Method for evaluating corrosion resistance of welded steel and application thereof

A technology for corrosion-resistant and welded steel, applied in the evaluation of corrosion-resistant performance of welded steel and its application field, can solve the problems of complicated operation, demanding sample specifications, and reducing the actual identification efficiency of materials, and achieves high detection accuracy, simple and fast operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

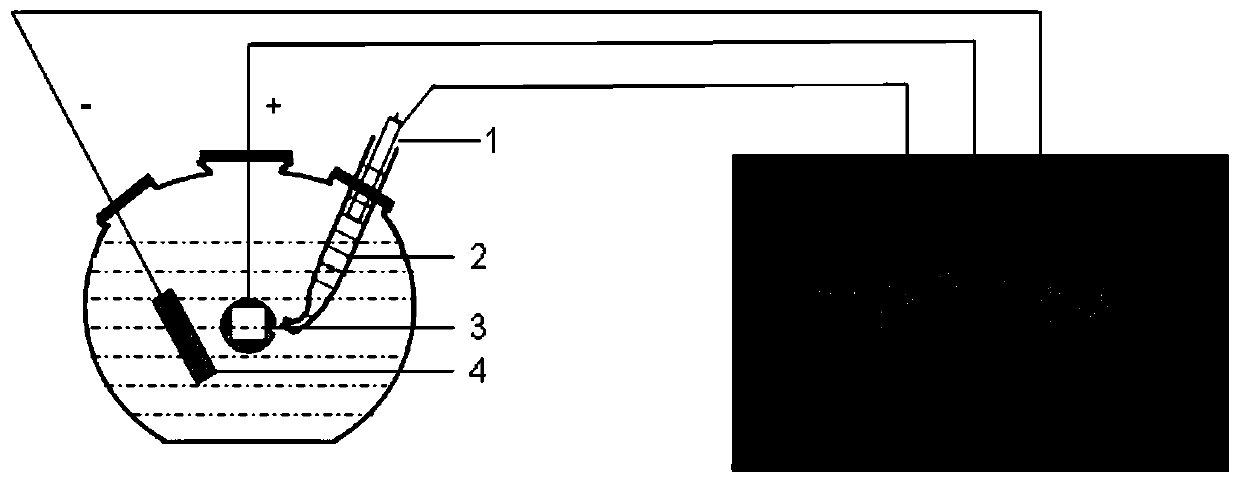

[0036] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. The embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

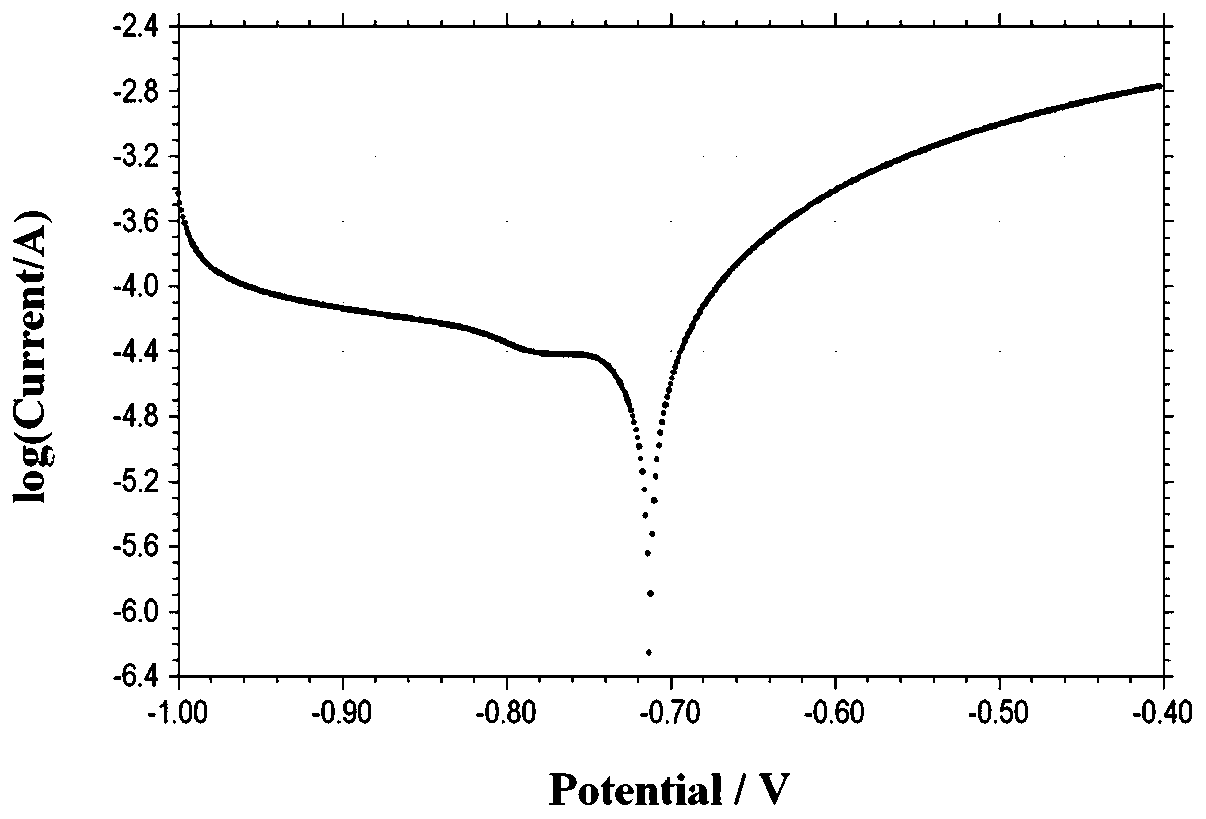

[0037] In this example, the evaluation of the corrosion resistance of the weather-resistant bridge steel after welding is carried out, and the corrosion resistance is evaluated by measuring the corrosion potential. The higher the corrosion potential, the better the corrosion resistance. Specific steps are as follows:

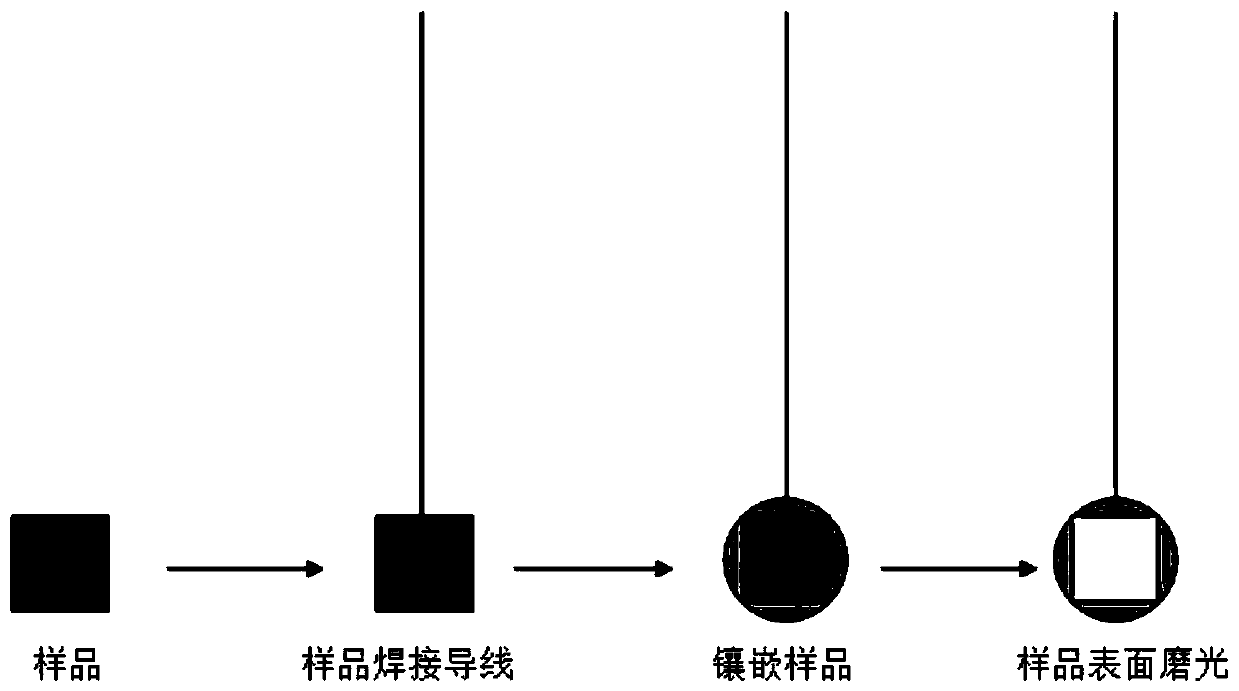

[0038] (1) Sampling

[0039] Sampling on the base metal after welding, the sample size is 10mm*10mm*3mm;

[0040] (2) Mosaic samples

[0041] First solder the copper wire to the side of the sample, mix the epoxy resin with the epoxy resin curing agent (1wt% of the system), and wait for the air bubbles to fully escape, then add the epoxy resin plasticizer (1wt% of the system) to mix. Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com