Variable Mach number rotating mechanism based on semicircular bearings

A rotating mechanism and semi-circular shaft technology, applied in the field of test equipment design, can solve the problems of Mach number control accuracy, airflow quality and airflow angle deviation, etc., to achieve the effect of ensuring Mach number adjustment accuracy, uniform flow field, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

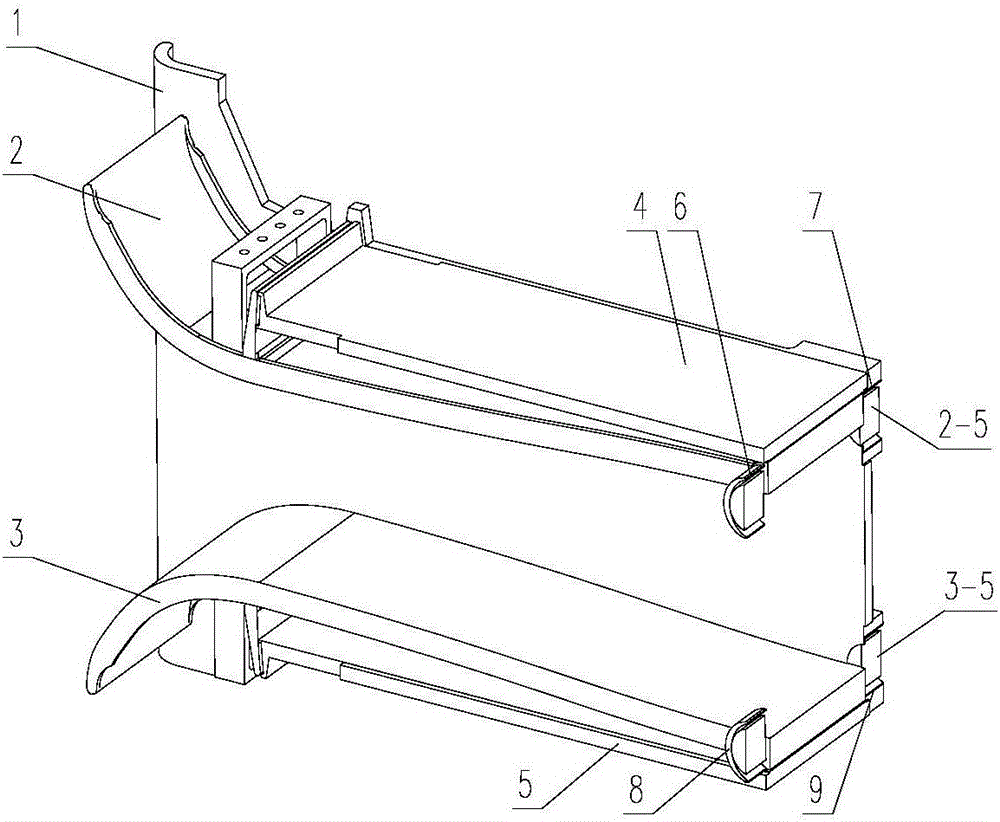

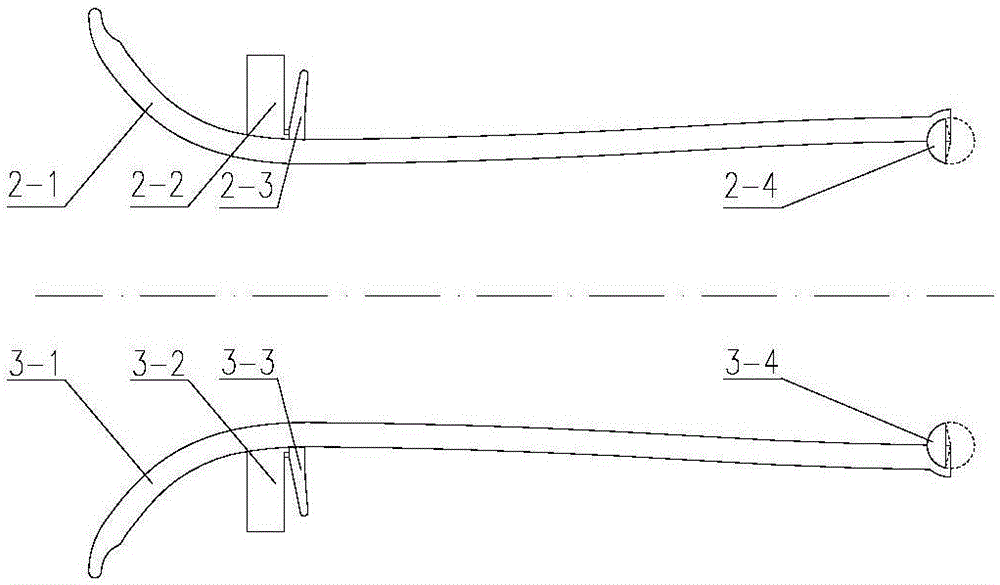

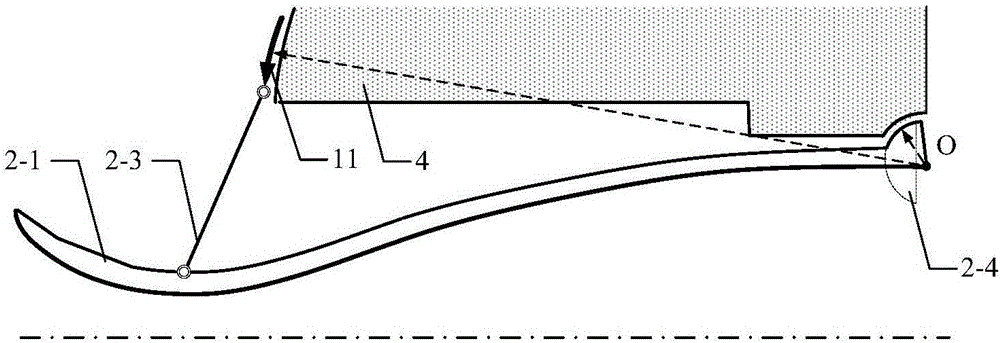

[0024] The working process of the nozzle is as follows: After the positive and negative directions of the sealing support plate and the support plate, the semicircular shaft lug and the side wall are limited, the profile driving mechanism drives the rotating support plate to move; drives the entire profile mechanism on the semicircular bearing , Rotate along the rotation center O under the action of the circular arc of the support plate; thereby realize the adjustment of the throat height of the profile mechanism, keep the O-axis unchanged at the profile outlet position, and then realize the precise adjustment of the Mach number of the nozzle outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com