X-ray detector structure and working method thereof

A technology of optical detectors and detector chips, which is applied in the field of X-ray detectors, can solve the problems of unresolved scintillators, absorption, and high quality, and achieve the effects of solving insufficient detection efficiency, improving absorption capacity, and reducing light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Based on the above structural basis, such as Figure 4-8 shown.

[0051] The working method of the X-ray detector structure of the present invention comprises the following steps:

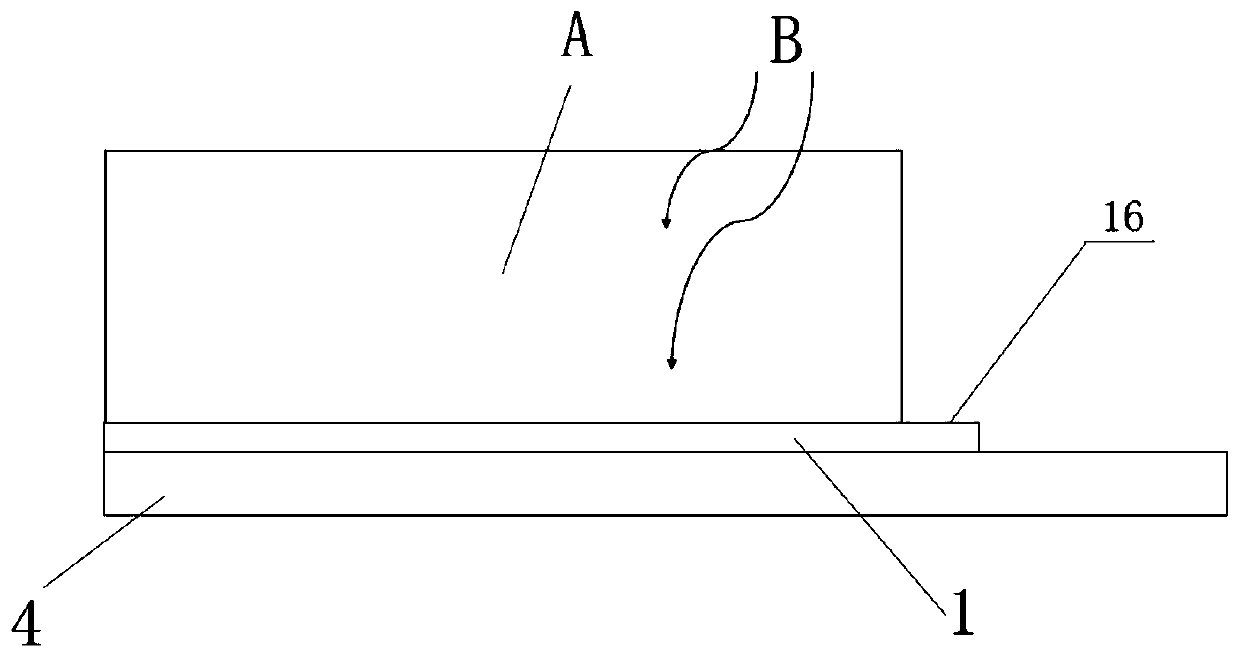

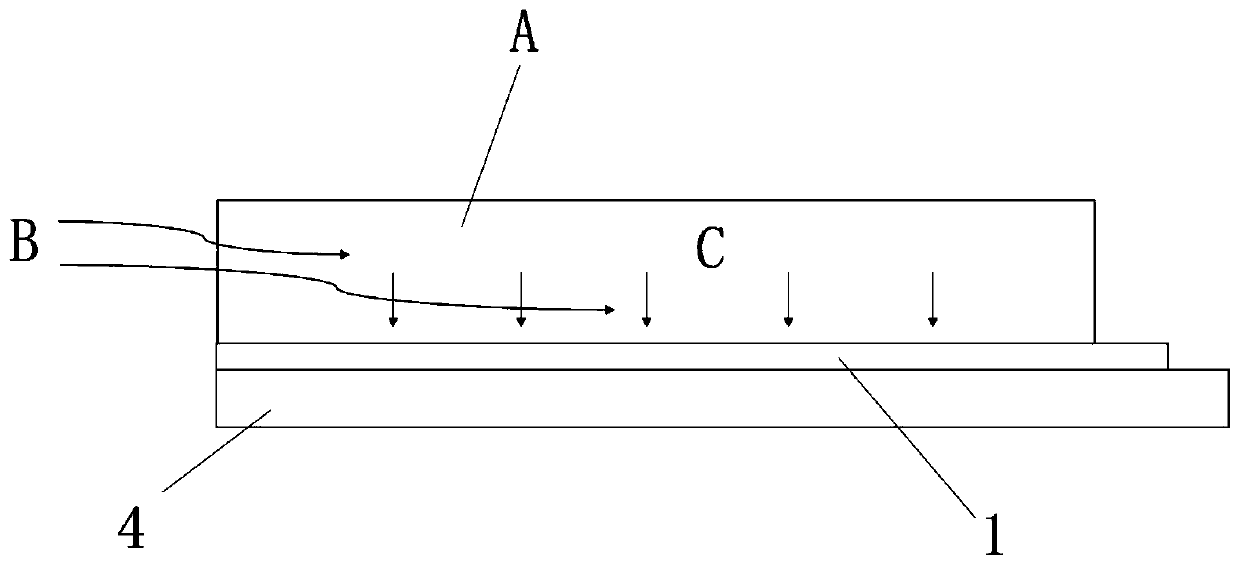

[0052] (1) The incident X-ray B enters the pixels 111 corresponding to the front scintillator 2 and the back scintillator 3, and is respectively absorbed in the respective pixels 111 of the front scintillator 2 and the back scintillator 3 to release visible light;

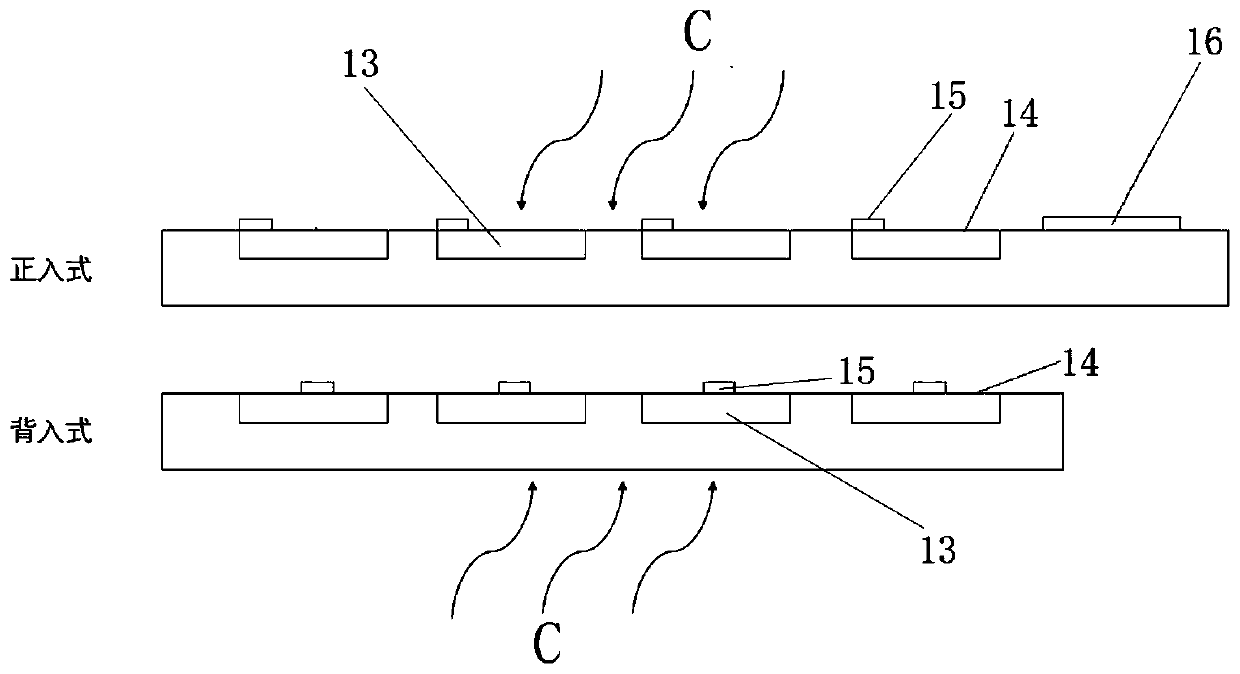

[0053] (2) After reflection, the visible light C produced by the front scintillator 2 enters the normal incident surface 111 of the detector chip 1 from the light-emitting surface of the front scintillator 2 and is absorbed by the detector chip 1 to form a photogenerated charge a; the back scintillator 3 After being reflected, the produced visible light C is irradiated from the light-emitting surface of the back scintillator 3 into the back incidence surface 12 of the detector chip 1, and is absorbed by the detector to form phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com