Patents

Literature

47results about How to "Meet different performance needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

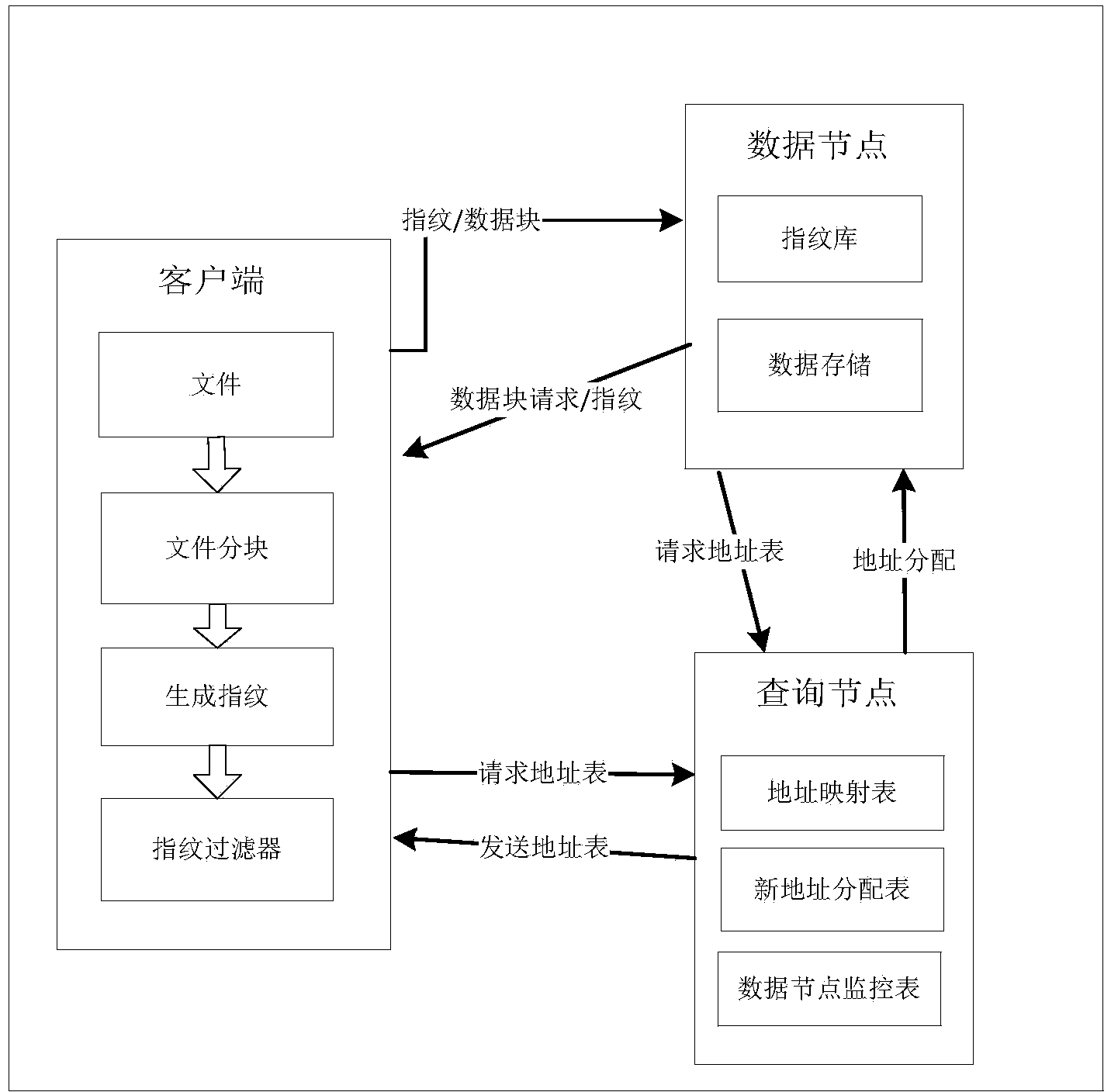

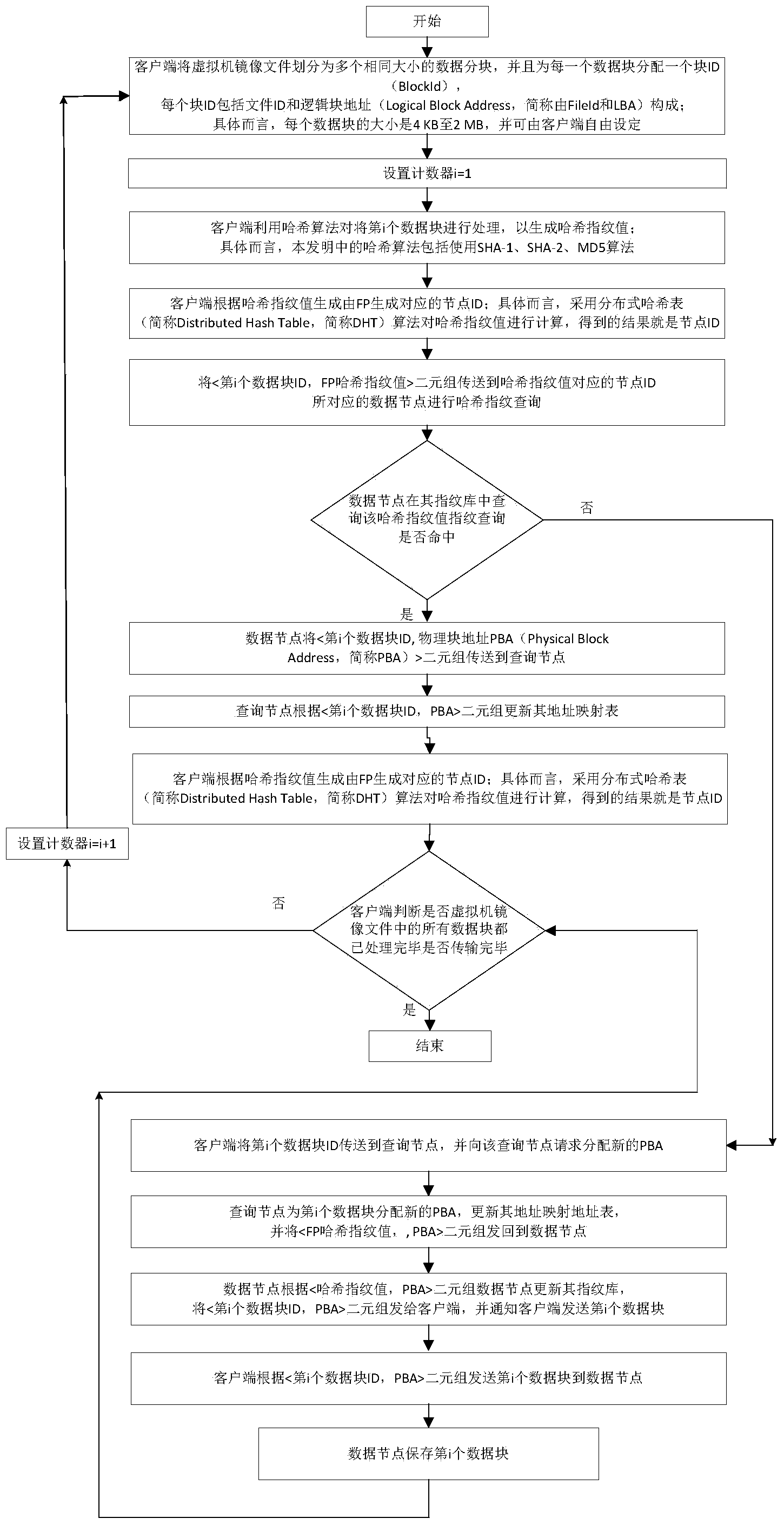

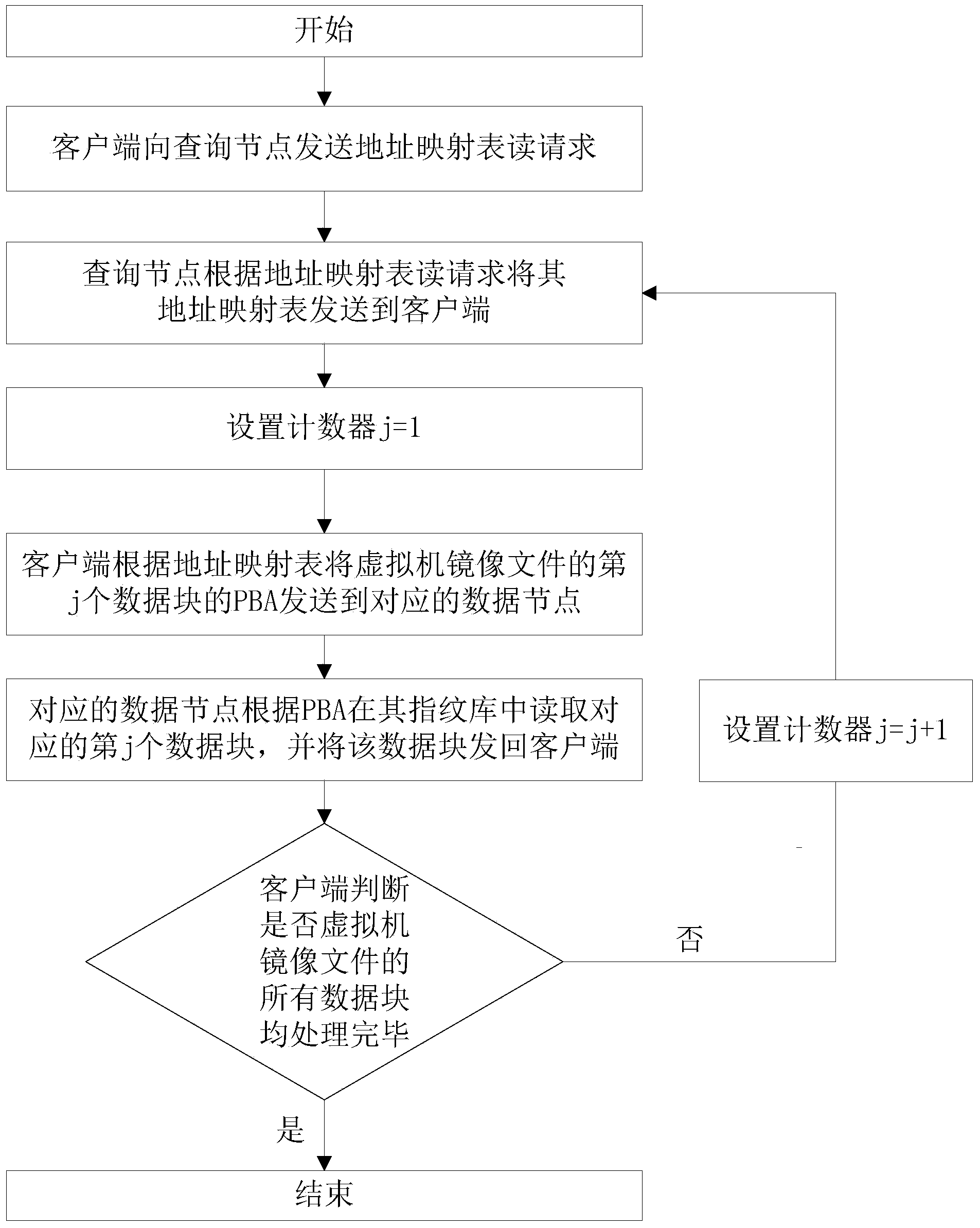

Parallel repeated data deleting method

ActiveCN103970875ASolve processing performance bottlenecksImprove scalabilitySpecial data processing applicationsHash functionData needs

The invention discloses a parallel repeated data deleting method. The method comprises the following steps that a client side firstly carries out block partitioning on data needing to be deleted again, the Hash fingerprint of each block is calculated according to a Hash function, and then the Hash fingerprints are sent to different re-deleting server nodes to carry out duplicate checking work of the fingerprints. If a certain fingerprint is confirmed to be a repeated fingerprint after comparison, only the metadata on a query server and a fingerprint counter on the re-deleting server nodes need to be updated. If a certain fingerprint is conformed to be a new data block through comparison, the data block is transmitted to a re-deleting server, and the metadata in a fingerprint database and the metadata in the query server are updated. The parallel repeated data deleting method has an expandability of re-deleting nodes, the needs of performance can be met by expanding different nodes according to different needs, the parallelism between multiple nodes is utilized to improve the performance of a re-deleting system effectively, and efficient and reliable services can be provided.

Owner:HUAZHONG UNIV OF SCI & TECH

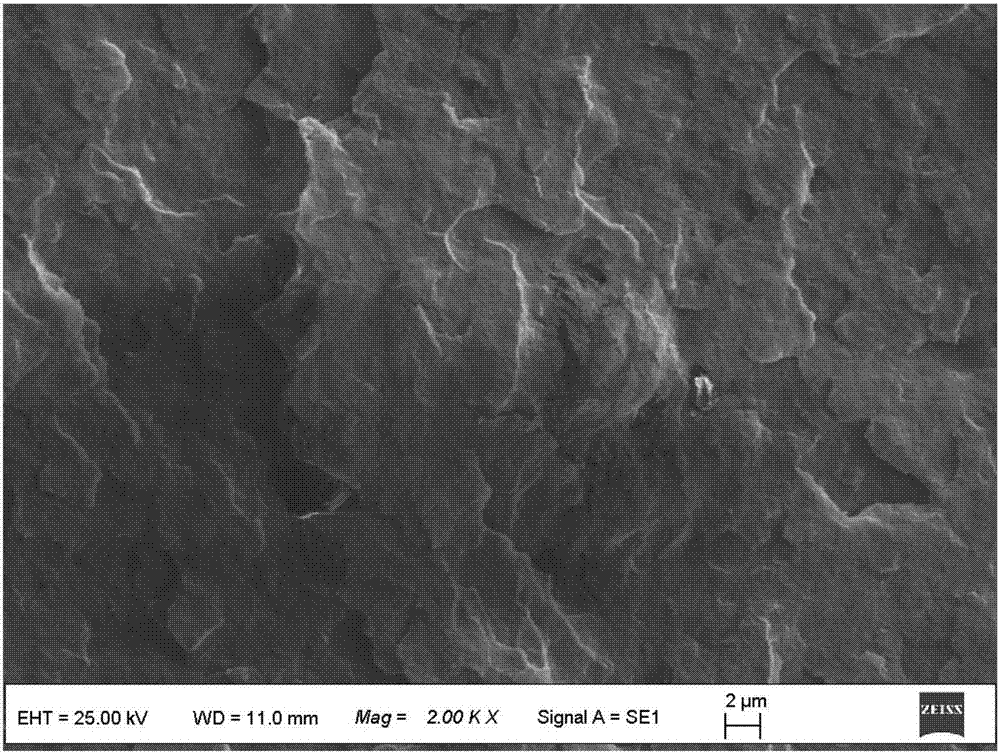

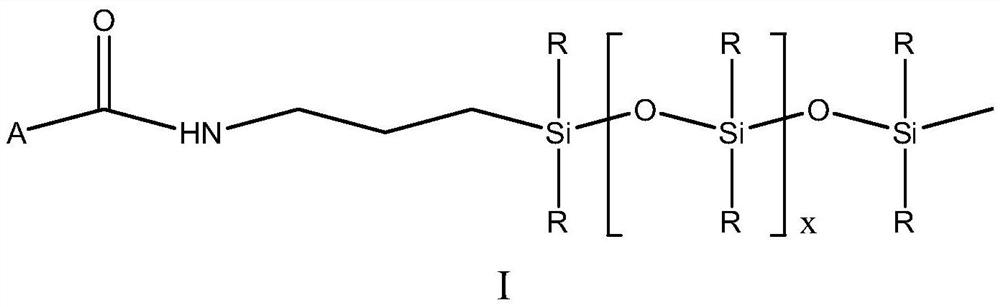

Dealcoholized silicone adhesive as well as preparation method and application thereof

InactiveCN110922936ALow raw material costSimple production processNon-macromolecular adhesive additivesSilicone sealantOrganosilicon

The invention discloses a dealcoholized silicone adhesive as well as a preparation method and application thereof and belongs to the technical field of organic silicone sealants. The dealcoholized silicone adhesive comprises the following components in parts by weight: 80-120 parts of hydroxyl-terminated polydimethylsiloxane, 1-5 parts of an alcohol type cross-linking agent, 1-5 parts of a titanium chelate catalyst, 6-12 parts of fumed silica, 0-15 parts of a plasticizer and 0.5-1.5 parts of a composite coupling agent. The embodiment of the invention provides the dealcoholized silicone adhesive which has the characteristics of low raw material cost, simple production technique, favorable storage stability, favorable binding property, favorable yellowing resistance and the like. According to the dealcoholized silicone adhesive, the titanium chelate with a dialkoxy titanium bis (beta-diketone compound) structure is used as the catalyst, and hydroxyl-terminated polydimethylsiloxane can bedirectly catalyzed to react with the alcohol type cross-linking agent, so that the dealcoholized silicone adhesive which is stable in storage and does not turn yellow is prepared.

Owner:东莞市博君来胶粘材料科技有限公司

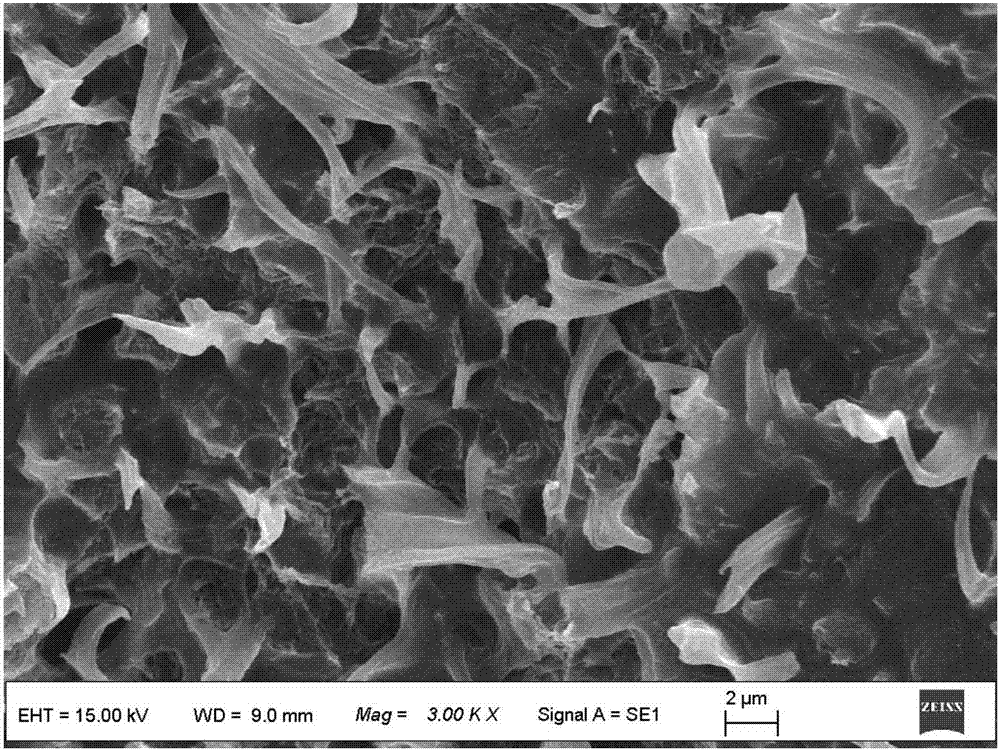

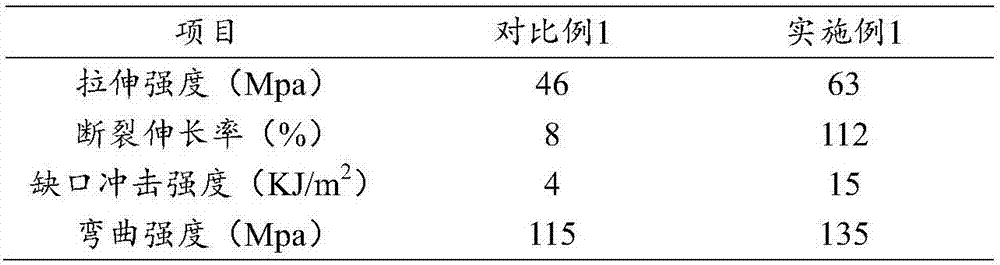

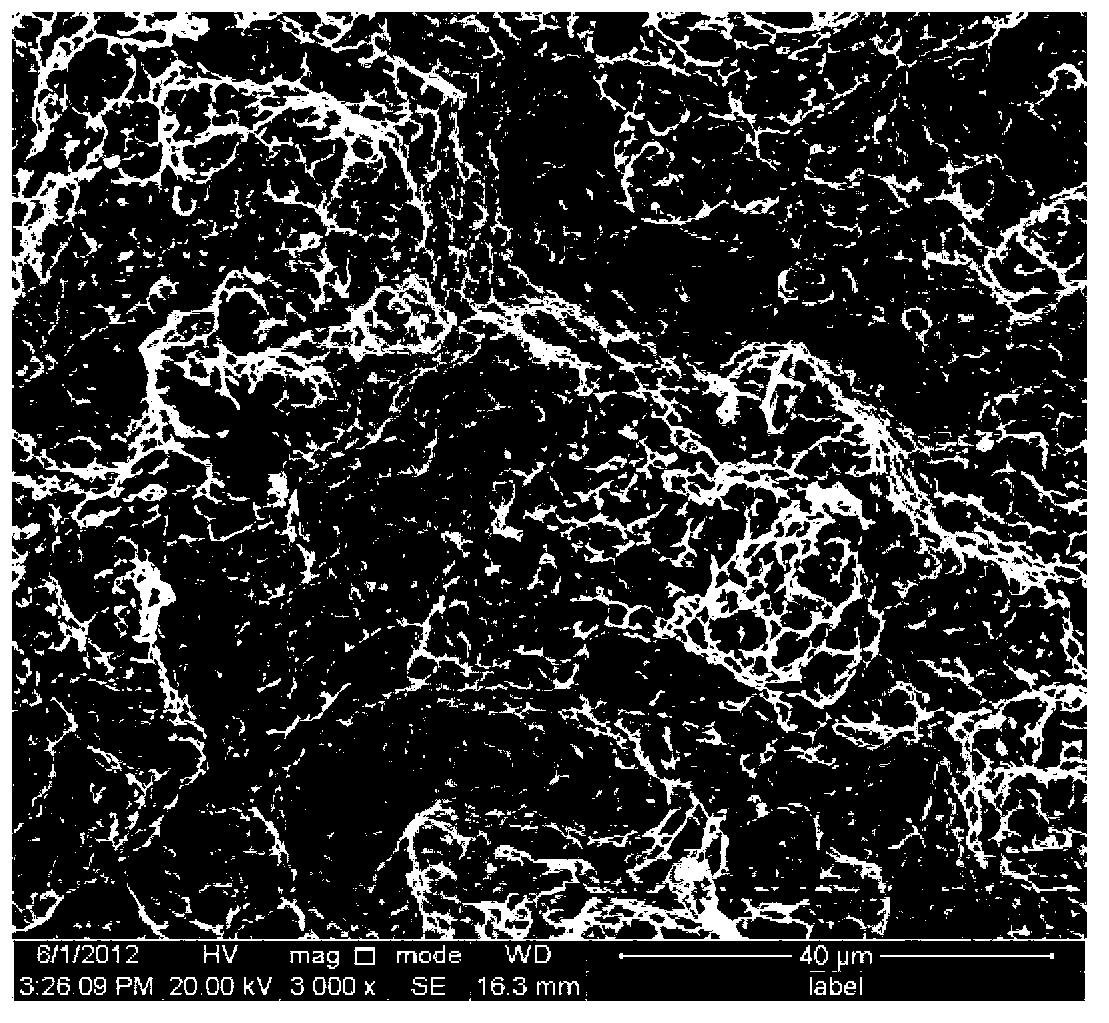

Reinforcing and toughening polylactic acid material and preparation method thereof

The invention provides a reinforcing and toughening polylactic acid material and a preparation method thereof, and relates to the field of polymer materials. The preparation method comprises the steps of mixing layered double hydroxides with epsilon-caprolactone and obtaining reactants, and after a ring opening polymerization, obtaining polycaprolactone modifier; conducting addition polymerization on the polycaprolactone modifier and diisocyanate, and obtaining prepolymer; making the prepolymer react with chain extender, and obtaining polyurethane modifier; melting and mixing the polyurethane modifier and polylactic acid, and obtaining the reinforcing and toughening polylactic acid material. Flexible chain segments of the polyurethane modifier improve the elasticity and flexibility of the material, rigid chain segments of the polyurethane modifier improve the strength and heat resistance of the material, and finally the overall mechanical property of the material is improved. Since the layered double hydroxides with a laminated structure are dispersed in a base material, the bending strength and stretching strength of the material are improved, and the anchoring effect of the material can avoid the modifier compatibility and migration problem which is easily generated from simple physical blending.

Owner:HUNAN UNIV OF TECH

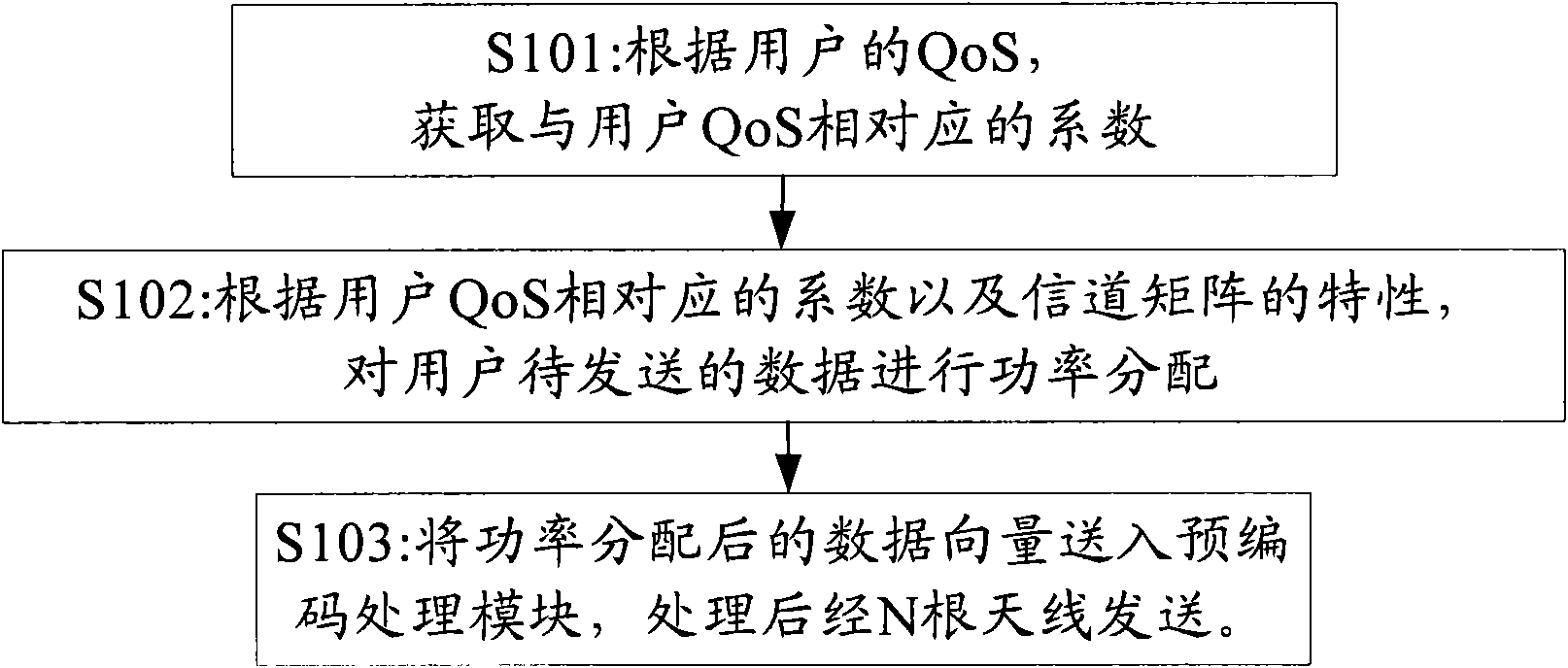

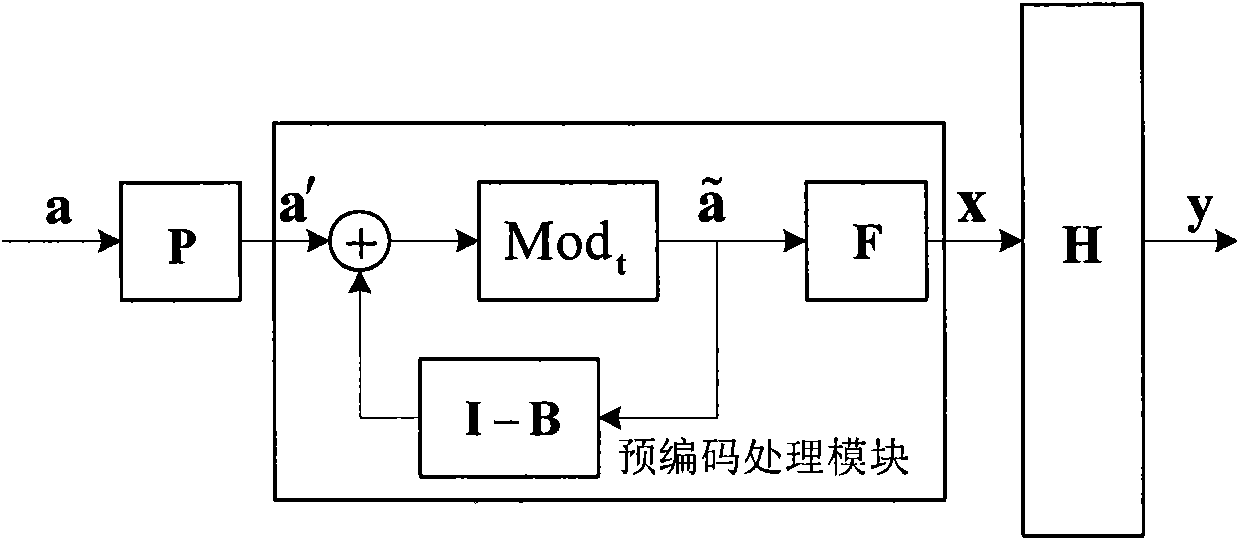

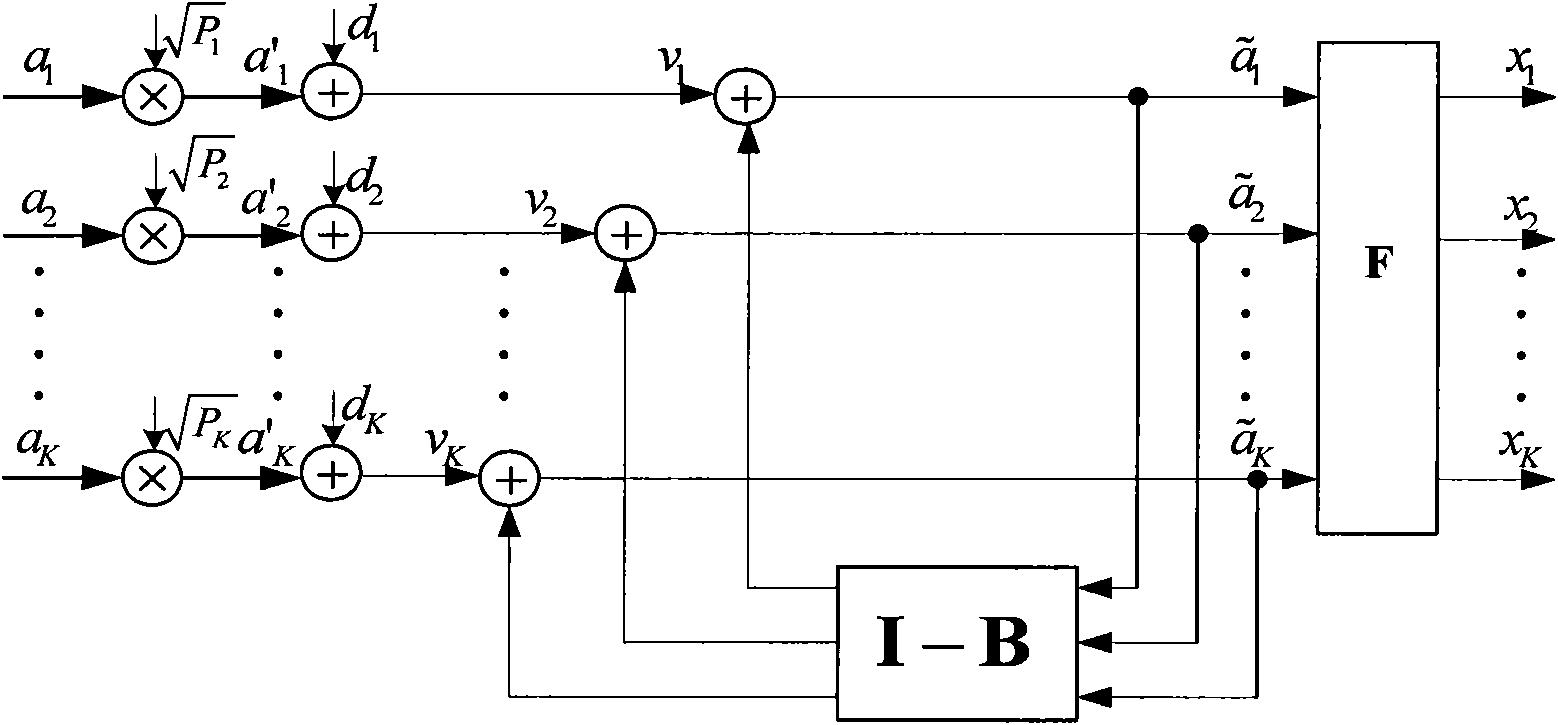

Method and equipment for sending multi-user MIMO

ActiveCN101938301AMeet different performance needsReduce bit error rateSpatial transmit diversityAllocation algorithmDistributed computing

The embodiment of the invention provides a method for sending multi-user MIMO, which comprises the following steps of: acquiring coefficients corresponding to QoS of users according to the QoS of the users; performing power allocation on the users according to the coefficients corresponding to the QoS of the users and the characteristic of a channel matrix; sending a data vector subjected to the power allocation to a precoding processing module; and after being processed, sending the data vector by using N antennae. The embodiment of the invention also provides equipment for sending the multi-user MIMO. In the technical scheme provided by the invention, the technology of the power allocation is introduced to a MIMO system, and the matrix is processed in a combined way by taking the transformation of a power allocation algorithm on a signal and the transformation of a precoding algorithm on a channel into consideration comprehensively; and on the basis of realizing diversity gain, power resources are allocated reasonably to different users by the user QoS-based power allocation algorithm so as to meet the different performance requirements of the users.

Owner:DATANG MOBILE COMM EQUIP CO LTD

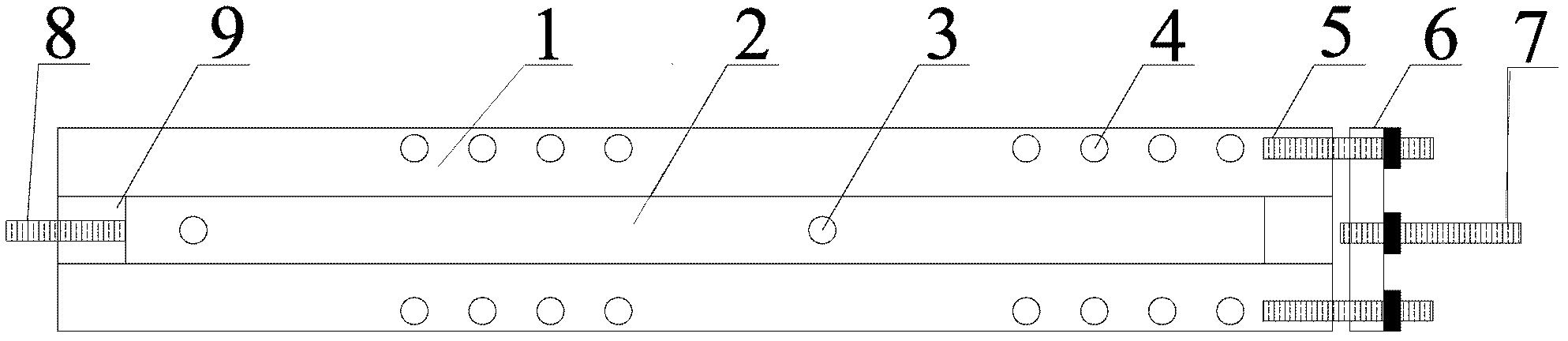

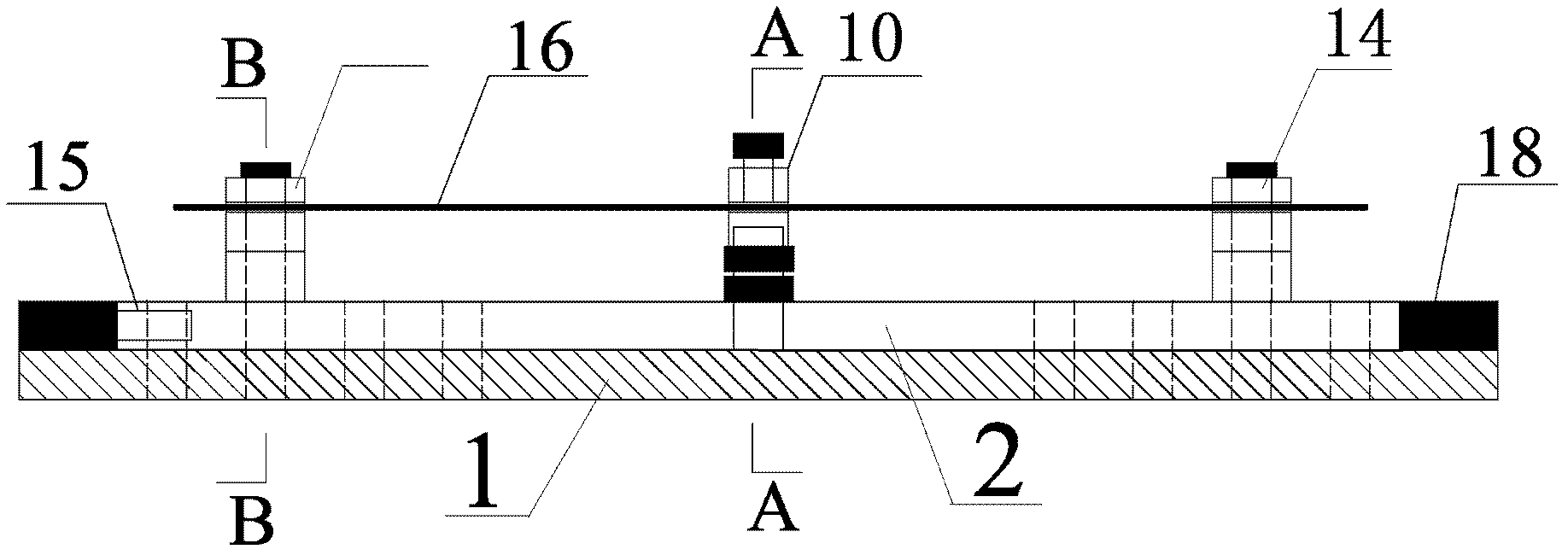

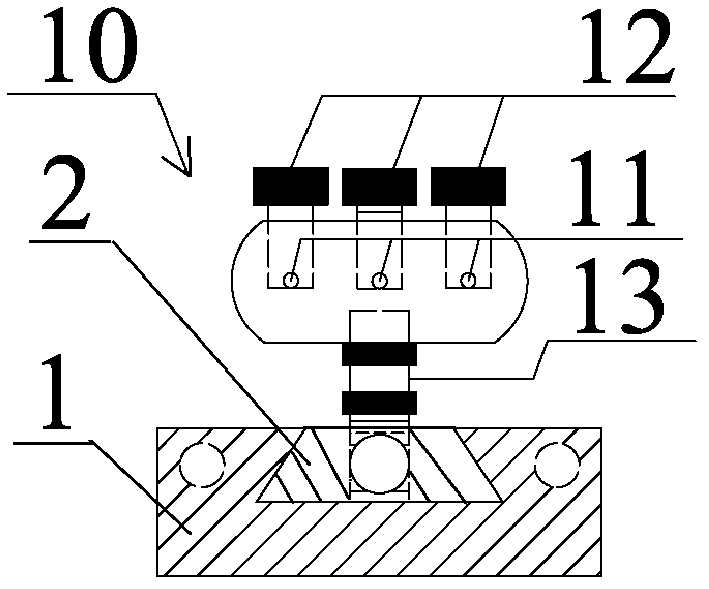

Sliding type performance-adjustable shape memory alloy damper

ActiveCN102425242AAdjustable lengthRealize the shock absorption effectShock proofingVibration attenuationShape-memory alloy

The invention discloses a sliding type performance-adjustable shape memory alloy damper belonging to fields of structure damping control, disaster prevention and reduction and protection. In order to solve the problem of incapability of regulating rigidity and energy consumption capacity of the traditional shape memory alloy damper, the sliding type performance-adjustable shape memory alloy damper comprises shape memory alloy wires arranged on at least one clamp I and at least one clamp II, a runner plate provided with a groove, and a sliding block arranged in the groove; and the runner plateand the sliding block are provided with a plurality of screw holes, the lower end of the clamp I is fixed on the sliding block, and the lower end of the clamp II is fixed on the runner plate. The sliding type performance-adjustable shape memory alloy damper can be mainly used for reset and energy consumption vibration attenuation (shock) after structure deformation, can also be used as a structure member for generating a nonlinear restoring force and can be used in simulation and test research of a structure nonlinear power behavior, and has the advantages of stable performance, simple structure and easiness in disassembly.

Owner:HUNAN UNIV

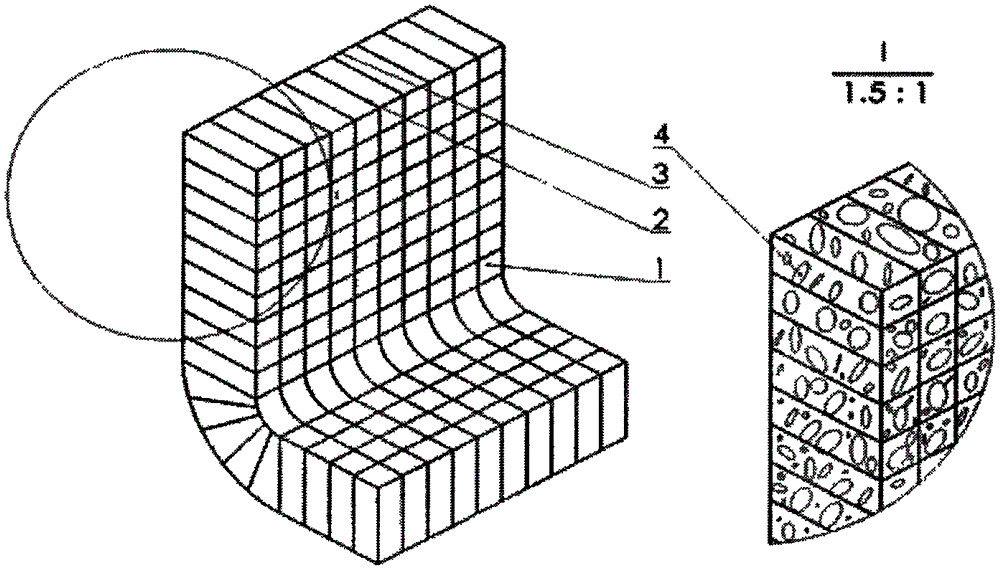

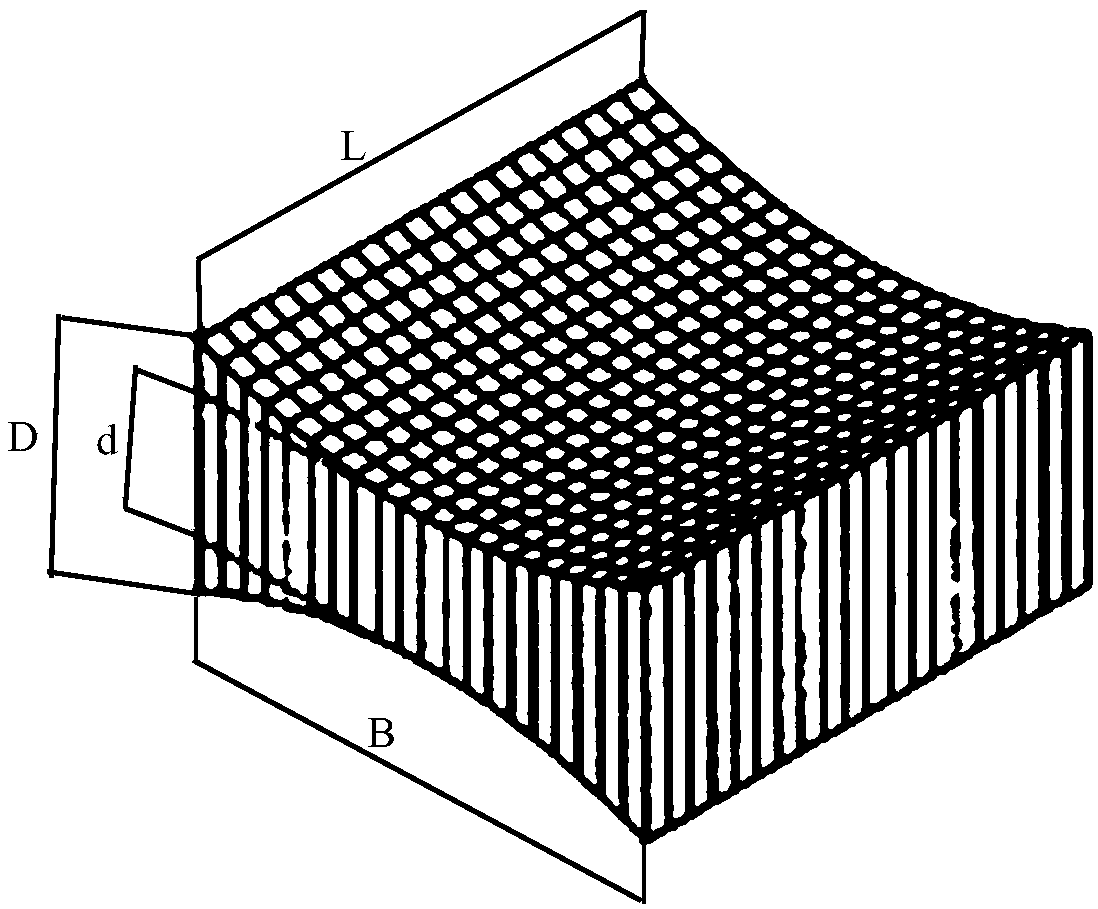

Three-dimensional spacer fabric reinforced cement-based composite material and preparation method thereof

InactiveCN106316177AFind the junctionImprove integritySurface layering apparatusShell moldingTransfer molding

The invention provides a three-dimensional spacer fabric reinforced cement-based composite material and a preparation method thereof and relates to a cement-based composite material. The preparation method comprises the following steps: putting a three-dimensional spacer fabric into a mold, and compositing resin with the three-dimensional spacer fabric by virtue of a resin transfer molding technique; curing the resin, so as to obtain a three-dimensional spacer fabric composite material skeleton; and uniformly mixing and stirring a cement binding material, water and an additive, pouring the mixture into the three-dimensional spacer fabric composite material skeleton, and carrying out compacting, hardening and maintenance forming, so as to obtain the three-dimensional spacer fabric reinforced cement-based composite material. According to the preparation method, composite material skeletons of various shapes can be obtained by virtue of the compositing of the three-dimensional spacer fabric and the resin and can be produced into building components of various shapes through cement pouring and solidification. Furthermore, the cement-based composite material has the advantages that the strength of common concrete is greatly improved, the construction is simple and convenient, and the performance is excellent.

Owner:TIANJIN POLYTECHNIC UNIV

In-situ synthesis process of polyelement reinforced titanium base composite material

The present invention relates to material preparing technology. The in-situ synthesis process of polyelement reinforced titanium base composite material includes the steps of: weighing and mixing spongy titanium, boron carbide, RE or RE alloy, boron oxide and alloying elements; smelting in cold mould furnace and pressing into electrode, welding and setting inside vacuum arc furnace, vacuumizing to 0.001-1 Pa, applying voltage and regulating current for smelting in twice or more times, and solidification. The present invention can prepare polyelement reinforced titanium base composite material in different sizes and shapes simply in low cost.

Owner:SHANGHAI JIAO TONG UNIV

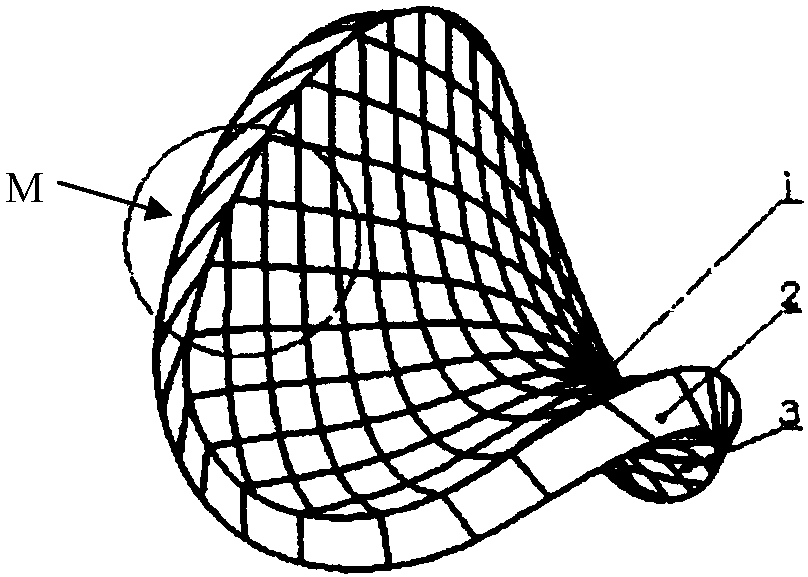

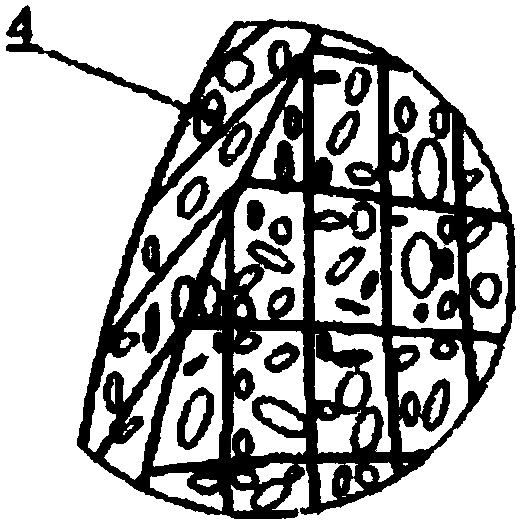

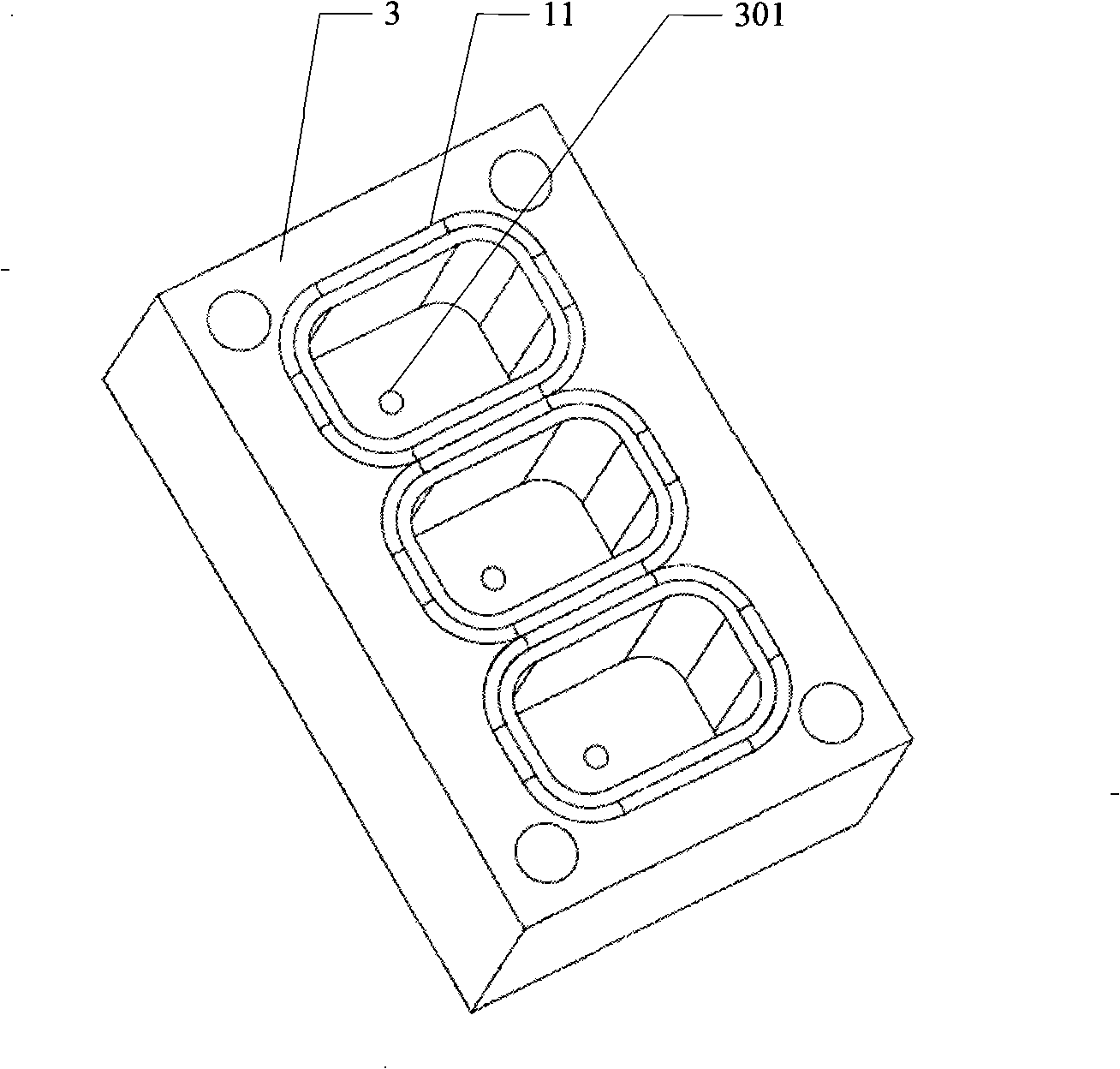

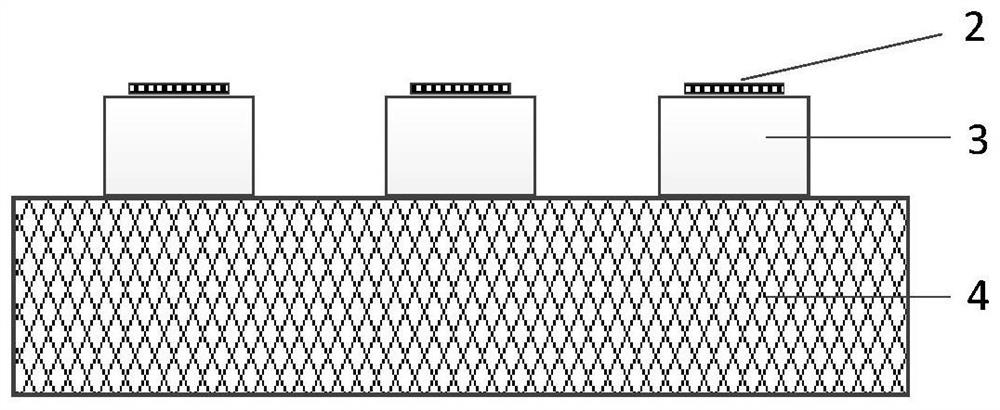

Three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material and preparing method thereof

The invention discloses a three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material and a preparing method thereof, and relates to foam reinforcing materials. The three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material is composed of a matrix and a reinforcing body, wherein the matrix is an organic foam material, the reinforcing body is three-dimensional spacer fabric, and the three-dimensional spacer fabric and the organic foam material are compounded. The preparing method comprises the steps of 1, selecting the three-dimensional spacerfabric, a polymer, a foaming agent and an additive; 2, placing the three-dimensional spacer fabric into a mold after cutting the three-dimensional spacer fabric, deforming the three-dimensional spacerfabric and fixing the shape in the mold; 3, preparing the organic foam material, wherein the polymer, the foaming agent and the additive which are selected in the step 1 are stirred and uniformly mixed; 4, casting raw materials which are uniformly mixed in the step 3 into the three-dimensional spacer fabric, and conducting foam enriching, curing and demolding to obtain the three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material.

Owner:福建福联精编有限公司

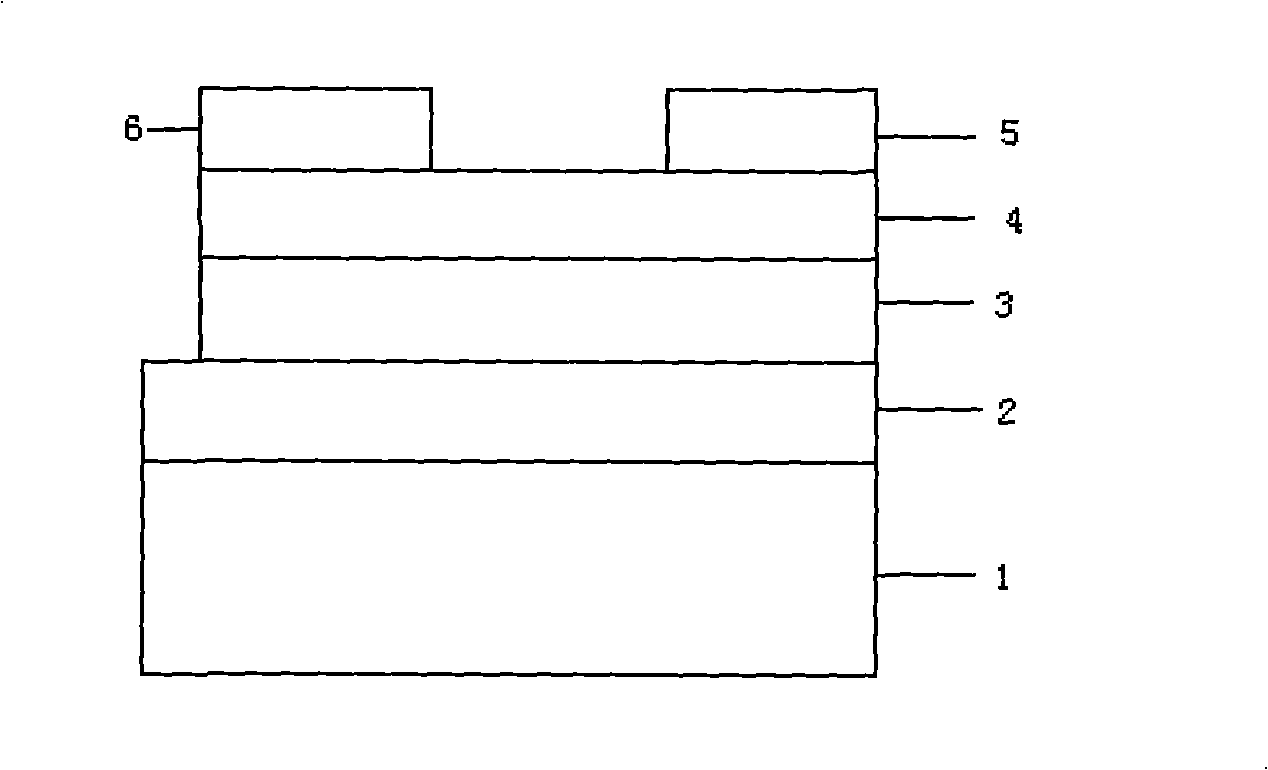

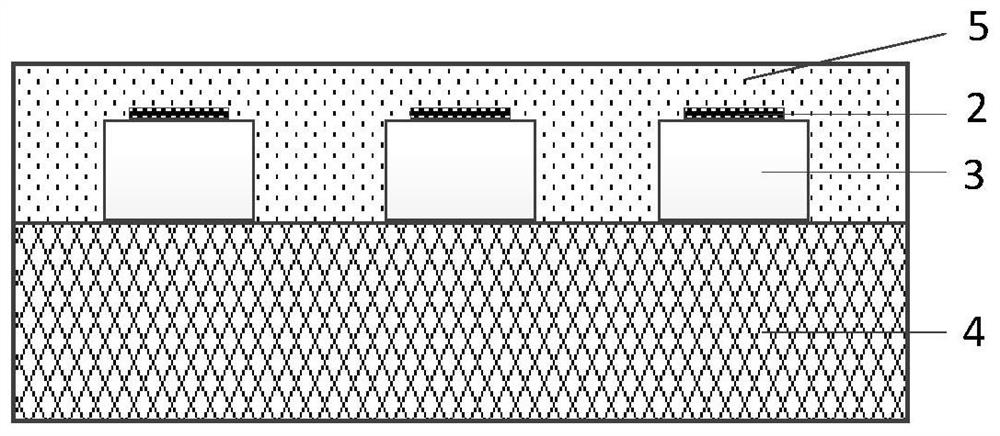

Flexible and wholly transparent ZnMgO thin film transistor and manufacturing method thereof

InactiveCN101527322ALow costHigh transparencyTransistorVacuum evaporation coatingInsulation layerRadio frequency magnetron sputtering

The invention discloses a flexible and wholly transparent ZnMgO thin film transistor which takes Zn1-xMgxO alloy as a semiconductor film, 0<x<1 as a channel layer, n type ZnO doped with Ga as a grid electrode, a source electrode and a drain electrode, Al2O3 as a gate insulation layer, polyethylene terephthalate, polycarbonate, organic glass or polyethylene naphthalate organic polymer as a substrate and the radio frequency magnetron sputtering method as the manufacturing method. The thin film transistor of the invention has the advantages of small photosensitive degeneration, high migration rate, fast response speed, flexibility and good stability of performance.

Owner:ZHEJIANG UNIV

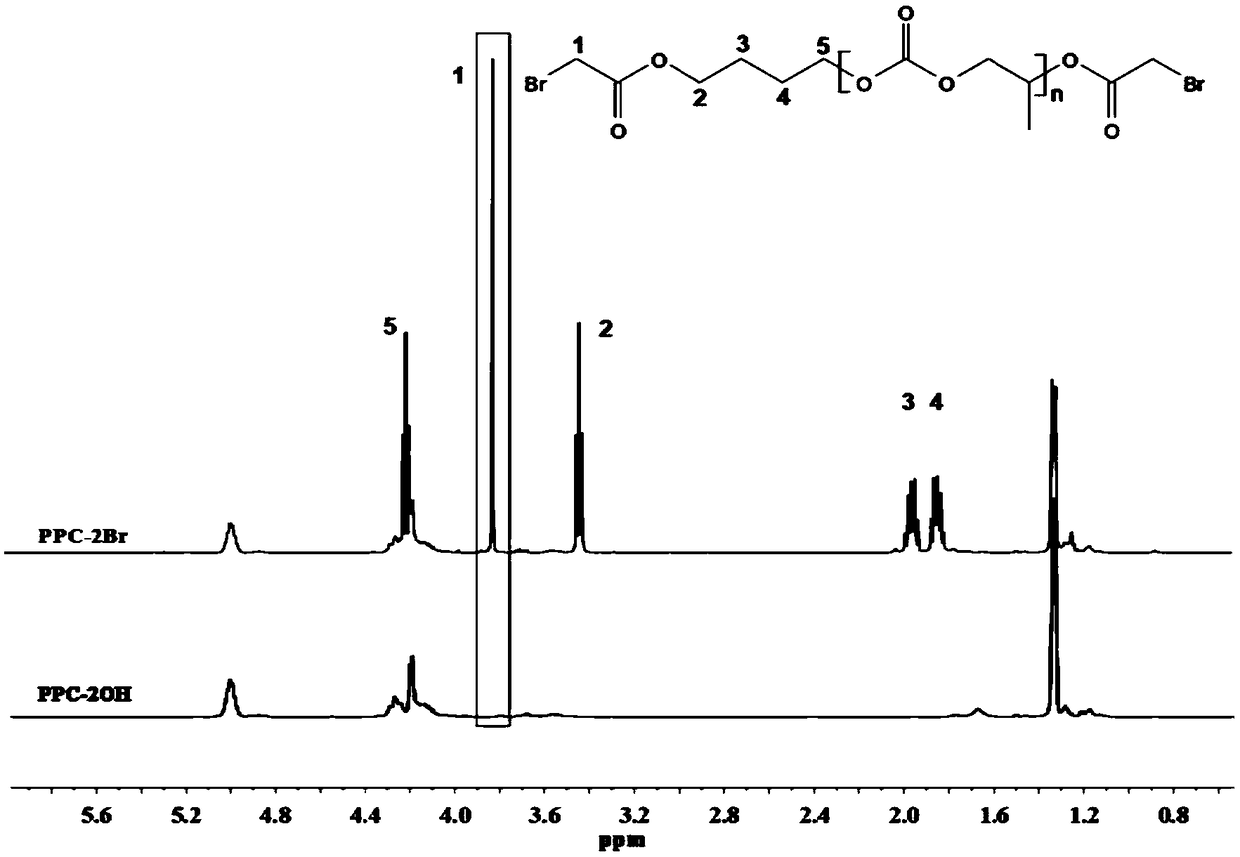

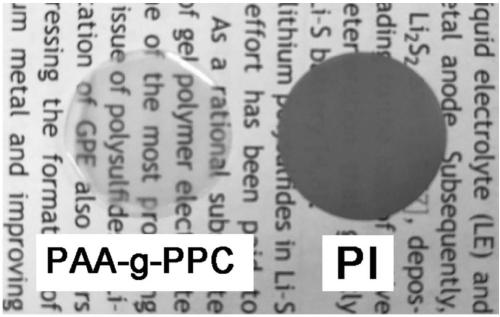

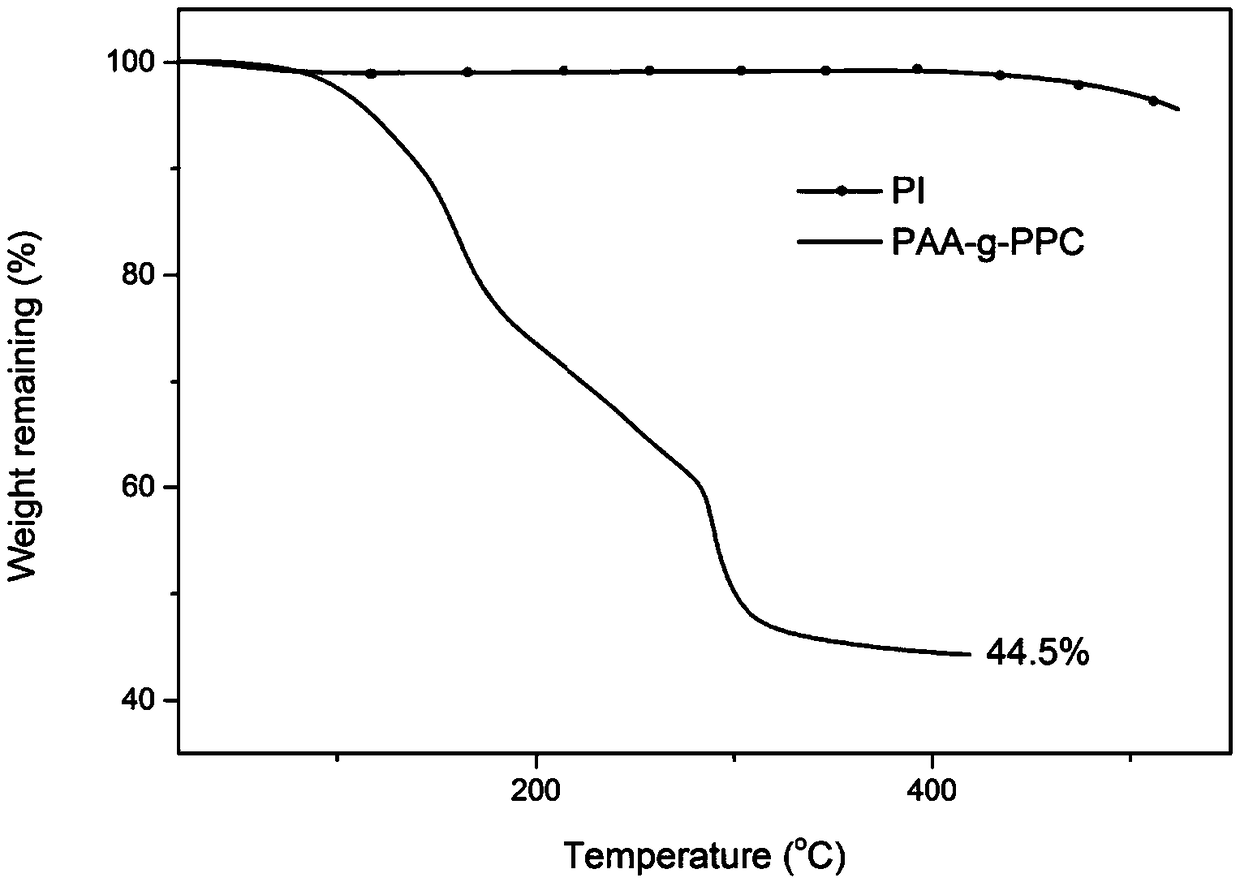

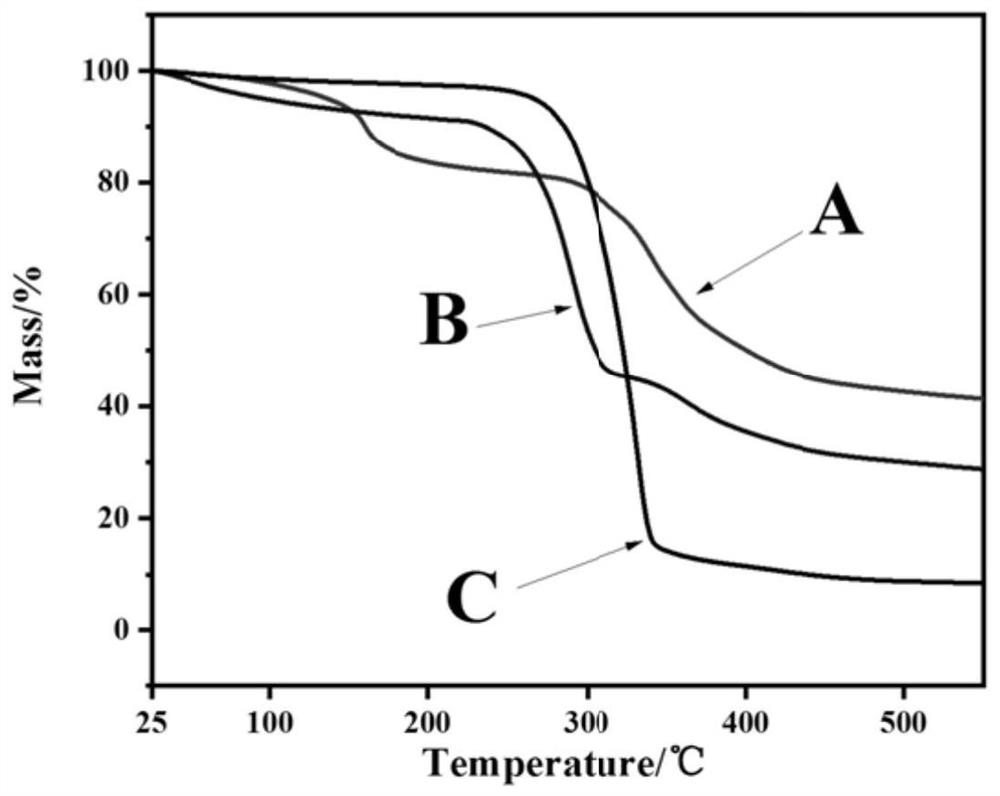

Method for preparing polyimide porous diaphragm

InactiveCN109473605AHigh reactivityHigh yieldLi-accumulatorsCell component detailsPorosityPolymer science

The invention relates to a method for preparing a polyimide porous diaphragm, wherein a thermally unstable polymer is used as a pore-forming agent, firstly, the thermally unstable polymer reacts withpolyamide acid (PAA) in a solvent to form a copolymer, a polymer film is laid, then, a thermally unstable chain segment is thermally pyrolyzed at a high temperature, and the polyamide acid is imidizedto obtain a polyimide porous diaphragm. According to the method in the invention, the pore-forming agent and the polyamide acid chemically react to achieve molecular-level dispersion; the reactivityof the pore-forming agent and the polyamide acid is high, and the porosity of the diaphragm can be adjusted at will. The diaphragm can be applied to the field of lithium ion and lithium sulfur batteries. The preparation method in the invention has the advantages of being simple, being high in reaction efficiency, and being easy for industrial production; the diaphragm has excellent high temperature resistance performance and good mechanical performance and can improve the electrochemical performance and safety of the battery.

Owner:SUN YAT SEN UNIV

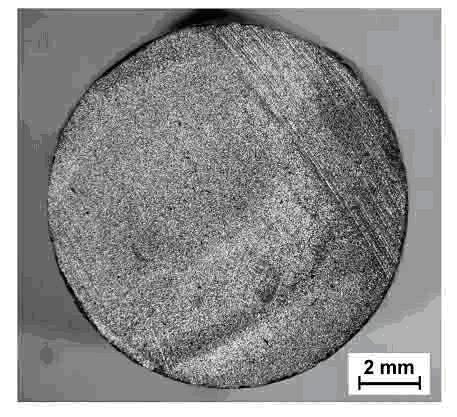

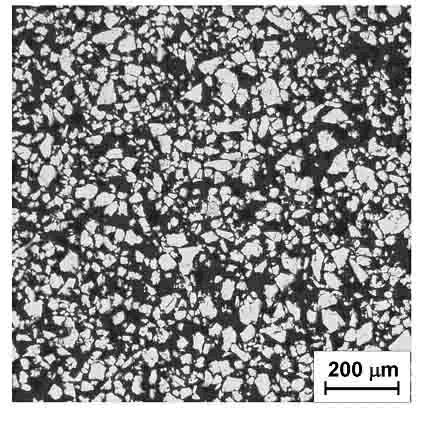

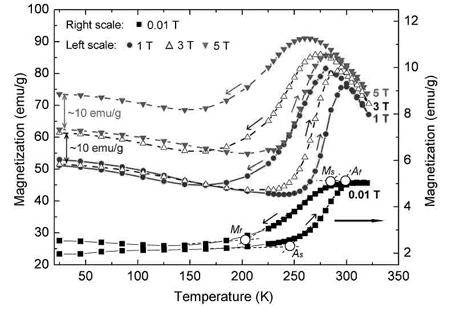

Resin-based Ni-Co-Mn-In alloy composite material and preparation method thereof

InactiveCN102181170AGood magnetic field induced strainReduced stress restraintWater bathsAlloy composite

The invention relates to the technical field of composite materials, in particular to a resin-based Ni-Co-Mn-In alloy composite material and a preparation method thereof. The resin-based Ni-Co-Mn-In alloy composite material consists of resin with the elastic modulus of 0.45Gpa and Ni45Co5Mn36.6In13.4 alloy with the particle size of 20-60 mum. A preparation method of the composite material comprises the following steps of: performing ball milling on a Ni-Co-Mn-In alloy material until the particle size of the Ni-Co-Mn-In alloy material is 20-60 mum, and uniformly mixing the Ni-Co-Mn-In alloy material with resin, wherein the alloy material accounts for 25-50 percent by volume of the composite material; stirring and mixing the mixture in a water bath of 60 DEG C for 20-40 minutes to obtain mixture slurry; and pouring the slurry into a mold, drying and curing to obtain a Ni45Co5Mn36.6In13.4 alloy material.

Owner:NORTHEASTERN UNIV LIAONING

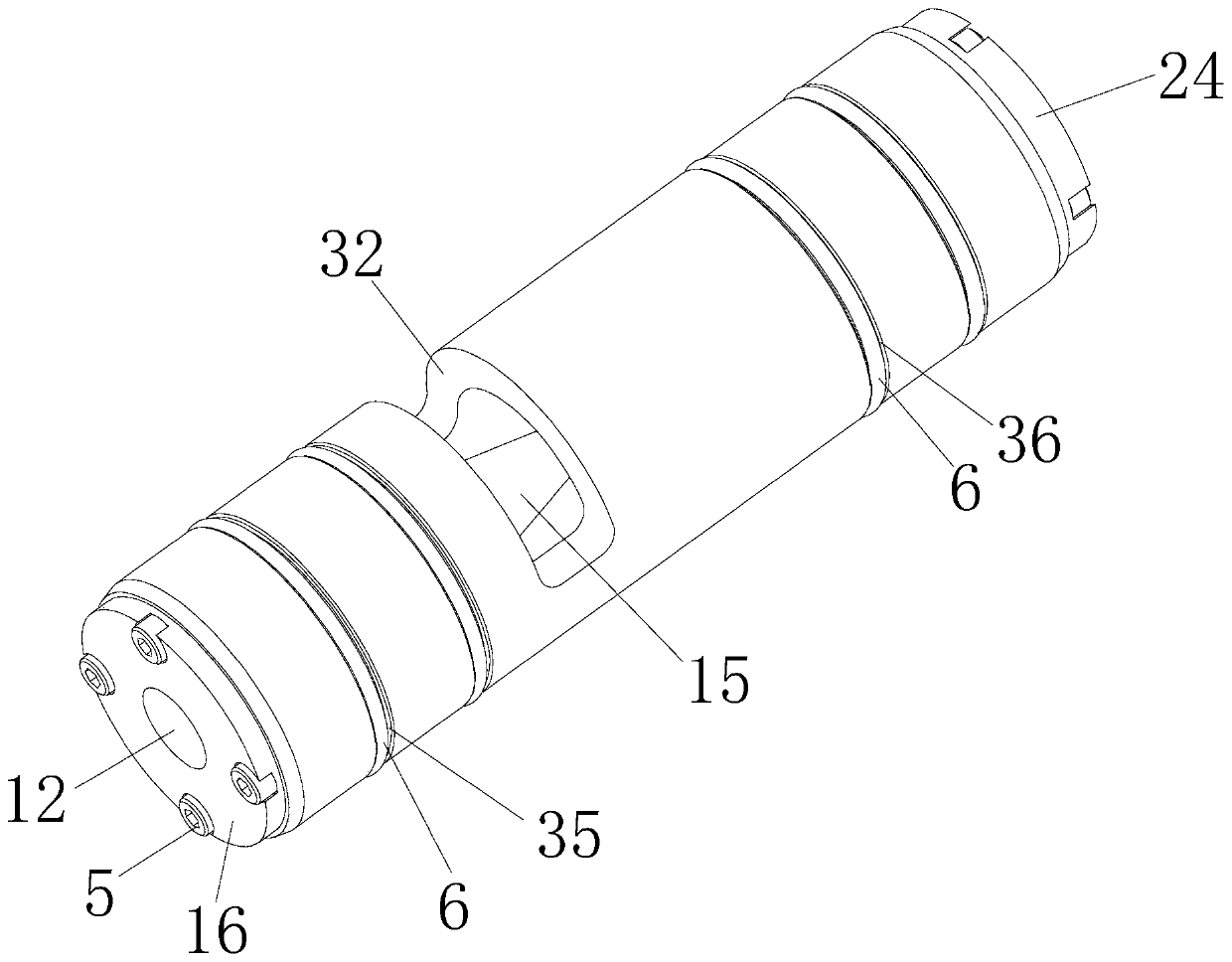

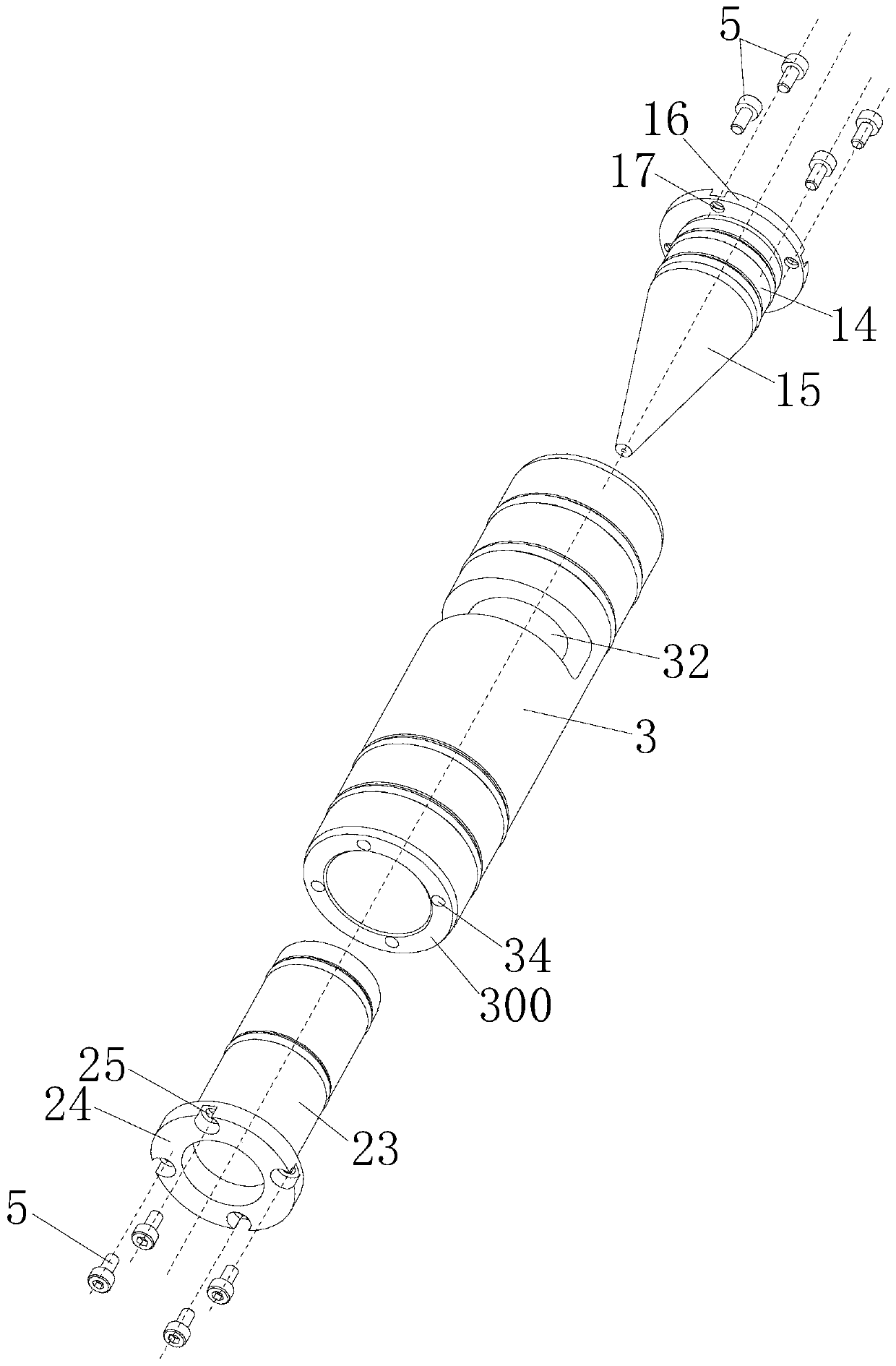

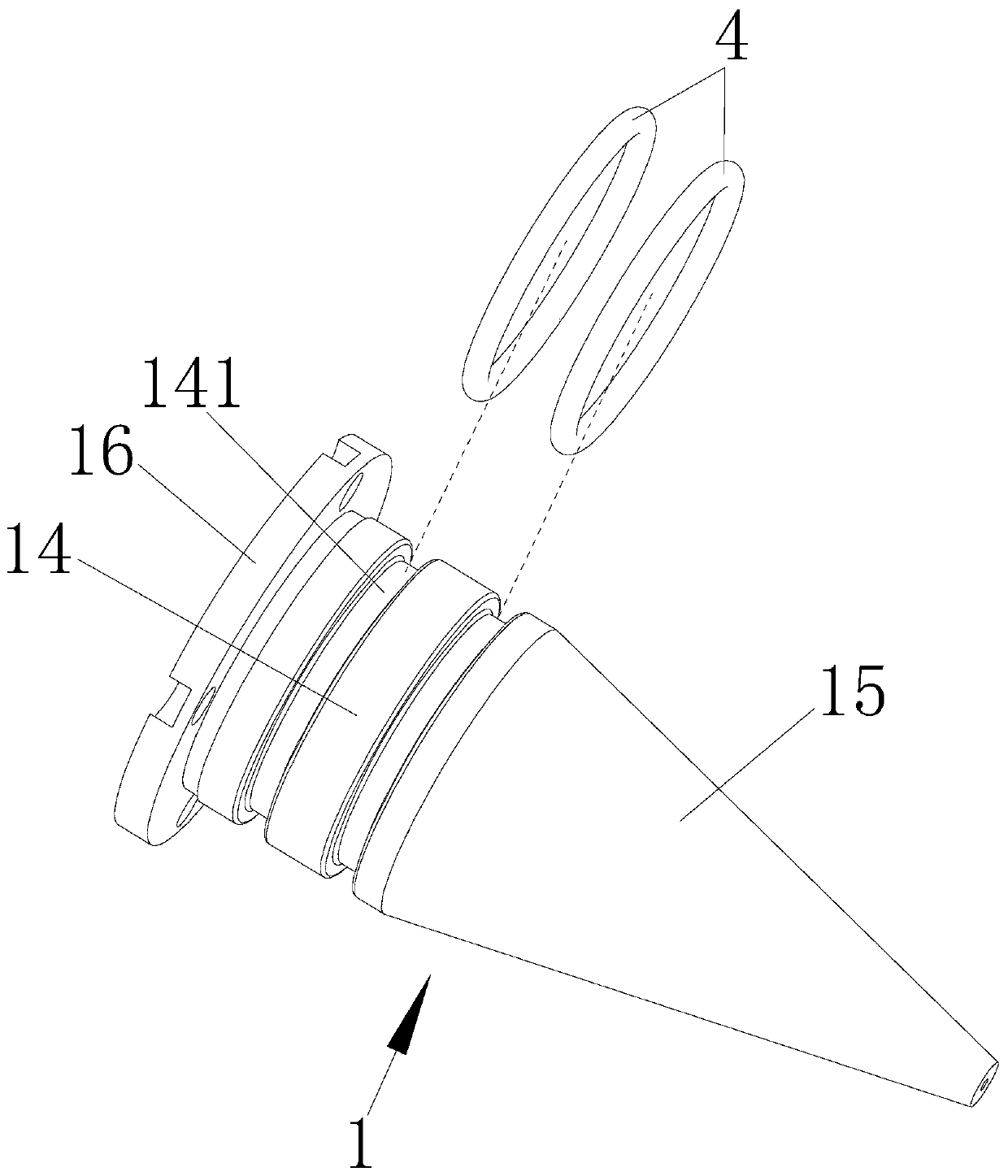

Ejector and fuel cell hydrogen inlet adjusting and hydrogen-returning device applying same

ActiveCN110224156AHigh design and processing precisionImprove machining accuracyJet pumpsMachines/enginesFuel cellsHydrogen

The invention discloses an ejector and a fuel cell hydrogen inlet adjusting and hydrogen-returning device applying the same. The ejector comprises a nozzle, a mixing chamber, an ejection sleeve, an inner sealing ring and a fastening screw, wherein the nozzle and the mixing chamber are arranged at the two ends of the ejection sleeve in a sleeving mode respectively; a notch is formed in the wall surface of the middle part of the ejection sleeve to serve as an inlet of a drainage fluid; a first flow channel is arranged in the middle of the nozzle and serves as a channel of a working high-pressurefluid; one end of the nozzle is provided with a high-pressure fluid inlet, and the other end of the nozzle is a high-pressure injection port; the mixing chamber is provided with a mixing section flowchannel and an expansion section flow channel; and the working high-pressure fluid ejected from the high-pressure injection port is mixed with the drained fluid flowed from the notch through the mixing section flow channel and then is ejected out after passing through the expansion section flow channel. The structure can adopt standardized and serialized design, and the part structure design is high in design and processing precision, high in interchangeability and low in cost, and the nozzle and the mixing chamber are replaced in a combined mode under the condition that the ejector sleeve isnot changed, so that different performance requirements can be met.

Owner:ZHONGSHAN BROAD OCEAN

Method for preparing SiCp enhanced AZ91D composite material blank

InactiveCN102728818AMeet high temperature strength requirementsHigh temperature bondingMagnesium matrix compositeHigh heat

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

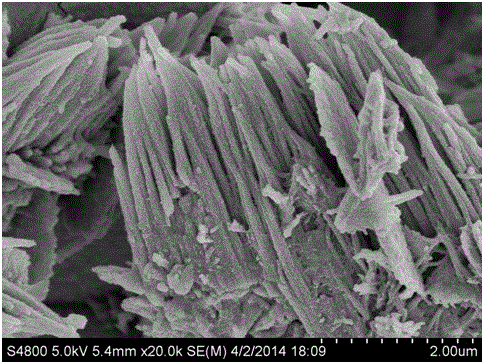

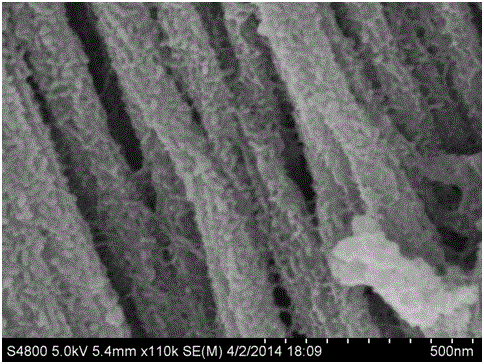

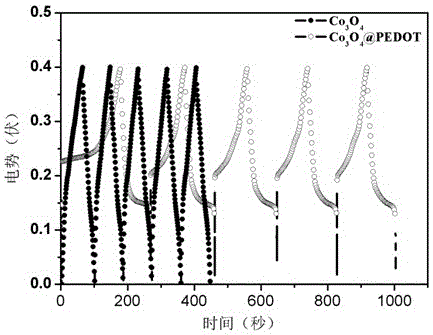

Co3O4@PEDOT porous nanorod material with core-shell structure and preparation method of Co3O4@PEDOT porous nanorod material

InactiveCN106449139AControl Deposition ThicknessMeet different performance needsHybrid capacitor electrodesOrganic-compounds/hydrides/coordination-complexes catalystsNanometreElectrochemistry

The invention discloses a Co3O4@PEDOT porous nanorod material with a core-shell structure and a preparation method of the Co3O4@PEDOT porous nanorod material. Co3O4@PEDOT is of a heterogeneous core-shell structure; a Co3O4 nanorod is taken as a core, PEDOT nanoparticles are taken as a shell, the PEDOT nanoparticles are densely attached to a Co3O4 nanorod core layer and a coarse porous structure is formed on the surface. The adopted preparation method comprises the steps of firstly preparing a Co3O4 nanowire with a core structure through a hydrothermal method; covering the surface of the Co3O4 nanowire with a layer of PEDOT particles through an electrochemical deposition method; and finally obtaining a Co3O4@PEDOT nanorod with the core-shell structure. The prepared Co3O4@PEDOT nanorod material is of a multistage structure which is formed by compounding two nano structures and is of a novel nano heterostructure; active sites of reaction are increased by a novel interface and large specific surface area of the nanorod material; the reaction characteristics of the nano composite material can be improved; and the application prospect in the fields of energy storage, catalysis and sensing is expanded.

Owner:ZHEJIANG UNIV

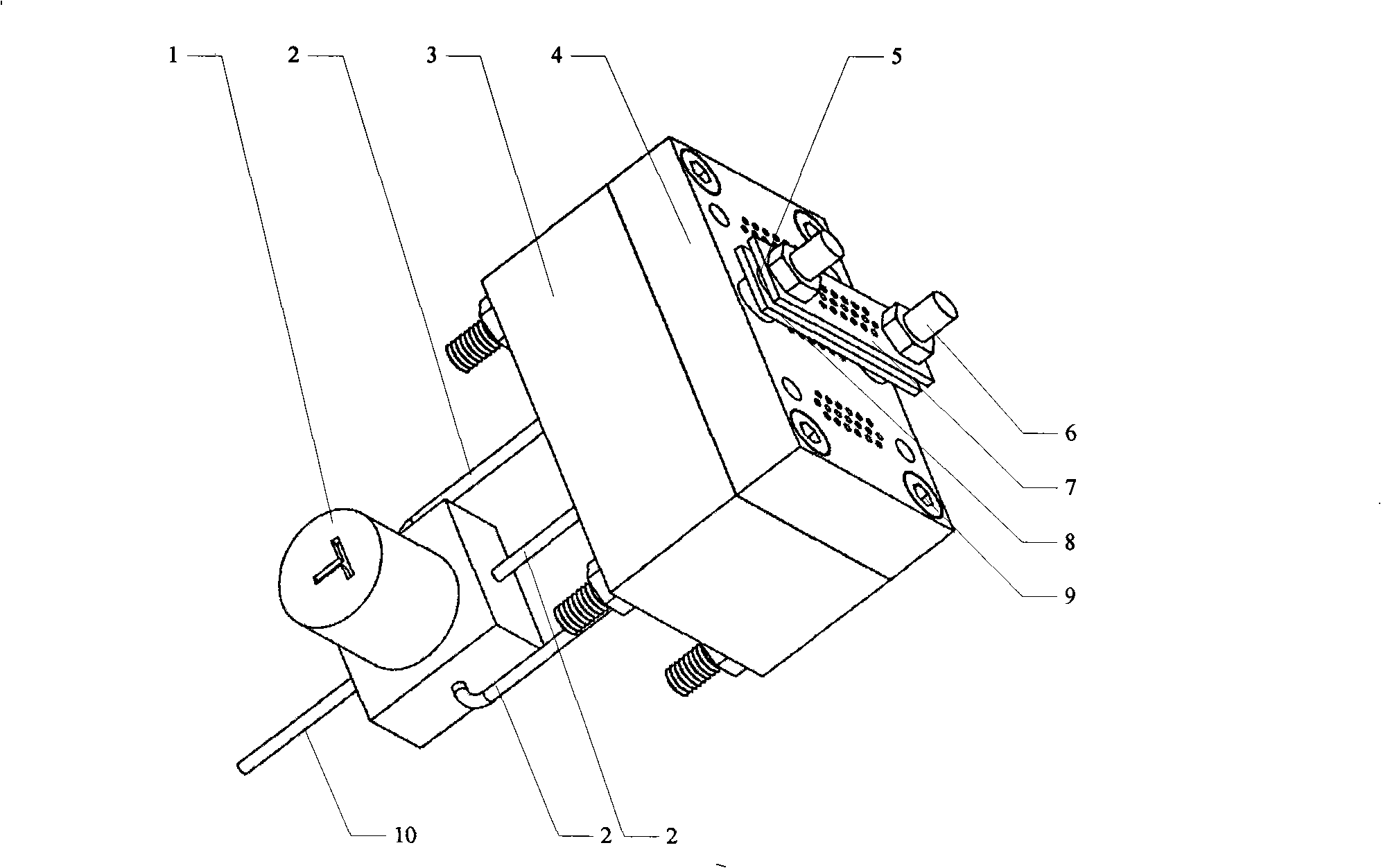

Hole type multi-cavity colloid thrustor

InactiveCN101539122ASimple compositionMeet different performance needsFrom muscle energyMachines/enginesPolyether ether ketoneColloid

The invention discloses a hole type multi-cavity colloid thrustor which comprises a multi-directional valve, stainless steel capillary pipelines, a storage tank, an insulating base, an insulating spacer, an insulating bolt, an accelerator, an extracting pole, a sunk screw and a PEEK pipeline; wherein, the multi-directional valve is connected with the stainless steel capillary pipelines and the PEEK pipeline, wherein, one PEEK pipeline is used for realizing one-way supply of propelling agent, and a plurality of stainless steel capillary pipelines are respectively connected between the multi-directional valve and the storage tank; the storage tank is connected with the insulating base by the sunk screw, and the sunk screw under the storage tank is locked by a nut; the insulating base is fixedly connected with the insulating bolt which is sequentially penetrated with the extracting pole, the insulating spacer and the accelerator, and the extracting pole, the insulating spacer and the accelerator are fastened with the insulating bolt by nuts; equidistant array through holes arranged on the insulating base are taken as channels, through which the propelling agent can flow out. The invention can conveniently form different types of thrustors in multiple ways, and realizes different adjusting ways of the performance of the thrustor, so as to meet the requirements of different performances.

Owner:BEIHANG UNIV

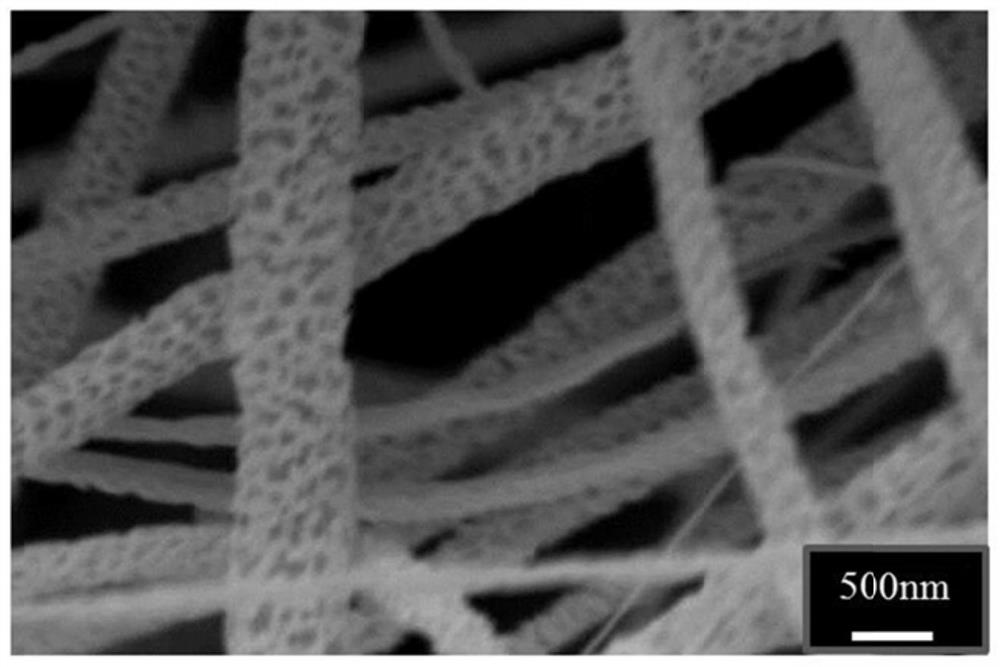

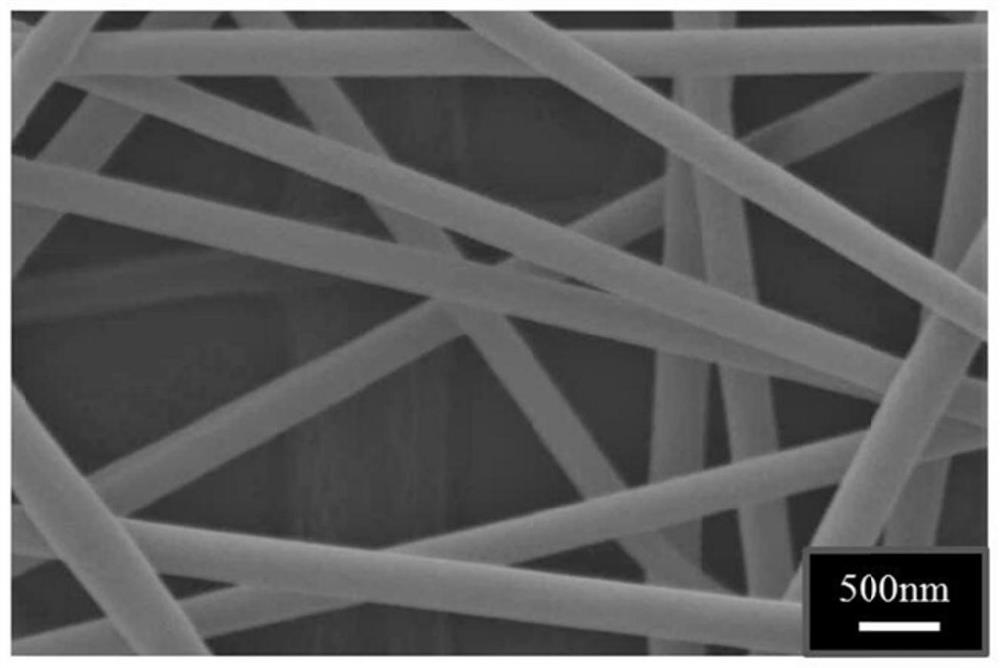

Fibroin polylactic acid porous nanofiber composite material as well as preparation method and application thereof

ActiveCN113046926AMeet different performance needsWill not emitBio-packagingConjugated cellulose/protein artificial filamentsFormic acidNanofibrous membrane

The invention discloses a fibroin polylactic acid porous nanofiber composite material and a preparation method and application thereof. The preparation method comprises the following steps: cutting cocoon shells into pieces to be subjected to degumming treatment, adding degummed domestic silkworm silk into a calcium chloride / formic acid solution to obtain a domestic silkworm silk protein solution, filtering the domestic silkworm silk protein solution, adding filtrate into a polylactic acid solution to be evenly mixed, and performing ultrasonic treatment; and performing electrospinning treatment on a fibroin polylactic acid solution subjected to ultrasonic treatment to obtain the fibroin polylactic acid porous nanofiber composite material. The preparation process is convenient to operate, low in production cost, short in production period and environmentally friendly, the prepared fibroin polylactic acid composite nanofiber membrane has a specific fiber morphology, and a specific hole structure and a secondary structure exist on a single fiber, and thus the requirements for different properties of materials are met; The fibroin polylactic acid porous nanofiber composite material can be applied to wound dressings, tissue engineering scaffold materials, and drug delivery and transfer materials.

Owner:NANJING NORMAL UNIVERSITY

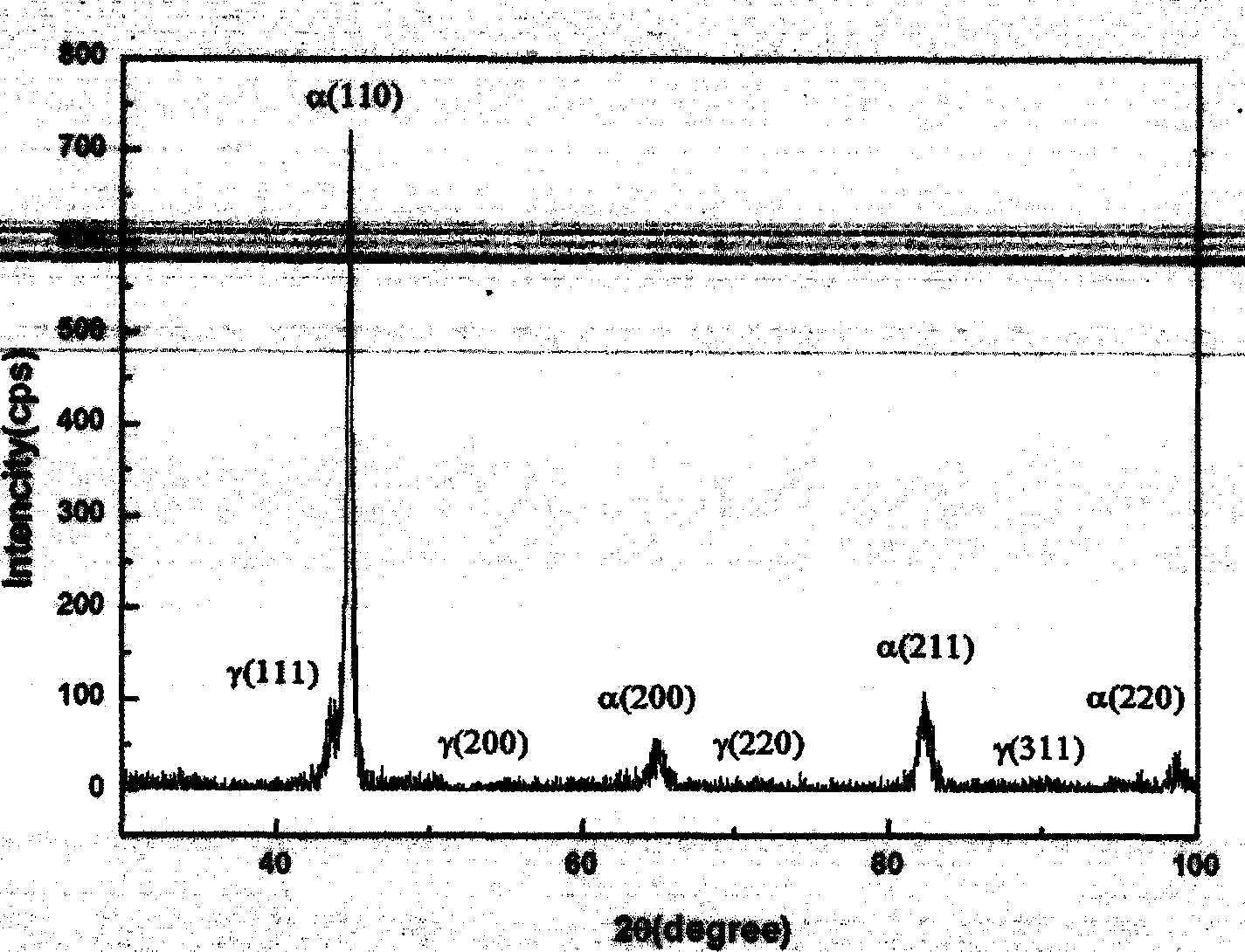

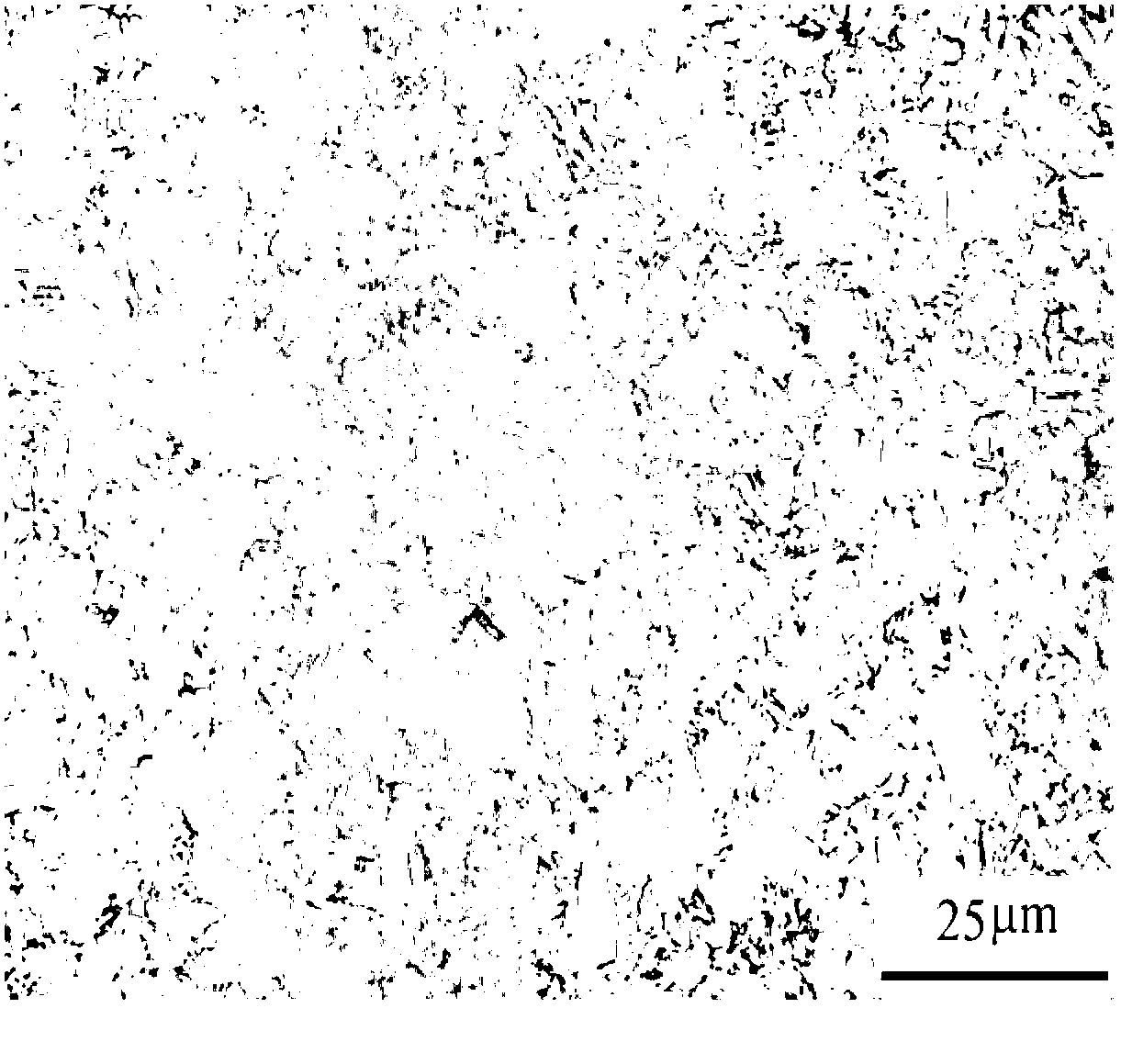

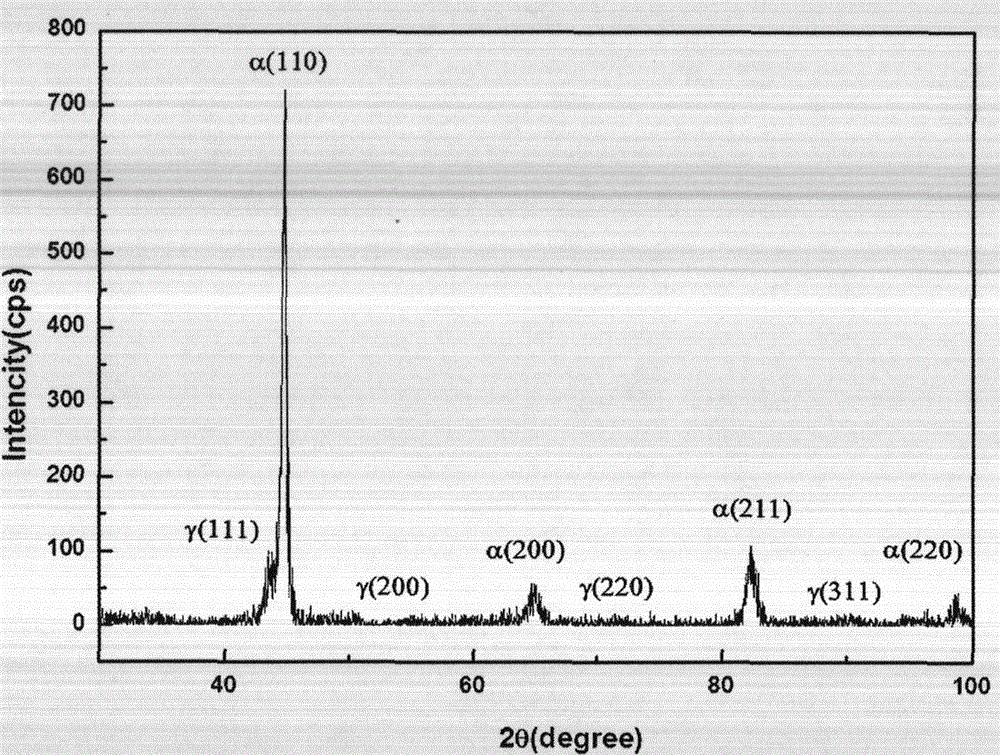

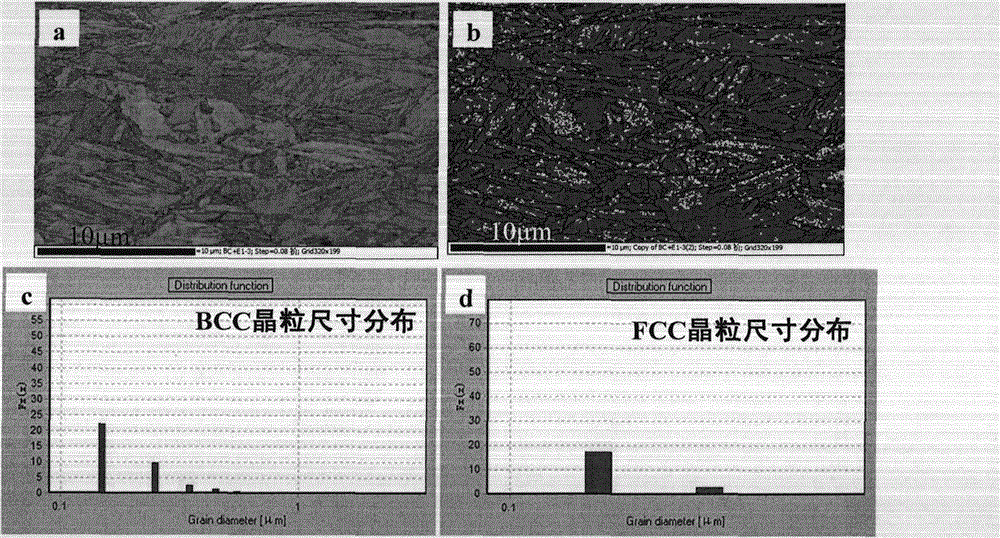

Bainite isothermal heat treatment method of medium-carbon silicomanganese nickel-chromium-series low-alloy steel

A bainite isothermal heat treatment method of medium-carbon silicomanganese nickel-chromium-series low-alloy steel aims to solve a problem that performance requirements of some key components cannot be satisfied since yield strength is significantly low when a temper temperature is lower than an isothermally quenching temperature in a conventional isothermal heat treatment technology. The method includes following steps: performing austenitizing treatment to the medium-carbon silicomanganese nickel-chromium-series low-alloy steel; carrying out isothermal oil-quenching or isothermal gas-quenching at a temperature which is higher than a martensite transformation temperature by 5-60 DEG C with the temperature being maintained for 120-180 min; and performing tempering at a temperature which is higher than an isothermal quenching temperature by 10-60 DEG C for 30-150 min. Through treatment by the method, the medium-carbon silicomanganese nickel-chromium-series low-alloy steel has a tensile strength reaching 1590-1980 MPa, a yield strength reaching 1350-1770 MPa and a ductility being 14-25%.

Owner:CAPITAL AEROSPACE MACHINERY +2

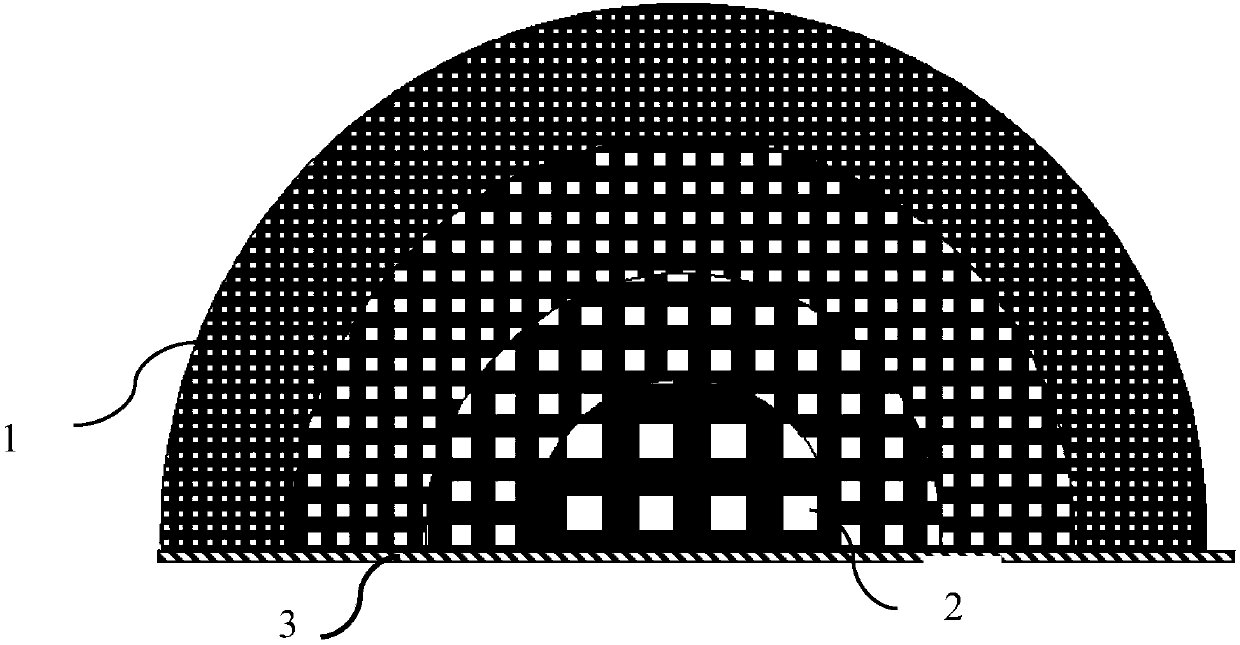

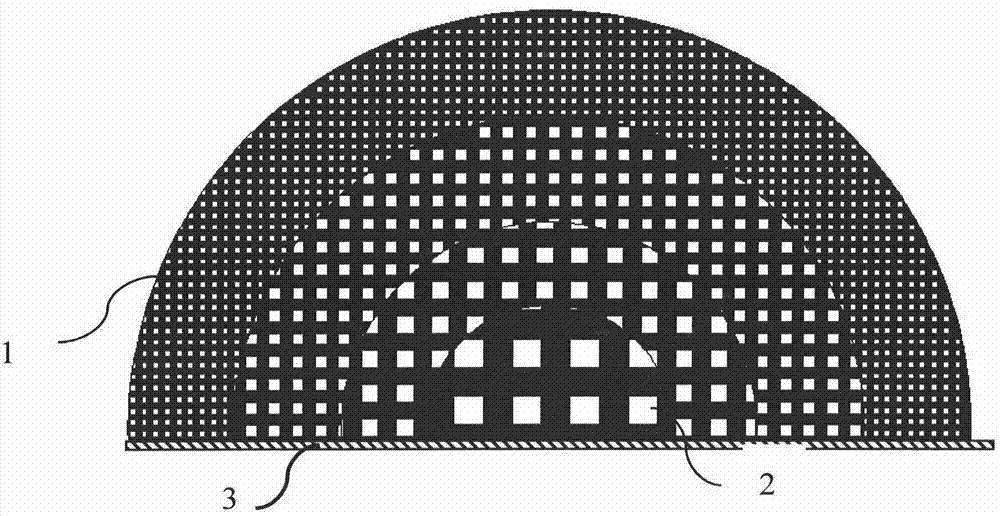

Application of hemispherical Luneberg lens antenna

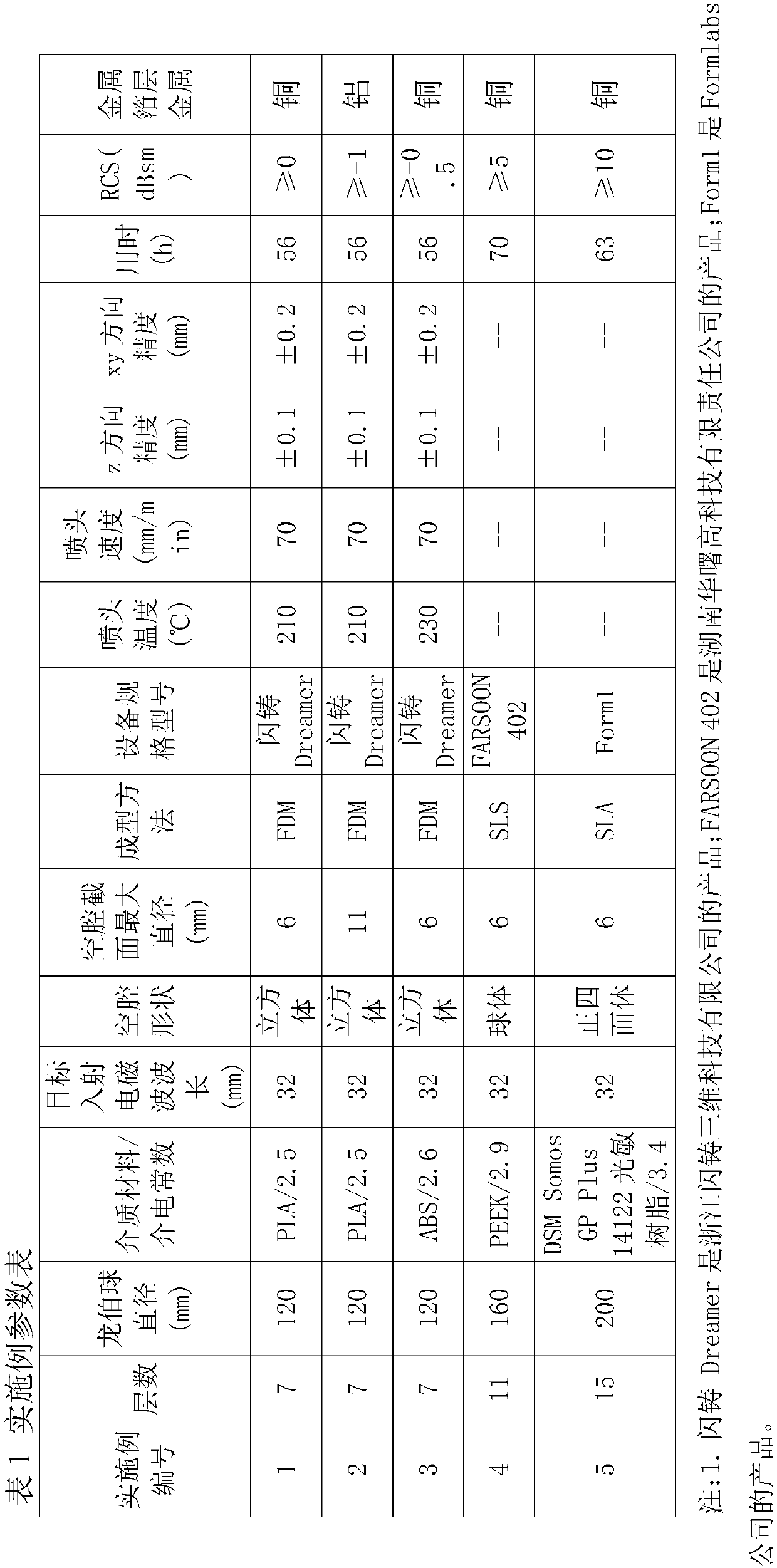

ActiveCN107611619AReduce performanceImprove product qualityAntennasDielectricDielectric permittivity

The invention discloses an application of a hemispherical Luneberg lens antenna, such as the application in satellite communication. The hemispherical Luneberg lens antenna is a hemisphere with radiusR and is designed to include n concentric layers, and the average dielectric constant epsilon(i) of the ith concentric layer is equal to 2-(ri / R)<2>, wherein n is an integer not less than 3, r1 is the radius of the center layer, rn=R, ri is the radius of the ith concentric layer, 1<=i<=n, and a cavity is distributed in at least one of the n concentric layers. The shape, size and distribution of the cavity structure of the hemispherical Luneberg lens antenna are adjustable and controllable. The average dielectric constant of the concentric layers can be precisely controlled. Different design requirements can be met. The hemispherical Luneberg lens antenna has a wide range of application. Moreover, there are a variety of materials which can be used, the production process is simple, the rate of finished products is high, there is no interlayer gap, and the product quality is more stable and reliable.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-strength and high-toughness heat treatment method of medium-carbon silicon-manganese-chromium-nickel series low alloy steel

The invention discloses a high-strength and high-toughness heat treatment method of medium-carbon silicon-manganese-chromium-nickel series low alloy steel, relating to a high-strength and high-strength heat treatment method of low alloy steel and aiming at solving the problem that the medium-carbon silicon-manganese-chromium-nickel series low alloy steel treated by a traditional heat treatment process cannot simultaneously obtain excellent strength, ductility and toughness. The high-strength and high-toughness heat treatment method comprises the following steps of: 1, carrying out austenitizing treatment on the medium-carbon silicon-manganese-chromium-nickel series low alloy steel, and then carrying out isothermal quenching to finish primary heat treatment; and 2, carrying out isothermal quenching on the medium-carbon silicon-manganese-chromium-nickel series low alloy steel subjected to the primary heat treatment in the step 1, and finally quenching to room temperature. The medium-carbon silicon-manganese-chromium-nickel series low alloy steel treated by using the method disclosed by the invention has the tensile strength of 1580MPa-2000MPa, the yield strength of 1340MPa-1870MPa, the ductility of 9.0-22.9 percent and the percentage reduction of area of 16.0-43.2 percent. The high-strength and high-toughness heat treatment method can be used for heat treatment of the medium-carbon silicon-manganese-chromium-nickel series low alloy steel.

Owner:HARBIN INST OF TECH

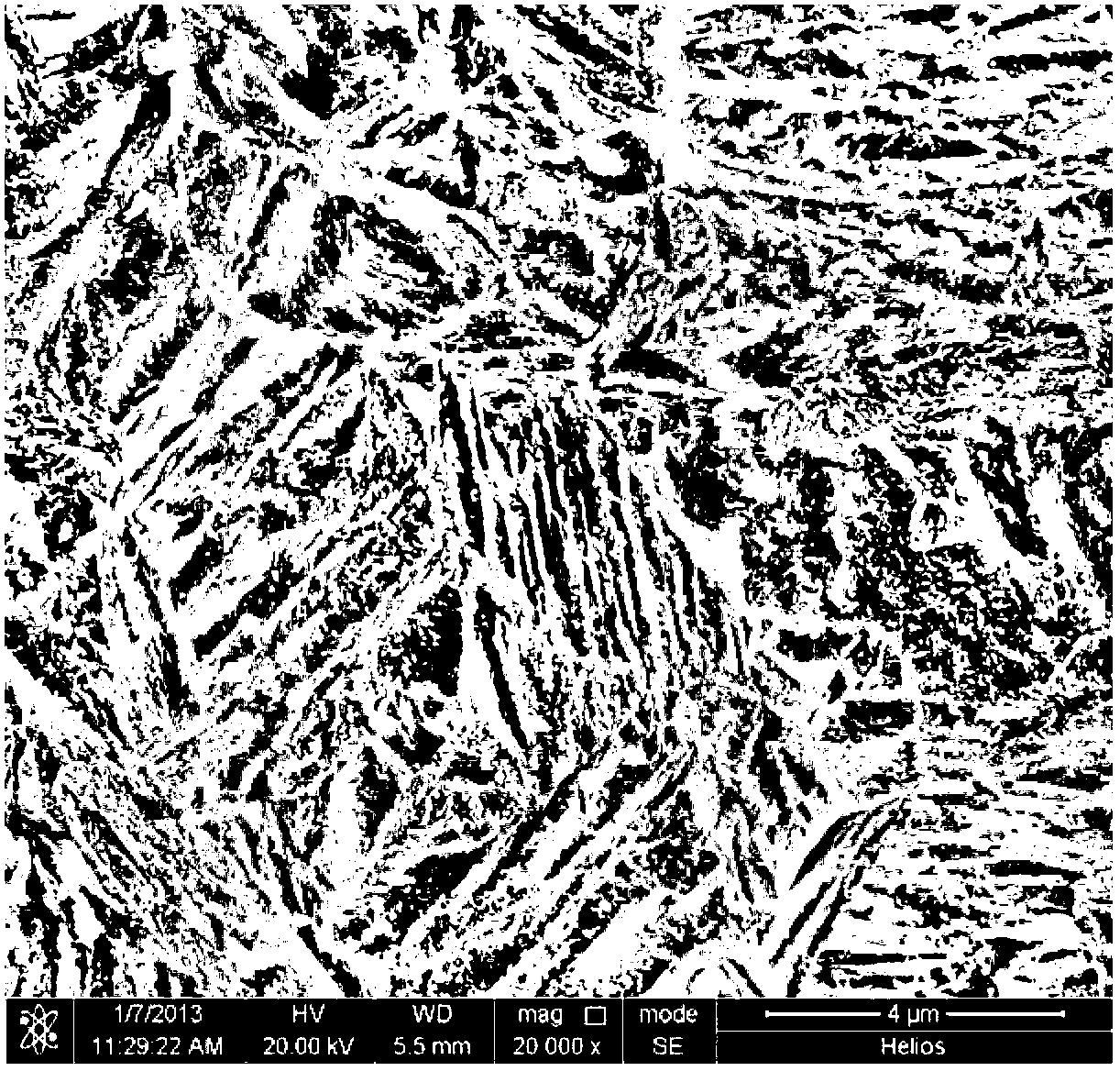

Strengthening and toughening heat treatment method of medium carbon manganese-vanadium low alloy steel

The invention discloses a strengthening and toughening heat treatment method of medium carbon manganese-vanadium low alloy steel, relating to a strengthening and toughening heat treatment method of low alloy steel. The method is used for solving the problems of low strength, bad toughness and incapability of simultaneously having both good strength and ductility and toughness of the medium carbon manganese-vanadium low alloy steel obtained by the traditional heat treatment technique. The method comprises the following steps: performing an austenitizing treatment on the medium carbon manganese-vanadium low alloy steel, and then, isothermal quenching the low alloy steel within a temperature section of 100-10 DEG C below a martensite transformation starting point Ms, holding for 60 s / mm according to the thickness of the medium carbon manganese-vanadium low alloy steel, and quenching the low alloy steel to the room temperature to finish the heat treatment of the medium carbon manganese-vanadium low alloy steel. The tensile strength of the obtained medium carbon manganese-vanadium low alloy steel is as high as 2060MPa, the yield strength is as high as 1540MPa, the ductility is as high as 15%, the percentage reduction of area is as high as 45%, and the low alloy steel has both high strength and plasticity, thereby being applicable to a strengthening and toughening heat treatment technique of medium carbon manganese-vanadium low alloy steel.

Owner:HARBIN INST OF TECH

Method of preparing precipitation method white carbon black by improved dropwise adding process

ActiveCN109368649AAvoid emissionsMeet different performance needsSilicon compoundsReaction temperatureReaction system

The invention provides a method of preparing precipitation method white carbon black by an improved dropwise adding process. The method comprises the following steps: preparing a base solution in a reaction kettle and controlling the content of water glass; controlling the stirring speed and the reaction temperature according to different generated products, spraying sulfuric acid from the bottomof the reaction kettle and spraying a water glass solution from the bottom or top of the reaction kettle till the water glass solution is sprayed over; raising the temperature, spraying sulfuric acidfrom the bottom of the reaction kettle, controlling the pH of the reaction system, and carrying out acidification and curing till the reaction is completed; and carrying out filter pressing, washing,pulpifying and drying on the obtained synthesized liquid to obtain the precipitation method white carbon black. Compared with an existing precipitation method, as white carbon black of different specifications is prepared by spraying sulfuric acid from the bottom and adding the water glass solution from the bottom or top, the specific surface areas and oil factors of different white carbon block products can be improved. In the production process, acidic emission is converted into neutral emission in tail gas emission, so that the product quality can be improved effectively, novel products aredeveloped, and the method is fully environment-friendly.

Owner:ZHUZHOU XINGLONG CHEM IND

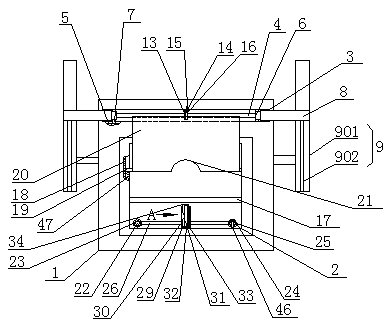

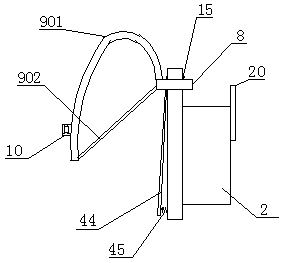

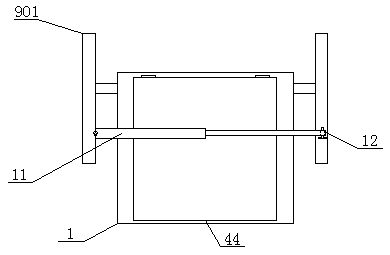

Stroke-adjustable stage device based on counterweight spring

PendingCN112761387AMeet different performance needsPlay a labor-saving roleStage arrangementsTheatresPhysicsEngineering

The invention relates to the technical field of stage performance, in particular to a stroke-adjustable stage device based on a counterweight spring. The stroke-adjustable stage device comprises a base, a performance rod and a springback mechanism; the base is located at the lowermost part and provides installation and fixation for the whole device; the springback mechanism is installed in the base, provides springback force for the performance rod and ensures that the performance rod and the base are located at a vertical position; and the lower half part of the performance rod is installed in the base and connected to the springback mechanism, and the upper half part of the performance rod provides a performance position for a performer.

Owner:湖北跨越天堑机械科技有限公司

Method for Preparing Precipitated White Carbon Black by Improving Dropping Process

ActiveCN109368649BAvoid emissionsMeet different performance needsSilicon compoundsEnvironmental engineeringGas emissions

The invention provides a method of preparing precipitation method white carbon black by an improved dropwise adding process. The method comprises the following steps: preparing a base solution in a reaction kettle and controlling the content of water glass; controlling the stirring speed and the reaction temperature according to different generated products, spraying sulfuric acid from the bottomof the reaction kettle and spraying a water glass solution from the bottom or top of the reaction kettle till the water glass solution is sprayed over; raising the temperature, spraying sulfuric acidfrom the bottom of the reaction kettle, controlling the pH of the reaction system, and carrying out acidification and curing till the reaction is completed; and carrying out filter pressing, washing,pulpifying and drying on the obtained synthesized liquid to obtain the precipitation method white carbon black. Compared with an existing precipitation method, as white carbon black of different specifications is prepared by spraying sulfuric acid from the bottom and adding the water glass solution from the bottom or top, the specific surface areas and oil factors of different white carbon block products can be improved. In the production process, acidic emission is converted into neutral emission in tail gas emission, so that the product quality can be improved effectively, novel products aredeveloped, and the method is fully environment-friendly.

Owner:ZHUZHOU XINGLONG CHEM IND

Ultra-high power limiter mmic and its preparation method based on bonding transfer

ActiveCN109300892BImprove convenienceImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingHemt circuitsThin layer

The invention discloses a super-power limiter MMIC based on bonding transfer and a preparation method thereof. The preparation method comprises: etching a PIN mesa structure and an upper electrode on the front side of a Si wafer; spin coating and adhering the front side of the Si wafer Bond the Si wafer with the front side of the temporary carrier; thin the Si wafer substrate; prepare the lower electrode on the back of the Si wafer; clean the thin layer of the PIN structure supported by the temporary substrate and the completed The SiC substrate prepared by the peripheral circuit; the thin layer of the PIN tube supported by the temporary substrate and the front side of the SiC substrate prepared by the peripheral circuit are bonded and interconnected; the temporary substrate is removed; the etching isolating the PIN mesa; the PIN The structure is interconnected with SiC circuits to obtain an ultra-high power limiter MMIC based on bonding transfer. The invention integrates the high-performance Si PIN limiter into the MMIC to realize the high-integration and high-power limiter MMIC.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Prop support straps for stage performers

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

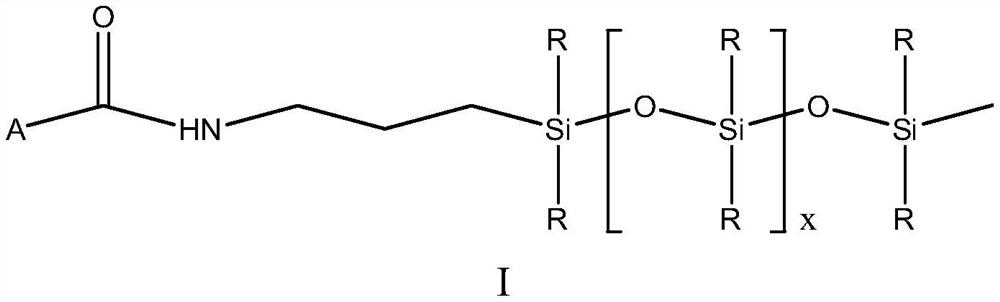

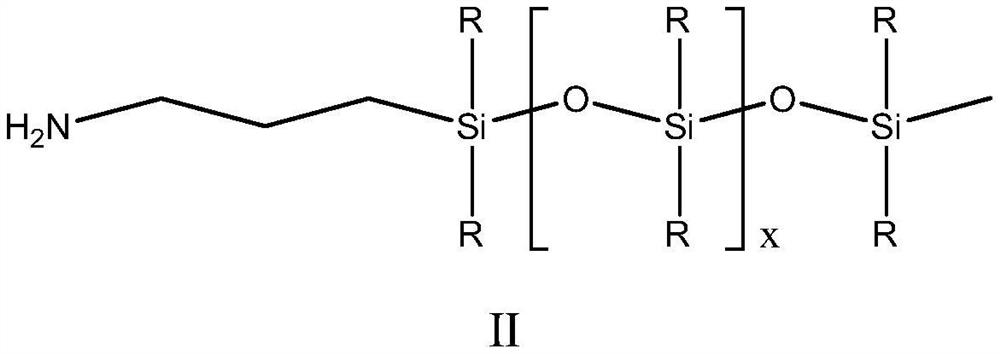

Rhamnolipid derivative as well as preparation method and application thereof

ActiveCN114213662AImprove smellGood emulsifying effectCosmetic preparationsNon-ionic surface-active compoundsRhamnolipidBiochemical engineering

The invention provides a rhamnolipid derivative as shown in a formula (I). The invention also provides a preparation method and application of the rhamnolipid derivative. The invention further provides a daily chemical product containing the rhamnolipid derivative. According to the rhamnolipid derivative provided by the invention, an organic silicon chain segment with a certain length is introduced into rhamnolipid, so that the rhamnolipid derivative can be effectively compatible with silicone oil, various properties such as smell, emulsifying capacity and the like of the rhamnolipid are obviously improved, and the variety and the application range of the rhamnolipid are greatly expanded. The rhamnolipid derivative provided by the invention can be applied to a variety of daily chemical products, especially cleaning wash supplies. The preparation method of the rhamnolipid derivative provided by the invention is simple and convenient in process, free of high cost and suitable for industrial production, thereby having important economic and social values;

Owner:WANHUA CHEM GRP CO LTD

Bainite isothermal heat treatment method for medium carbon silicon manganese chromium nickel series low alloy steel

A bainite isothermal heat treatment method of medium-carbon silicomanganese nickel-chromium-series low-alloy steel aims to solve a problem that performance requirements of some key components cannot be satisfied since yield strength is significantly low when a temper temperature is lower than an isothermally quenching temperature in a conventional isothermal heat treatment technology. The method includes following steps: performing austenitizing treatment to the medium-carbon silicomanganese nickel-chromium-series low-alloy steel; carrying out isothermal oil-quenching or isothermal gas-quenching at a temperature which is higher than a martensite transformation temperature by 5-60 DEG C with the temperature being maintained for 120-180 min; and performing tempering at a temperature which is higher than an isothermal quenching temperature by 10-60 DEG C for 30-150 min. Through treatment by the method, the medium-carbon silicomanganese nickel-chromium-series low-alloy steel has a tensile strength reaching 1590-1980 MPa, a yield strength reaching 1350-1770 MPa and a ductility being 14-25%.

Owner:CAPITAL AEROSPACE MACHINERY +2

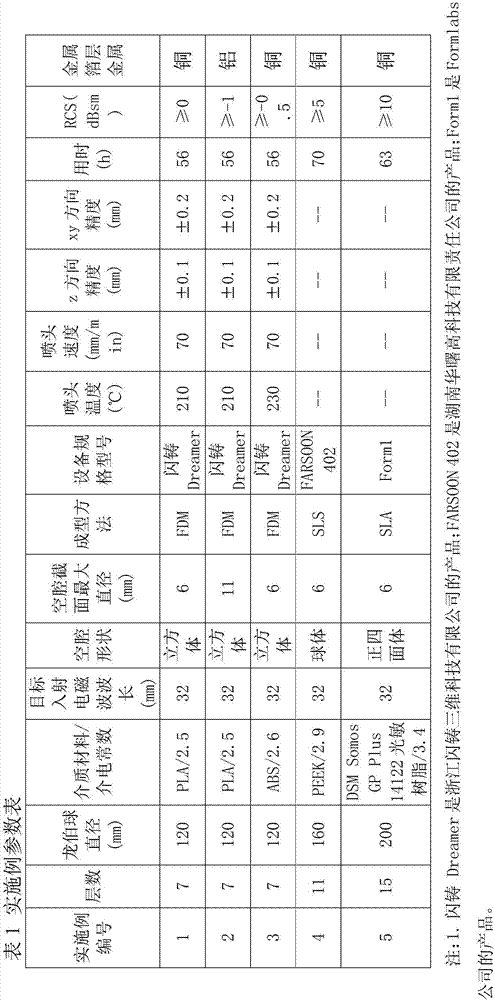

A method of manufacturing a hemispherical Lunberg lens antenna

The invention discloses a manufacturing method of a hemispherical Lunberian lens antenna. The hemispherical Lunberian lens antenna is distributed with cavities, has a hemispherical surface and a bottom plane, and the bottom plane is a plane passing through the center of the sphere; it is characterized in that the Described method comprises the steps: (1) select the material that is used to manufacture hemispherical Lunberg lens antenna; (2) determine the structural parameter of hemispherical Lunberg lens antenna; (3) make the hemispherical Lunberg lens antenna with described structural parameter A three-dimensional digital model; and (4) manufacturing the hemispherical Lunberg lens antenna according to the three-dimensional digital model by using an additive manufacturing method; and (5) pasting a metal foil layer on the bottom plane. The shape, size and distribution of the cavity structure in the hemispherical Lunberg lens antenna produced by the present invention are adjustable and controllable, which realizes the precise control of the average dielectric constant of the concentric layer and can meet different design requirements; and the production materials are widely used , The production process is simple, the yield is high, and there is no gap between layers, which makes the product quality more stable and reliable.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-strength and high-toughness heat treatment method of medium-carbon silicon-manganese-chromium-nickel series low alloy steel

Owner:HARBIN INST OF TECH

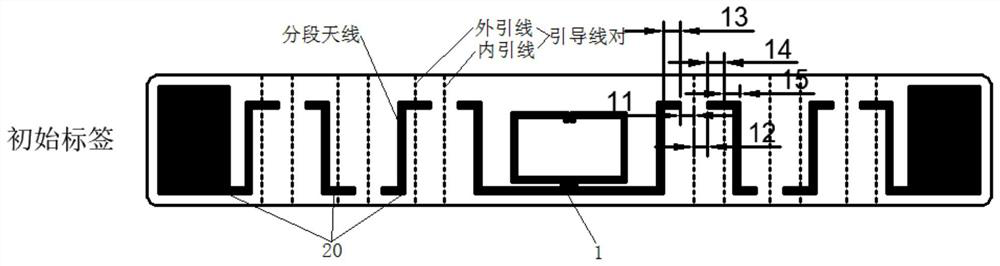

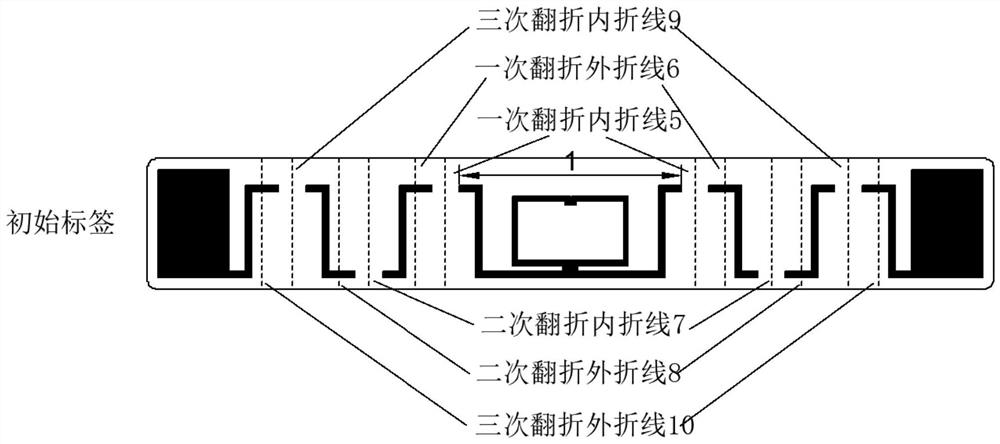

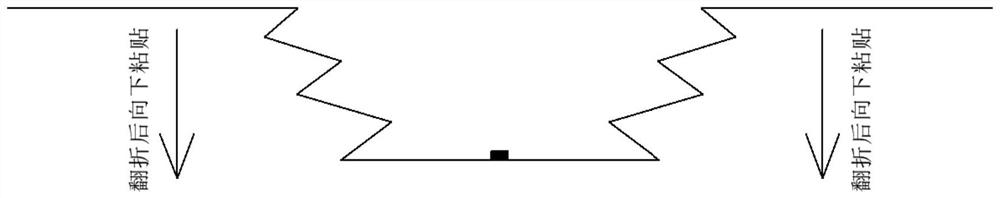

Performance-variable ultrahigh frequency RFID tag

ActiveCN112766447AImprove performanceIncrease the lengthRecord carriers used with machinesUhf antennasGuide wires

The invention relates to the technical field of ultrahigh-frequency RFID, and particularly discloses a performance-variable ultrahigh-frequency RFID tag which is provided with an etching antenna layer and a guide wire, the etching antenna layer comprises a main body antenna and an additional antenna separated from the main body antenna, and the guide wire is arranged in the area where the additional antenna is located; and the additional antenna is connected with the main body antenna in a manner of folding along the guide line. The main body antenna and the additional antenna can be conducted by limiting the proportion, the size and the position of the guide wire, a new antenna is formed, the length of the main body antenna is enlarged, and the performance is expanded; when the tag is pasted on an object according to an original shape, namely when the tag is not folded (an initial tag), only the main body antenna plays a role, and the main body antenna is short in size, low in performance and suitable for application scenes of short-distance reading and writing; according to the invention, the additional antenna is arranged to be a plurality of segmented antennas, and a guide wire pair is arranged corresponding to each segmented antenna, so that the segmented gradual extension of the main body antenna is realized, and the requirements of different performances of the ultrahigh frequency antenna are met.

Owner:江苏科睿坦电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com