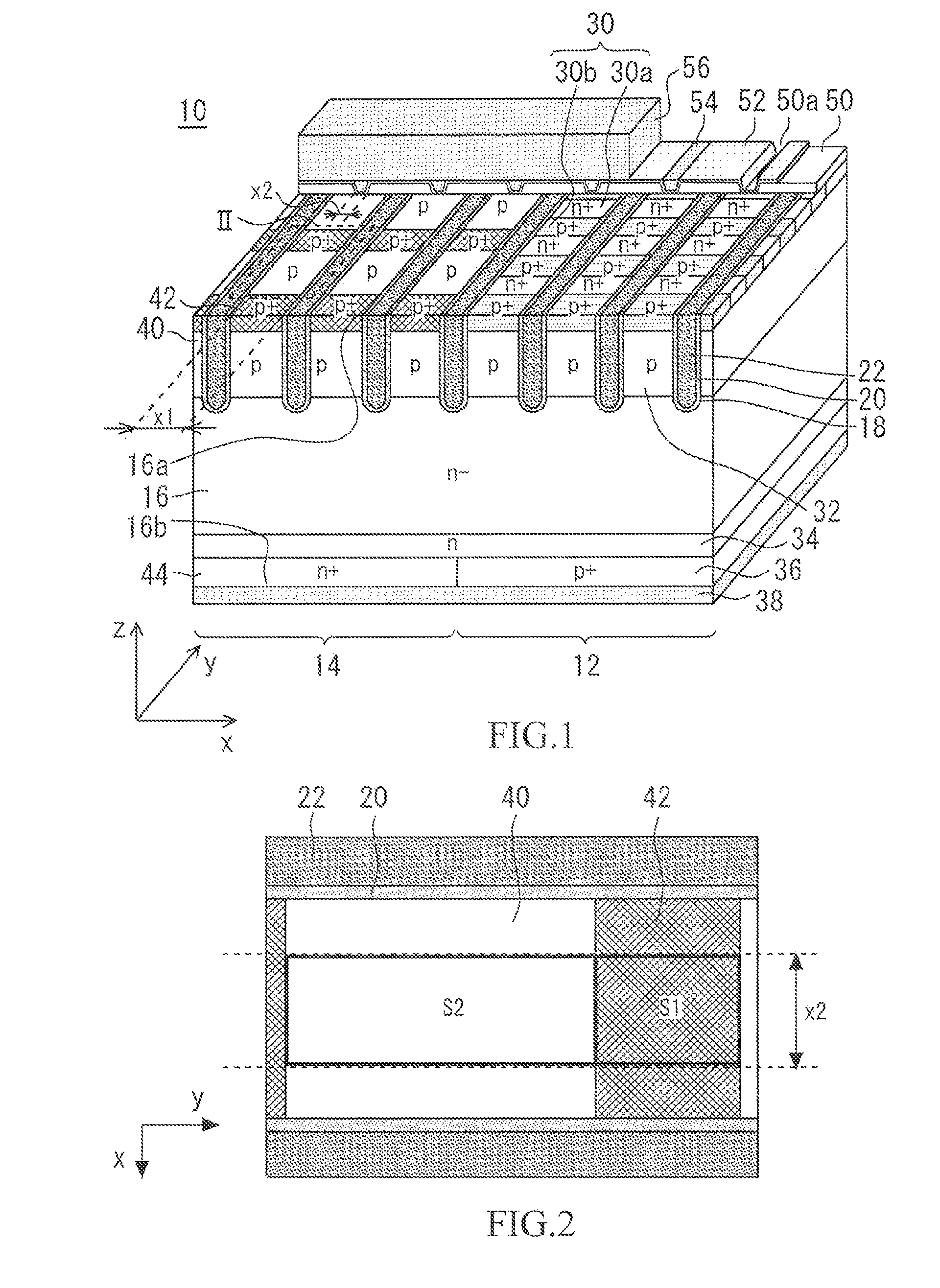

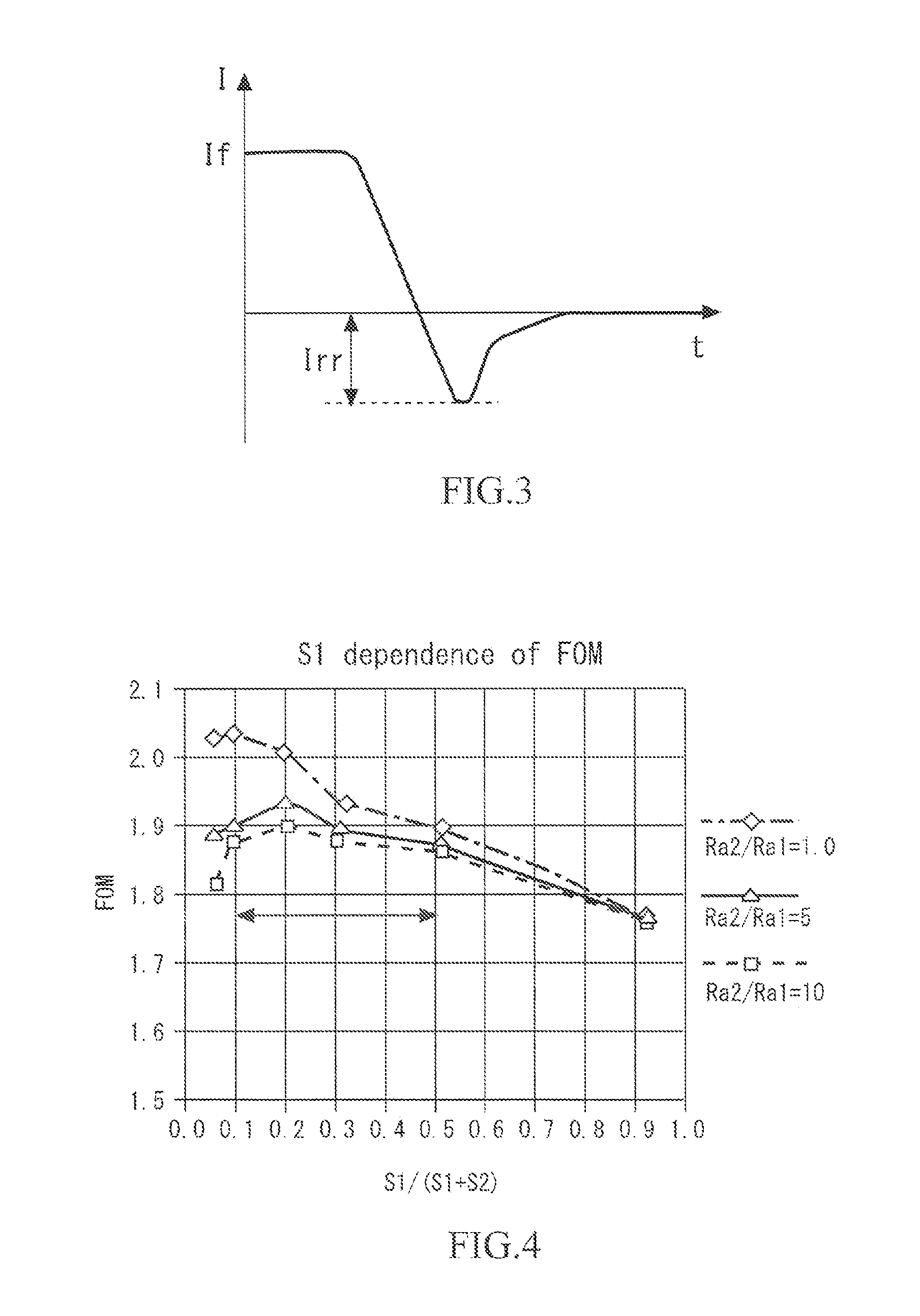

Reverse conducting semiconductor device

ActiveUS20160148928A1Large widthConstant areaTransistorSemiconductor/solid-state device detailsHigh concentrationDevice material

A reverse conducting semiconductor device includes a high-concentration anode layer and a barrier metal layer, the width of the high-concentration anode layer is set larger than the width of contact of the barrier metal layer and the high-concentration anode layer, thereby ensuring that the area of contact between the barrier metal layer and the high-concentration anode layer is constant.

Owner:MITSUBISHI ELECTRIC CORP

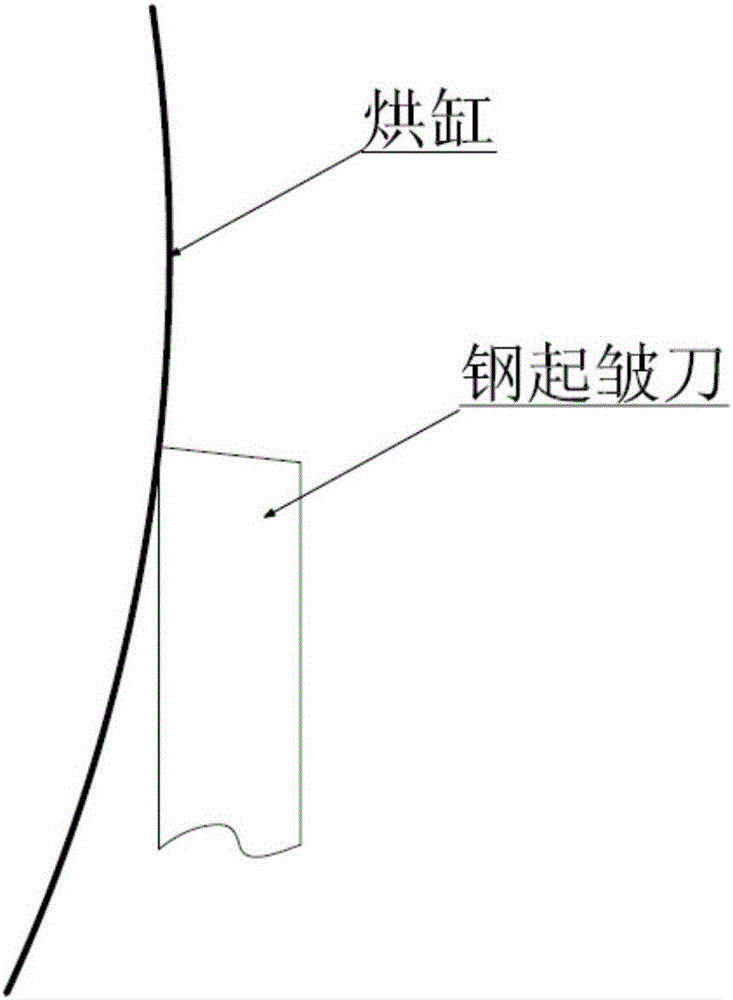

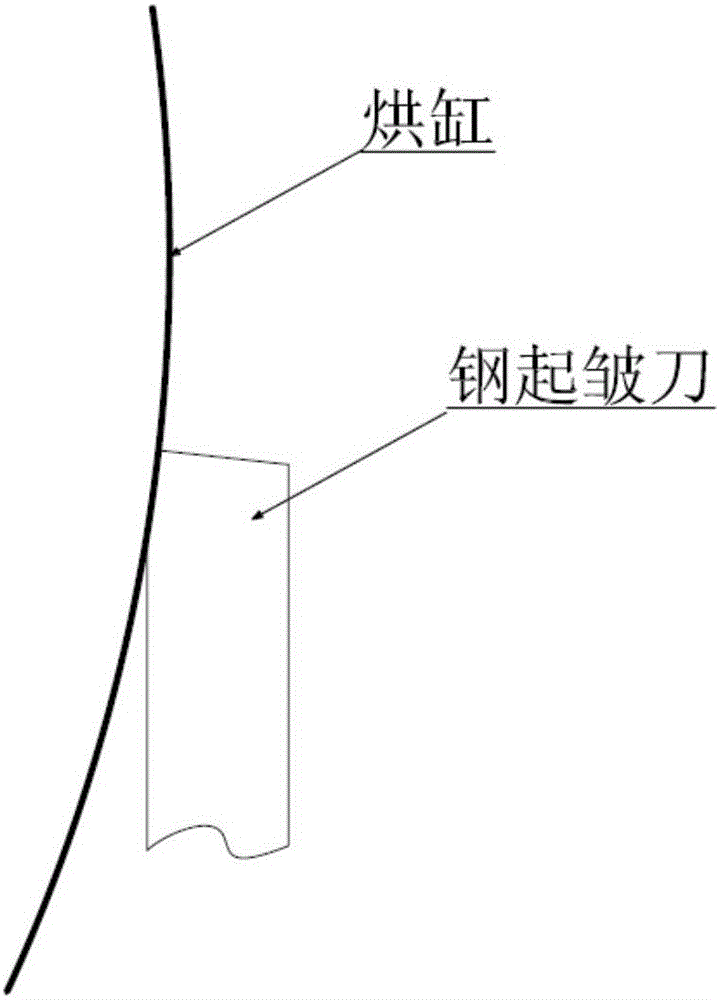

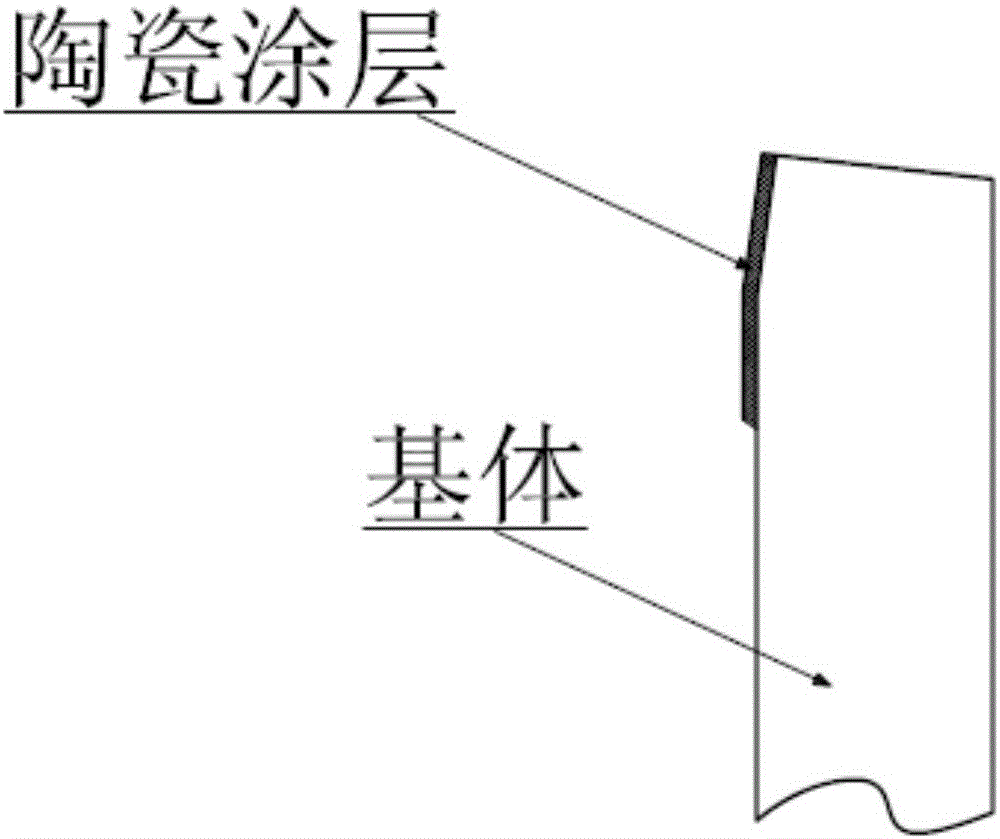

Wrinkling cutter and manufacturing method thereof

InactiveCN106182906AConstant friction areaConstant areaMechanical working/deformationWrinkled structureWear resistant

The invention provides a wrinkling cutter and a manufacturing method thereof. The wrinkling cutter comprises a base. The top end face and the work face of the base are provided with wear-resistant coatings. The manufacturing method of the wrinkling cutter comprises the following steps that the wear-resistant coatings are formed on the top end face and the work face of the base, and the wrinkling cutter is obtained through grinding. The contact portion of the wrinkling cutter and a drying cylinder is very small and constant, the shape is stable, and the wrinkling cutter is of a strip-shaped structure with the width being just 0.15-0.40 mm, so that the paper surface wrinkle structure on paper basically has no change. By the adoption of the technical scheme, the linear pressure of a cutting edge of the wrinkling cutter is generally 2.5-3 N / mm, so that friction force between the wrinkling cutter and the drying cylinder is effectively reduced, resistance in the rotation process of the drying cylinder is reduced, and the purpose of saving energy is achieved. The wrinkling cutter integrates the advantages that the friction portion is constant in area and is provided with the high-wear-resistance coatings, the paper surface impacted portion has the high wear resistance and high impact resistance, and the service life is 30-60 times that of a common steel wrinkling cutter.

Owner:北京华恩表面工程技术有限公司

Circular loading shear apparatus for observing earth and structural member contact face mechanical property

InactiveCN1188688CGuaranteed to leakClose contactMaterial strength using tensile/compressive forcesRelative displacementControl system

A cyclic loading shear tester for observing the mechanical characteristics of interface between earth and structural member is composed of the earth container carriage with organic glass window, normal boundary control unit put on structural plate on the earth, data acquisition system, and hydraulic loading and control system. Its advnatages are high test and measuring precision, and use of digital photography.

Owner:TSINGHUA UNIV

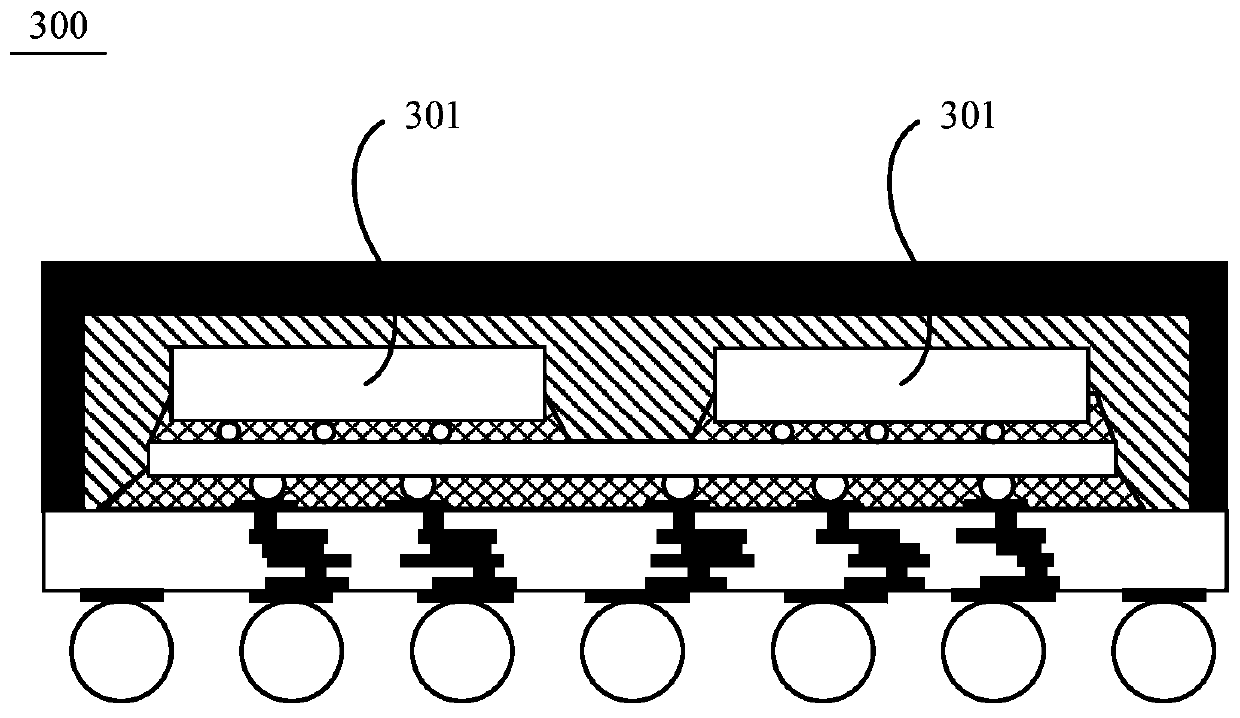

Circuit board assembly and terminal

ActiveCN111511108ALarge capacitySave spaceCircuit arrangements on support structuresHigh voltage circuit adaptationsElectrical connectionStructural engineering

The invention discloses a circuit board assembly and a terminal, relates to the technical field of electronic devices, and aims to solve the problem that various electronic components cannot be integrated on a circuit board at the same time under the condition that the planar area occupied by the circuit board in the whole electronic product is limited. The circuit board assembly comprises at least two layers of circuit boards and at least one first adapter plate, wherein the circuit board is provided with an upper surface and a lower surface which are oppositely arranged, the upper surface and the lower surface of the circuit board are used for integrating electronic components, and the first adapter plate is arranged on at least one side of the at least two layers of circuit boards and is electrically connected with the at least two layers of circuit boards.

Owner:HUAWEI TECH CO LTD

Reverse conducting semiconductor device

Owner:MITSUBISHI ELECTRIC CORP

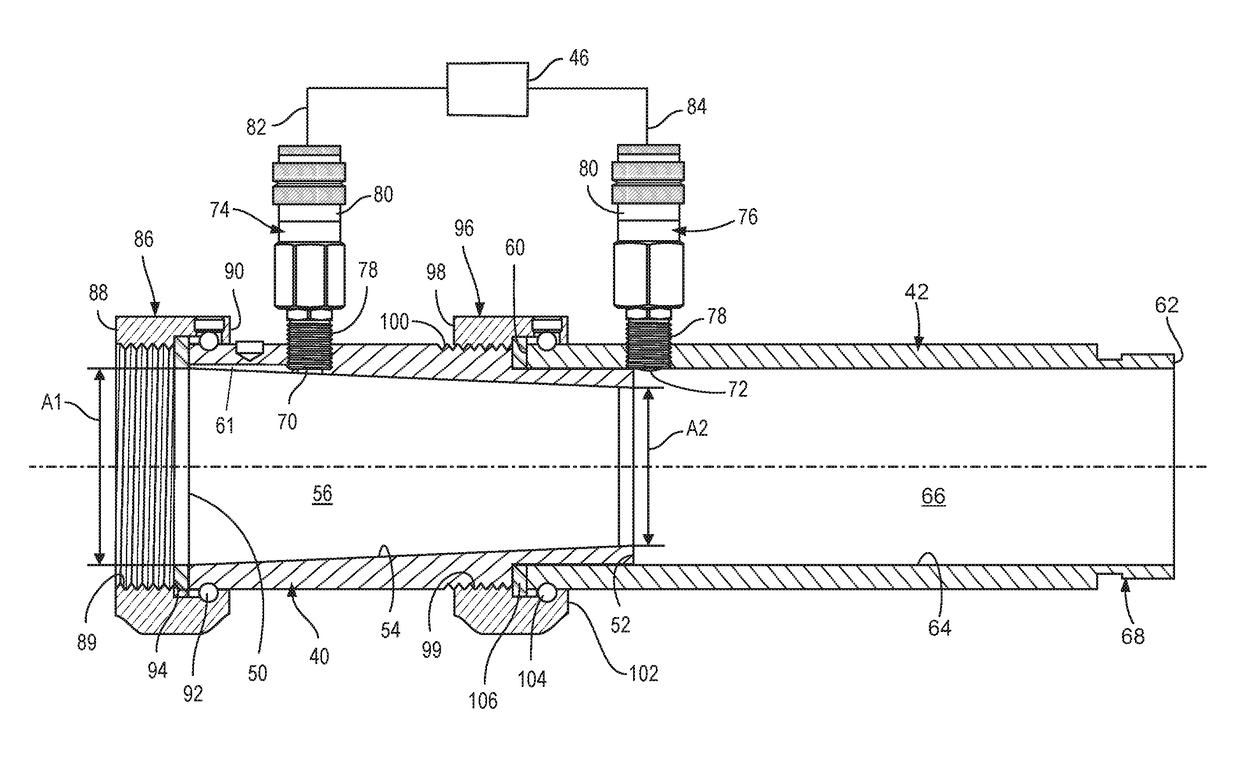

Ion beam irradiation apparatus

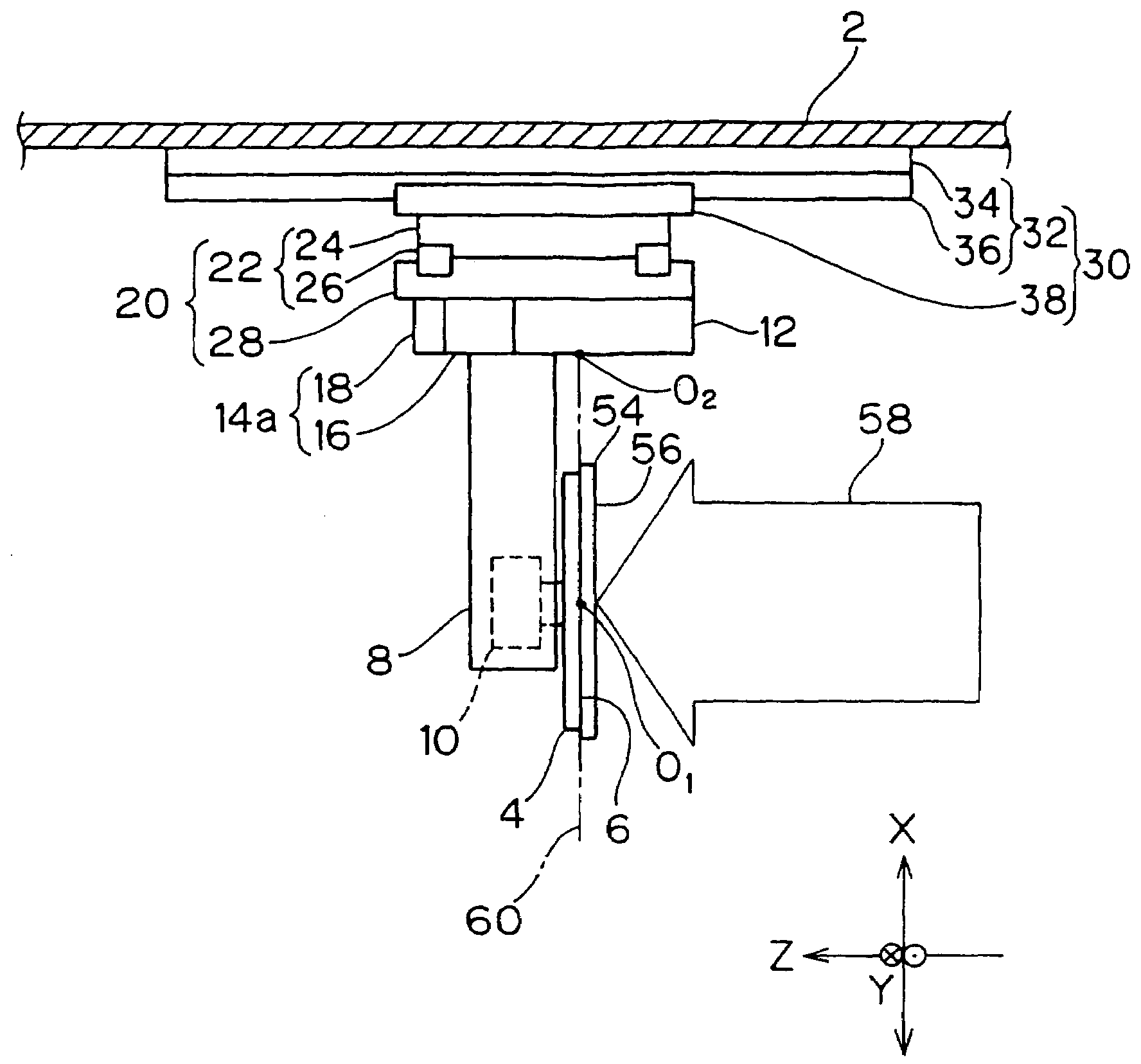

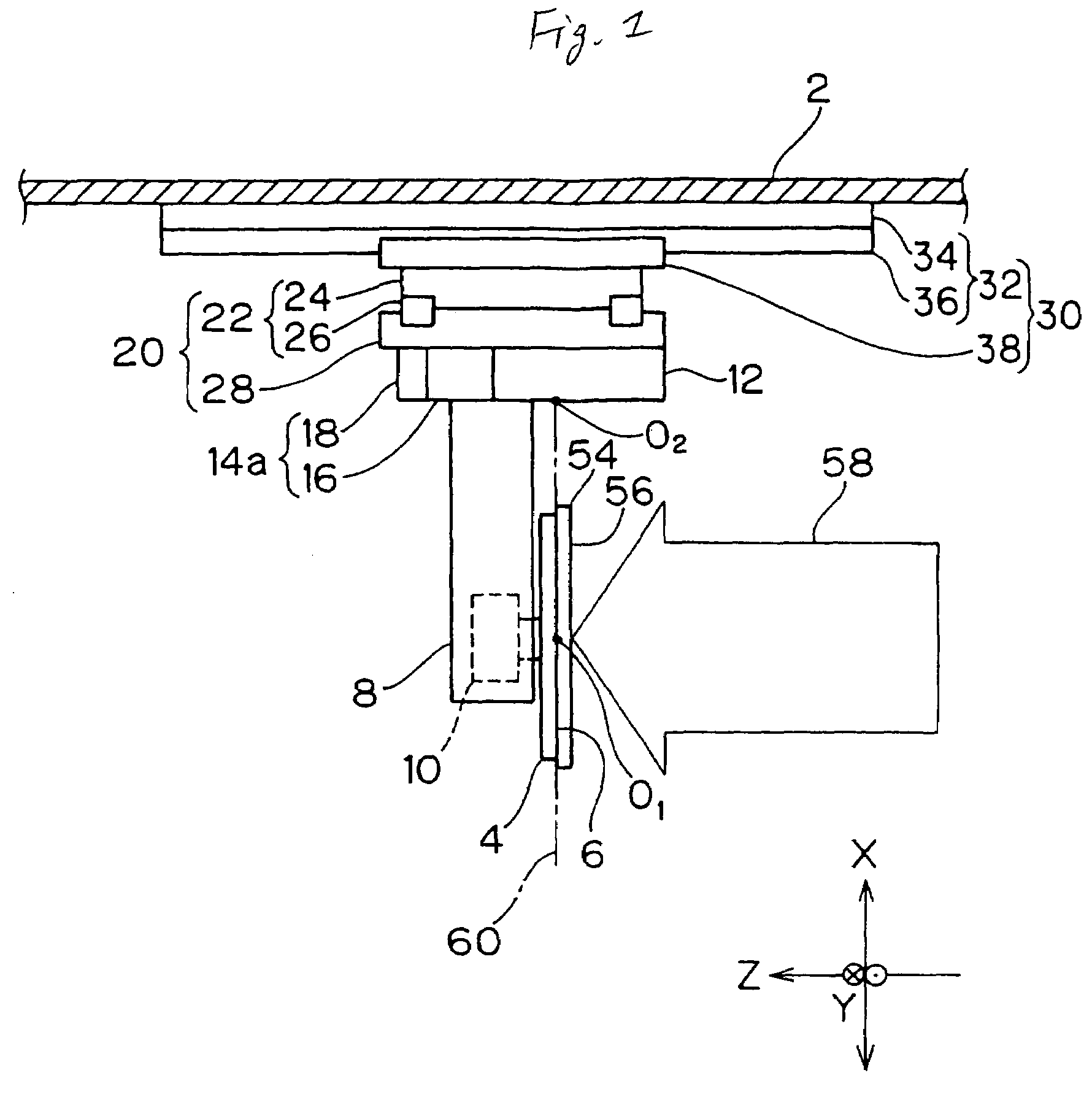

InactiveUS7439527B2Prevent the density of the ion beam applied onto the substrateUniform surfaceMaterial analysis using wave/particle radiationElectric discharge tubesReciprocating motionClassical mechanics

Three axes that are orthogonal to each other at one point are taken as an X-axis, a Y-axis and a Z-axis. An irradiation angle setting motor holds a holder, and sets an irradiation angle θ of an ion beam by rotating this holder around a center axis that is parallel to the X-axis. A Y-axis linear motor causes the holder and the irradiation angle setting motor to ascend and descent in the direction of the Y-axis. A Z-axis linear motor moves the holder, the irradiation angle setting motor and the Y-axis linear motor in the direction of the Z-axis. A control unit operation-controls synchronously the Y-axis linear motor and the Z-axis linear motor so that a substrate holding surface of the holder reciprocates and scans linearly along an S-axis that is parallel to the substrate holding surface and orthogonal to the X-axis.

Owner:NISSIN ION EQUIP CO LTD

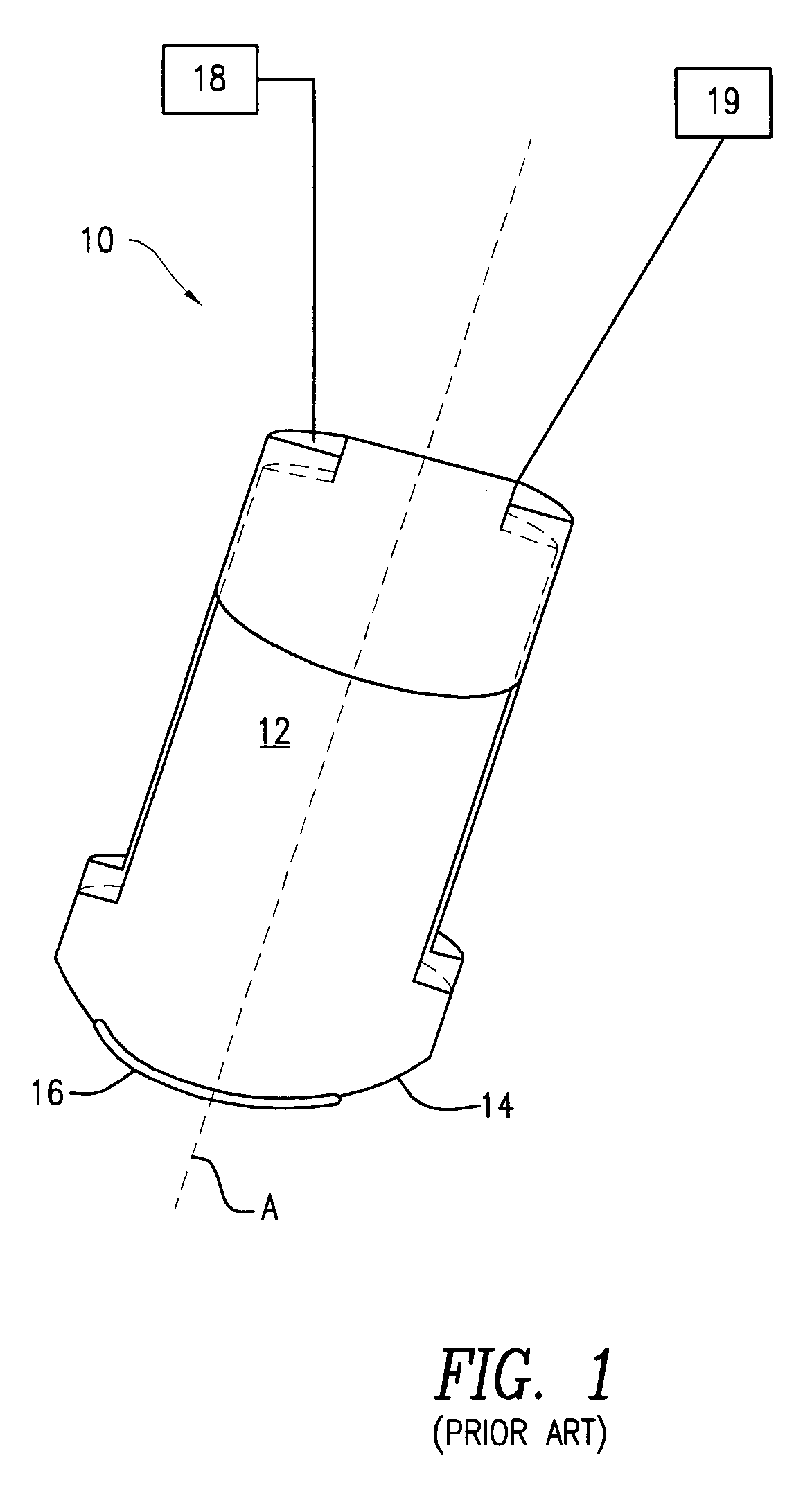

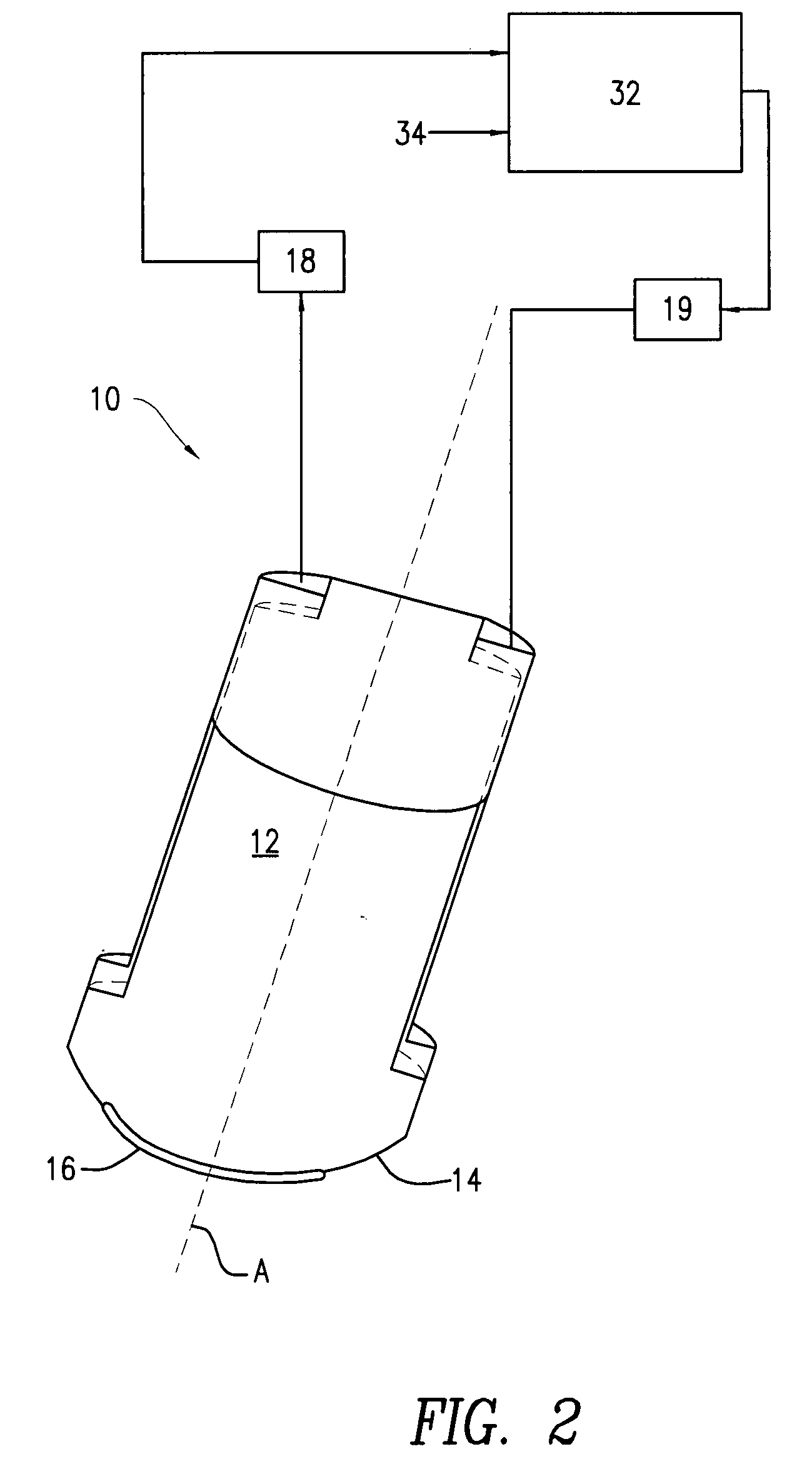

Precision abrasive machining of work piece surfaces

InactiveUS20080132148A1Eliminating spot size variationProduce surface heightEdge grinding machinesPolishing machinesMaterial removalSurface level

The spacing between an abrasive type surface polishing tool and the surface of the work piece that is being polished is controlled dynamically so that variations in the area of the abrasive pad in contact with the surface of the work piece compensated, thereby eliminating size variations in this contact area and the accompanying variations in material removal that produce surface height fluctuations.

Owner:CORNING INC

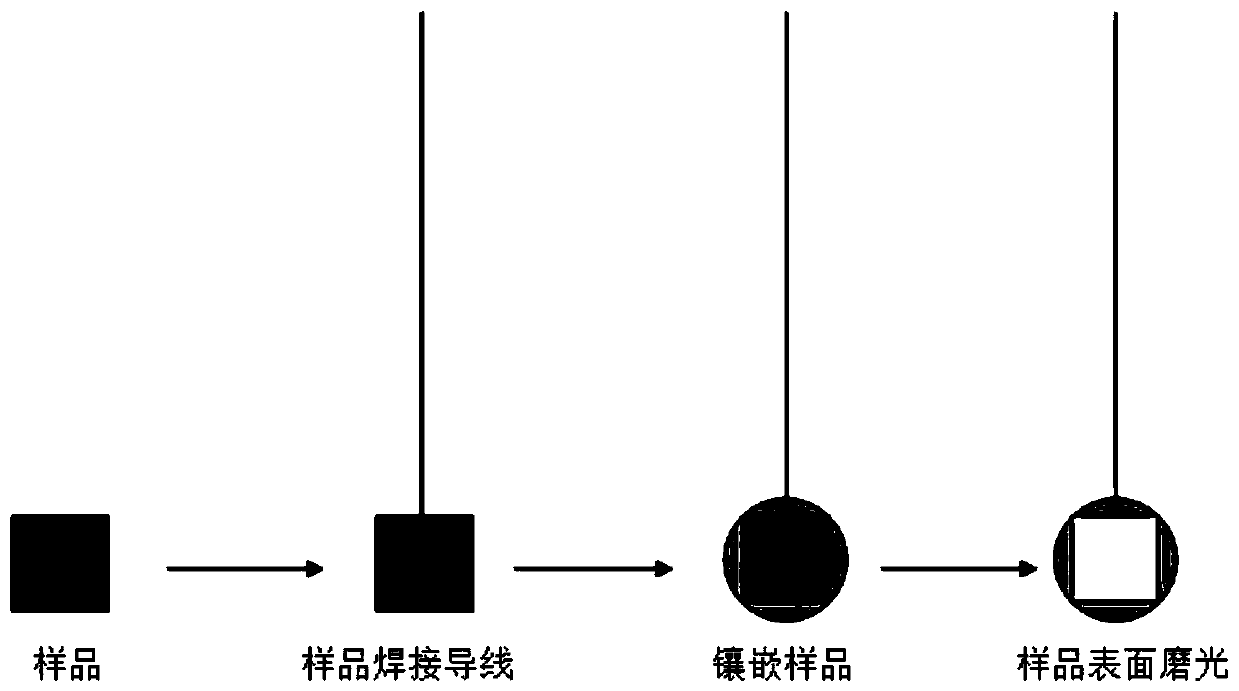

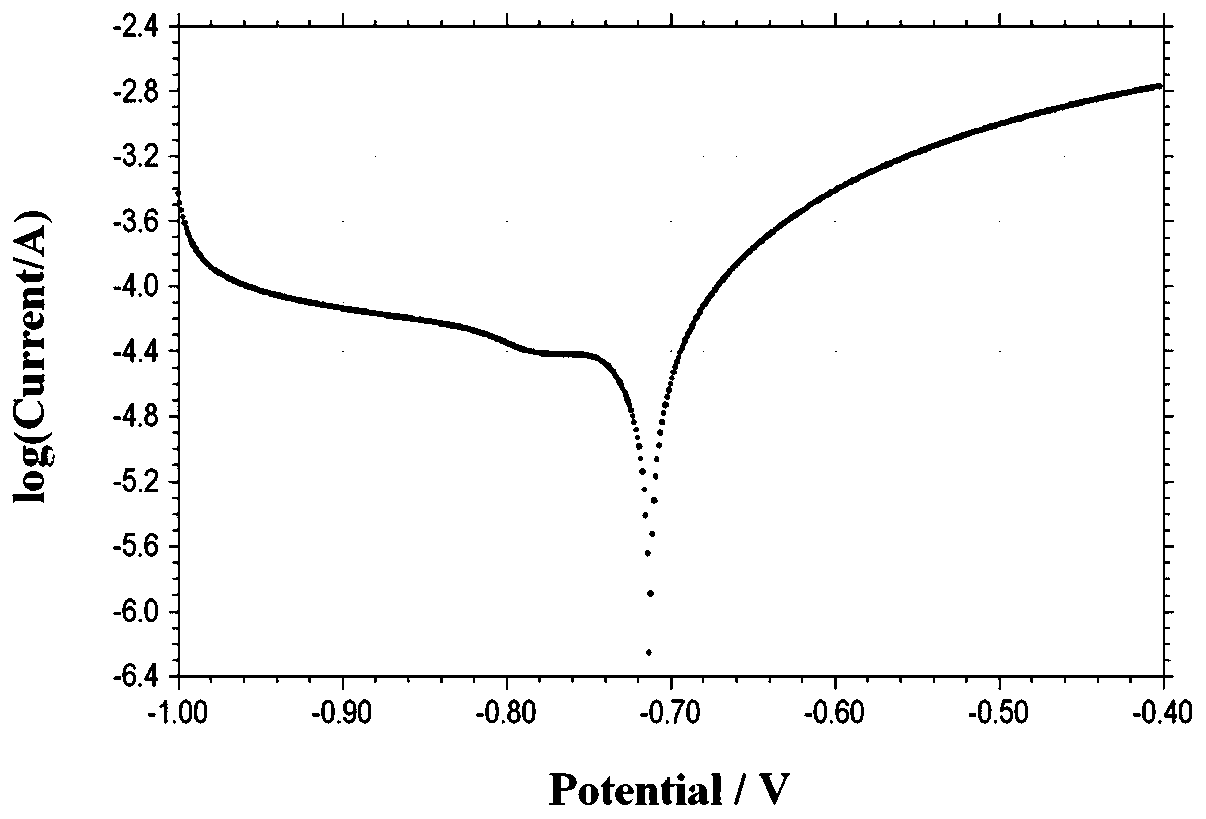

Method for evaluating corrosion resistance of welded steel and application thereof

PendingCN111595771ASimple and efficient operationImprove detection accuracyWeather/light/corrosion resistancePreparing sample for investigationCorrosion resistantTest sample

The invention relates to a method for evaluating the corrosion resistance of welded steel and an application thereof, and provides a method for evaluating the corrosion resistance of materials in allregions after welding by utilizing an electrochemical polarization curve so as to solve the problem that the corrosion resistance of weather-proof bridge steel after welding is difficult to measure. The method specifically comprises the steps: respectively sampling a welded base metal, a weld metal and a heat affected zone, measuring open-circuit potentials and polarization curves of all samples in a simulated industrial atmospheric environment, and evaluating the corrosion resistance of the material according to the self-corrosion potentials of the tested samples. The method can be applied todetermination of the corrosion resistance of the weather-resistant bridge steel, has the advantages of simplicity and convenience in operation and quickness and accuracy in analysis, and can be usedfor evaluating the corrosion resistance of all post-welding materials.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

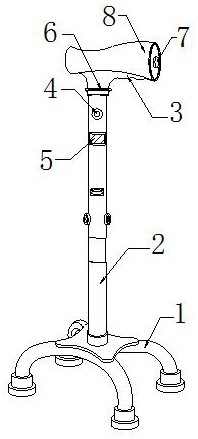

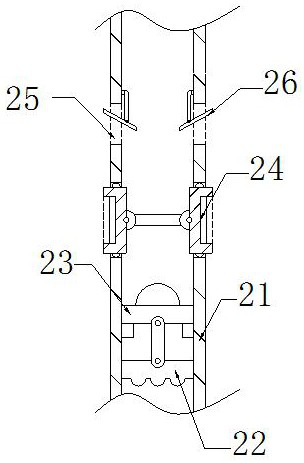

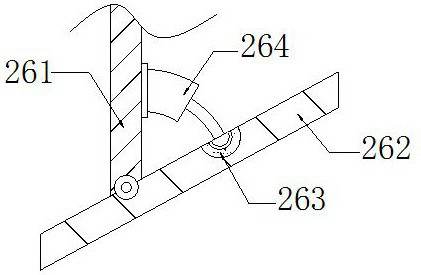

Intelligent walking stick based on grid laser omnidirectional vision

The invention discloses an intelligent walking stick based on grid laser omnidirectional vision. The intelligent walking stick structurally comprises a base, a supporting rod, a handle, a help seeking button, a voice broadcast opening, a noctilucent ring, a glove and a temperature control button, due to the fact that the distance between a refractor and the ground is changed, the area of an obtained light source is changed, and by changing the installation mode of a mirror plate of the spherical refractor, the mirror plate is limited through the limiting mechanism, the angle of the mirror plate can be changed according to different users, the area of a light source can be obtained after the distance between the refractor and the ground is changed, the front light source can be obtained and refracted into the camera in time, and the walking stick can normally provide front road surface information for the users; when a user passes through a wet muddy ground, the friction force between the base and the muddy ground is small, the borne supporting force is reduced, and the slipping phenomenon is likely to occur, the inserting rods in the sleeve plates are inserted into the ground, the slipping phenomenon occurring when the base passes through the wet muddy ground is reduced, and safe use of personnel is facilitated.

Owner:ZHEJIANG UNIV CITY COLLEGE

X-ray detector structure and working method thereof

ActiveCN111522052AReasonable structural designPromote absorptionRadiation intensity measurementImaging qualityEngineering

The invention discloses an X-ray detector structure and a working method thereof. The X-ray detector structure comprises a detector chip, a front scintillator, a back scintillator, a substrate and a fixing structure, wherein the detector chip comprises a front incident plane and a back incident plane; the photosensitive area of the front incident surface is attached to the front scintillator, andthe photosensitive area of the back incident surface is attached to the back scintillator; the non-photosensitive area of the detector chip is attached to the substrate; and one end or two ends of thedetector chip is / are provided with a signal transmission area which is conducted to the substrate through binding wires. According to the X-ray detector structure and the working method thereof, thestructural design is reasonable, and the working method is simple; a double-sided incidence mode is adopted, so that the thickness of the whole scintillator of the X-ray detector is increased, and meanwhile, the light output of the scintillator is not reduced; and the area of the detector chip is not increased, the signal magnitude is ensured, the imaging quality is improved, and the application prospect is wide.

Owner:奕瑞新材料科技(太仓)有限公司

Method of preparing precipitation method white carbon black by improved dropwise adding process

ActiveCN109368649AAvoid emissionsMeet different performance needsSilicon compoundsReaction temperatureReaction system

The invention provides a method of preparing precipitation method white carbon black by an improved dropwise adding process. The method comprises the following steps: preparing a base solution in a reaction kettle and controlling the content of water glass; controlling the stirring speed and the reaction temperature according to different generated products, spraying sulfuric acid from the bottomof the reaction kettle and spraying a water glass solution from the bottom or top of the reaction kettle till the water glass solution is sprayed over; raising the temperature, spraying sulfuric acidfrom the bottom of the reaction kettle, controlling the pH of the reaction system, and carrying out acidification and curing till the reaction is completed; and carrying out filter pressing, washing,pulpifying and drying on the obtained synthesized liquid to obtain the precipitation method white carbon black. Compared with an existing precipitation method, as white carbon black of different specifications is prepared by spraying sulfuric acid from the bottom and adding the water glass solution from the bottom or top, the specific surface areas and oil factors of different white carbon block products can be improved. In the production process, acidic emission is converted into neutral emission in tail gas emission, so that the product quality can be improved effectively, novel products aredeveloped, and the method is fully environment-friendly.

Owner:ZHUZHOU XINGLONG CHEM IND

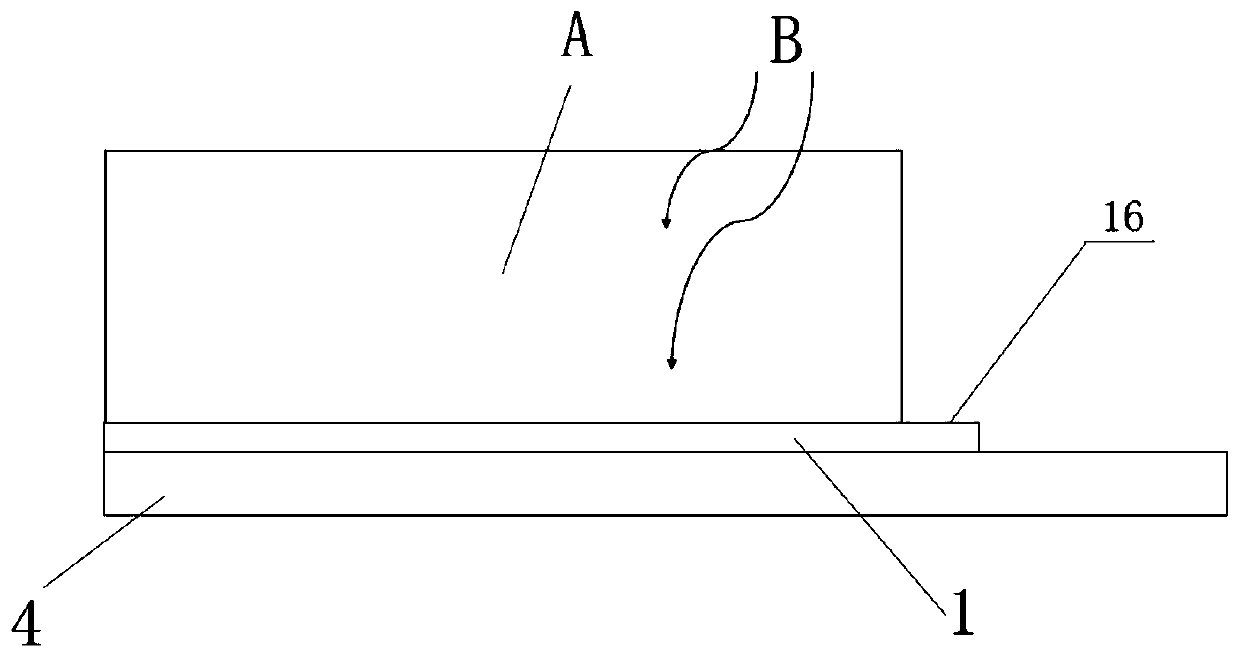

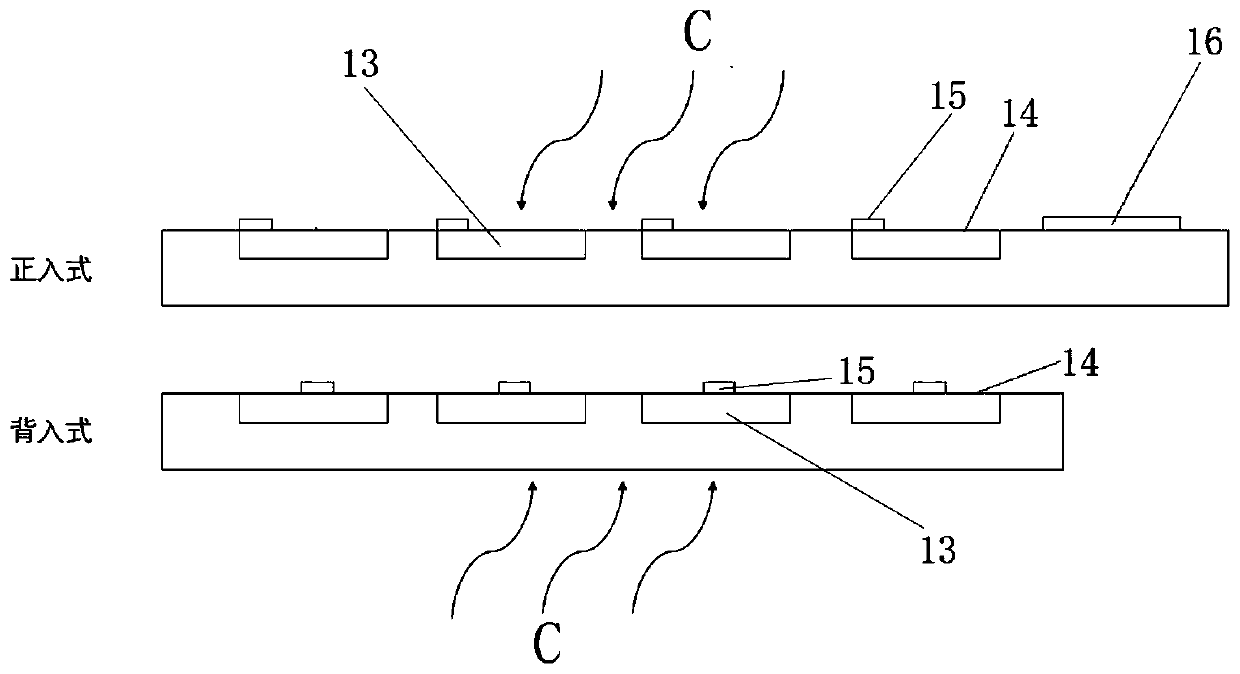

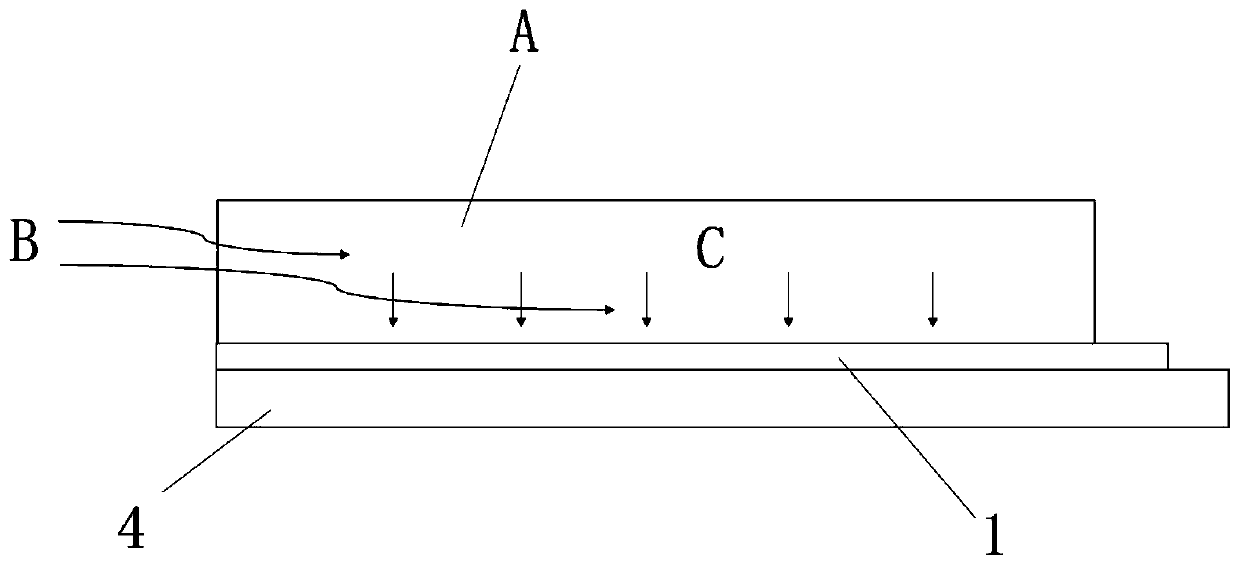

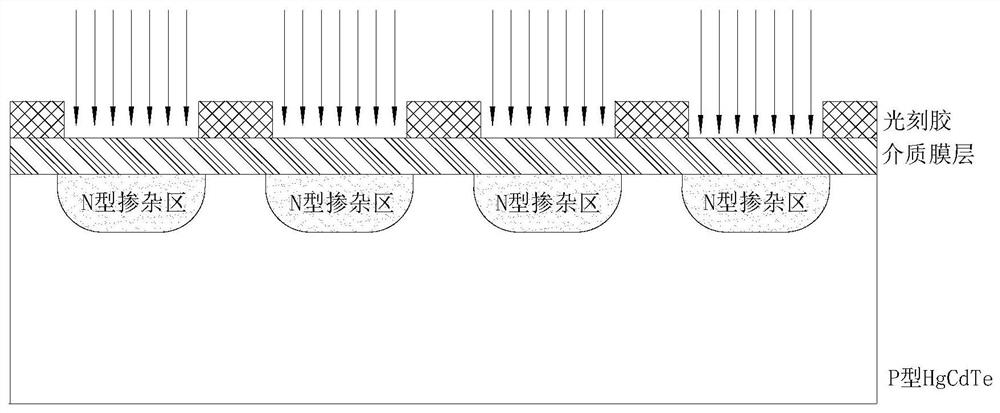

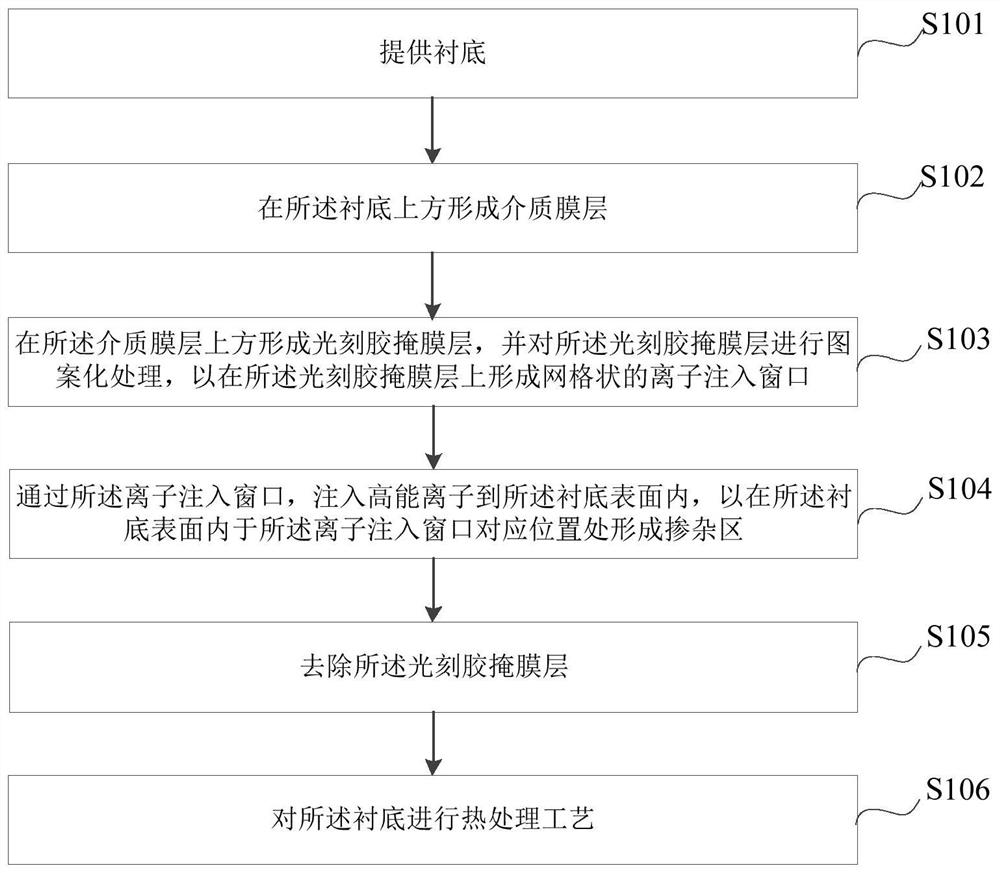

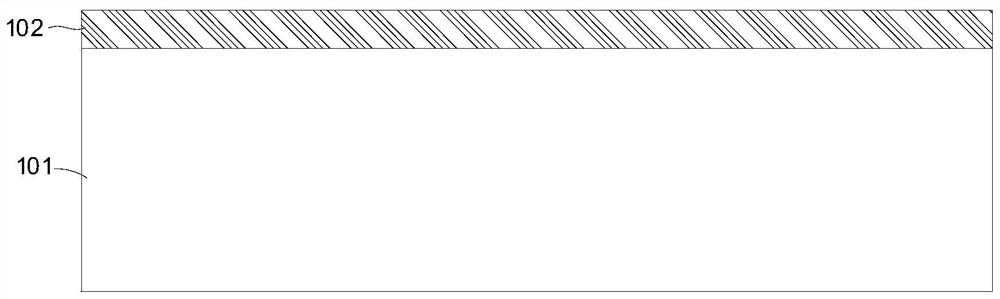

Ion implantation method, preparation method of mercury cadmium telluride chip, and mercury cadmium telluride chip

ActiveCN112086363BAvoid damageLow densityFinal product manufactureSemiconductor/solid-state device manufacturingMercury cadmium tellurideEngineering

The disclosure provides an ion implantation method, a method for preparing a mercury cadmium telluride chip, and a mercury cadmium telluride chip. The preparation method for the mercury cadmium telluride chip includes: forming a dielectric film layer on the P-type mercury cadmium telluride substrate; The P-type mercury cadmium telluride substrate and the dielectric film layer are subjected to a heat treatment process; a photoresist mask layer is formed above the dielectric film layer, and the photoresist mask layer is patterned to A grid-shaped ion implantation window is formed on the photoresist mask layer; through the ion implantation window, high-energy ions are implanted into the surface of the P-type HgCdTe substrate, so that the P-type HgCdTe Forming an N-type doped region in the surface of the mercury substrate; removing the photoresist mask layer; performing a heat treatment process on the P-type HgCdTe substrate. This method effectively protects the dielectric film layer in the implantation region that is not bombarded by high-energy ions, and reduces the damage to the good interface formed by heat treatment between the dielectric film layer and HgCdTe.

Owner:北京智创芯源科技有限公司

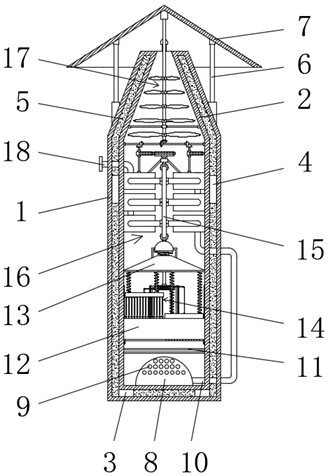

A clean and environmentally friendly toxic gas vocs efficient treatment device

ActiveCN110425555BReduce consumptionIncrease profitIncinerator apparatusSolid removalToxic gasPtru catalyst

The invention discloses a clean and environmental-friendly efficient disposal device for toxic gas VOCs. The clean and environmental-friendly efficient disposal device for toxic gas VOCs comprises a shell. A liner is arranged in the shell, a cushion block is connected to the bottom surface of an inner cavity of the shell, the top surface of the cushion block is connected to the bottom surface of the liner, a distraction block is connected to the inner wall of the shell, the other face of the distraction block is connected to the outer surface of the liner, insulating cotton is arranged in a cavity between the shell and the liner, a fixed bar is connected to the top of the shell, and a flue gas hood is connected to the top end of the fixed bar. A tar scraping device is driven by an eliminating device to operate, so that the tar scraping device can scrape ash on the inner wall of an inner hexagonal catalyst hole to make sure that the inner wall of the inner hexagonal catalyst hole can bein full contact with exhaust gas, and the contact area of a catalyst and exhaust gas is constant, and therefore, the catalytic combustion speed is increased and the disposal effect is better. No toxic gas VOCs is remained in the disposal gas, so that the clean and environmental-friendly efficient disposal device is good in environmental-friendliness, and the practicality of the clean and environmental-friendly efficient disposal device for toxic gas VOCs is improved.

Owner:茂裕环保科技南通有限公司

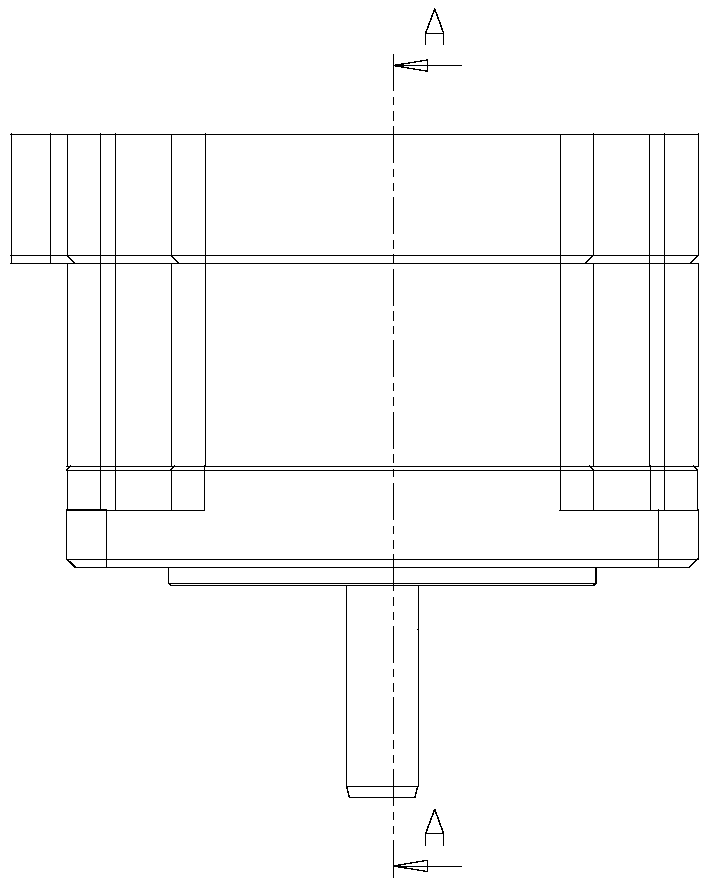

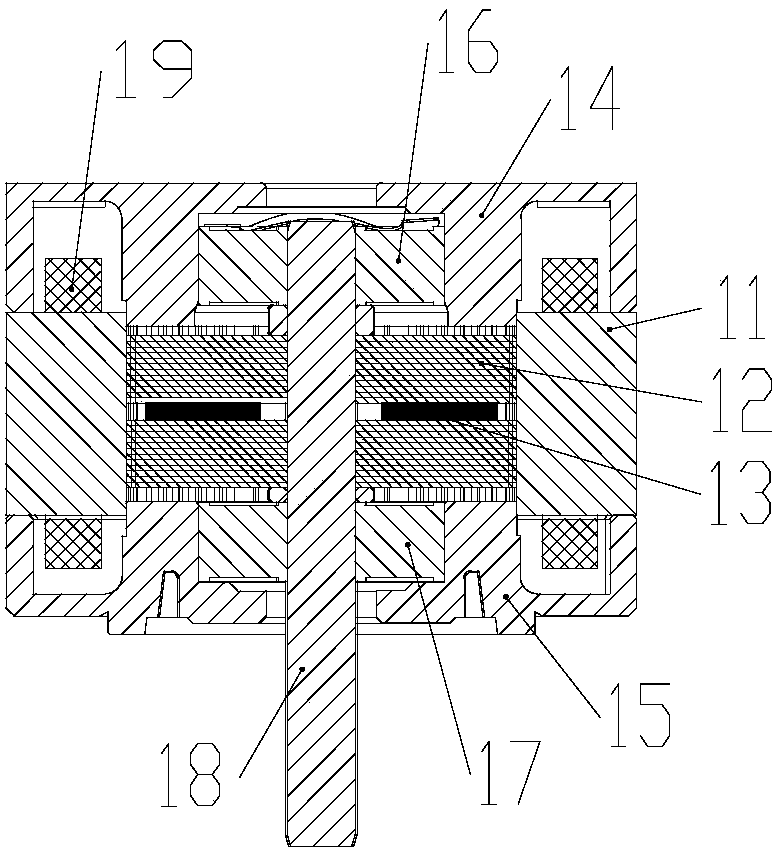

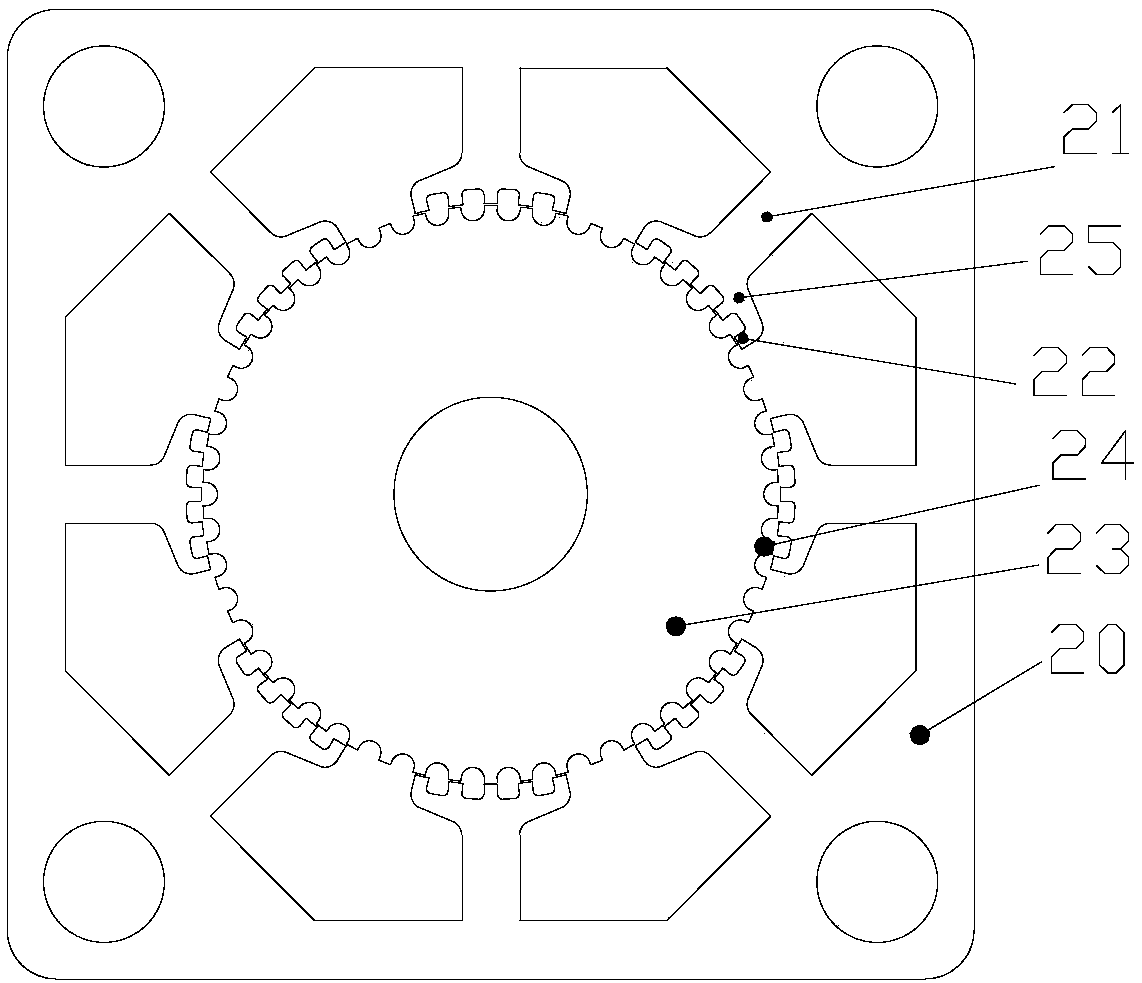

Stepping motor

PendingCN108574389AImprove the magnetic density distribution of the main poleHigh saturationMagnetic circuit stationary partsElectric machineDensity distribution

The invention relates to a stepping motor. The stepping motor includes a stator core (11) and a rotor core (12). The stator core (11) includes a stator core body (20); the stator core body (20) is uniformly provided with eight stator main poles (21) along with a peripheral direction; a pole shoe part (25) of each of the stator main poles (21) is provided with multiple uniformly distributed statortoothlets; and the width of each of the stator main poles (21) is gradually increased from outside to inside. Compared with the prior art, the stepping motor has the advantages of improving the main pole magnetic density distribution of the motor, reducing the saturation degree of the motor, increasing the output torque of the motor, and the like by increasing the width of the main poles near thepole shoe part.

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

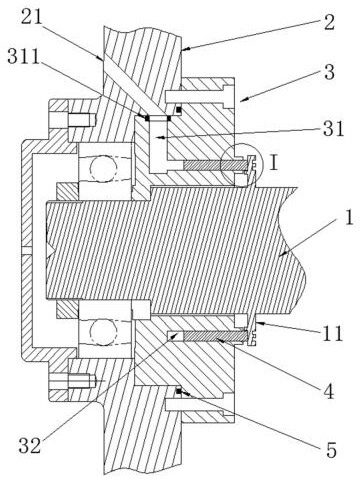

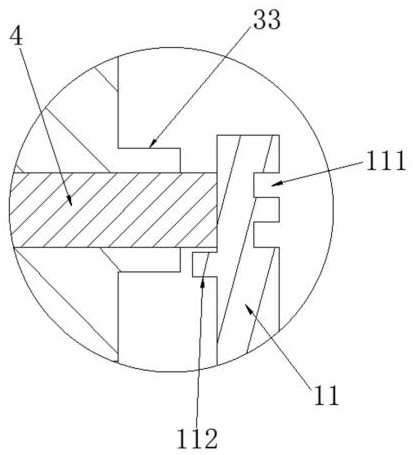

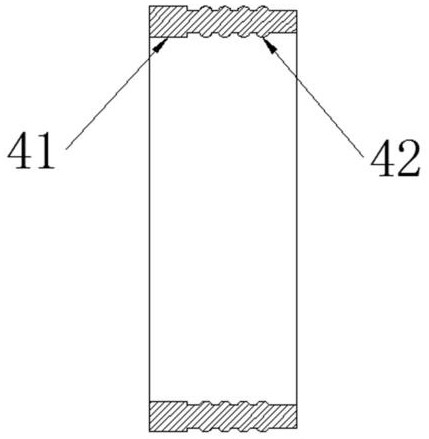

End shaft sealing structure of compressor

Owner:无锡索贝克精密机械有限公司

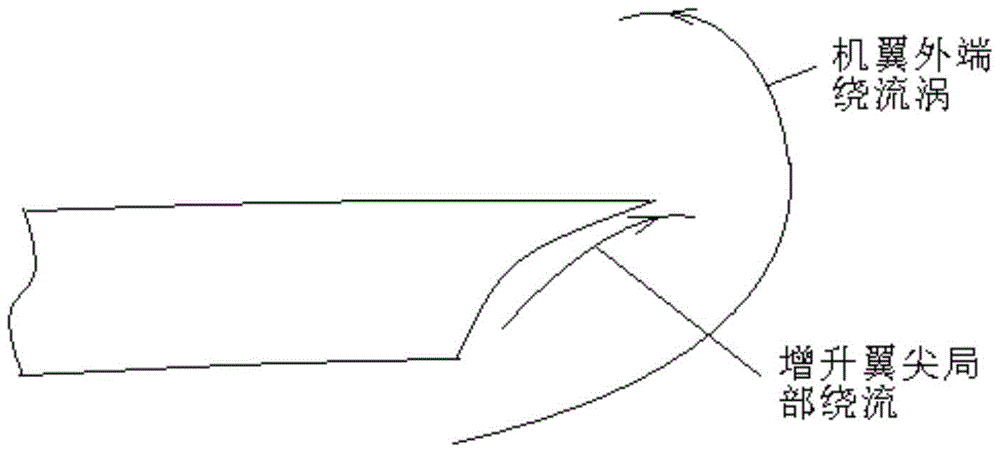

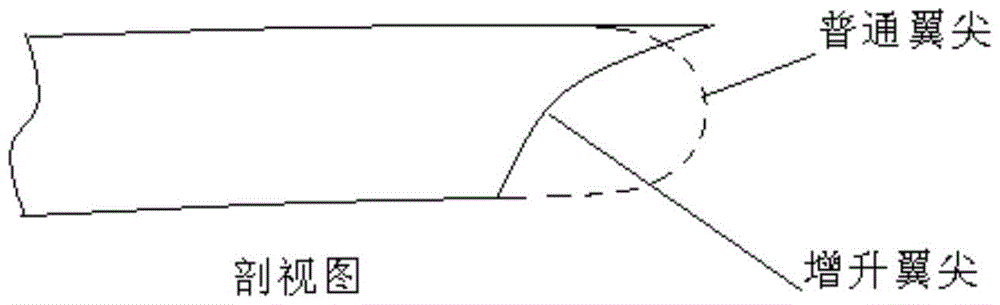

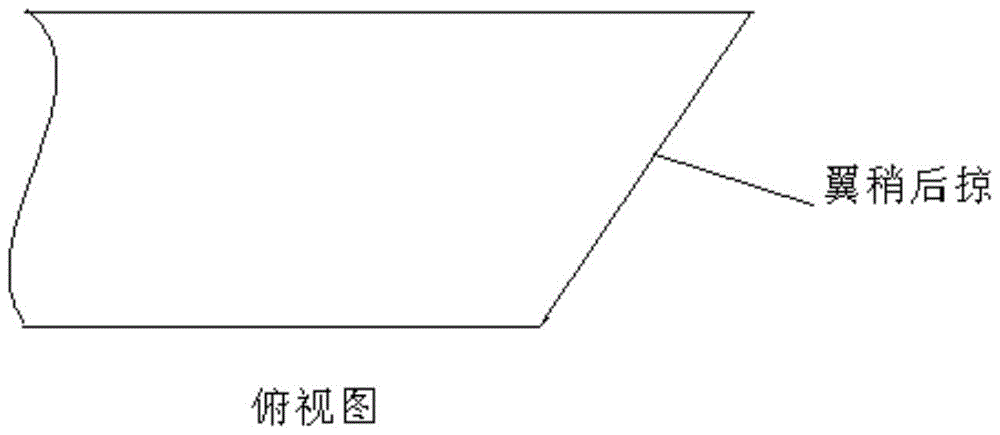

A Design Method for Increased Lift Wing Tip

The invention belongs to the field of aircraft pneumatic layout design, and relates to a rising wingtip design method. The method comprises the steps of: building a vorticity calculating method for reducing the wingtip vortex streaming by using the wingtip reverse streaming vortex; designing a rising wingtip to partially counteract the circular reactor of the wingtip vortex to reduce the loss of wingtip three-dimensional streaming so as to achieve the purposes of reducing the whole aircraft resistance and improving the whole aircraft lift; calculating the position and the feature size of a space-inclined curved surface through the fluid mechanics to perform optimal adjustment and selection; and further performing the verification and the optimization for the design through a wind tunnel test. The rising wingtip design method creatively builds the resistance-reducing and lift-improving design principle of the wingtip reverse streaming vortex, and initiates the rising wingtip design principle and method capable of improving the lift while reducing the structural weight and simplifying the structural design.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Flow-rate measurement nozzle with velocity pressure pickup channel

Velocity pressure measuring apparatus and methods include a nozzle having a nozzle inlet end and a nozzle outlet end. A side wall of the nozzle extends along a nozzle axis and has an exterior surface and an interior surface. The interior surface defines a nozzle chamber and has a nozzle inlet cross-sectional area at the nozzle inlet end that is greater than a nozzle outlet cross-sectional area at the nozzle outlet end. A first pressure port extends through the side wall from the exterior surface of the nozzle to the interior surface of the nozzle, and includes a velocity pressure pickup channel extending along a channel axis oriented substantially parallel to the nozzle axis.

Owner:GRENNING FREDERICK H

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com